Treatment system and method for nitrite and nitrate absorption liquid after wet flue gas denitration

A nitrite and treatment system technology, applied in the field of treatment systems containing nitrite and nitrate absorption liquid after wet flue gas denitrification, can solve the application range of ion exchanger varieties and cost constraints, high cost is not suitable for large Large-scale treatment of water pollutants, secondary pollution of water quality, etc., to achieve the effect of rapid treatment, simple treatment method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

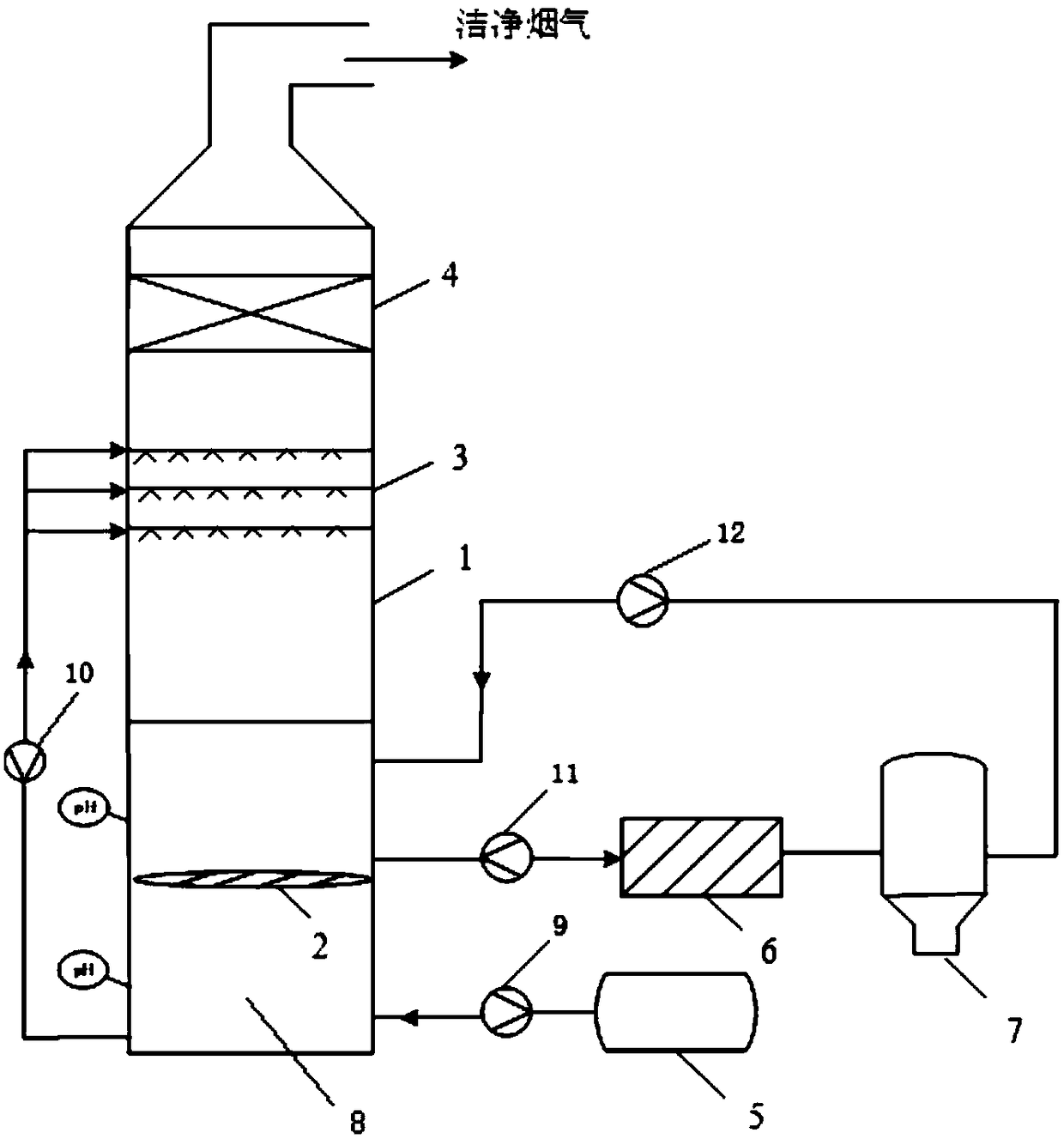

[0036] The invention as figure 1 As shown, it includes a desulfurization tower 1 for simultaneous desulfurization and denitrification of the dust-removed and oxidized flue gas through the absorption liquid, and is used to provide an absorption liquid supply system containing alcohol amine ionic liquid additives and ammonia water and a by-product separation and recovery system; The desulfurization tower 1 is provided with a straight chimney, a multi-stage demister 4, a spray layer 3, and a slurry pool 8 from top to bottom; the slurry pool 8 is provided with a double-zone separation sieve plate 2 for the slurry to form a double-zone slurry pool, that is, the absorption zone at the lower part of the slurry pool 8 and the self-decomposition reaction zone at the upper part of the slurry pool 8; the bottom of the slurry pool 8 is connected to the spray layer 3 through the slurry circulation pump 10, and the flue gas after dust removal and oxidation is reversed to the spray slurry Co...

Embodiment 2

[0042] Process flow of the present invention comprises the steps:

[0043] Step 1: Wet Denitrification

[0044] After dedusting and oxidation, the flue gas is sent to the entrance of the desulfurization tower 1, and the absorption zone at the lower part of the slurry pool 8 is added with 0.5-5% ammonia water and 10-30% alcohol amine ionic liquid absorption liquid, The slurry circulation pump 10 sends the absorption liquid to the spray layer 3, sprayed out from the atomizing nozzle, and reacts with the bottom-up dedusted and oxidized flue gas to remove NO 2 and SO 2 , the purified flue gas is dried by the multi-stage demister 4 and then discharged from the chimney at the top of the desulfurization tower 1. Absorption liquid removes NO 2 Then generate the corresponding ammonium nitrate and ammonium nitrite. NO 2 It is mainly absorbed through the oxidation-reduction reaction with sulfite, so most of the absorption liquid is nitrite. The main function of ionic liquid in the r...

Embodiment 3

[0051] With the treatment method described in embodiment 2, in the absorption liquid storage tank 5, the ammoniacal liquor of 2% and the alcohol amine ionic liquid absorption liquid of 15% by mass fraction are prepared in the absorption liquid storage tank 5, and it is transported to the bottom of the slurry pool 8, The absorption liquid is sent to the spray layer 3 through the slurry circulation pump 11, sprayed out from the atomizing nozzle, contacts with the dust-removed and oxidized flue gas from bottom to top, and removes NO therein 2 and SO 2 . Absorption liquid removes NO 2 Then generate the corresponding ammonium nitrate and ammonium nitrite. The absorption solution containing ammonium nitrite and ammonium nitrate enters the self-decomposition reaction zone of the slurry tank 8, and the pH value of this section is controlled to be 5.5, and the temperature of the absorption solution is controlled to be 52°C. Ammonium nitrite can undergo self-decomposition reaction rap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com