Medical PVC particle production system

A technology of production system and pellets, which is applied in the field of medical PVC pellets production system, can solve the problems that product quality cannot be guaranteed, affect the economic benefits of enterprises, and the degree of automation is low, so as to reduce molecular groups and impurities and achieve a high degree of automation , Guarantee the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

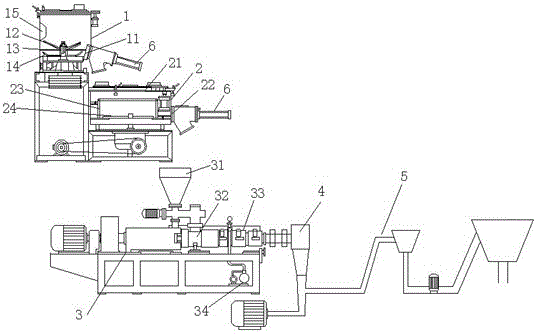

[0014] Such as figure 1 Shown is a production system for medical PVC pellets, comprising a heat mixer 1, a cold mixer 2, an extruder 3, a pelletizer 4 and an air delivery system 5, the heat mixer 1 is arranged on the top of the cold mixer 2, and the extruder The press 3 is arranged at the lower part of the cold mixer 2, the extruder 3 is connected with the pelletizer 4 and the air delivery system 5 in turn, the discharge port 11 of the thermomixer 1 is vertically arranged at the top of the feed port 21 of the cold mixer 2, and the cold The discharge port 22 of the mixer 2 is vertically arranged on the upper part of the hopper 31 of the extruder 3, the stirring device is provided in the heat mixer 1, the cooling device is provided in the cold mixer 2, and the screw rod is provided in the extruder 3 The conveying component 32 and the screw conveying component 32 are provided with a heating device 33 outside to ensure the temperature of the material and the quality of the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com