Sewing machine bottom plate machining method and lower shaft hole and edge shaft hole machining device

A processing method and sewing machine technology, applied in the field of sewing machine parts processing, can solve problems such as large processing errors, low production efficiency, and long use time, and achieve the effects of preventing processing errors, ensuring clamping efficiency, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with accompanying drawing, the present invention is further elaborated.

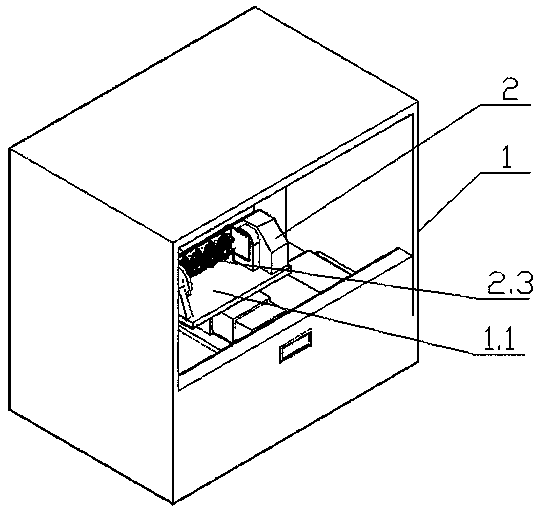

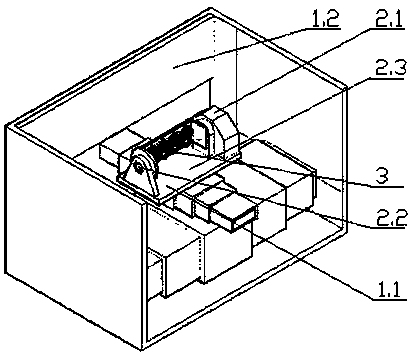

[0023] Such as Figure 2-5As mentioned above, a processing device for the lower shaft hole and the side shaft hole of the sewing machine bottom plate includes a four-axis vertical machining center 1, a four-axis turntable 2 and multiple sets of positioning fixtures 3, and the workbench 1.1 of the four-axis vertical machining center 1 A four-axis turntable 2 is fixed on the top, and the surrounding turntable 2.1 includes a turntable 2.1, a turntable tailstock 2.2 and a fixture base plate 2.3. The positions of the turntable 2.1 and the turntable 2.1 are fixed on the worktable 1.1, and pass The fixture base plate 2.3 is fixed by means of bolt fastening, and the two ends of the fixture base plate 2.3 are respectively connected with the turntable 2.1 and the turntable tailstock 2.2 (L-shaped plates are fixed on both the turntable 2.1 and the turntable tailstock 2.2, and the fixture b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com