Stirring device for investment casting of wax liquid

A stirring device and investment casting technology, which are applied to mixers with rotary stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of difficult control of wax liquid quality, poor stirring effect, and difficulty in cleaning, etc. Simple and effective, easy to clean, good effect of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

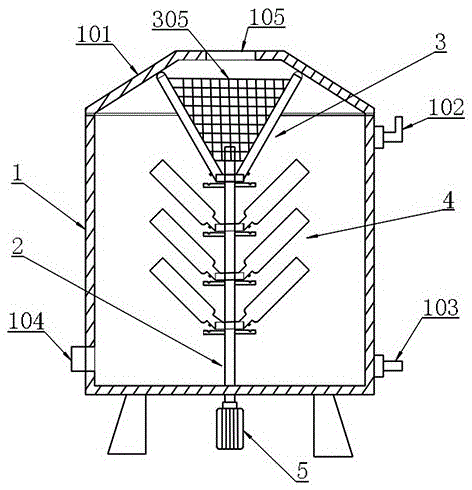

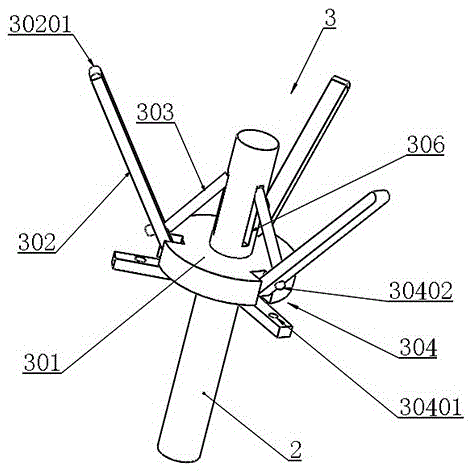

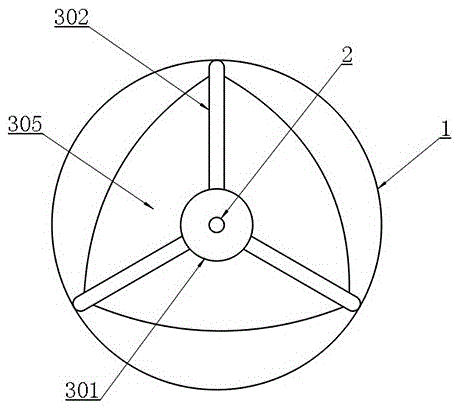

[0022] Example: as attached figure 1 , attached figure 2 , attached image 3 and attached Figure 4 As shown, a stirring device for investment casting wax liquid includes a stirring device main body 1 and a stirring column 2 arranged in the stirring device main body 1, and the stirring column 2 is sequentially provided with The filter screen unit 3 and the stirring rod unit 4 can be folded by elastic tension, the wax liquid enters the stirring device through the filter screen unit 3, and the stirring device has the advantage of convenient and thorough stirring, and the filter screen unit 3 And the stirring rod unit 4 has the feature of being foldable, which makes the cleaning of the inner wall of the stirring device more convenient and effective.

[0023] The stirring column 2 passes through and is fixed on the lower end plate of the main body 1 of the stirring device, and is driven to rotate by a motor 5 . The filter screen unit 3 includes a filter screen fixed chassis 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com