Shock-absorbing device for engine support

A technology of engine bracket and shock absorbing device, which is applied in the field of automobile shock absorption, can solve the problems that the strength of the metal bracket cannot be well guaranteed, the metal bracket consumes a lot of materials, and the performance requirements cannot be met, so as to achieve simple structure and reduced material consumption , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

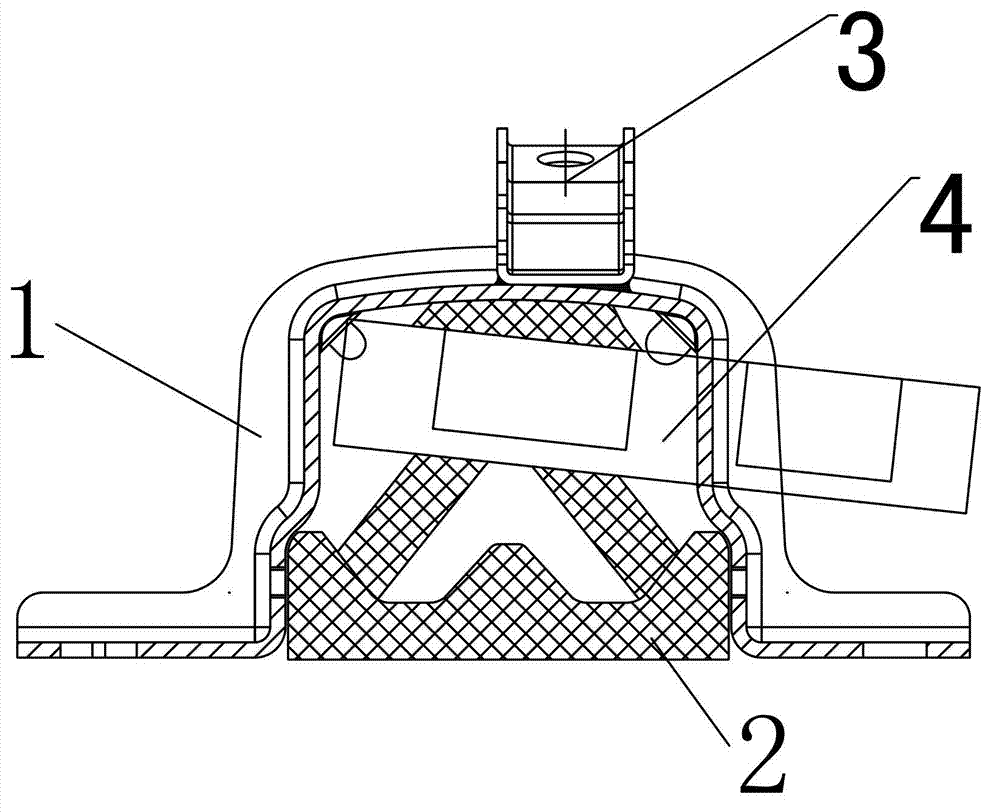

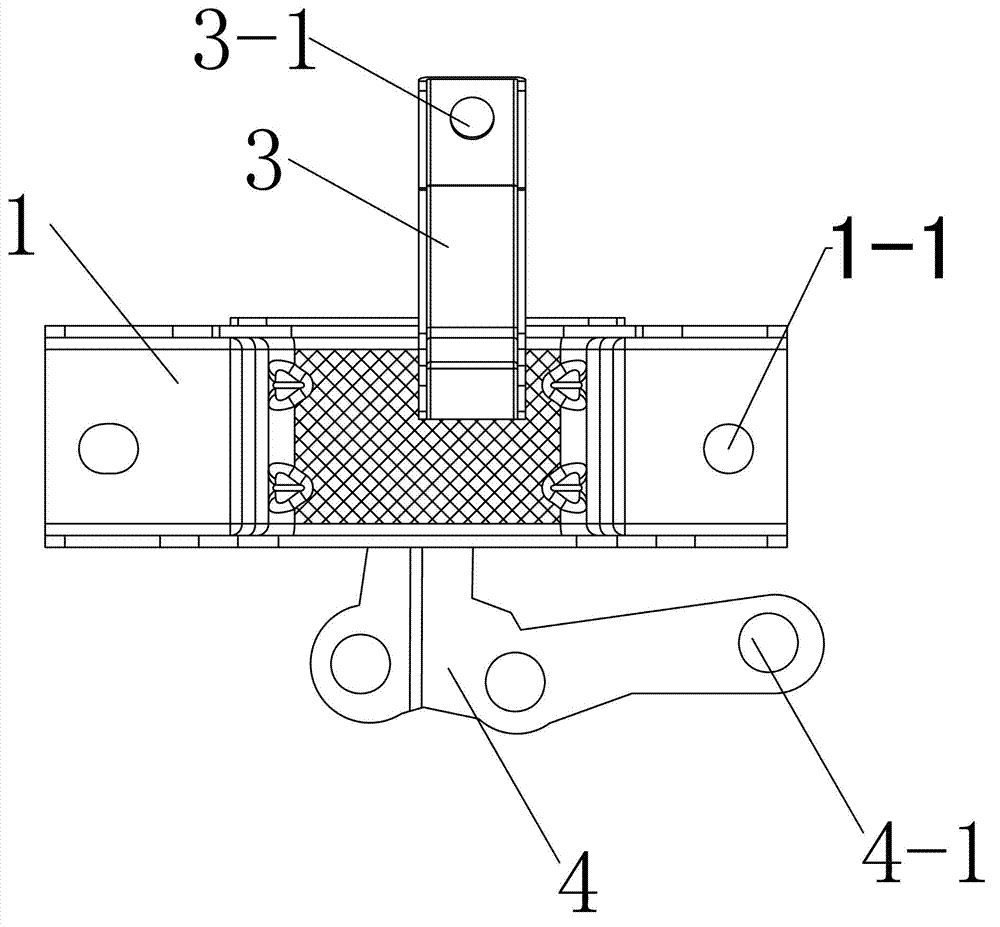

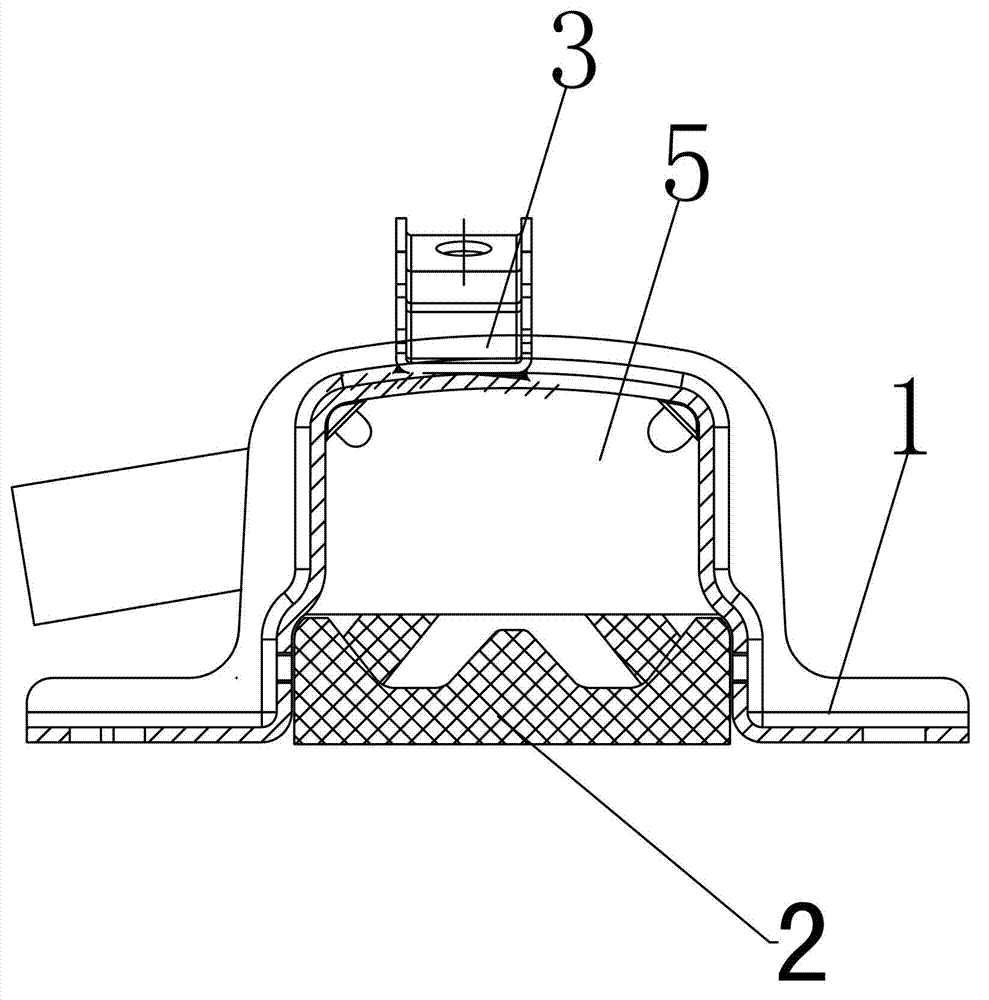

[0016] Such as Figure 1~3 As shown, the present invention includes a metal bracket 1, a shock-absorbing rubber 2, a chassis connection bracket 3, an engine connecting rod 4 and a support plate 5, the metal bracket 1 is a bow-shaped structure, and first connection holes 1-1 are provided on both sides. The first connecting hole 1-1 is used for connecting the chassis of the car. The metal bracket 1 is inlaid with shock-absorbing rubber 2, and the shock-absorbing rubber 2 is used for buffering up and down vibrations, and the motor connecting rod 4 is fixed in the shock-absorbing rubber 2. The engine connecting rod 4 is made of aluminum, which reduces weight, saves energy, reduces emissions, and realizes low carbonization. The engine connecting rod 4 is provided with a second connecting hole 4-1, and the second connecting hole 4-1 is used for connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com