Paint processing equipment for construction

A processing equipment and construction technology, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve the problems that different raw materials cannot be fully mixed together, affect the performance of architectural coatings, pollute the surrounding environment, etc., and increase the stability of connection and installation performance, improve the overall stability, and increase the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the content, features, and effects of the present invention, the following embodiments are listed in conjunction with the accompanying drawings.

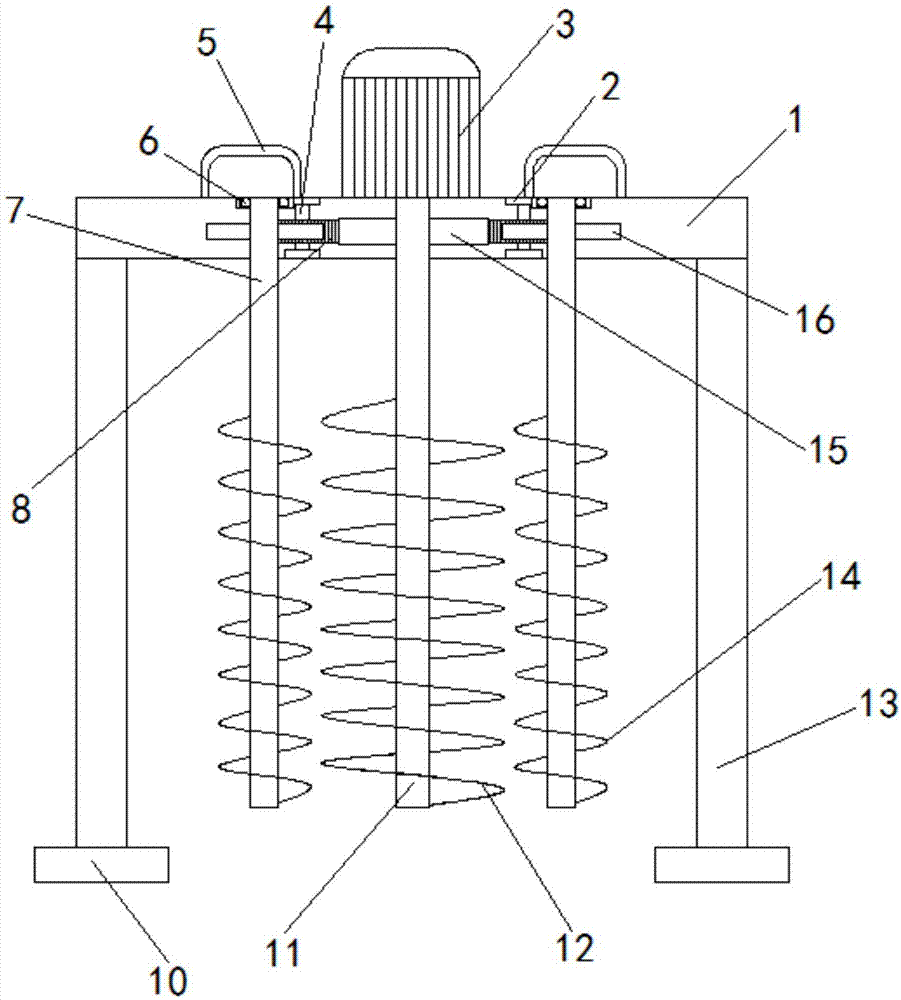

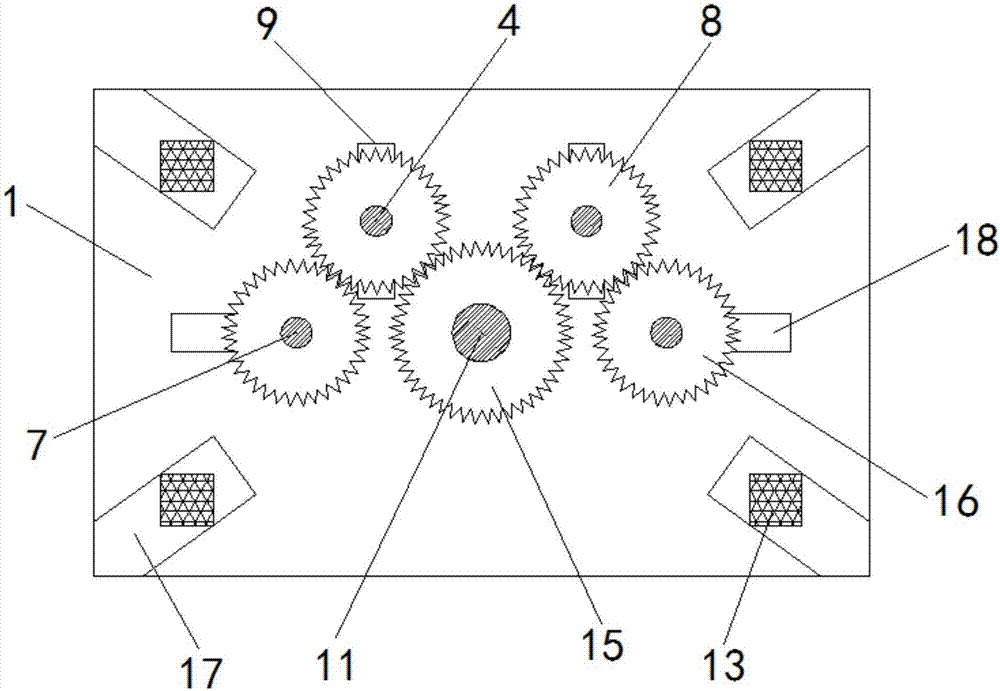

[0020] Combine below Figure 1-2 The structure of the construction coating processing equipment of the present invention will be described in detail: a construction coating processing equipment, including an upper cover box 1, a motor 3, a handle 5, a foot 10, a main rotating rod 11, a main stirring blade 12, and a leg 13 and auxiliary stirring paddle 14, the upper surface of the upper box 1 is provided with a motor 3 in the middle of the upper surface, the motor 3 is provided with handles 5 on both sides, the handle 5 is fixedly connected to the upper surface of the upper box 1, the motor 3 The output end is connected with a main rotating rod 11 through a coupling. A main stirring paddle 12 is provided on the outer side of the lower section of the main rotating rod 11, and a driving gear 15 is sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com