Linkage process of municipal waste pre-treatment and cement kiln resource comprehensive utilization and system thereof

A municipal waste and combined system technology, which is applied in the joint process and system field of municipal waste pretreatment and comprehensive utilization of cement kiln resources, can solve thermal system fluctuations, heat consumption rising rotary kiln systems, clinker product quality fluctuations, etc. problems, to achieve a high fuel substitution rate and save the use of traditional fossil fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

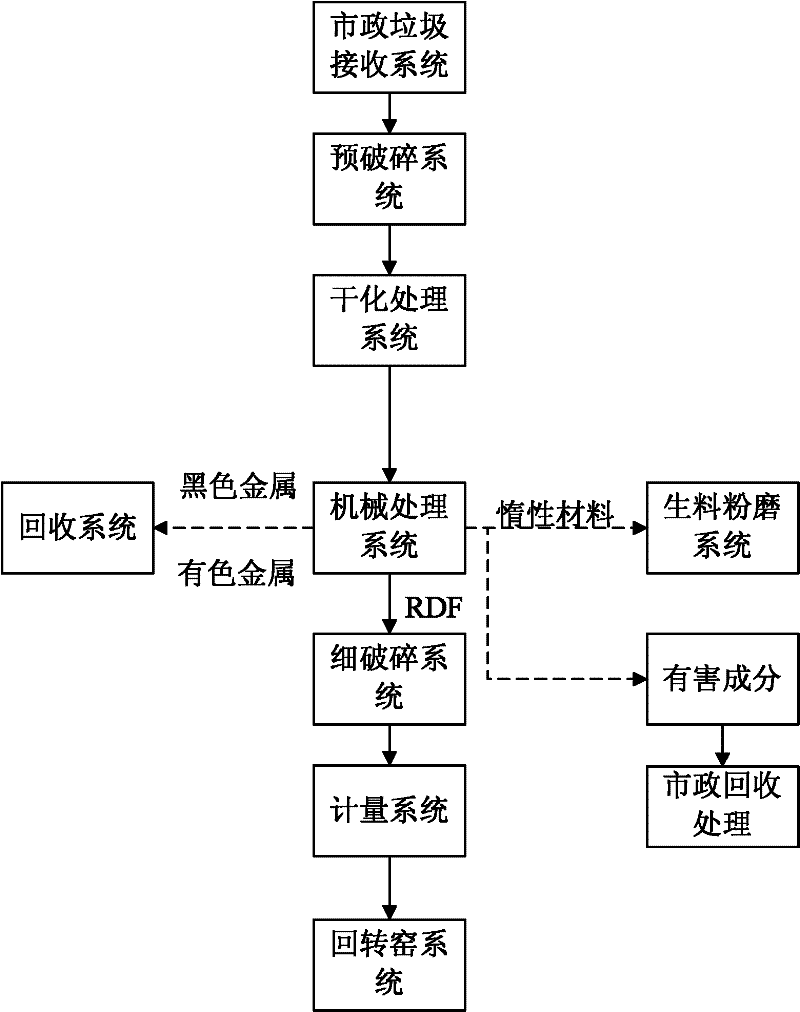

[0030] Such as figure 1 As shown, the combined process of municipal waste pretreatment and comprehensive utilization of cement kiln resources includes the following steps:

[0031] 1) After the municipal waste is measured and radioactively detected, it enters the waste receiving system (that is, the municipal waste receiving system);

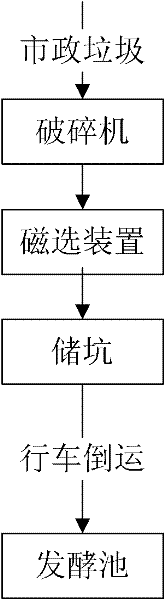

[0032] 2) Pre-shredding: The municipal waste received by the waste receiving system is sent to the pre-shredding system, first crushed by the crusher, and then the crushed waste is sent to the storage pit, and the Fe metal is separated by a magnetic separation device during the transportation process to obtain crushed waste. Garbage; the pre-crushing system includes a crusher, a magnetic separation device and a storage pit (such as figure 2 shown);

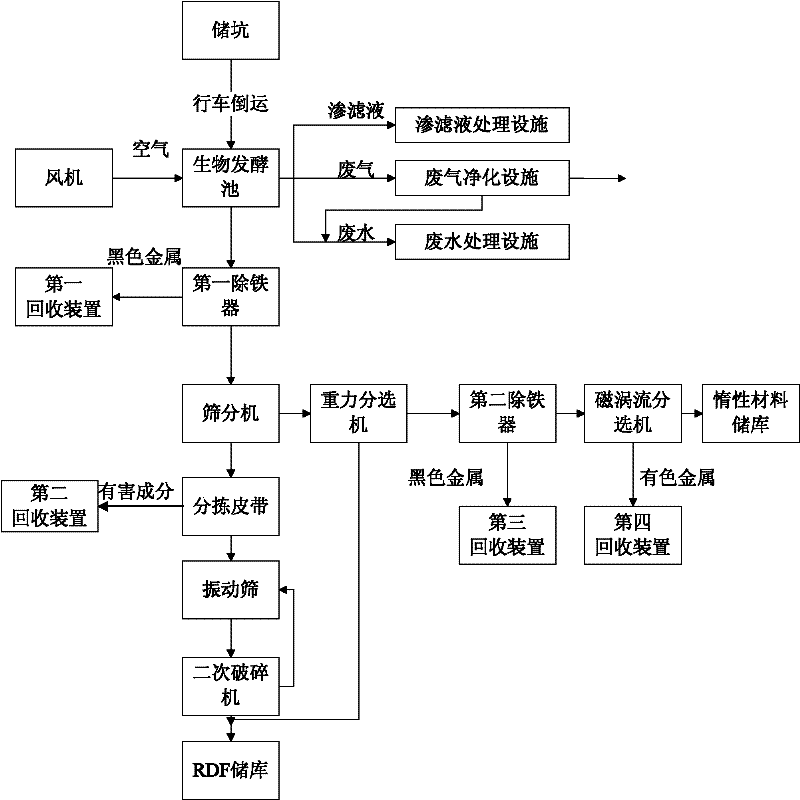

[0033] 3) Utilize drying treatment system (such as image 3 As shown, that is to use aerobic fermentation) to dry and stabilize the broken garbage: transfer the broken garbage in the storage pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com