Middle core wire oiling device for wire and cable production

A wire and cable core wire technology, applied in the field of wire and cable production equipment, can solve the problems of excessive oiling on the core wire, low degree of automation, poor oiling effect, etc., achieve uniform oiling, save production costs, reduce oil the wasteful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

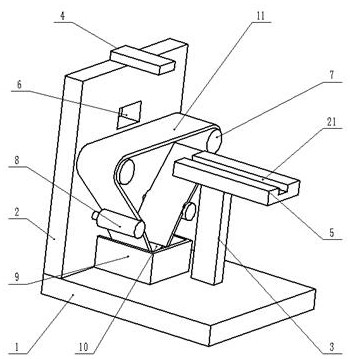

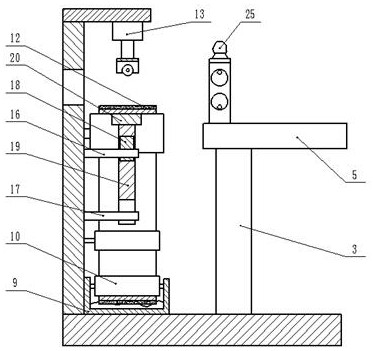

[0022] Example 1: Please refer to figure 1 , a center wire oil passing device for wire and cable production, comprising a base plate, a vertical plate 2 and a support plate 3, the vertical plate 2 is fixedly connected to the left end of the base plate, the upper end of the vertical plate 2 is fixedly welded with a horizontal plate 4, and the support plate 3 is fixed Connected to the bottom plate, the upper end of the support plate 3 is fixedly connected with a guide plate 5, and the vertical plate 2 is provided with a wire inlet 6, and the right side of the vertical plate 2 is rotated and connected with a front and back symmetrical main belt roller 7, and the main belt roller 7 is arranged below There are auxiliary belt rollers 8, which are rotatably connected with the vertical plate 2, and the auxiliary belt rollers 8 are arranged symmetrically front and rear, and the junction of the vertical plate 2 and the bottom plate is fixedly connected with an open box 9, and the open bo...

Embodiment 2

[0032] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the main belt roll 7, the auxiliary belt roll 8 and the oil immersion roll 10 are all made of high-strength plastic materials.

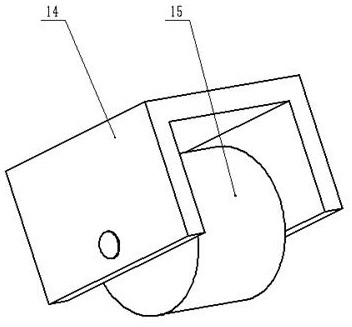

[0033] The working principle of the present invention is: through the wire inlet 6, the center wire is penetrated, the micro motor 25 is started to drive the turntable 23 to rotate, and the wire end of the center wire is clamped by the clamping roller 24, and the lead wire mechanism is in the chute of the guide plate 5 21 to move to the right, at this time the driving shaft 16 rotates to drive the eccentric wheel to rotate 18, the friction pad 20 on the driving rod 19 makes the conveyor belt 11 carry out turnover, the oil soaking roller 10 dips the oil cloth 12 in the open box 9, and the auxiliary belt roller 8 Squeeze the tarpaulin 12, the excess oil flows back into the open box 9, the electric push rod 13 starts, pushes the crimping device to move down, the cri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com