Flower cultivating soil stirring device

A stirring device and flower soil technology, which is applied to mixers with rotating stirring devices, transportation and packaging, mixers, etc., can solve problems such as uneven mixing, troublesome cleaning, etc.

Inactive Publication Date: 2017-11-03

闫淑军

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is no specific device for flower soil mixing on the market. Generally, the flower soil is mixed directly on the ground, which will be very troublesome when cleaning up, and the mixing is not uniform

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0017] Embodiment 2: Replacing the electronically controlled telescopic rod 14 with a telescopic cylinder can also achieve the effect of pushing the No. 2 rotating motor 15, and other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

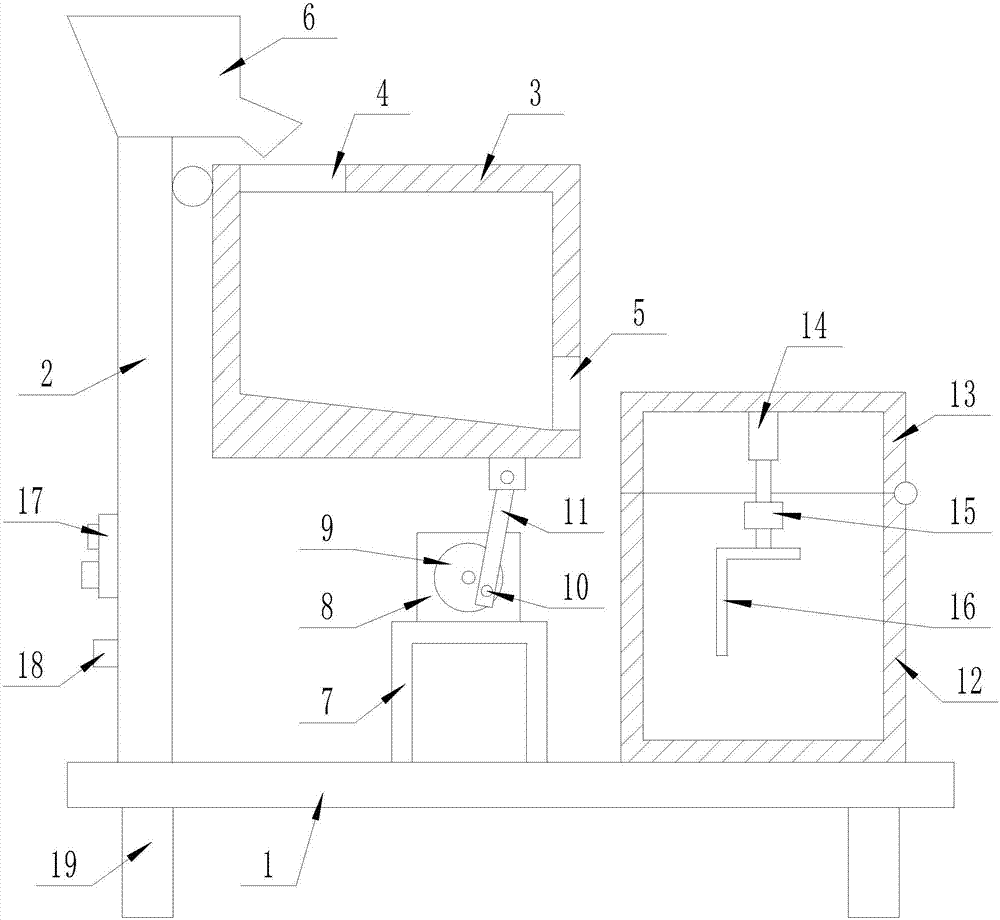

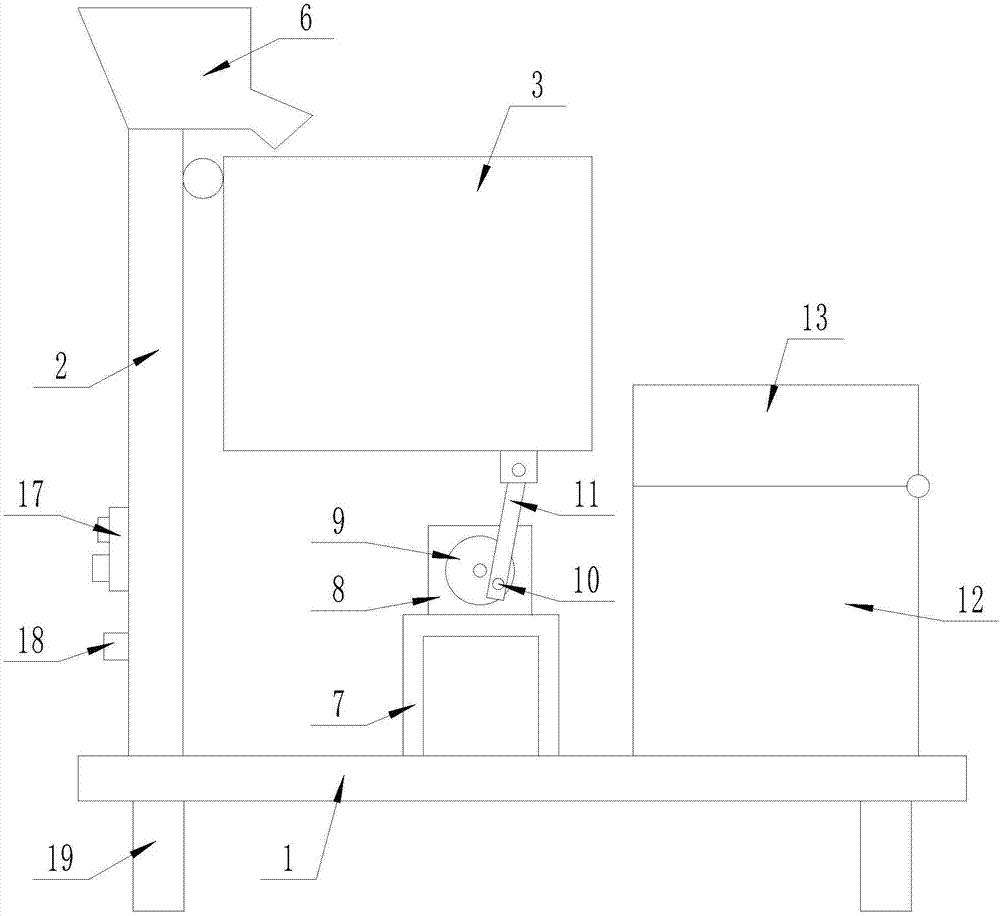

The invention discloses a flower cultivating soil stirring device. The device comprises a rectangular pedestal, a door-shaped supporting rack is arranged at the left side of the upper surface of the rectangular pedestal, a rectangular jittering box body is hinged to the surface of the right side of the door-shaped supporting rack, the left side of the upper surface of the rectangular jittering box body is provided with a material inlet, the lower end of the side surface of the rectangular jittering box body is provided with a discharging opening, the upper surface of the door-shaped supporting rack is provided with a feeding hopper lap-jointed to the material inlet, a motor fixing rack is arranged on the upper surface of the rectangular pedestal and positioned below the rectangular jittering box body, the upper surface of the motor fixing rack is provided with a first rotating motor with the rotating end being horizontal, the rotating end of the first rotating motor is provided with a rotating disc, and the edge of the front surface of the rotating disc is provided with a rotating circular rod. The device preliminarily jitters flower cultivating soil in the flower cultivating soil stirring process to break large soil blocks, and stirs and mixes the broken soil to form flower cultivating soil, so the flower cultivating soil is uniformly and thoroughly stirred.

Description

technical field [0001] The invention relates to the field of flower soil mixing, in particular to a flower soil stirring device. Background technique [0002] Flower soil is the soil used for cultivating plants and can provide sufficient nutrients for plants. At present, the common flower soils on the market include pastoral soil, humus soil, peat soil, cultivation soil, Clivia soil, etc. Common auxiliary materials include volcanic particles, vermiculite, perlite, oak leaves, pine needles, coconut peat, activated carbon, etc. . [0003] Usually people will carefully select and configure nutrient-rich flower soil before planting flowers and plants, and then place them in flower pots to plant plants. However, there is no specific device for flower soil mixing on the market. Generally, the flower soil is mixed directly on the ground, which will be very troublesome when cleaning up, and the mixing is not uniform. In order to cope with this situation, it is necessary to design...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01F7/16B01F3/20B01F23/70

CPCB01F23/70B01F27/11B01F27/80

Inventor 闫淑军

Owner 闫淑军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com