Cold-pressing sintering method and cold-pressing sintering apparatus for Bi2O3 ceramic

A sintering device and sintering method technology, applied in the field of low-temperature sintered ceramics, can solve problems such as energy consumption, easy deformation, and coarse grains, and achieve the effects of improving quality, stirring evenly and thoroughly, and dissolving thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

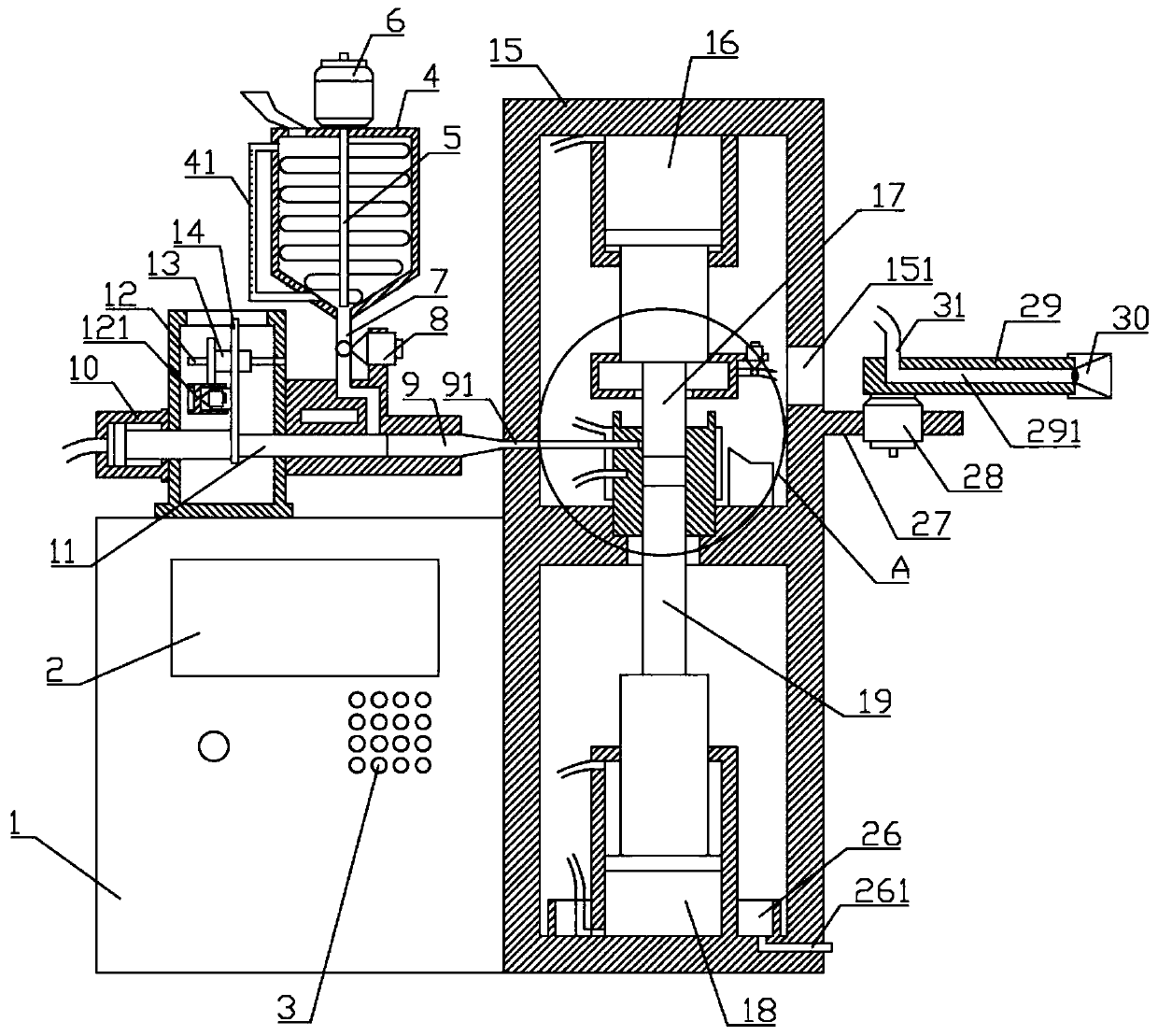

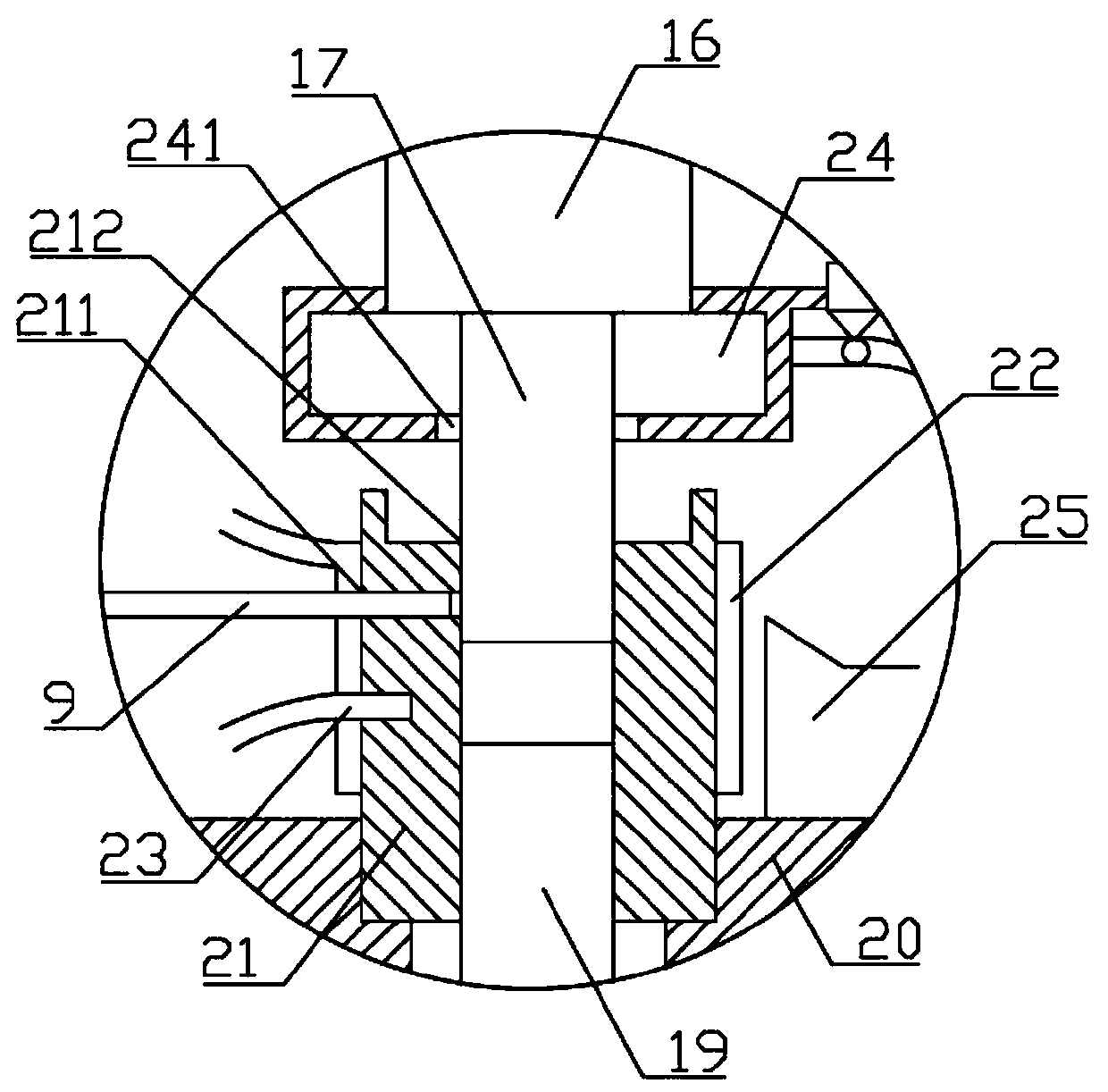

[0043] A kind of Bi of the present invention 2 o 3 The ceramic cold-press sintering device includes a control box, a feeding device and a sintering device that are fixedly connected together. The feeding device is fixedly installed on the upper end of the control box, and one end of the sintering device is fixedly connected to the control box. The control box includes Box 1, a display screen 2 and an input key 3 are embedded and installed on the box body 1, and a control system circuit board is installed in the control box to control the operation of all components in the cold-press sintering device. The feeding device includes a barrel 4 , a raw material balance meter 41 is installed on the barrel, a stirring shaft 5 is installed in the barrel 4, and one end of the stirring shaft 5 stretches out of the barrel 4, and the first drive motor 6 is fixedly connected outside the barrel 4, and the barrel 4 There is a feed inlet at the top of the tank, a discharge pipe 7 is fixedly c...

Embodiment 2

[0050] S1: First weigh 5kg of Bi 2 o 3 Pour the powder into the barrel, then take a propionic acid solution with a concentration of 0.5mol / L and press Bi 2 o 3 10% of the powder mass is added to barrel 4.

[0051] S2: Turn on the main switch of the control system, set the heating curve, heat the mold 21 to 70°C at a heating rate of 15°C / min, keep it for 10 minutes, then heat it to 280°C at a heating rate of 15°C / min and keep it for 0.5 hours, set 200MPa pressure, keep the pressure for 0.5 hours, and start the program.

[0052] S3: Start the program, the first driving motor 6 drives the stirring shaft 5 to rotate and mix the raw materials for five minutes to fully mix the raw materials, and at the same time adjust the feeding adjustment device to adjust the injection volume, and use the two-way hydraulic machine 10 to drive the hydraulic piston 11 to move to the left to the limit.

[0053] S4: Open the electric throttle valve 8 to make the mixed raw materials fill the injec...

Embodiment 3

[0062] S1: First weigh 7kg of Bi 2 o 3 Pour the powder into the barrel, then take a propionic acid solution with a concentration of 5mol / L and press Bi 2 o 3 The proportion of 20% of the powder mass is added to barrel 4.

[0063] S2: Turn on the main switch of the control system, set the heating curve, heat the mold 21 to 150°C at a heating rate of 10°C / min, keep it for 18 minutes, then heat it to 250°C at a heating rate of 5°C / min and keep it for 0.5 hours, set 300MPa pressure, keep the pressure for 0.5 hours, and start the program.

[0064] S3: Start the program, the first driving motor 6 drives the stirring shaft 5 to rotate and mix the raw materials for five minutes to fully mix the raw materials, and at the same time adjust the feeding adjustment device to adjust the injection volume, and use the two-way hydraulic machine 10 to drive the hydraulic piston 11 to move to the left to the limit.

[0065] S4: Open the electric throttle valve 8 to make the mixed raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com