Improved material mixing device

An improved stirring shaft technology, which is applied to mixers with rotating stirring devices, transportation and packaging, mixer accessories, etc., can solve the problems of reduced mixing efficiency, uneven seed quality, and seeds that cannot be stirred, and achieve guaranteed Quality, improve the effect of stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

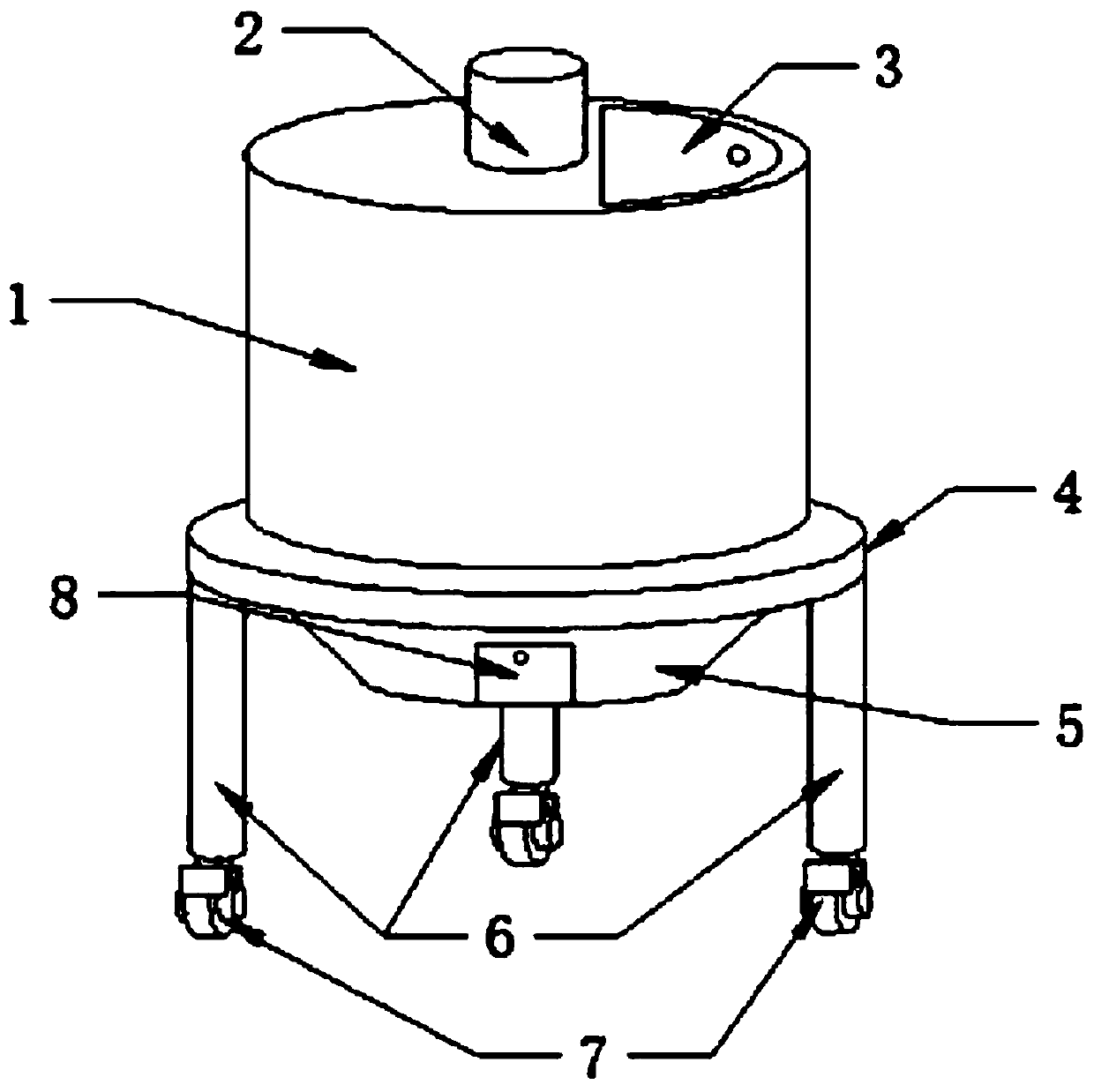

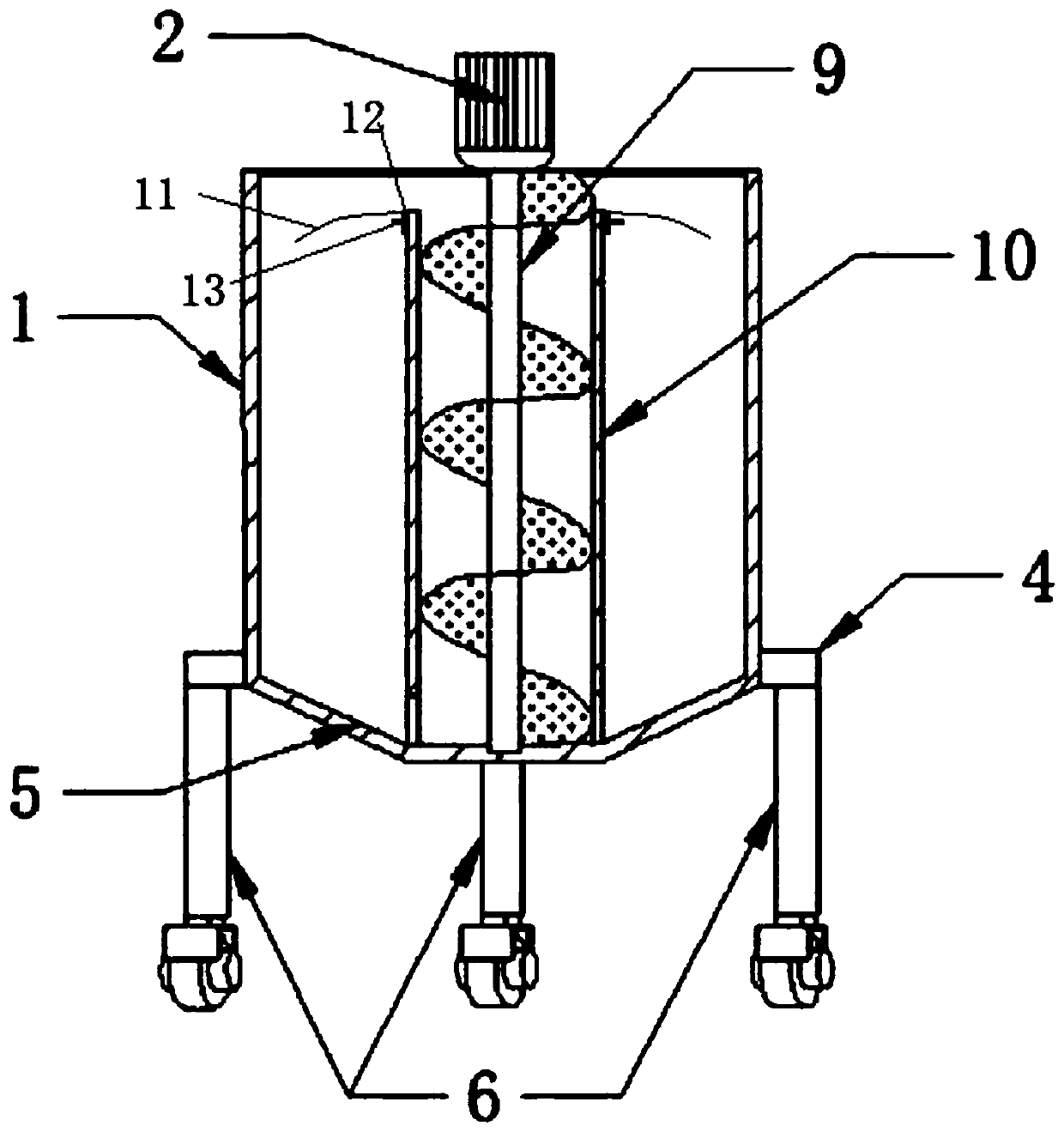

[0020] refer to Figure 1-3 : An improved mixing device, comprising a body 1; the body 1 is cylindrical; the lower end of the body 1 is fixedly equipped with a funnel 5, the funnel 5 is in the shape of an inverted frustum, and a discharge port 8 is installed on the side of the funnel 5; the body 1 A fixed ring 4 is installed around the bottom of the outer wall, and three outriggers 6 are uniformly fixedly installed under the fixed ring 4, and universal wheels 7 are installed under the outriggers 6, and a self-locking structure is provided; the upper end surface of the body 1 is embedded with a A door 3, the door 3 is in the shape of a semicircular plate;

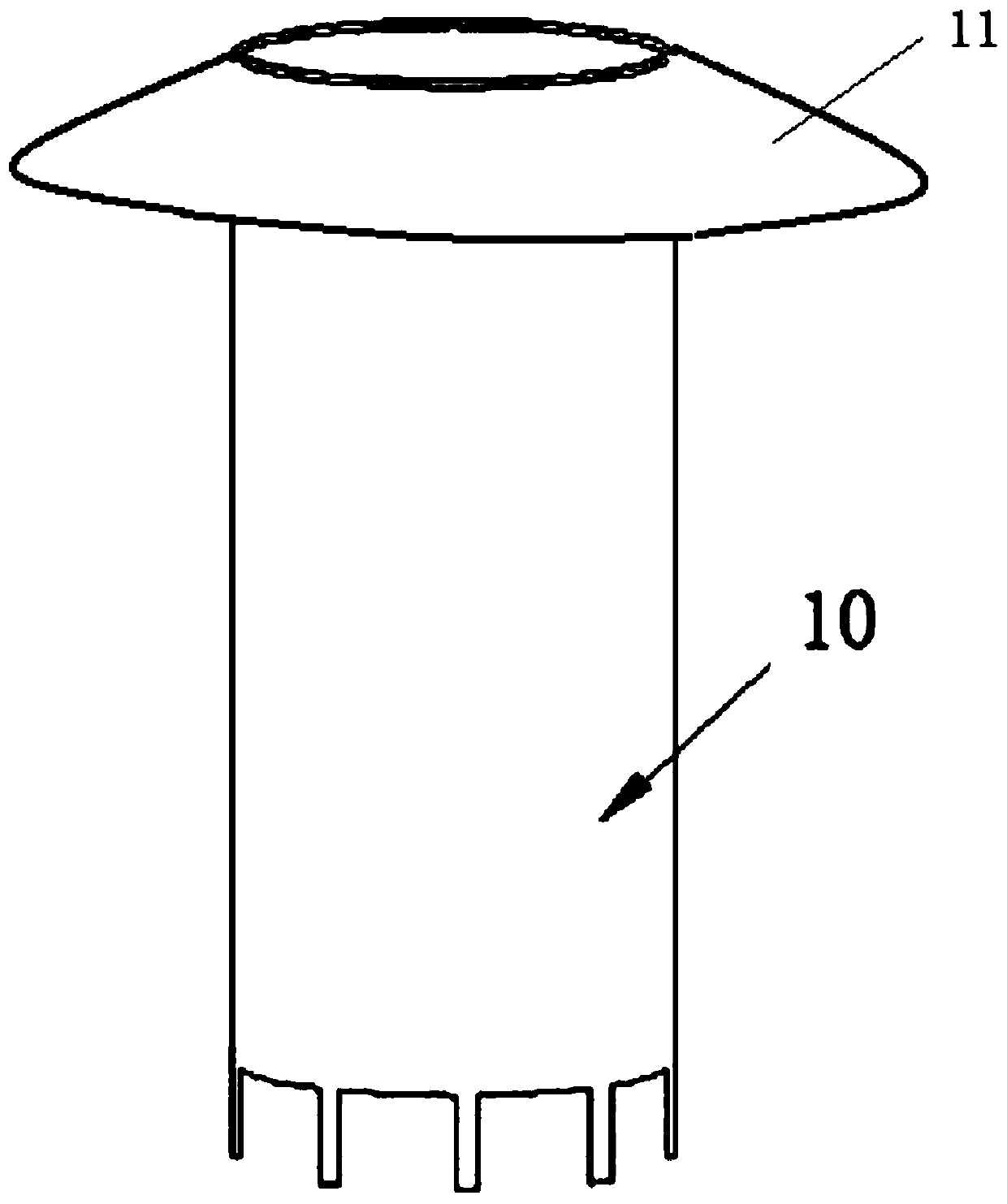

[0021] A stirring shaft 9 is installed at the center of the body 1, and a protective plate 10 is installed around the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com