Rich-lean separated pulverized coal burner

A technology of pulverized coal burner and thick-lean separation, which is applied in the direction of burner, burner for burning powder fuel, combustion method, etc., and can solve the problems that cannot meet the production and operation requirements of power plants, and have a long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

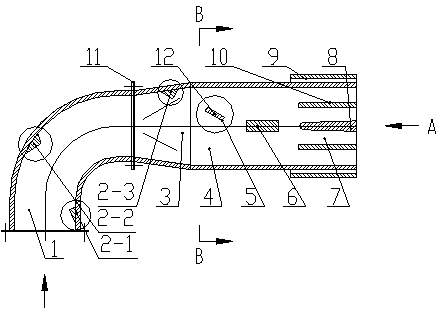

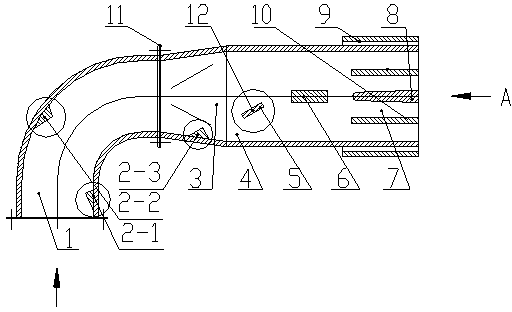

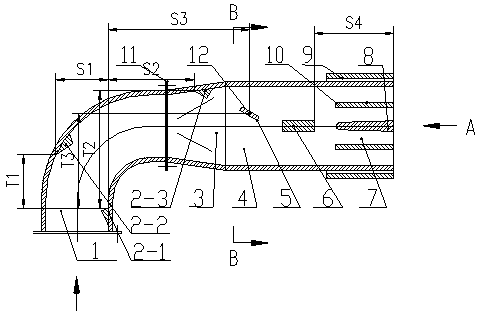

[0006] Specific implementation: it includes burner inlet elbow 1, fixed separation block I2-1, fixed separation block II2-2, fixed separation block III2-3, burner inlet square and round joint 3, pulverized coal concentrator 4 , adjustable block 5, equalizer plate 6, burner nozzle 7, concave blunt body 8, offset secondary air nozzle 9, partition 10, flange 11, rotating shaft 12, inlet elbow 1 and burner inlet The square and round joints 3 are connected by flanges 11, the square and round joints 3 at the burner inlet are connected with the pulverized coal concentrator 4 by welding, and the pulverized coal concentrator 4 and the burner nozzle 7 are connected by welding. It is characterized in that: the burner inlet elbow 1 The fixed separation block I2-1 and the fixed separation block II2-2 are provided on both sides of the inner wall, and the fixed separation block III2-3 is provided on both sides of the inner wall of the burner inlet radius joint , said adjustable stopper 5 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Vertical distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com