Anaerobic fermentation system and method for producing biogas by carrying out sludge digestion reaction through anaerobic fermentation system

An anaerobic fermentation and fermentation bin technology, applied in the field of waste treatment, can solve problems such as difficult to achieve continuous feeding and discharging, uneven decomposition of organic matter, large volume, etc., and achieve the effect of maintaining balance, stabilizing temperature, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

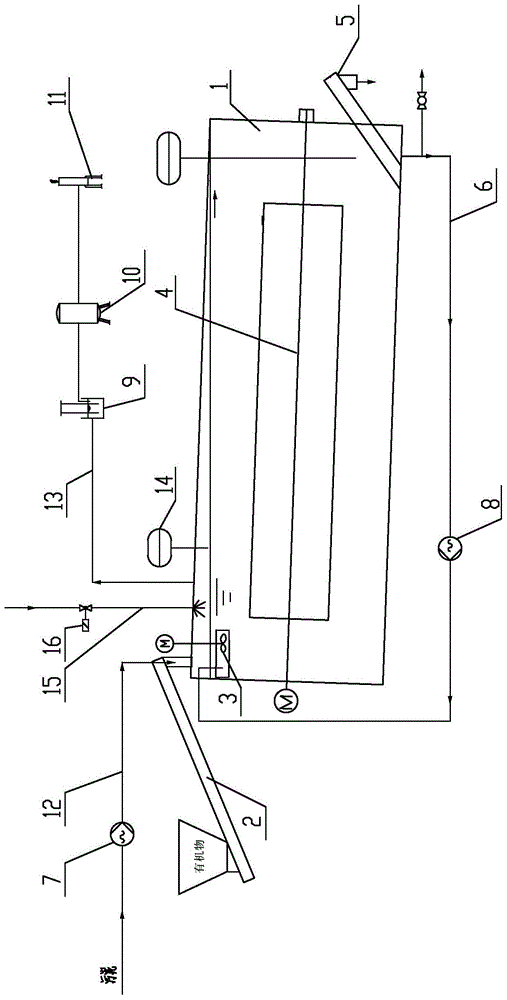

[0028] like figure 1 As shown, a kind of anaerobic fermentation system of the present invention comprises fermentation bin 1, feeding screw conveying device 2, mixing device 3, horizontal stirring device 4, screw conveying device (band filter screen) 5, return pipeline 6, feed Mud pump 7, circulating pump 8, water seal 9, gravel filter 10, torch 11, sludge conveying pipeline 12, biogas pipe 13.

[0029] The design volume of fermentation bin 1 is about 40m 3 , When installed, the overall level of the fermentation chamber is slightly inclined, and the angle with the horizontal direction is about 2°.

[0030] Sludge (water content 95%-99%) from sewage treatment equipment and organic matter cornstalks (water content 65%) enter the fermentation bin 1 through the mud inlet pump 7 and the feeding screw conveying device 2 respectively. A mixing device 3 is installed on the top of the front end of the fermentation bin 1 for mixing organic matter and recirculating biogas slurry. A hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com