Novel plastic construction stirring machine

A mixer and mixing motor technology, applied in roads, construction, road repair, etc., can solve the problems of uneven mixing, high labor intensity, troublesome operation, etc., achieve uniform and thorough mixing, improve construction efficiency, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with specific embodiments.

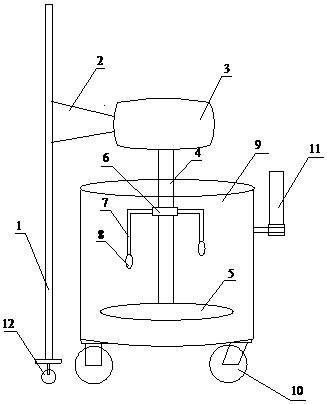

[0012] as attached figure 1 As shown, this embodiment includes a barrel 9 and a frame 1, the frame 1 is provided with a slide rail, a stirring motor 3 is installed on the slide rail through a motor base 2, and the output shaft of the stirring motor 3 is in phase with the stirring shaft 4 The bottom end of the stirring shaft 4 is equipped with a stirring roller 5, the middle part of the stirring shaft 4 is provided with a fixed sleeve 6, the fixed sleeve 6 is provided with a plurality of stirring claws 7 of different lengths, and the end of the stirring claw 7 is provided with a stirring blade 8; A universal brake wheel 10 is installed at the bottom of the barrel 9, and a retractable handle 11 is installed on the side of the barrel 9.

[0013] Described motor base 2 is driven by the lifting motor that is installed on the support.

[0014] Rollers 12 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com