Stirrer and smelting furnace with stirrer

A technology of stirrer and stirring paddle, which is applied in the direction of stirring devices, furnaces, furnace materials, etc., can solve the problems of high labor intensity, limited stirring effect, and harsh working environment for workers, achieve uniform and thorough stirring, and avoid space occupation and waste , Improve the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

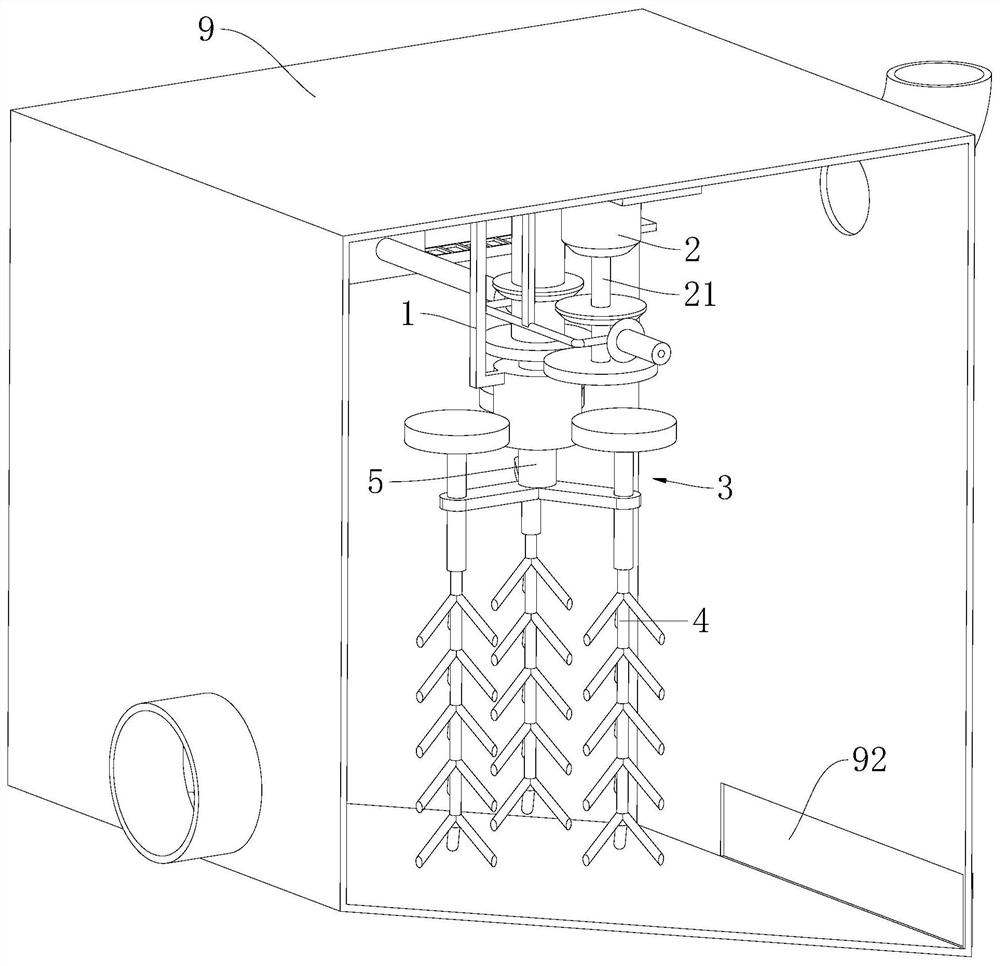

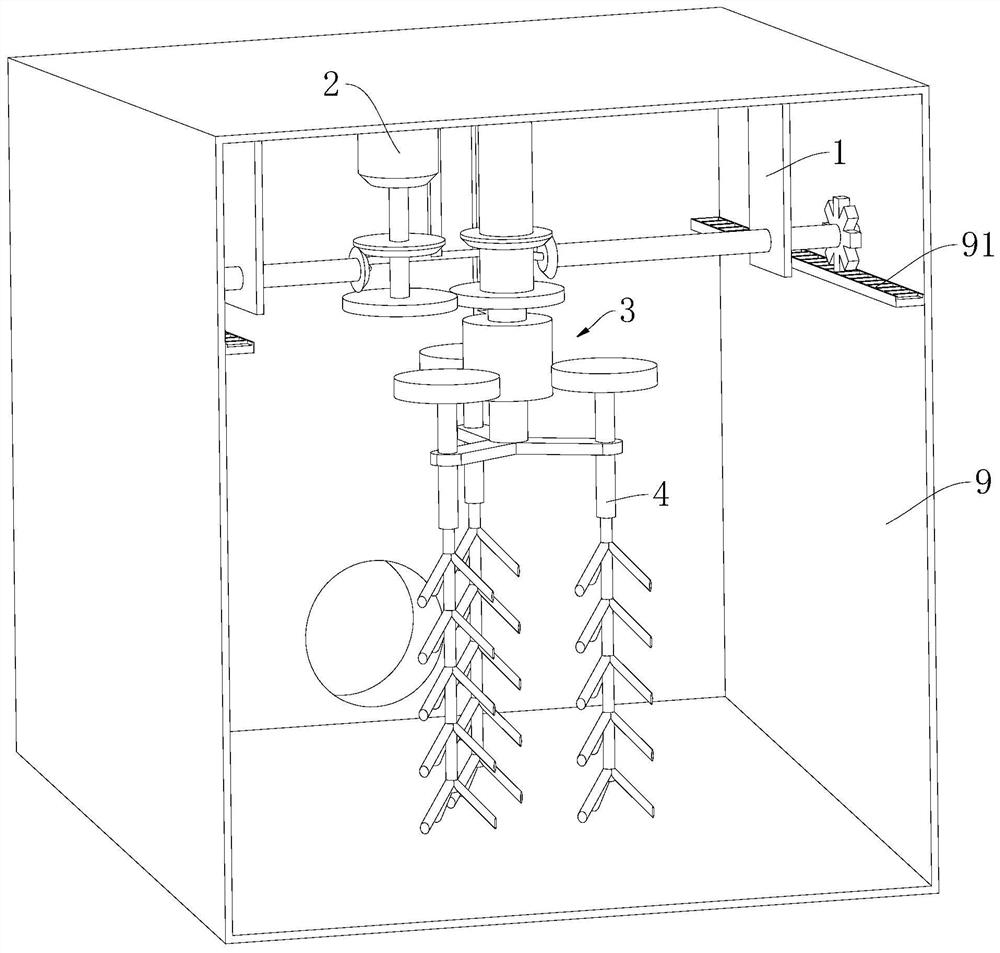

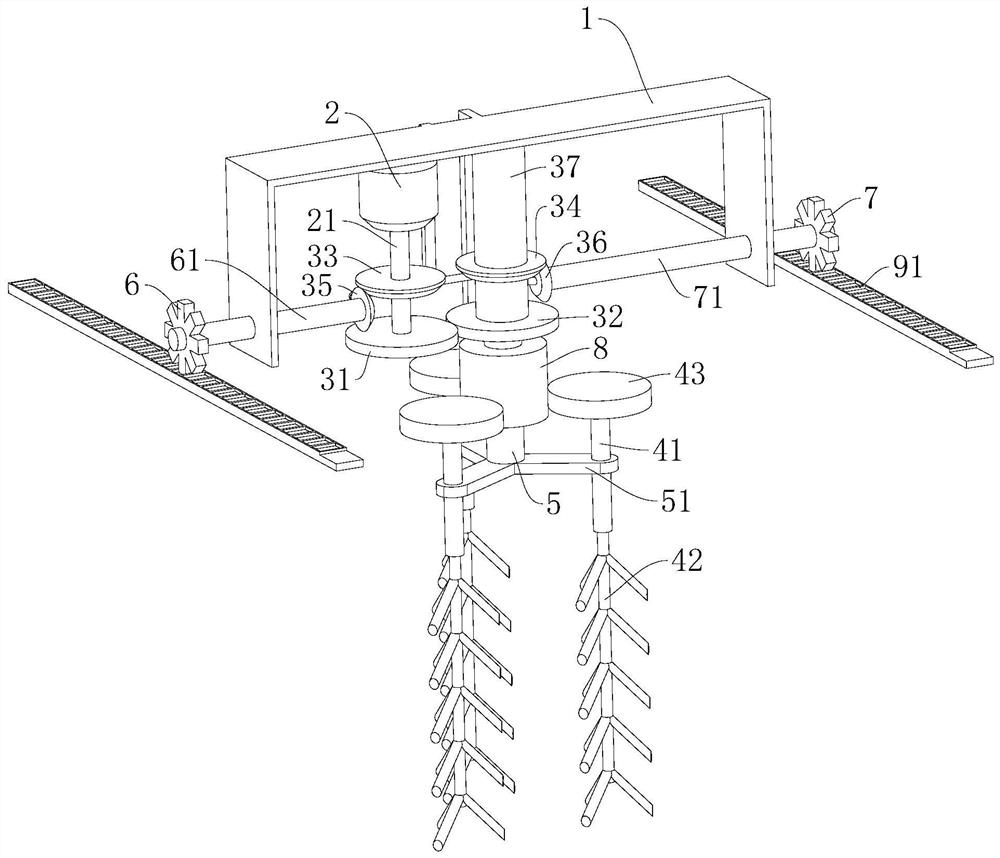

[0029] A furnace with a stirrer, incorporating Figure 1-5 As shown, it includes a housing 9 and an agitator arranged in the housing 9. The cross section of the housing 9 is rectangular, and guide rails 91 are arranged on the opposite inner walls of the housing 9, and the guide rails 91 are along the length direction of the housing 9. extend. The housing 9 is provided with a material inlet, a material outlet and a liquid outlet, and the bottom of the housing 9 is inclined. The feed inlet is set above the shell 9 for putting scrap aluminum into the furnace, and the liquid outlet is located on the higher side of the bottom of the shell 9, and the molten aluminum liquid is guided to the next process through the guide pipe In the refining furnace, the discharge port of the shell 9 is located at the lower side of the bottom of the shell 9, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com