Soles with grading design and manufacturing method thereof

A manufacturing method and staged technology, applied in shoe soles, footwear, applications, etc., can solve problems such as limiting flexibility, and achieve the effect of reducing complexity, reducing the number of molds, and facilitating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

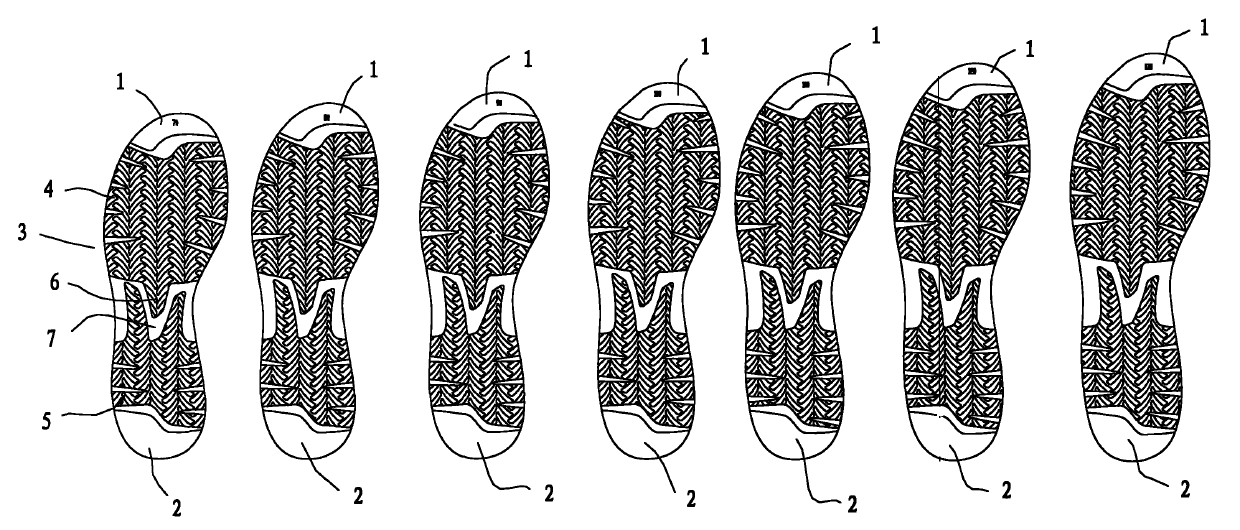

[0020] refer to figure 1 , a shoe sole with a graded design, consisting of a toe cap 1, a shoe sole 3, and a heel 2 that are separated from each other. The head 1 and the heel 2 are the same respectively, and the sole 3 is different, but they are all cut from a size 13 sole. In this embodiment, the shoe sole 3 is composed of a forefoot part 4 and a heel part 5 separated from each other, and a protrusion 6 is provided on the lower part of the forefoot part 4 , and a recess 7 is correspondingly provided on the upper part of the heel part 5 . In the sole of each size, the sole of the size is formed by splicing the toe cap 1, the front palm part 4, the heel part 5 and the heel 2 respectively.

[0021] like figure 1 The step-down soles of various sizes shown are manufactured as follows:

[0022] a. The molds for toe cap 1 and heel 2 are set to manufacture toe cap 1 and heel 2 respectively, and the toe cap and heel are respectively the same in the soles of each size;

[0023] b....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com