Fuel oil/gas control and switching system of dual-fuel internal combustion engine

A dual-fuel internal combustion engine and conversion system technology, applied in engine control, internal combustion piston engine, combustion engine and other directions, can solve problems such as the increase of dual-fuel engines, potential safety hazards, explosion of air intake boxes, etc., to achieve high fuel substitution rate and improve safety. performance, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

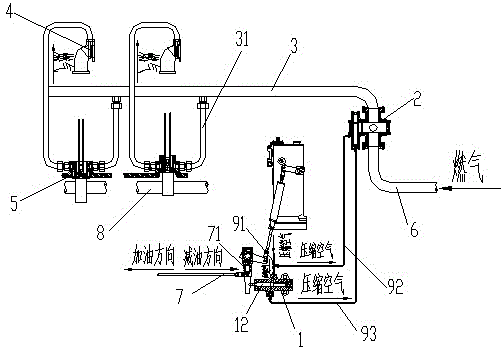

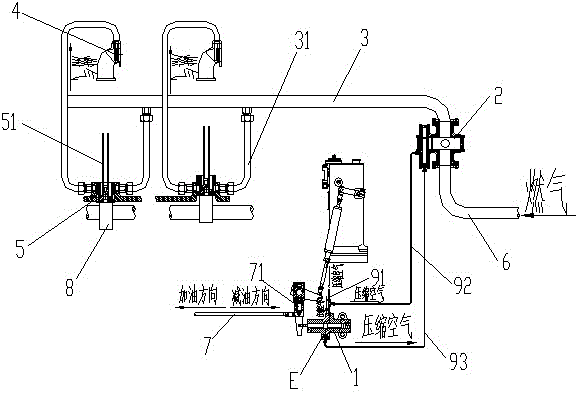

Embodiment 1

[0034] In the first embodiment, the pneumatic control pipeline using compressed air as the power source of the present invention will be described in further detail: In the embodiment, the system mainly consists of a fuel gas control valve 1, a gas automatic pressure regulating valve 2, a single cylinder gas control valve 5 and The single-cylinder gas nozzle 4 consists of four main unit components and control pipes. The control pipeline is provided with compressed air by a compressed air pump, and the control pipeline includes a control main pipe 91, a control branch pipe 92, and an intake and discharge control pipe 93. From Figure 1 to Figure 3 It can be seen that one end of the control header 91 is directly connected to the compressed air pump, and the other end of the control header 91 is connected to the air inlet A of the fuel gas control valve 1. One end of the control branch pipe 92 is connected to the control main pipe 91, and the other end is connected to the upper c...

Embodiment 2

[0048] Embodiment 2. In the embodiment, the control pipeline is a hydraulic control pipeline using hydraulic pressure as a power source, and the control pipeline is equipped with a hydraulic pump that provides hydraulic pressure. Other principles are the same as those in the first embodiment.

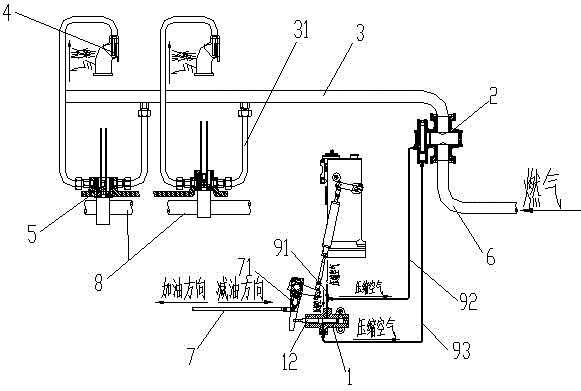

[0049] The advantage of the present invention is that it can realize the automatic conversion of two fuels without stopping the switch. When the gas fuel is disconnected, the governor will automatically push the fuel control lever 7 to move in the refueling direction to increase the fuel volume. At this time the invention is at figure 2 In the state shown, compressed air opens the automatic gas pressure regulating valve 2 to the maximum. Since the gas has been disconnected, no gas enters the cylinder to participate in the combustion. The dual-fuel engine can only burn pure liquid fuel, and the dual-fuel engine becomes Pure diesel engine; when the gas supply is restored, the automatic gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com