Patents

Literature

61results about How to "Reliable connector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

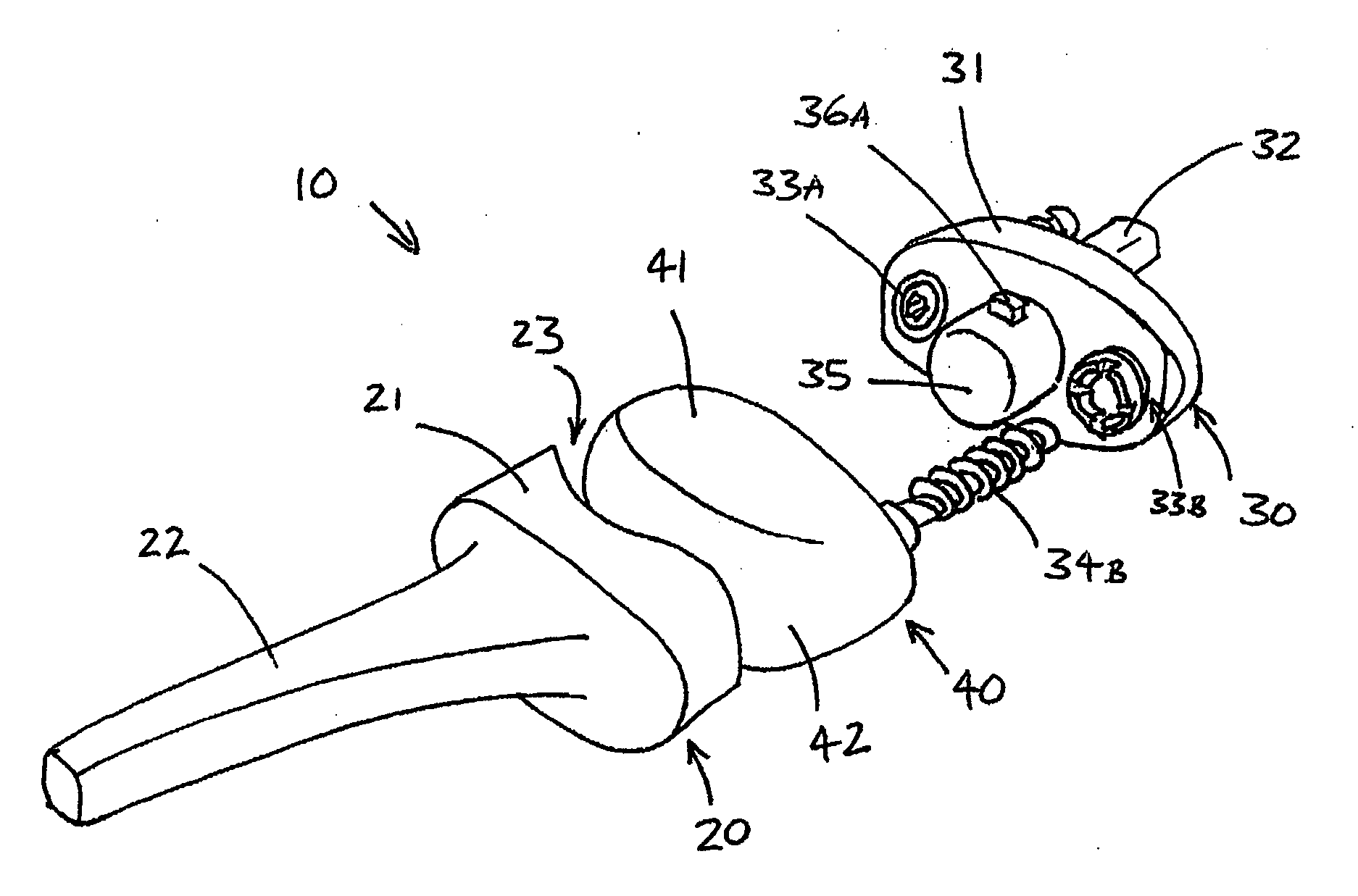

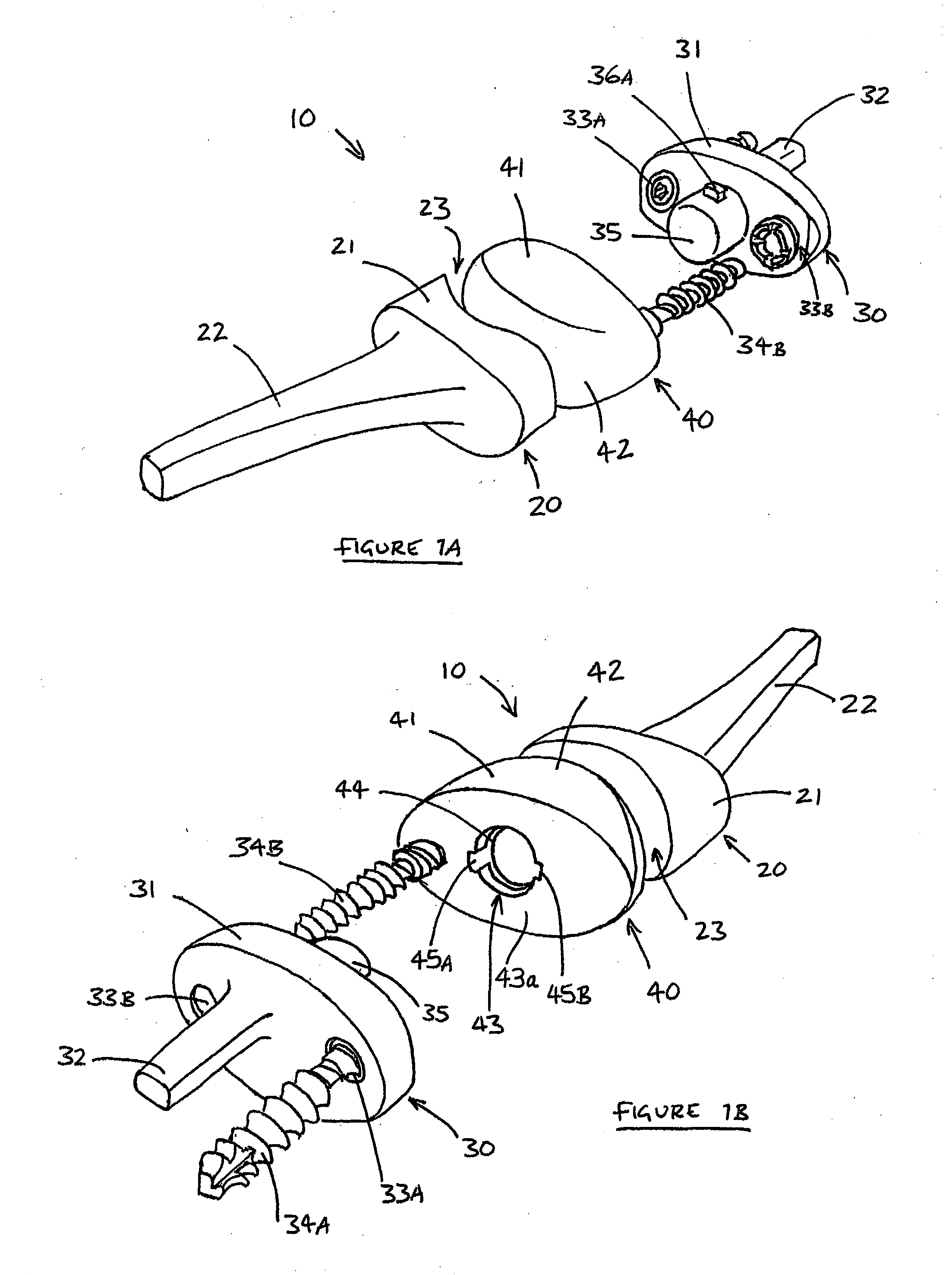

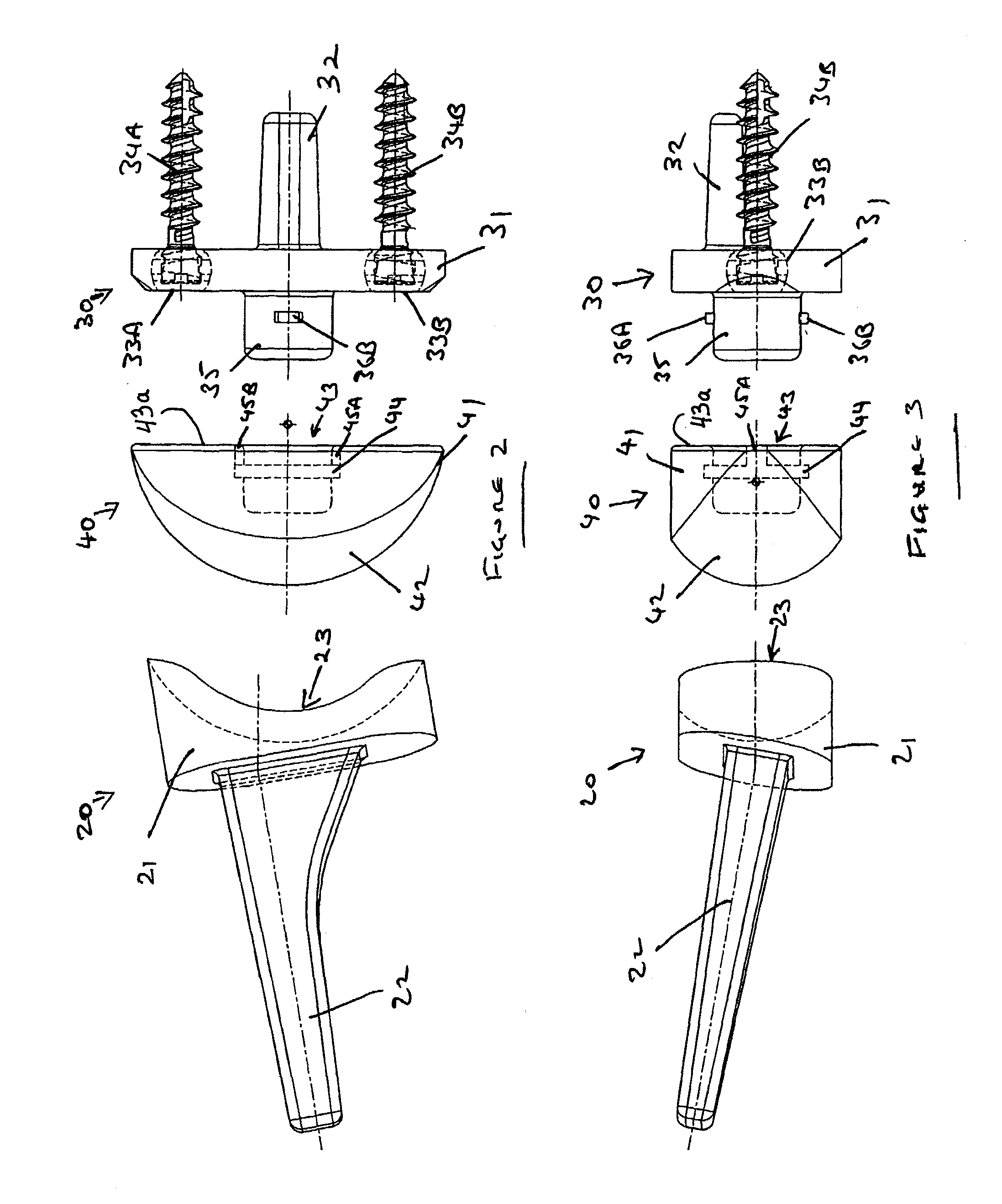

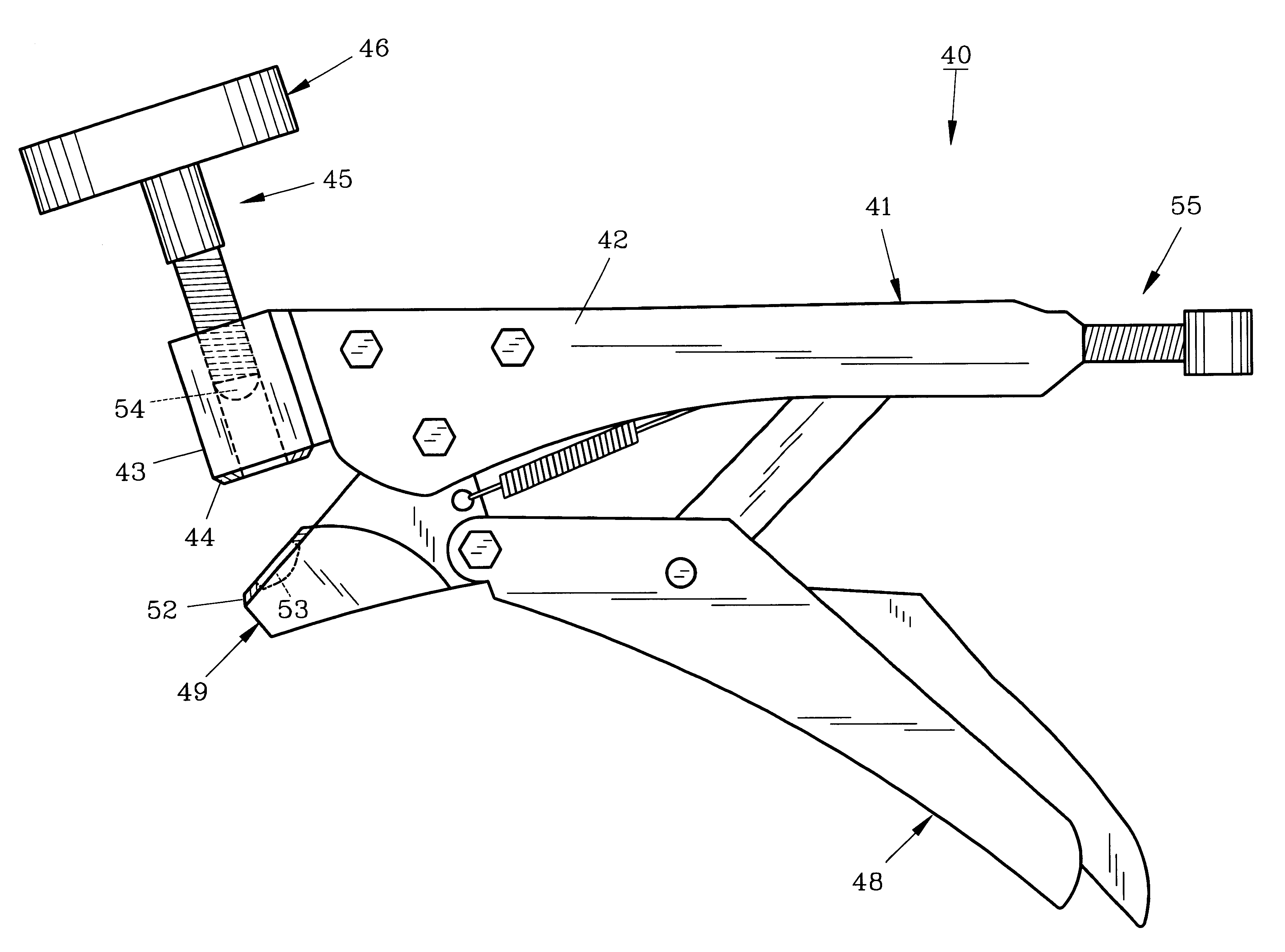

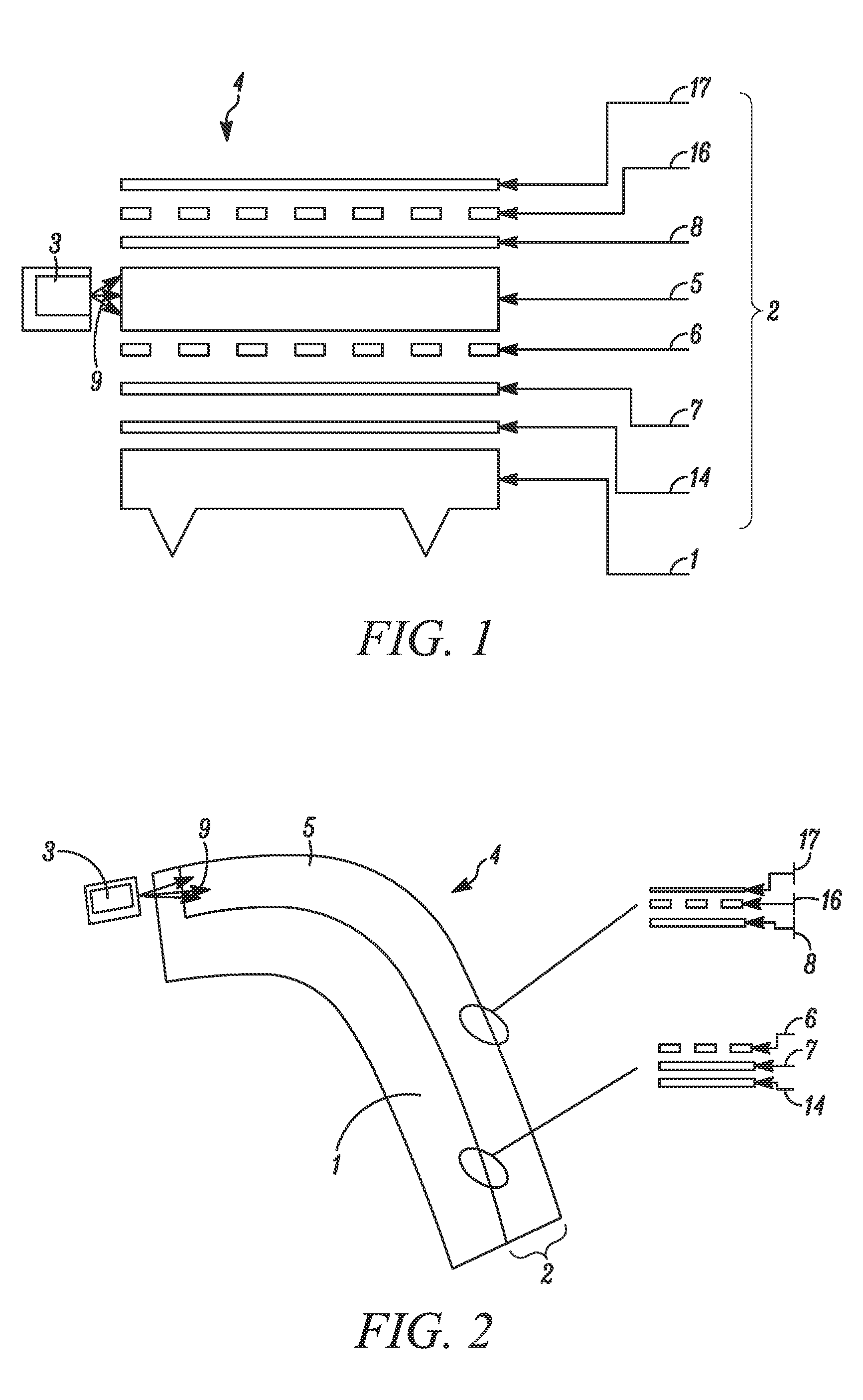

Total wrist prosthesis

InactiveUS20070225820A1Reduce chanceReliable connectorWrist jointsAnkle jointsTransverse planeLigament structure

Total wrist prosthesis comprising a radial component with a stem for fixation into the radius, a carpal component with one or more stems for fixation into the capitate and an intermediate bearing component which articulates with the radial component and allows rotational movement of the carpal component relative to the radial component plus hinged movement in two transverse planes. The radial component body may have a concave or convex surface to articulate with a matching surface on the intermediate bearing component. The carpal body may have a projection which is received in a recess in a base surface of the intermediate bearing component, and which has a pair of lugs that are received in an annular groove in the recess for an axially secure connection that allows small relative rotational movement as permitted by tendons and ligaments of the wrist.

Owner:ASCENSION ORTHOPEDICS

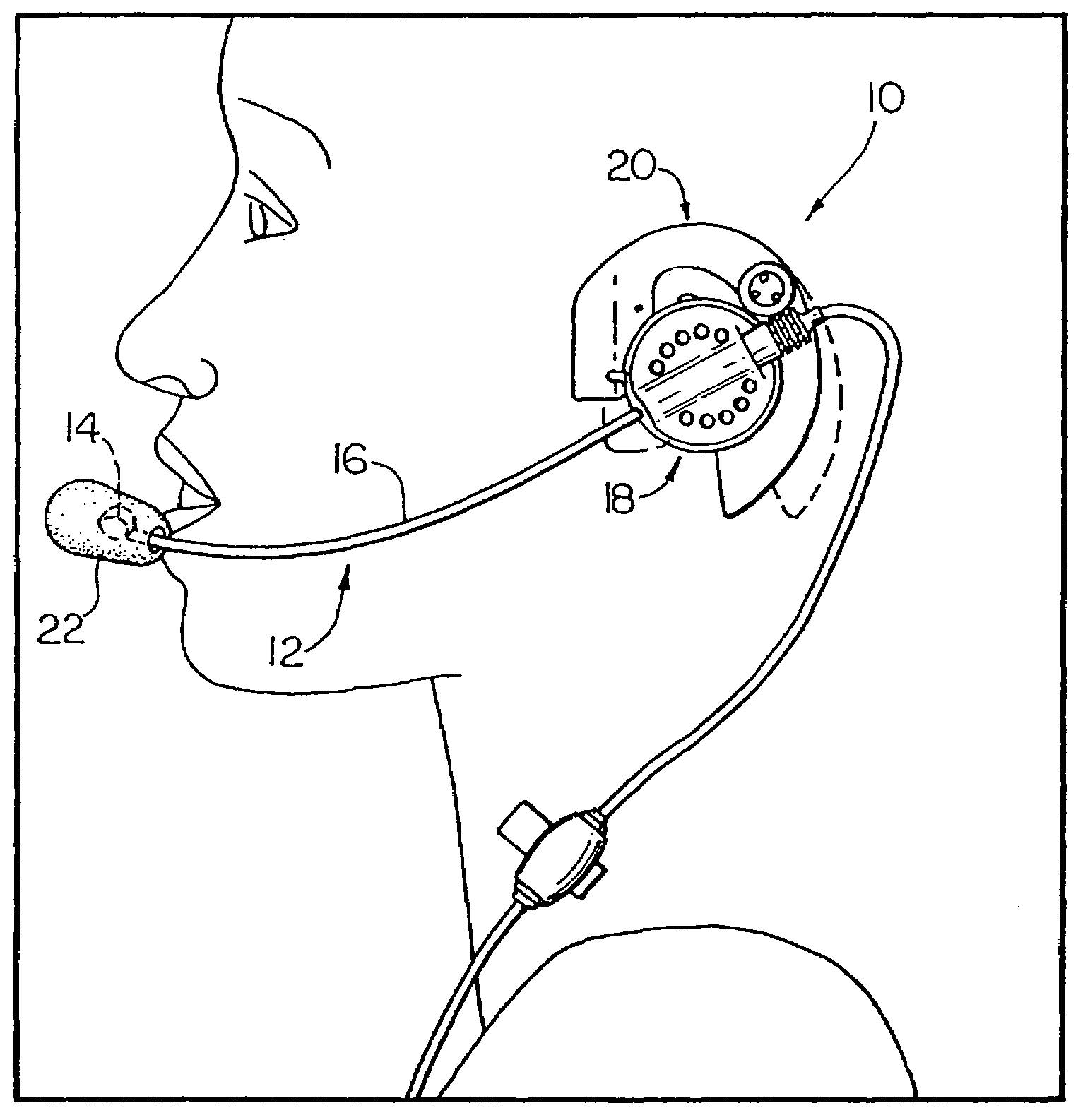

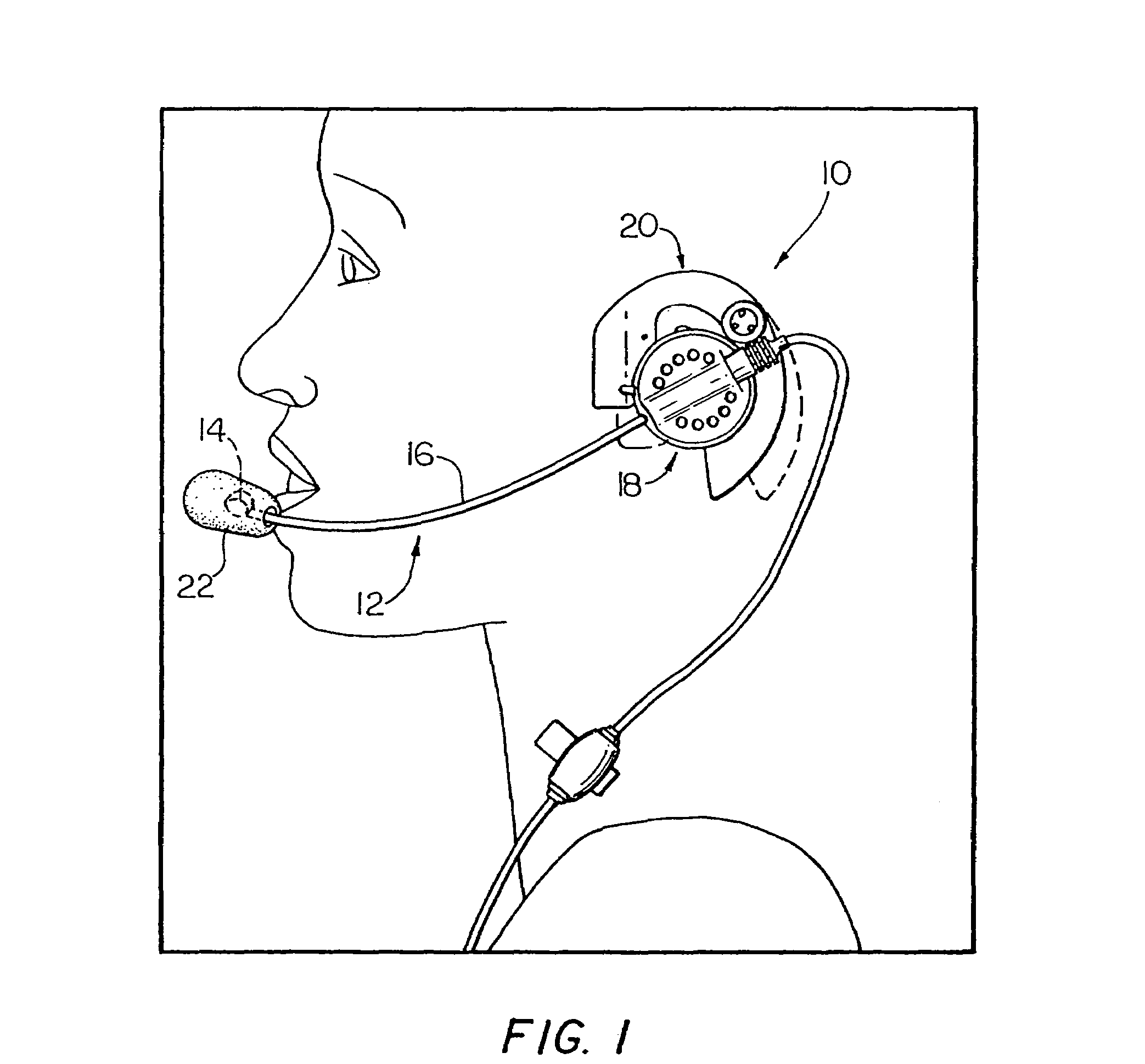

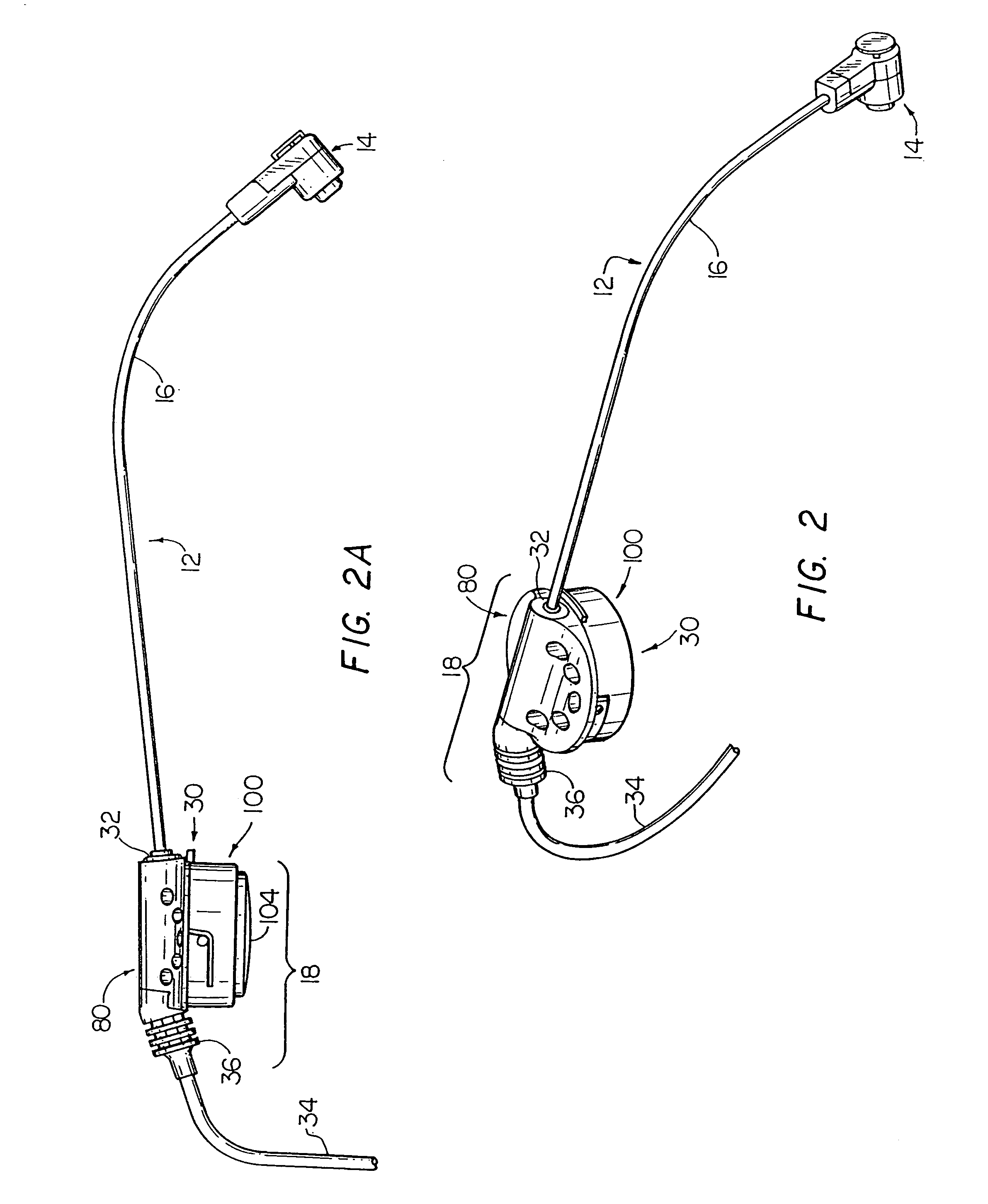

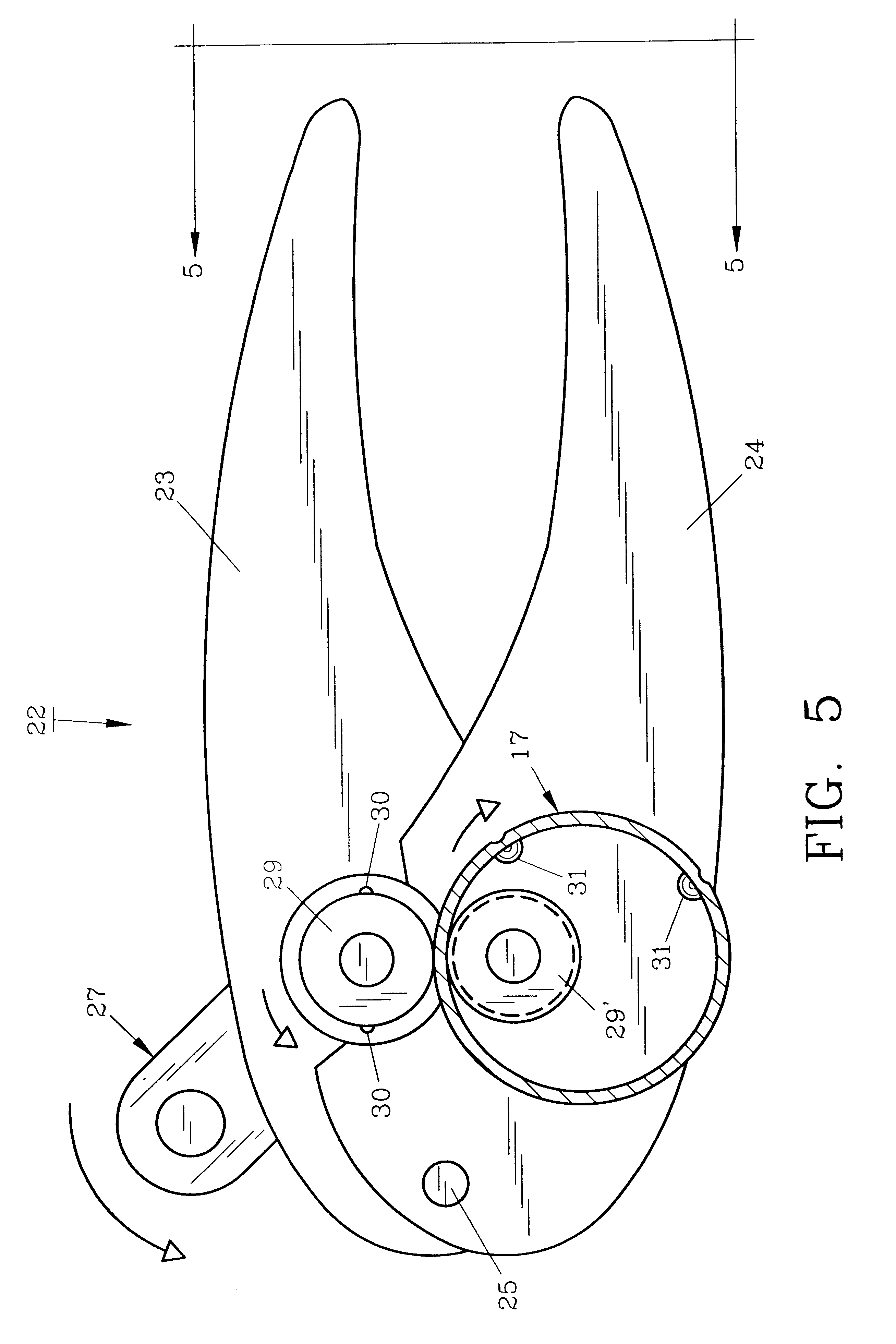

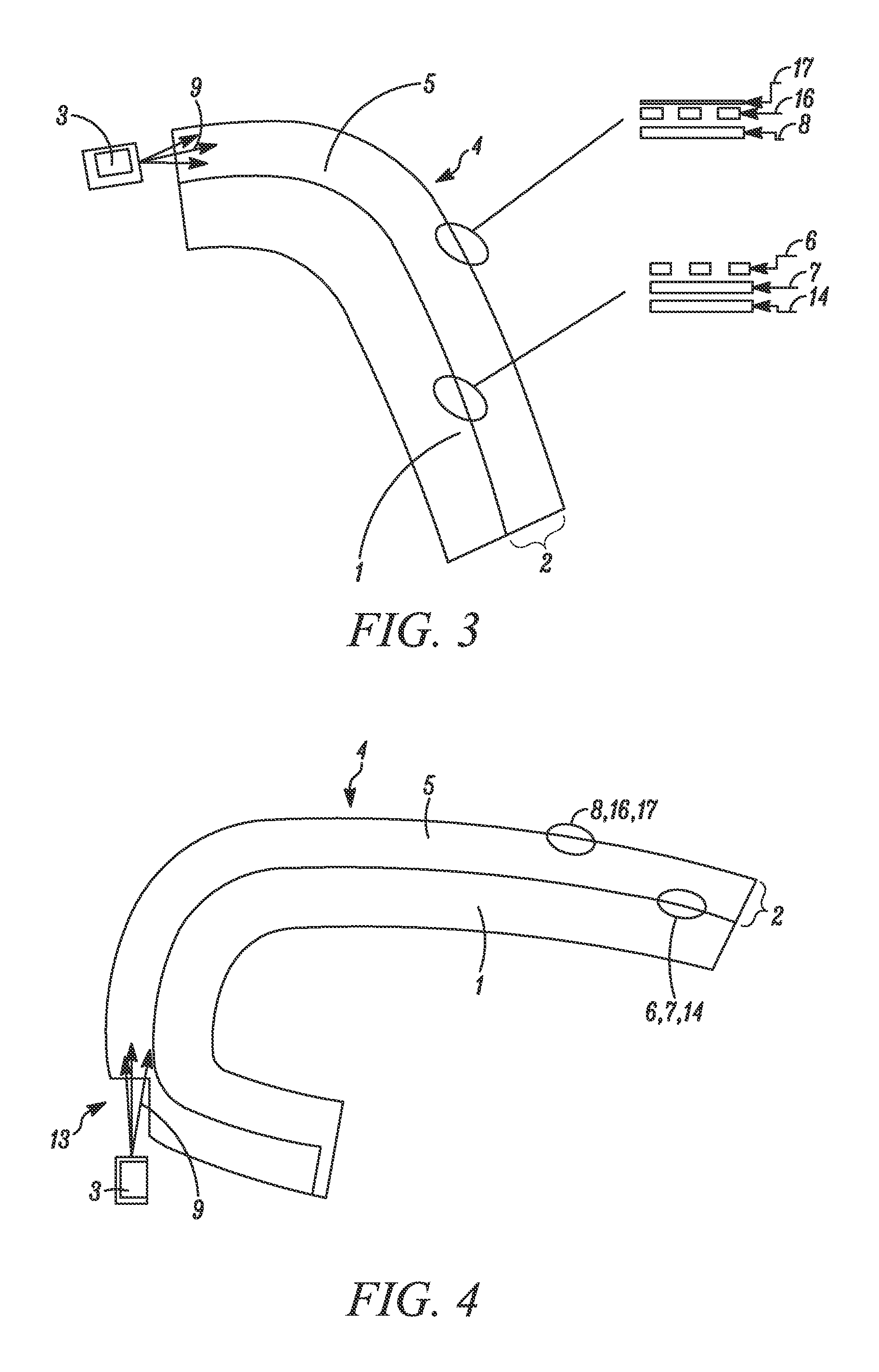

Telephone headset

InactiveUS7099464B2Good acoustic couplingEliminate torqueMicrophonesInterconnection arrangementsElectrical connectionEngineering

A telephone headset including a boom microphone, an earphone, and an ear support constructed and arranged to be adjusted and comfortable for a wearer. The headset is configured with an adjustable ear support to fit a variety of ear sizes without affecting the balance of the ear support on the ear of the wearer. The ear support includes a rotational hinge which is biased into a given position by a compression washer. The earphone is removably and adjustably attached to a mounting ring which in turn is smoothly is movably attached to the ear support by a spring biased ball and socket joint. The combination of flexible joints and removability of the earphone provides the degrees of freedom and striction necessary to permit the earphone to be worn comfortably on either ear of the wearer. A strain relief for the electrical connections is attached to the earphone which directs the electrical connections toward the plane of the head, thereby eliminating a torque which otherwise would tend to dislodge the ear support from the ear. The earphone includes a series of openings in its rear surface to maximize its acoustics. The boom microphone includes a spring biased ball and socket joint to movably fix the orientation of the microphone with respect to the wearer to a good comfort level. The boom microphone ball and socket joint is configured with a tab and stop to prohibit 360 degree rotation of the boom to prevent strain on the electrical connections to the microphone.

Owner:UNAX CORP

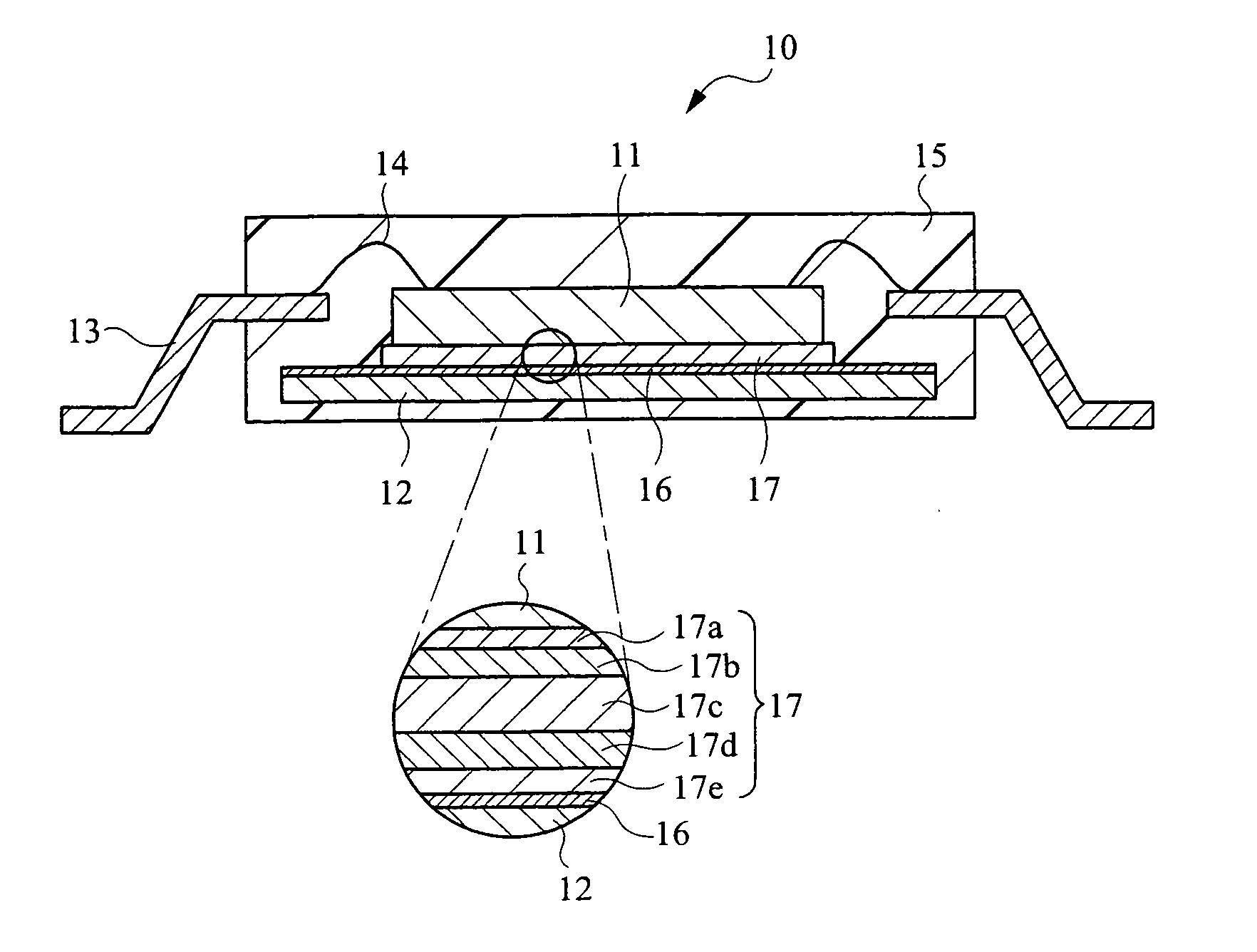

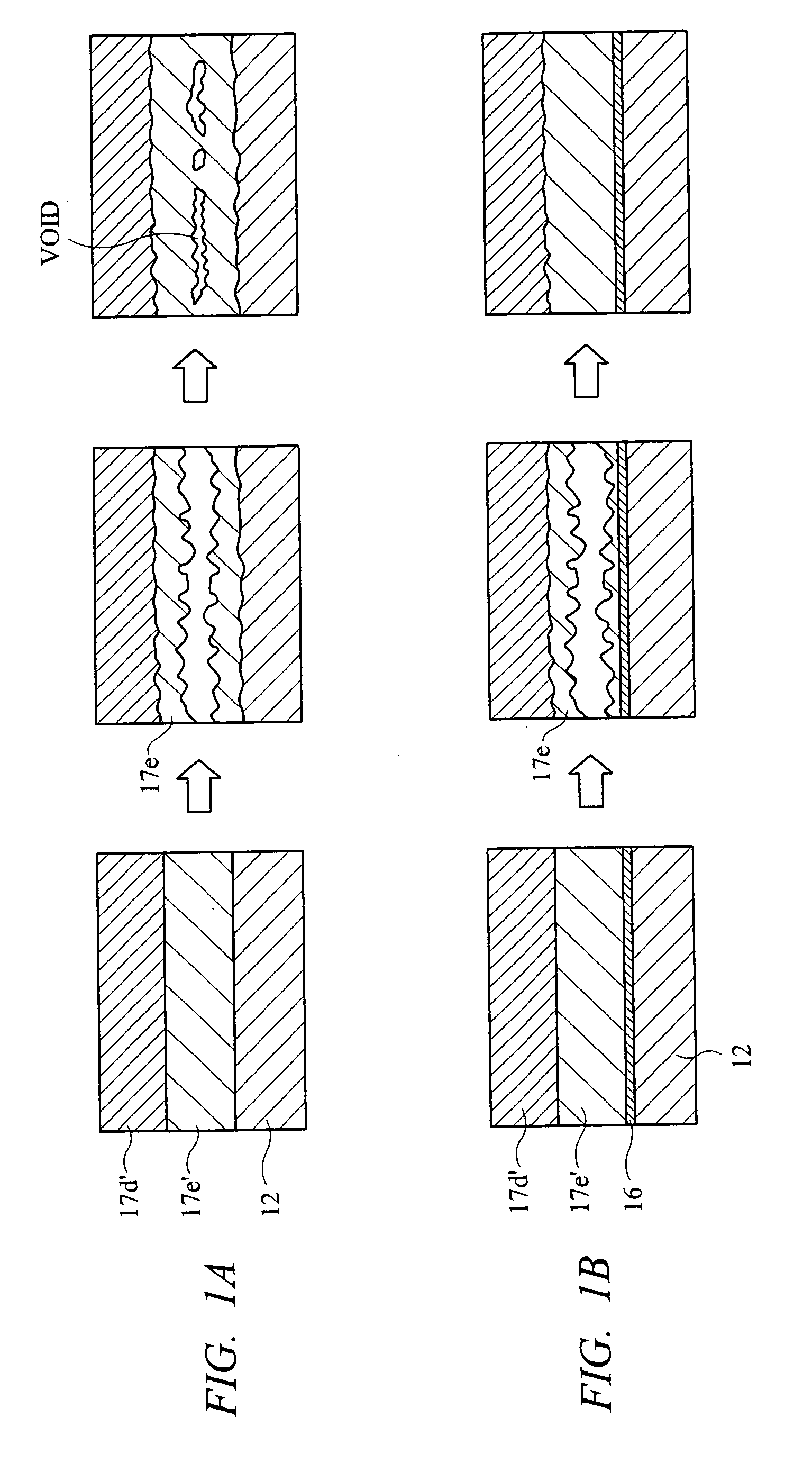

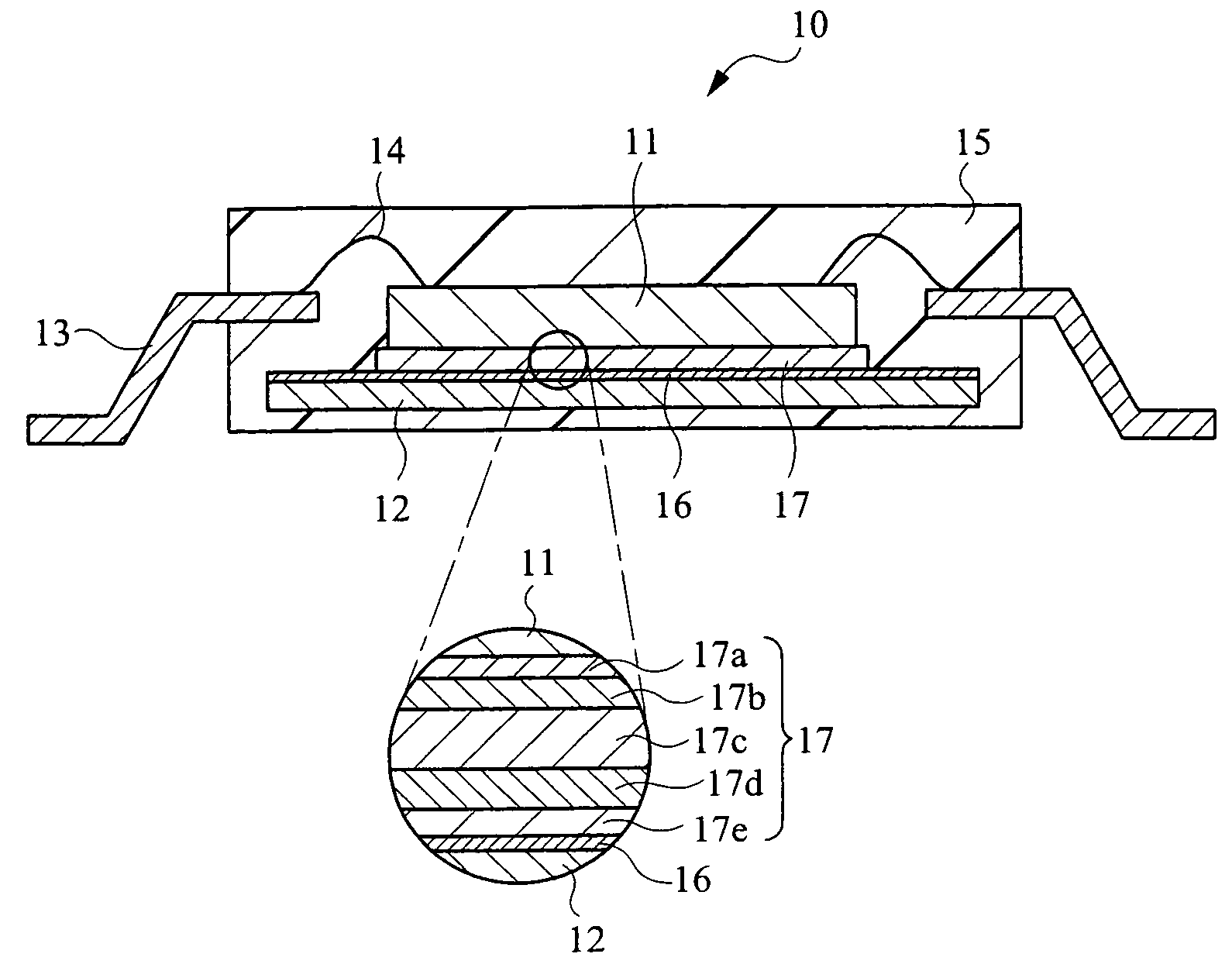

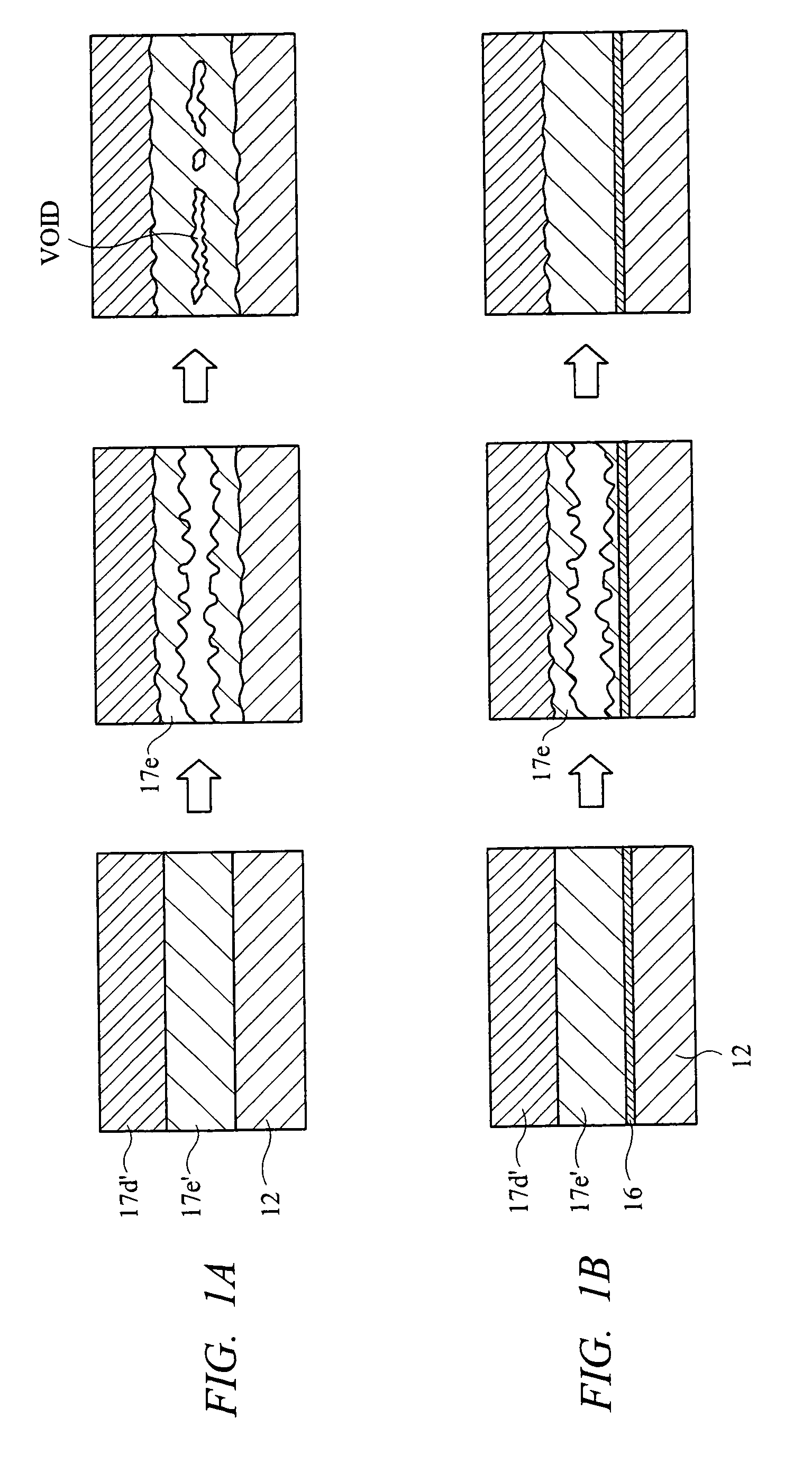

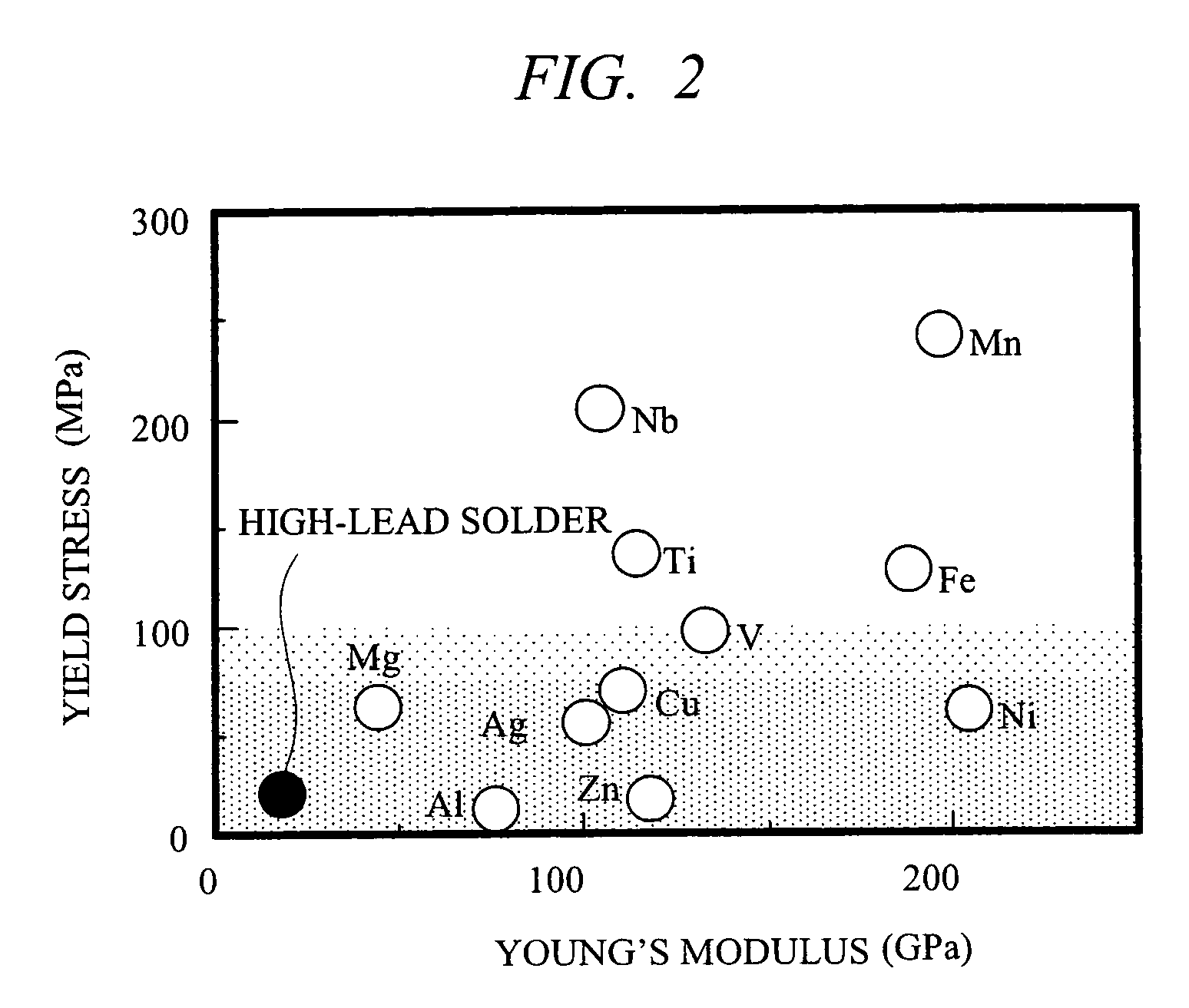

Semiconductor device and method for manufacturing thereof

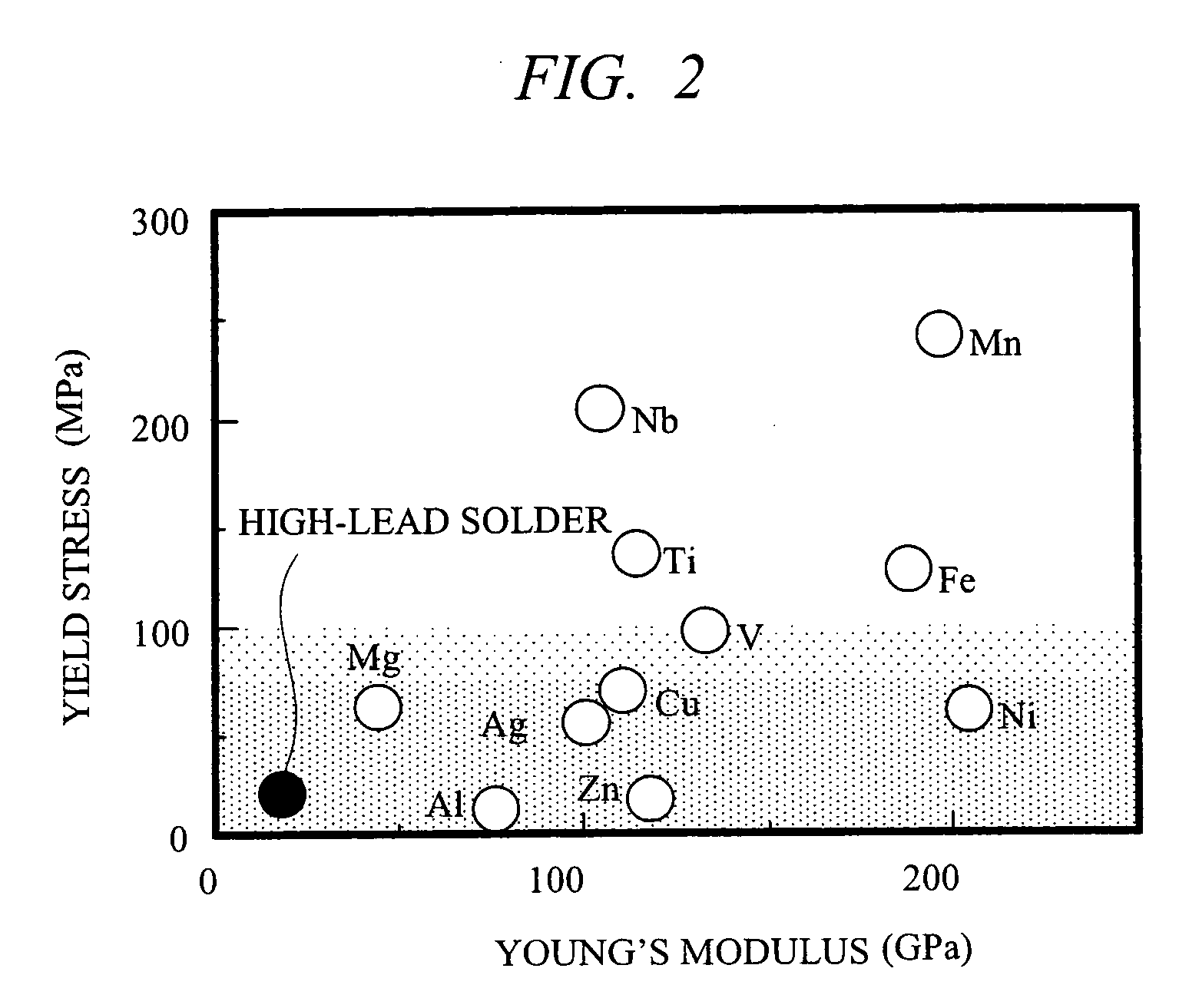

InactiveUS20070089811A1High melting pointIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceDevice material

In a power semiconductor device, a joint between the power semiconductor element and frame plated with Ni is composed of a laminated structure comprising, from the power semiconductor element side, an intermetallic compound layer having a melting point of 260° C. or higher, a Cu layer, a metal layer having a melting point of 260° C. or higher, a Cu layer and an intermetallic layer having a melting point of 260° C. or higher. The structure of the joint buffers the stress generated by the secondary mounting and temperature cycle at the bond for the semiconductor element and the frame having a large difference in thermal expansion coefficient from each other.

Owner:RENESAS ELECTRONICS CORP

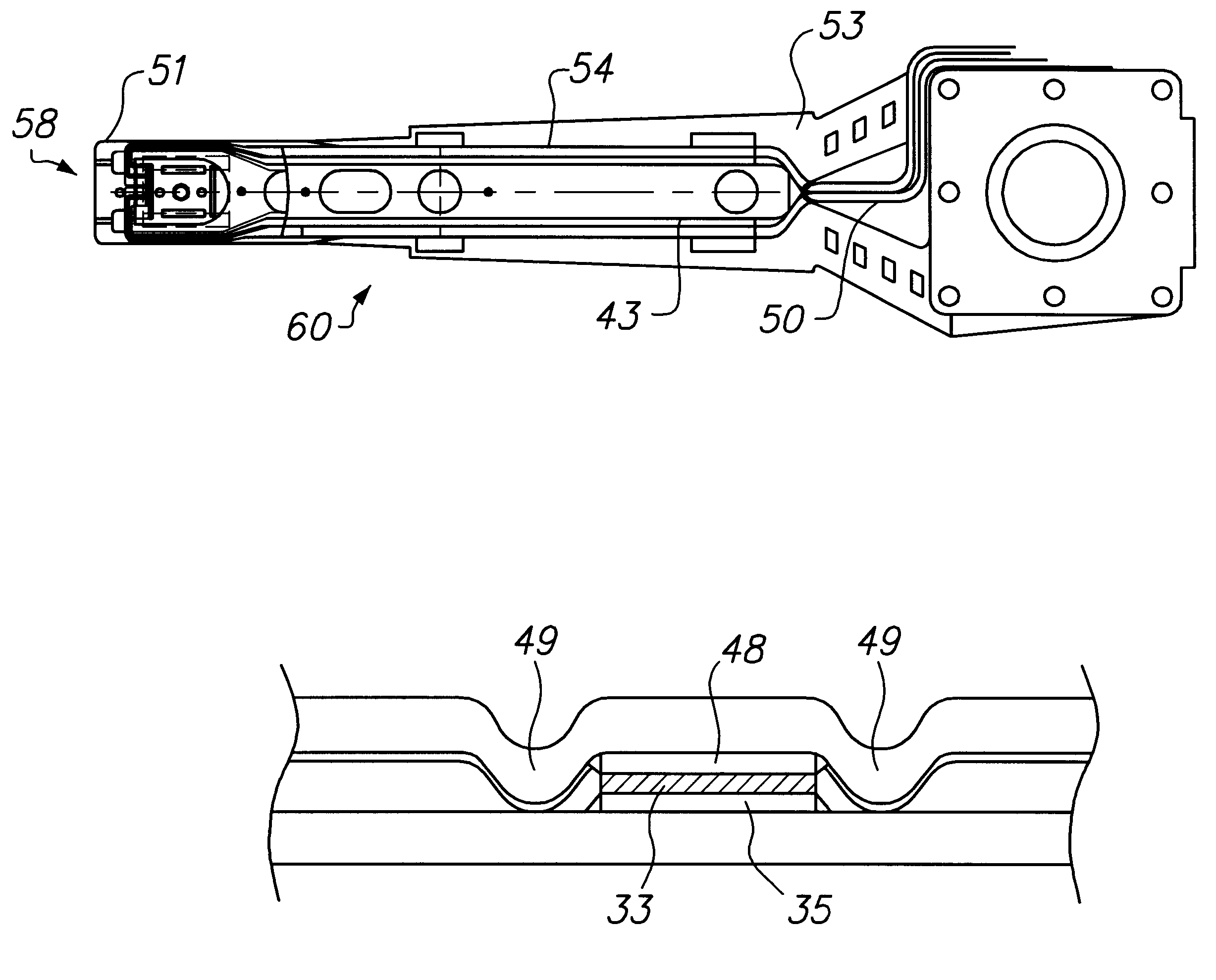

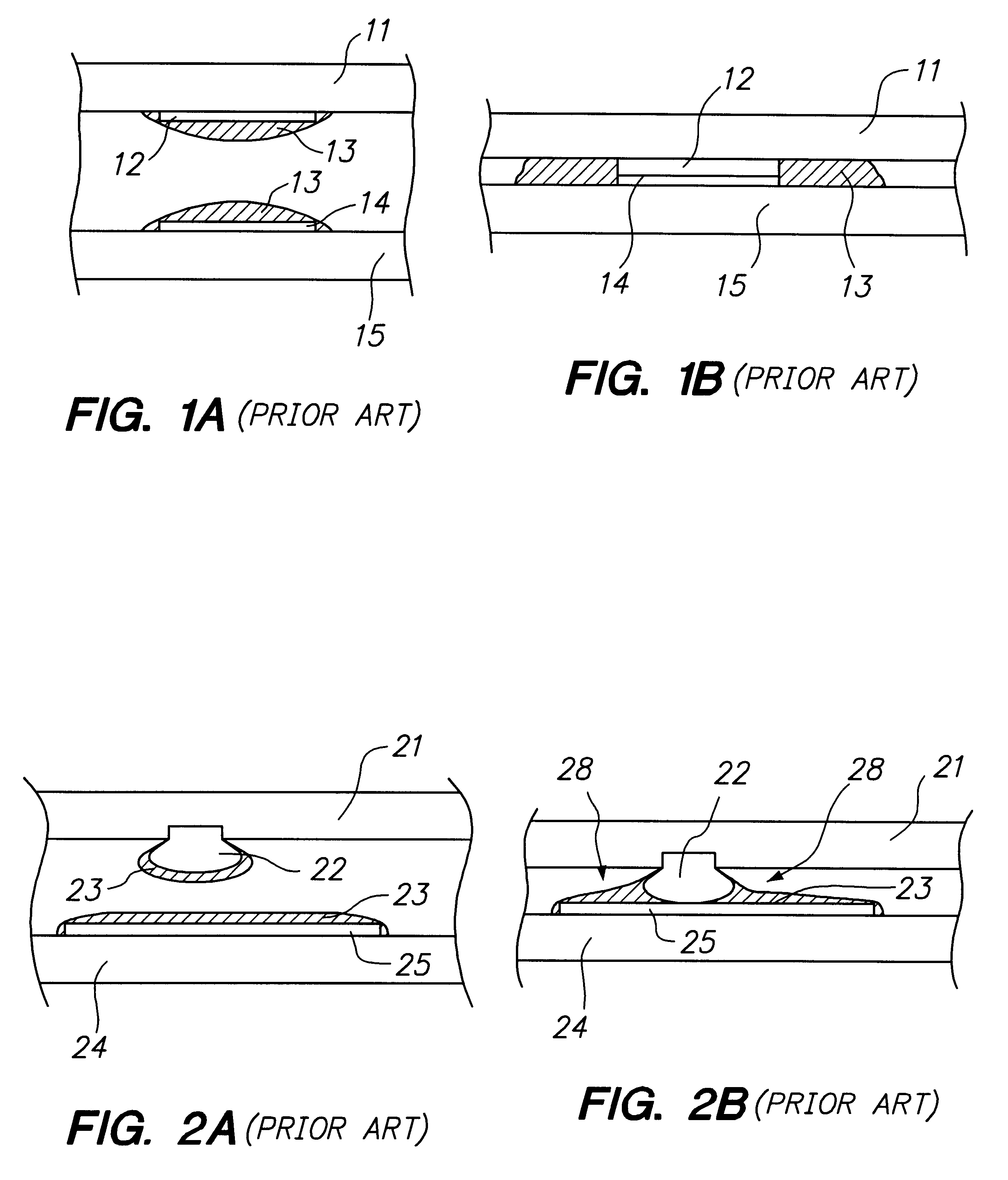

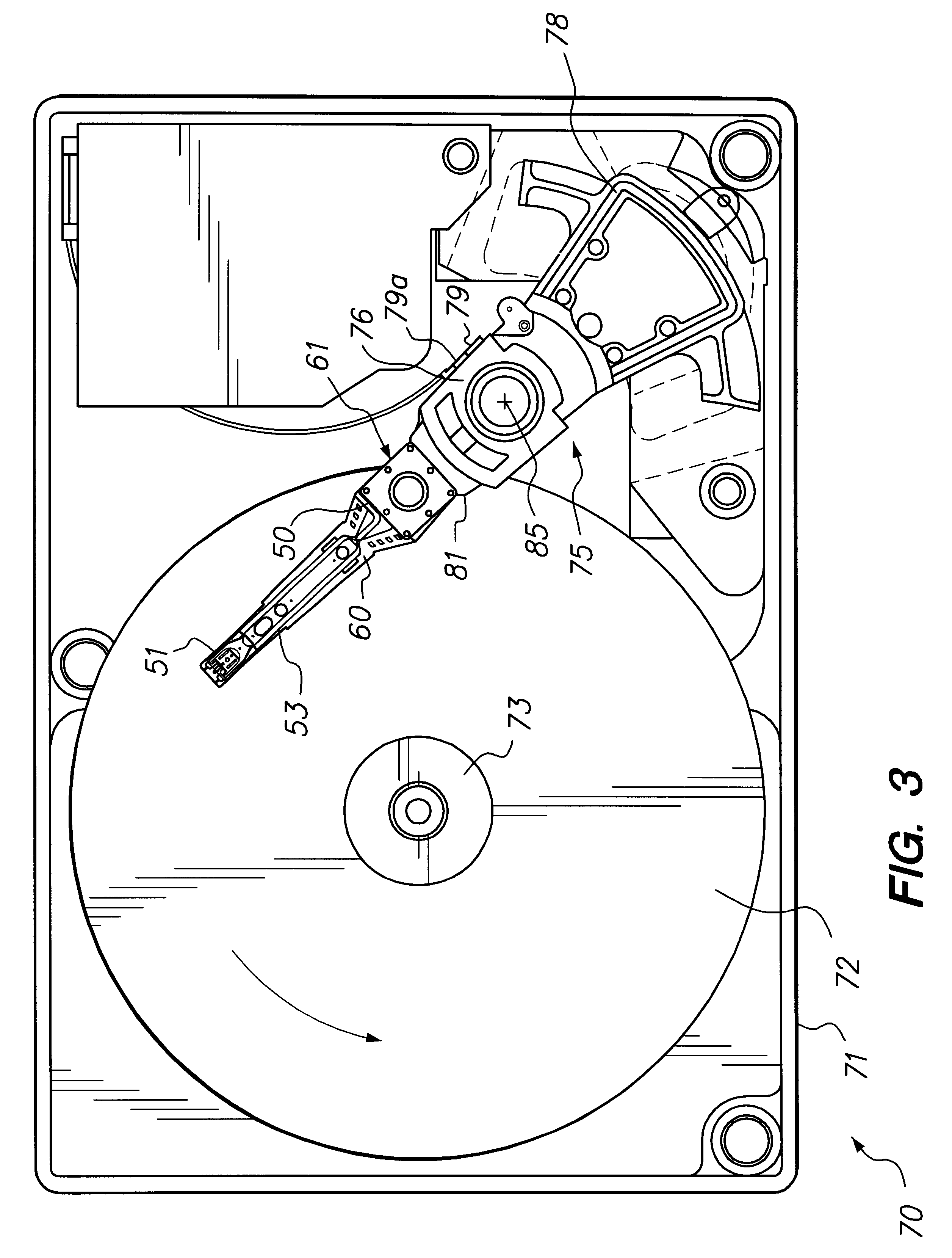

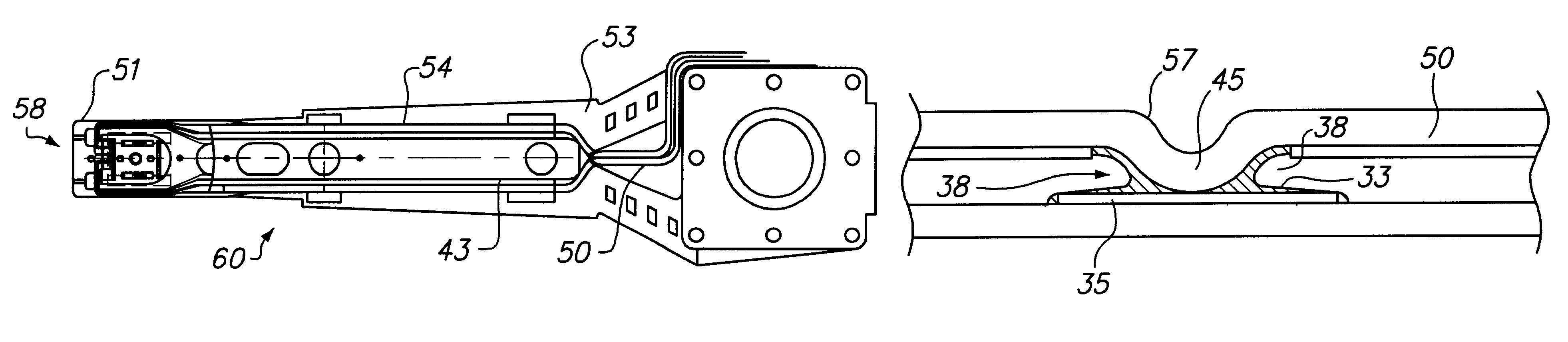

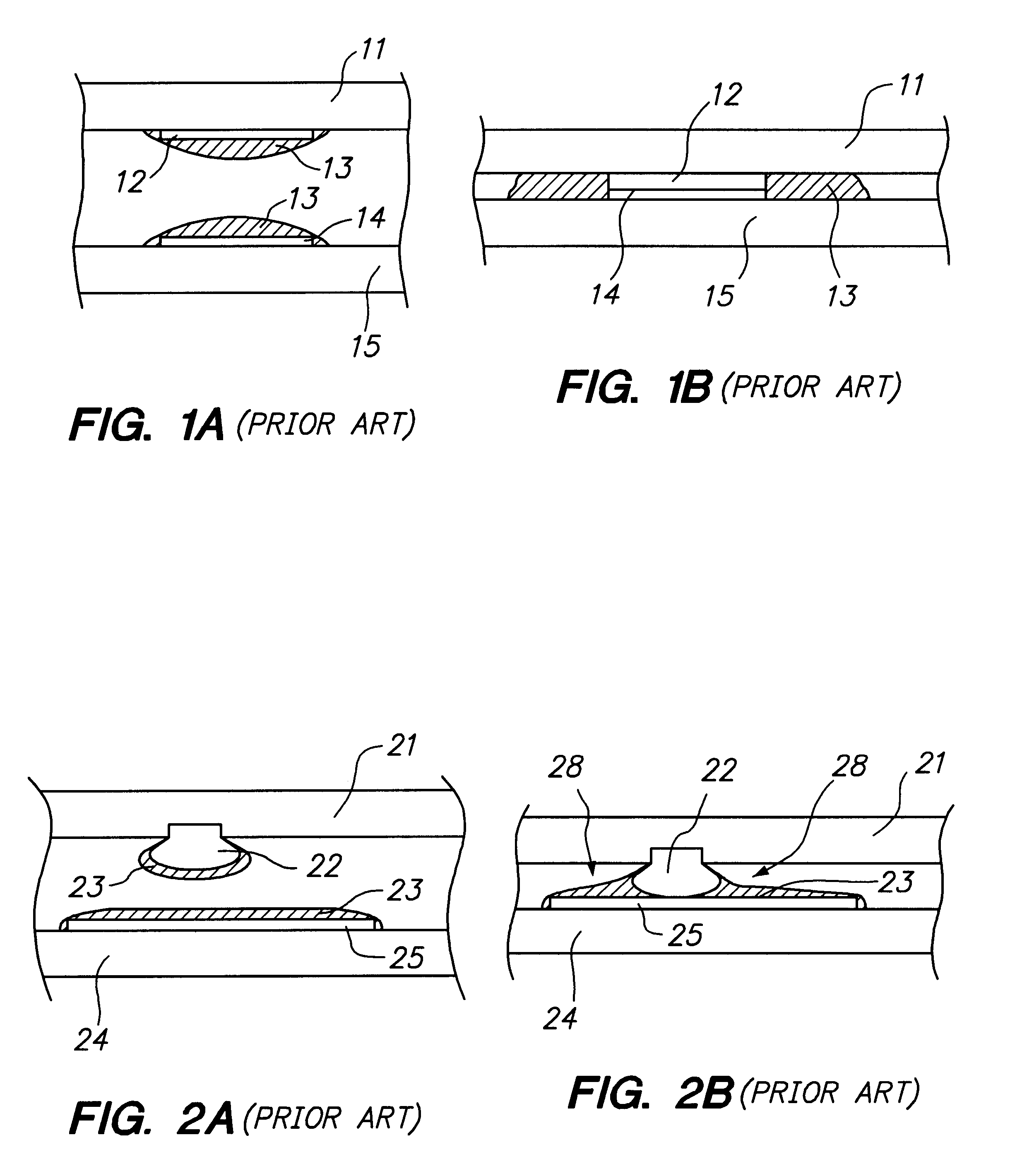

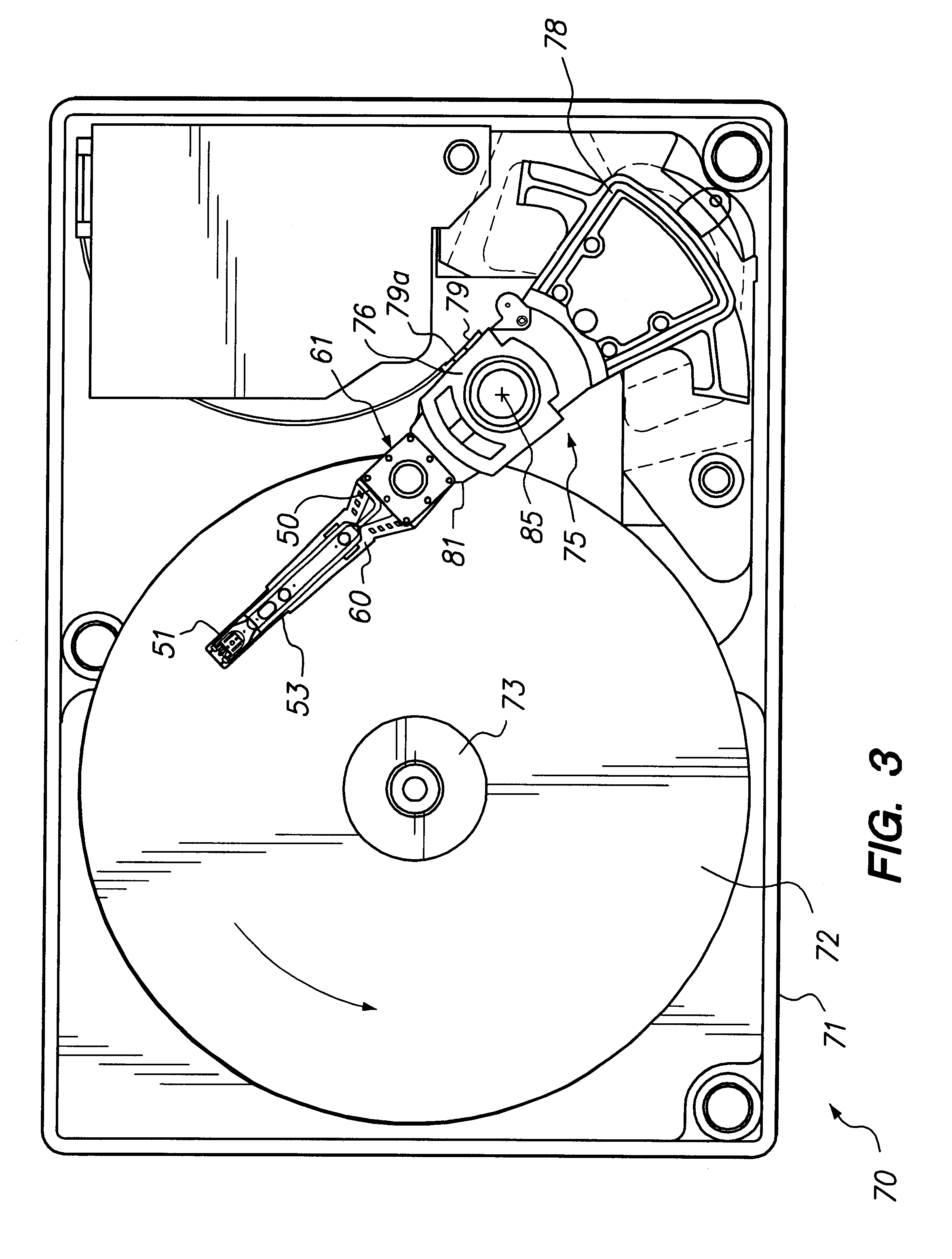

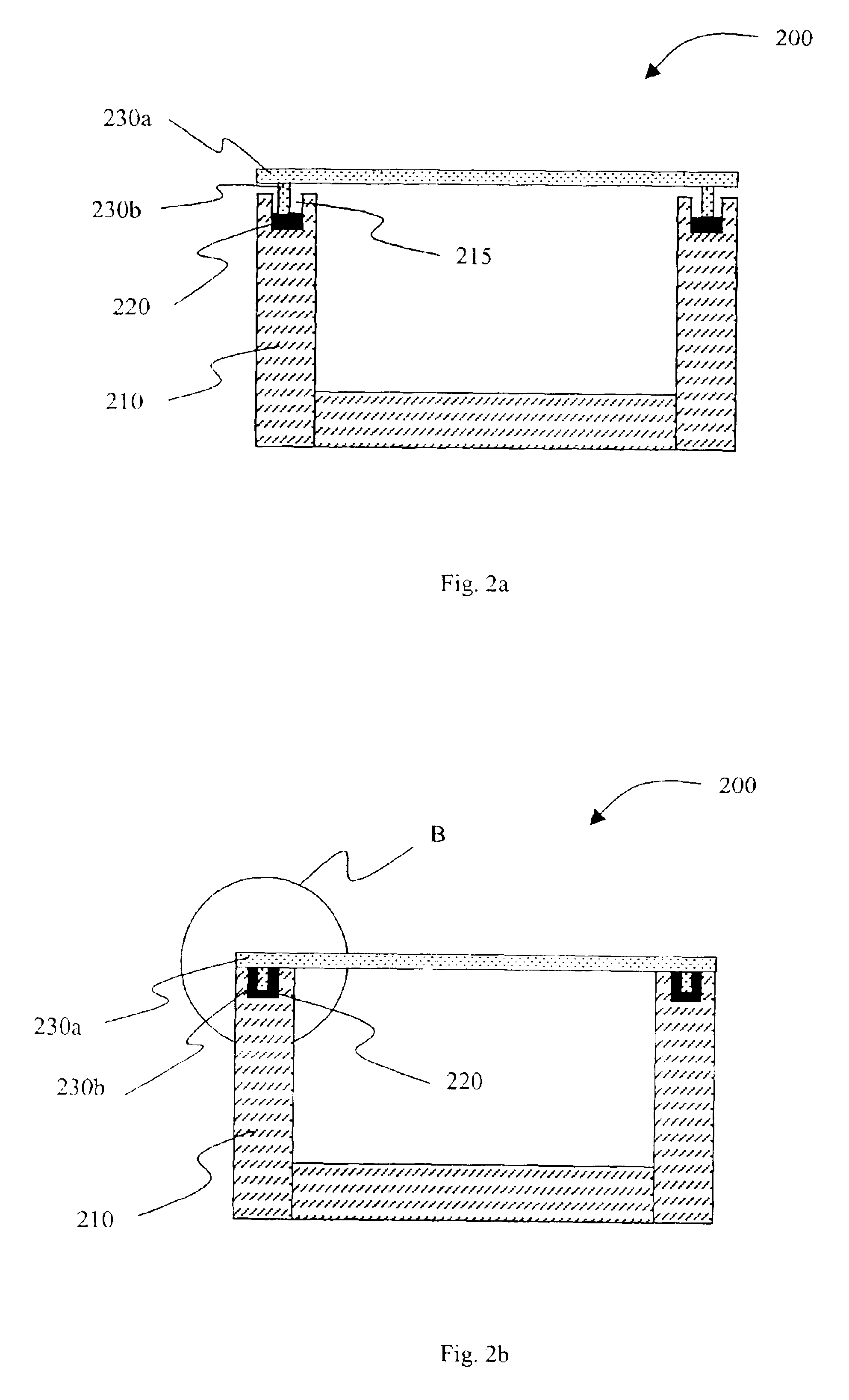

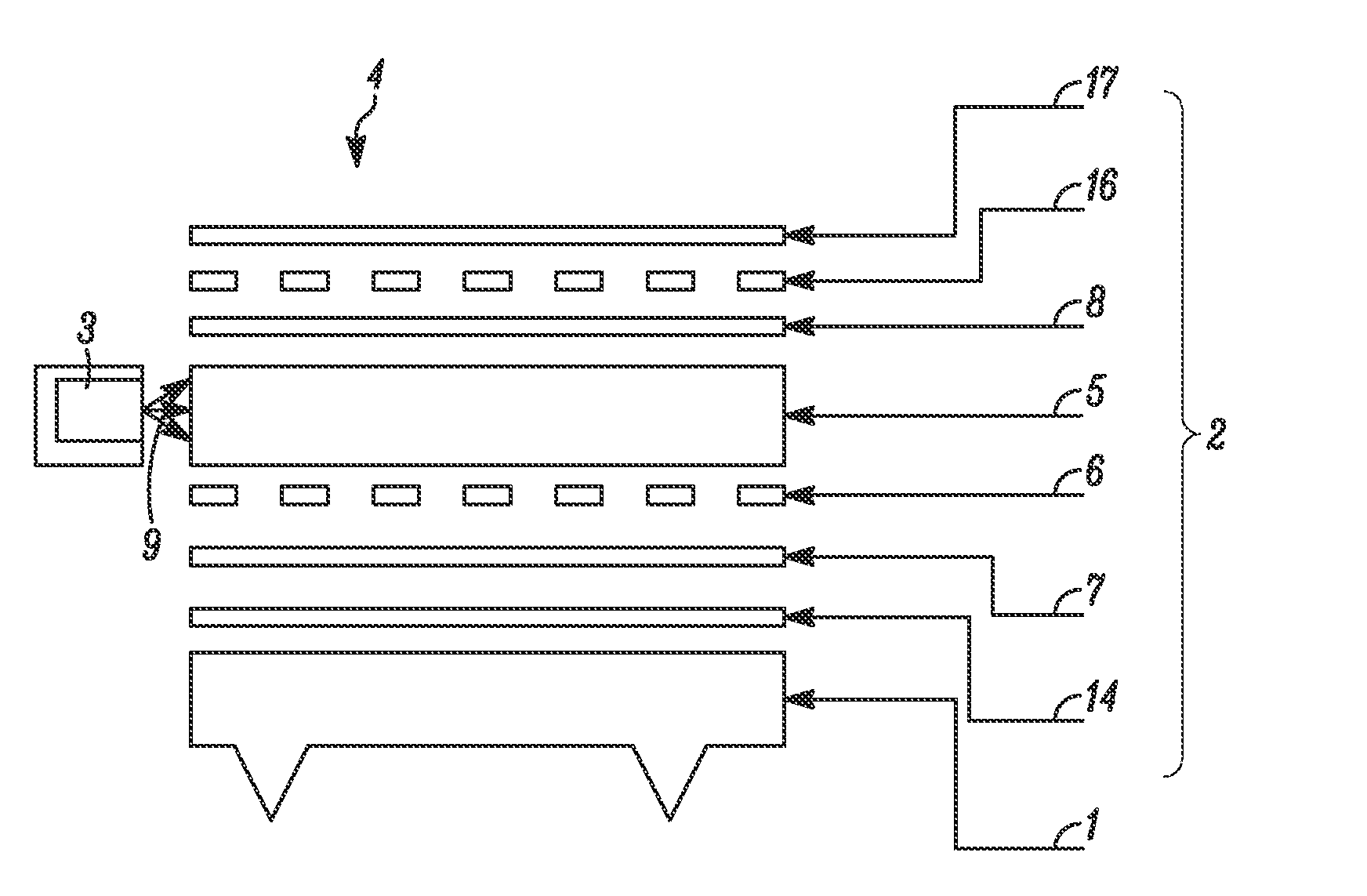

Mechanically formed standoffs in a circuit interconnect

InactiveUS6246548B1Low costReliable connectorPrinted circuit assemblingElectrical connection between head and armIntegrated circuit interconnectBonding process

Mechanically formed standoffs in a disk drive integrated circuit interconnect reduces the cost of manufacturing and improves the reliability of the electrical interconnections thereof. Connection pads defined along the interconnect are bonded with bonding pads of a signal producing source and a signal processing source. The standoffs provide mechanical stops during the bonding process, enabling sufficient bonding material to form between bonding areas. The standoffs are mechanically formed with a punch and die assembly either directly through a bonding pad predefined along traces on the interconnect or adjacent the bonding pad. The standoffs formed through the bonding pads are covered with solder or other electrically conductive bonding material.

Owner:MAXTOR

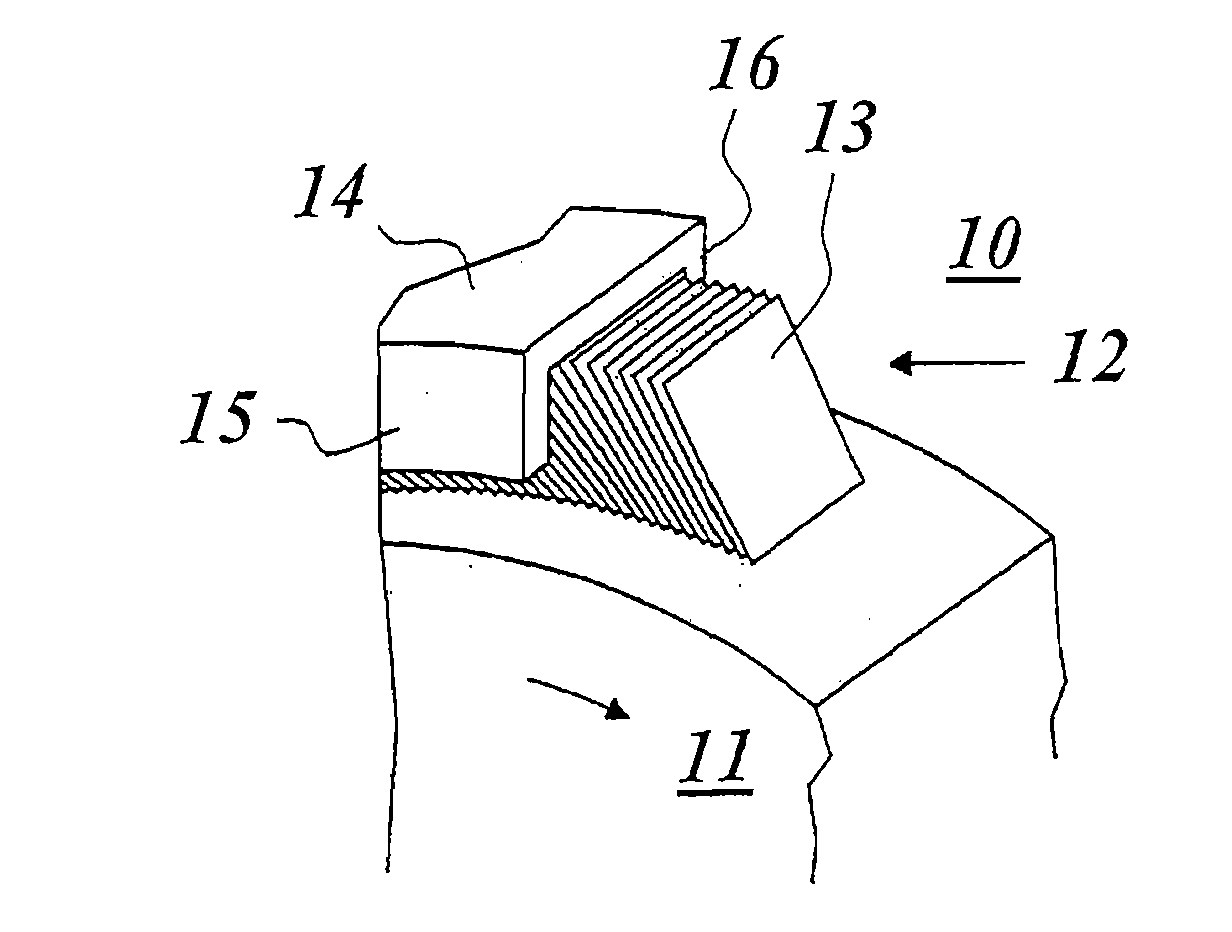

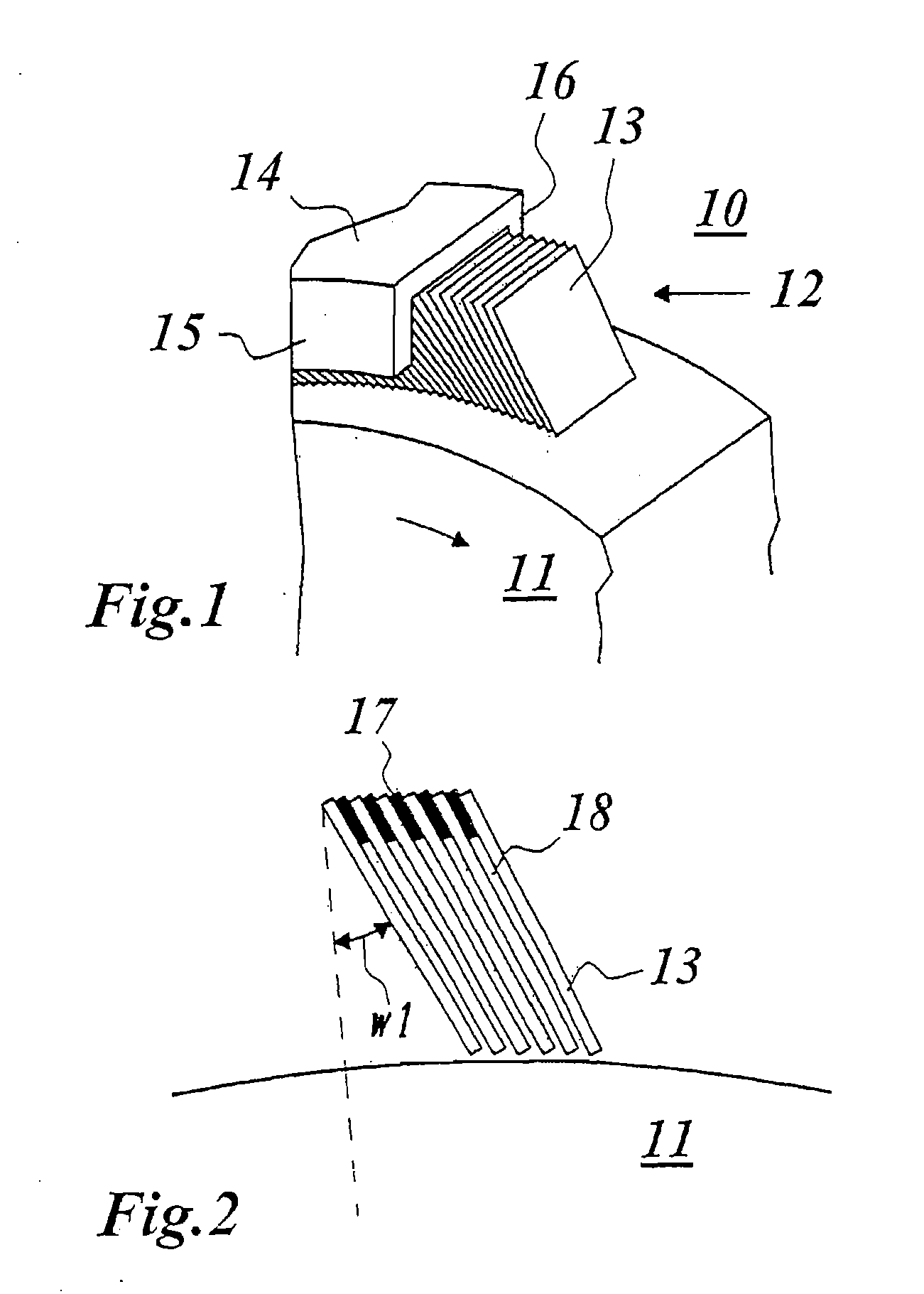

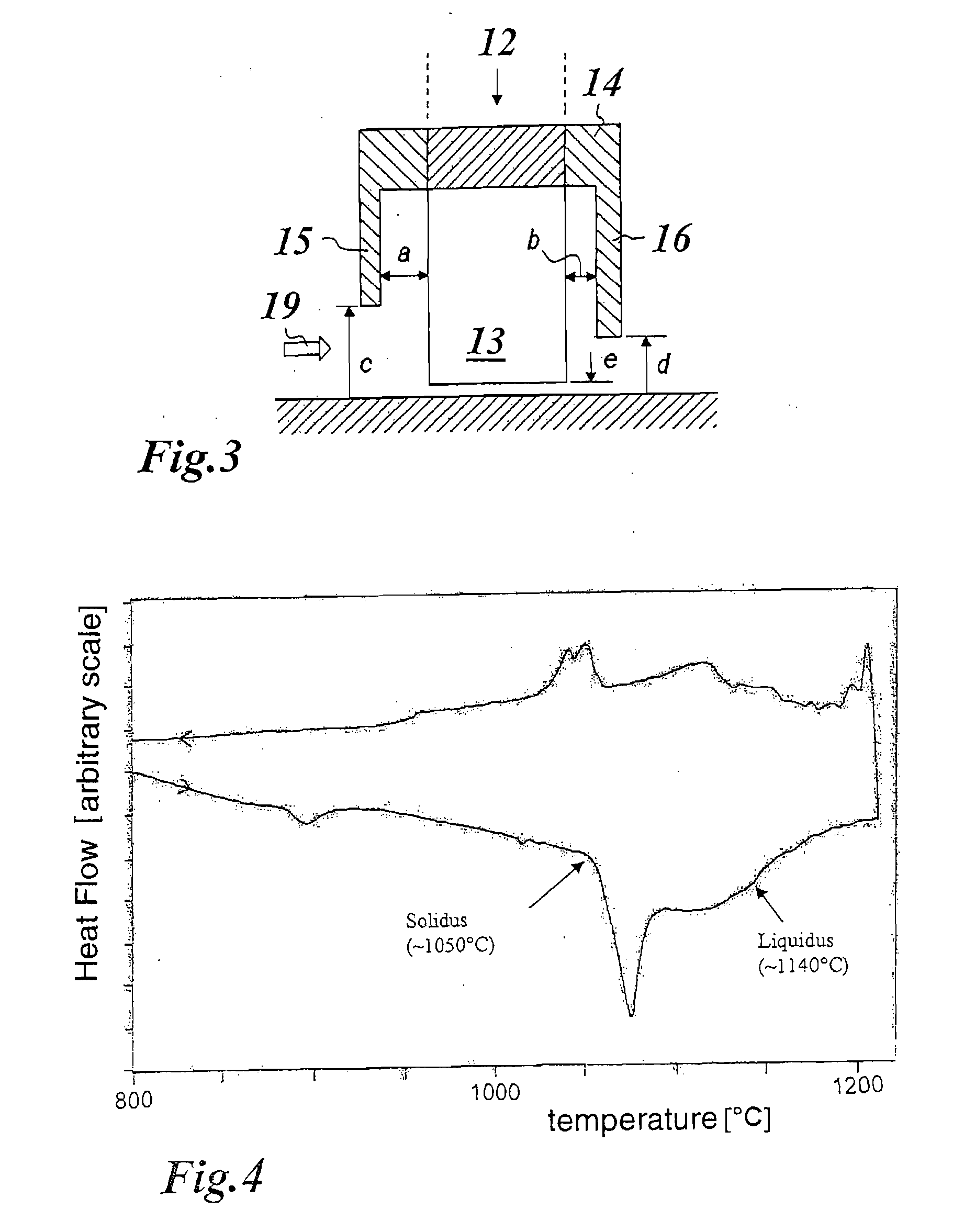

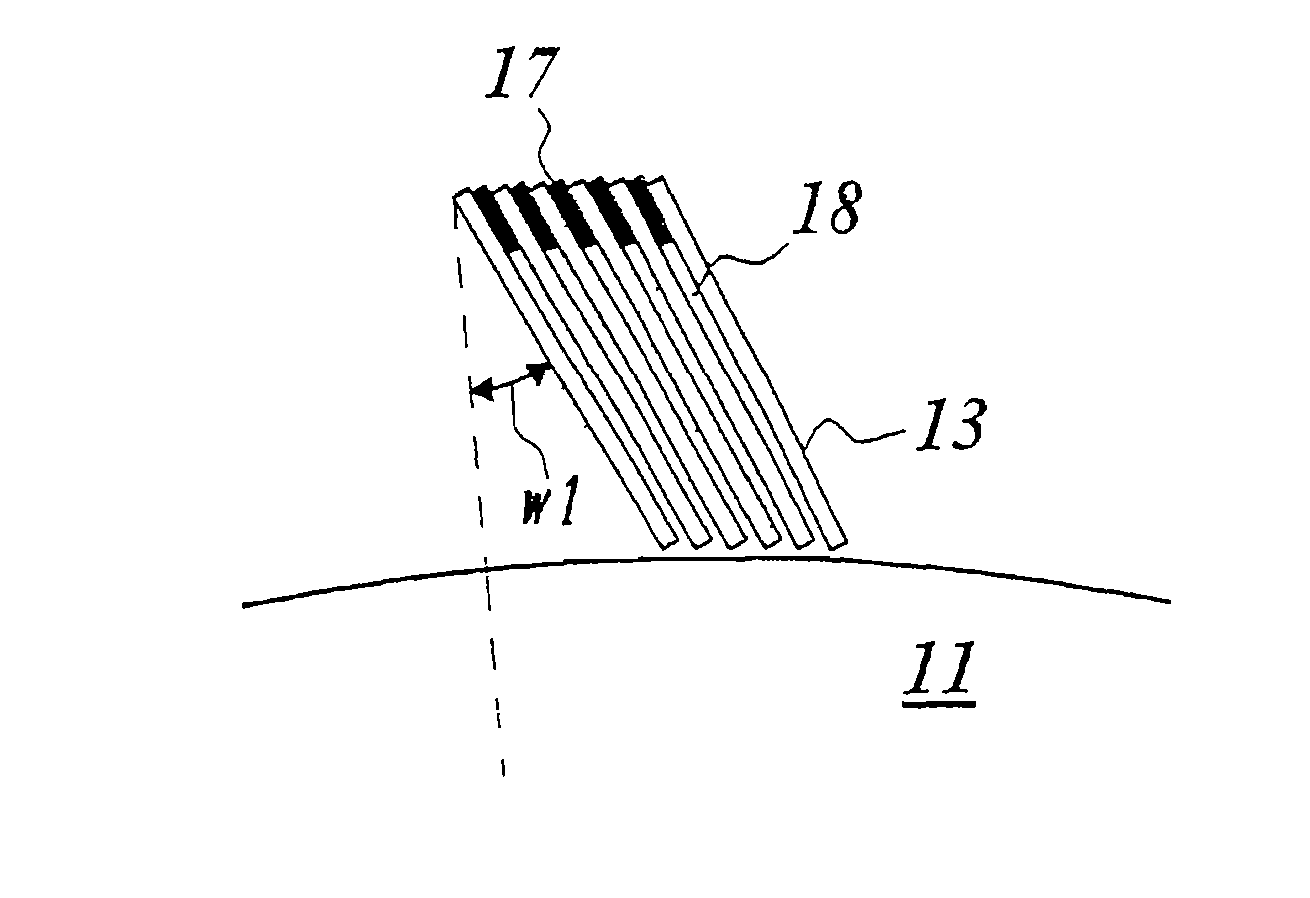

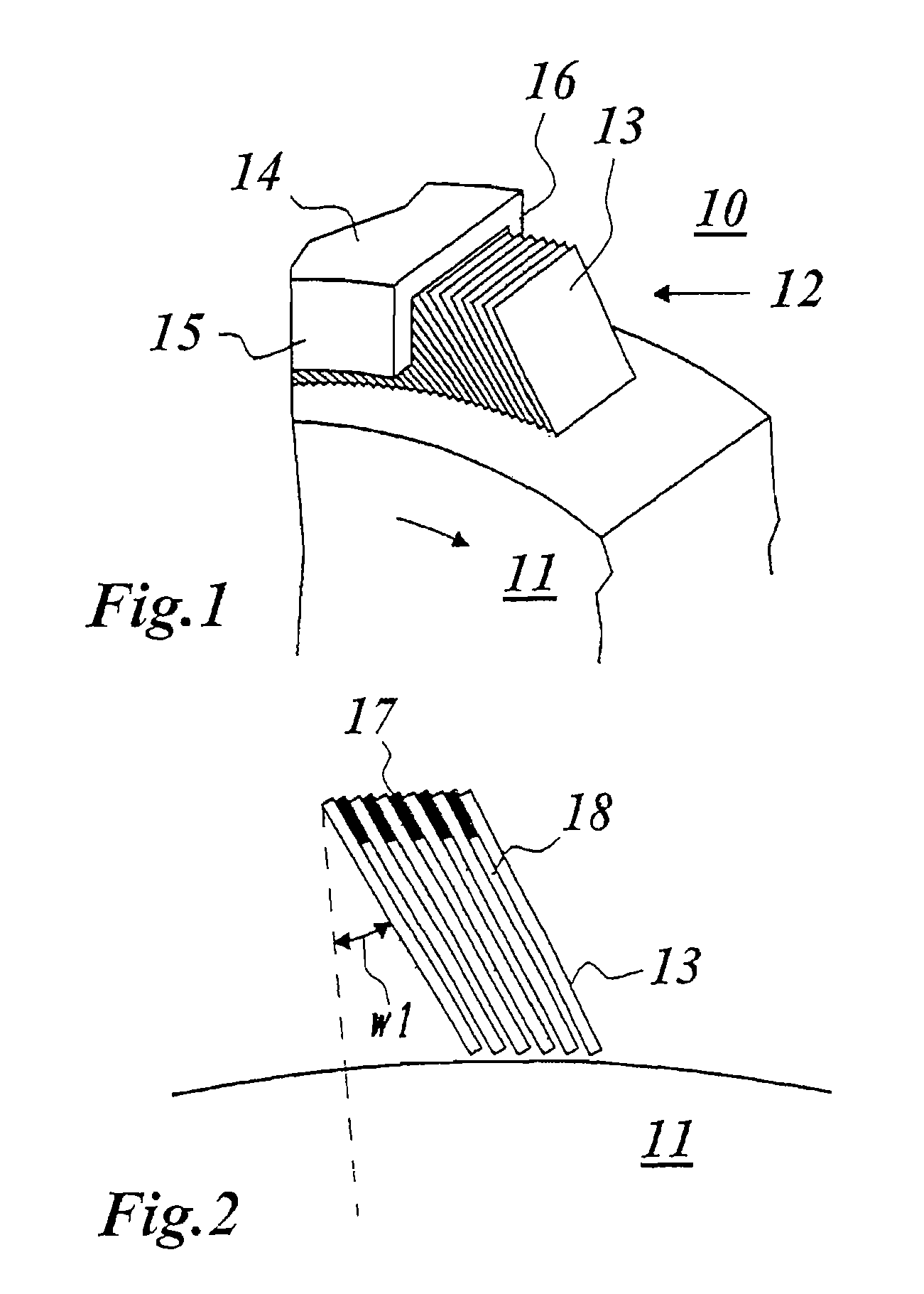

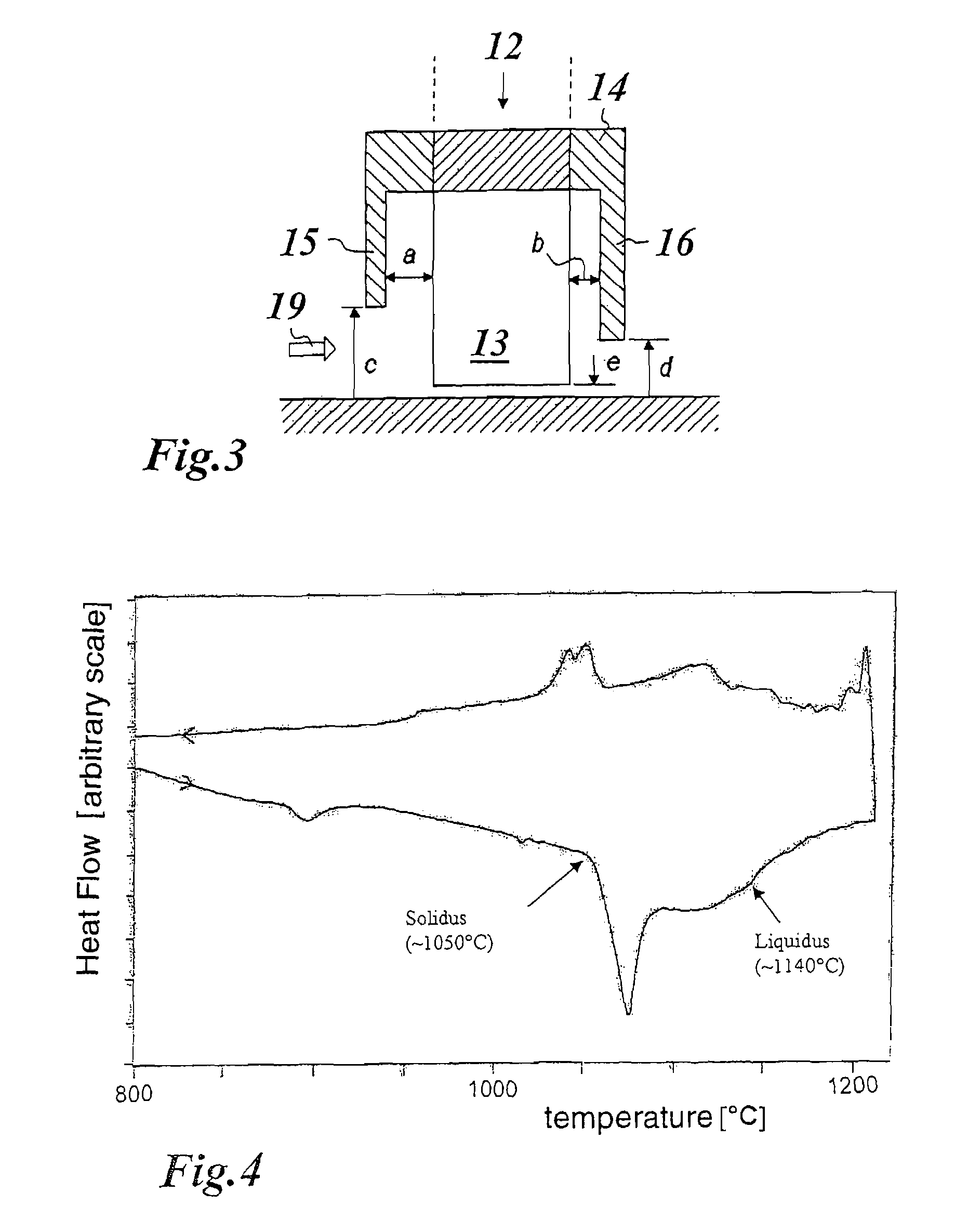

Leaf seal, in particular for a gas turbine, and method of producing it

InactiveUS20070120326A1DistanceAccurate settingEngine sealsLeakage preventionLiquid stateBraze alloy

A leaf seal for sealing a shaft rotating about an axis, in particular in a gas turbine, includes a plurality of spaced-apart leaves arranged in a concentric circle around the axis and fixed in position by brazing, the leaves having surfaces oriented essentially parallel to the axis. The leaves are brazed to one another via intermediate spacers made of a brazing foil, so that a brazed joint is produced by brazing alloy from the brazing foils. The brazing temperature may be set to an optimum value just above the solidus temperature of the brazing foil, at which partial melting of the brazing foil occurs and penetration of liquid brazing alloy into the gap between the leaves is avoided.

Owner:ANSALDO ENERGIA IP UK LTD

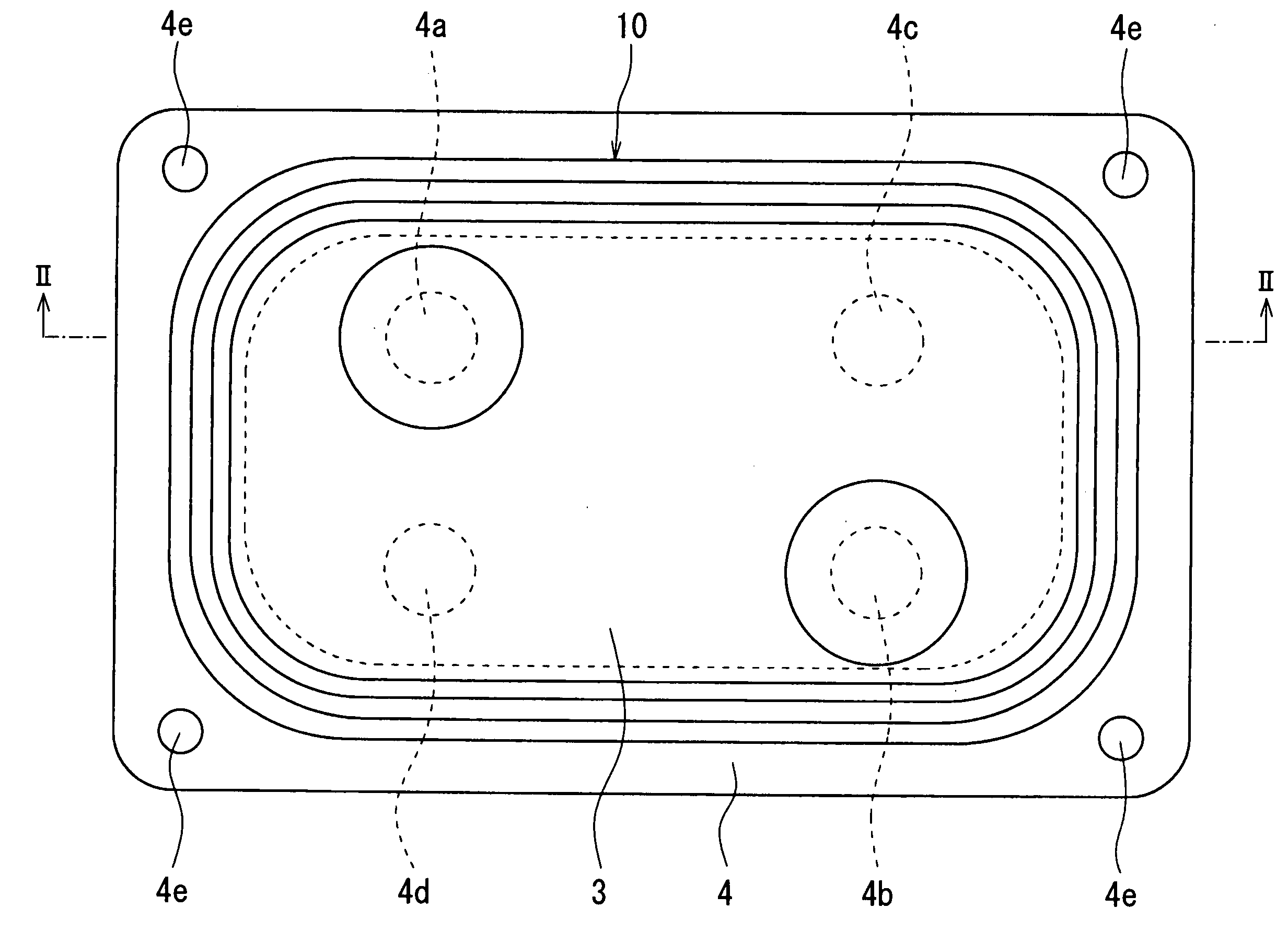

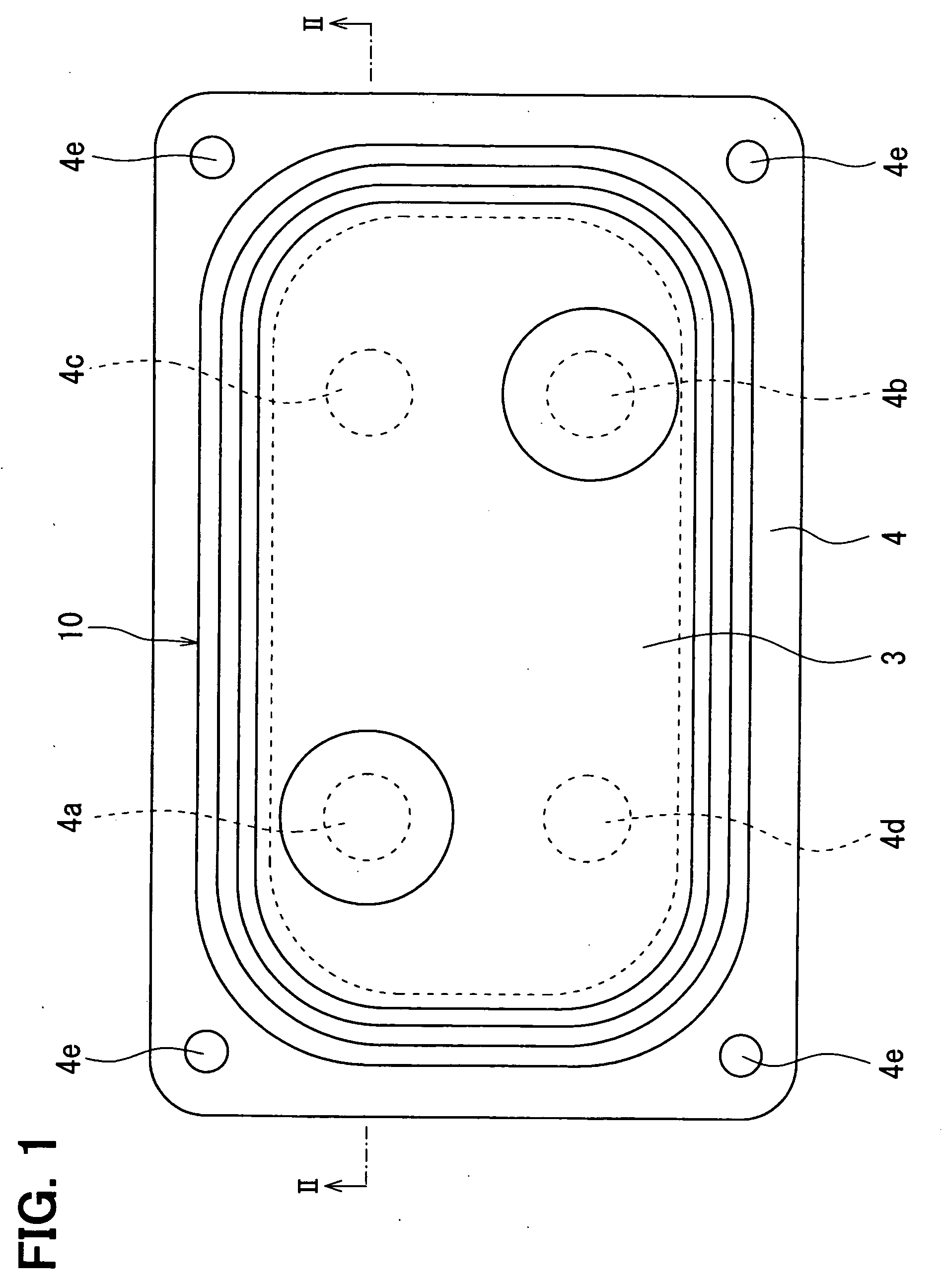

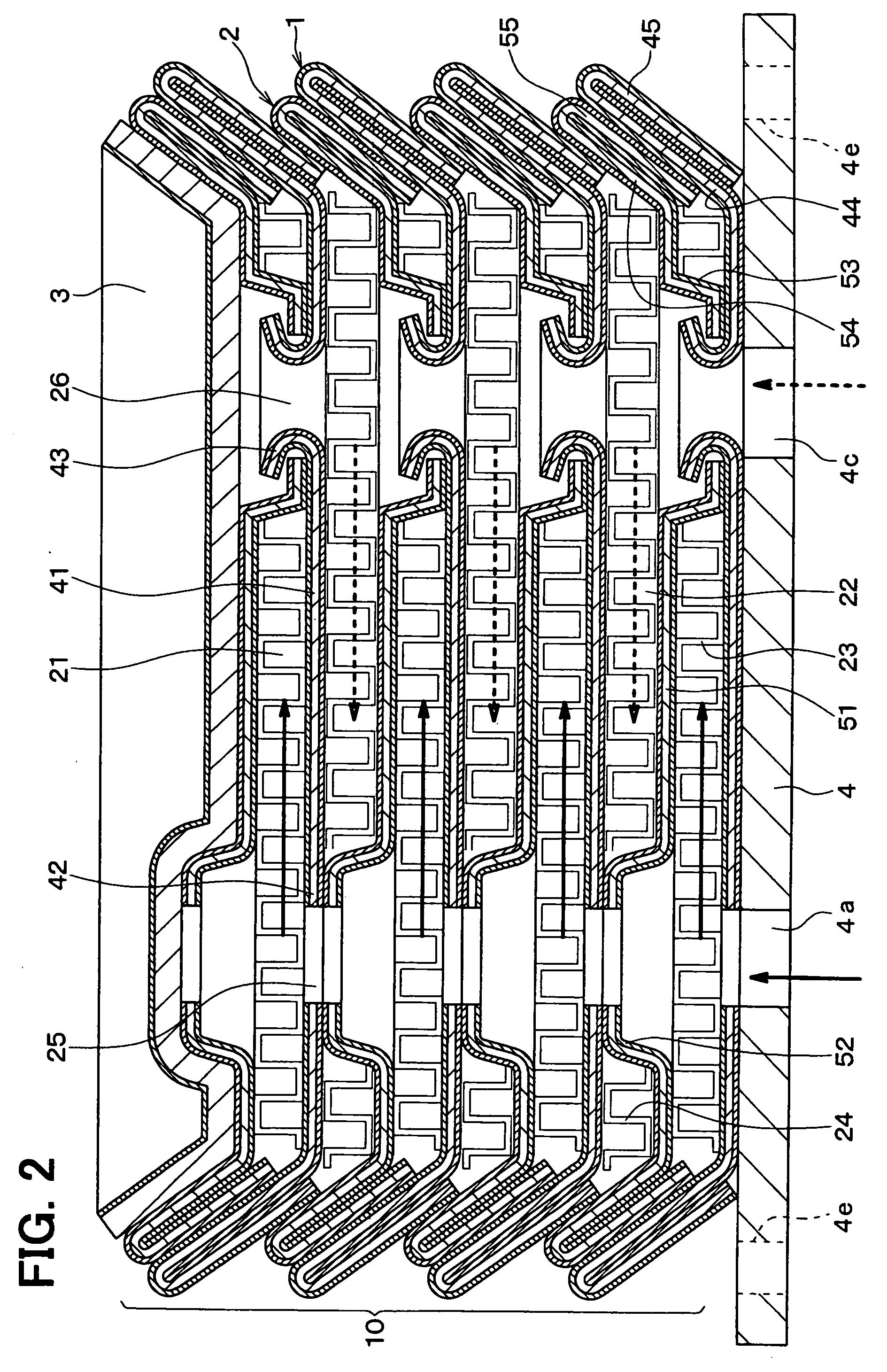

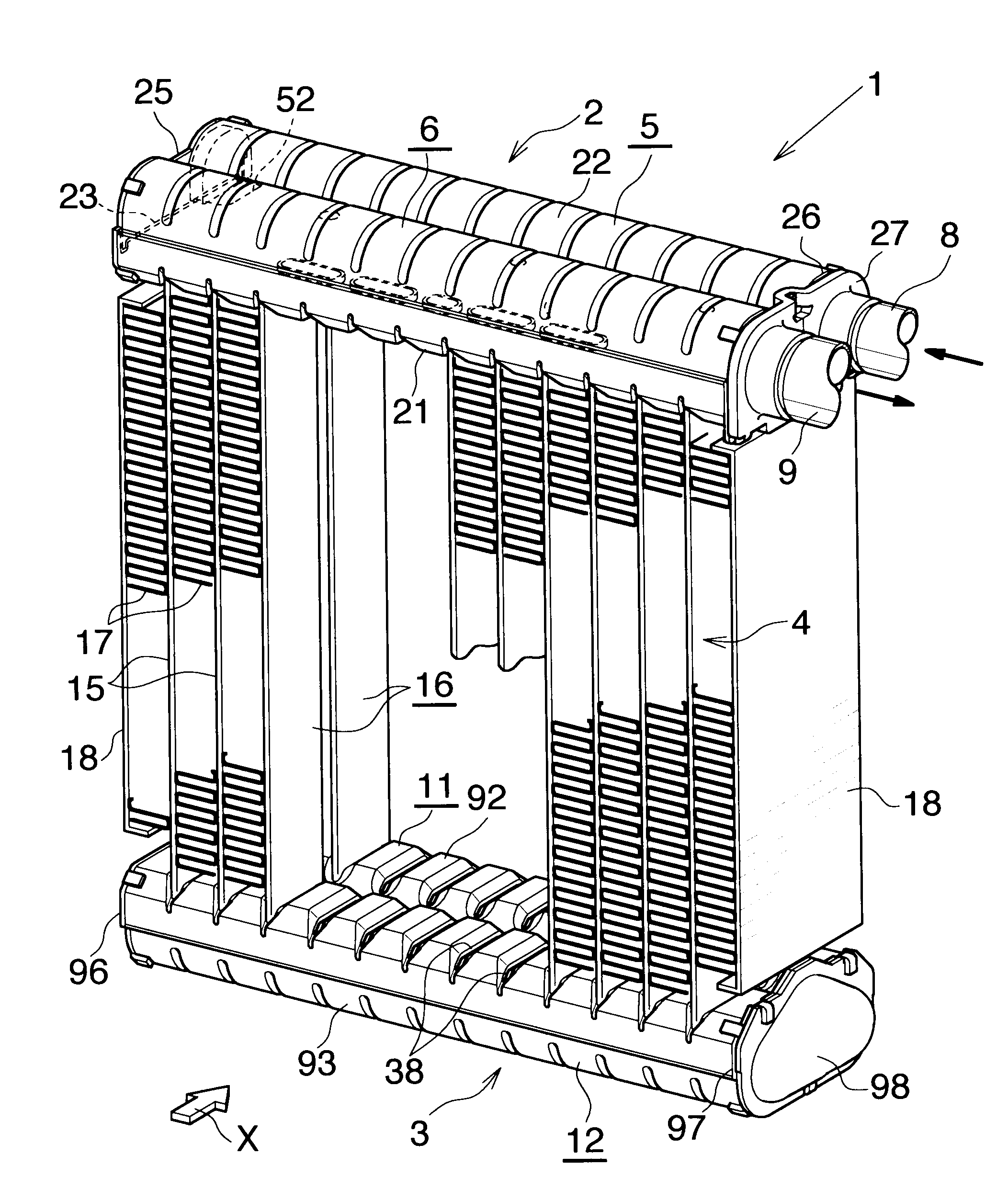

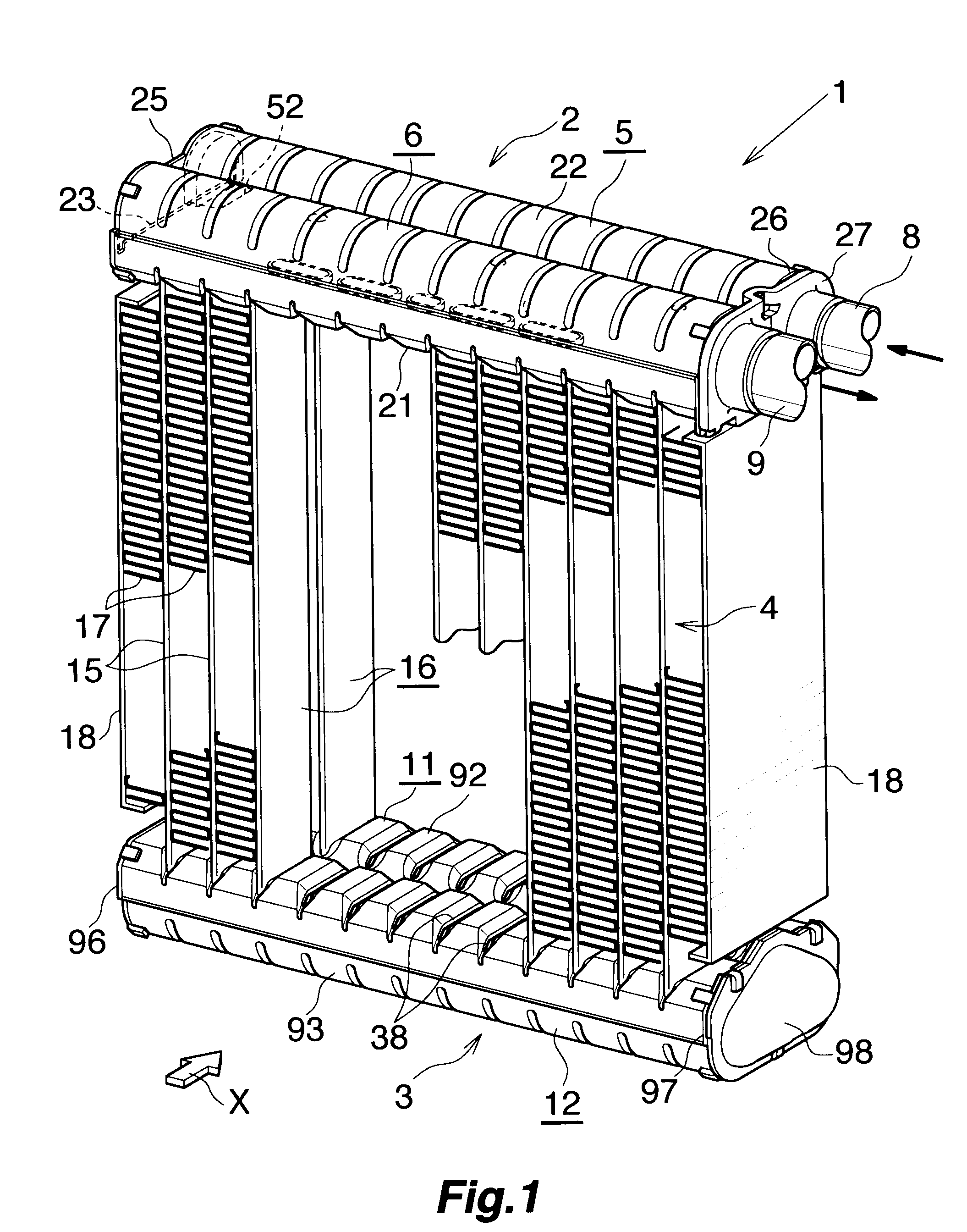

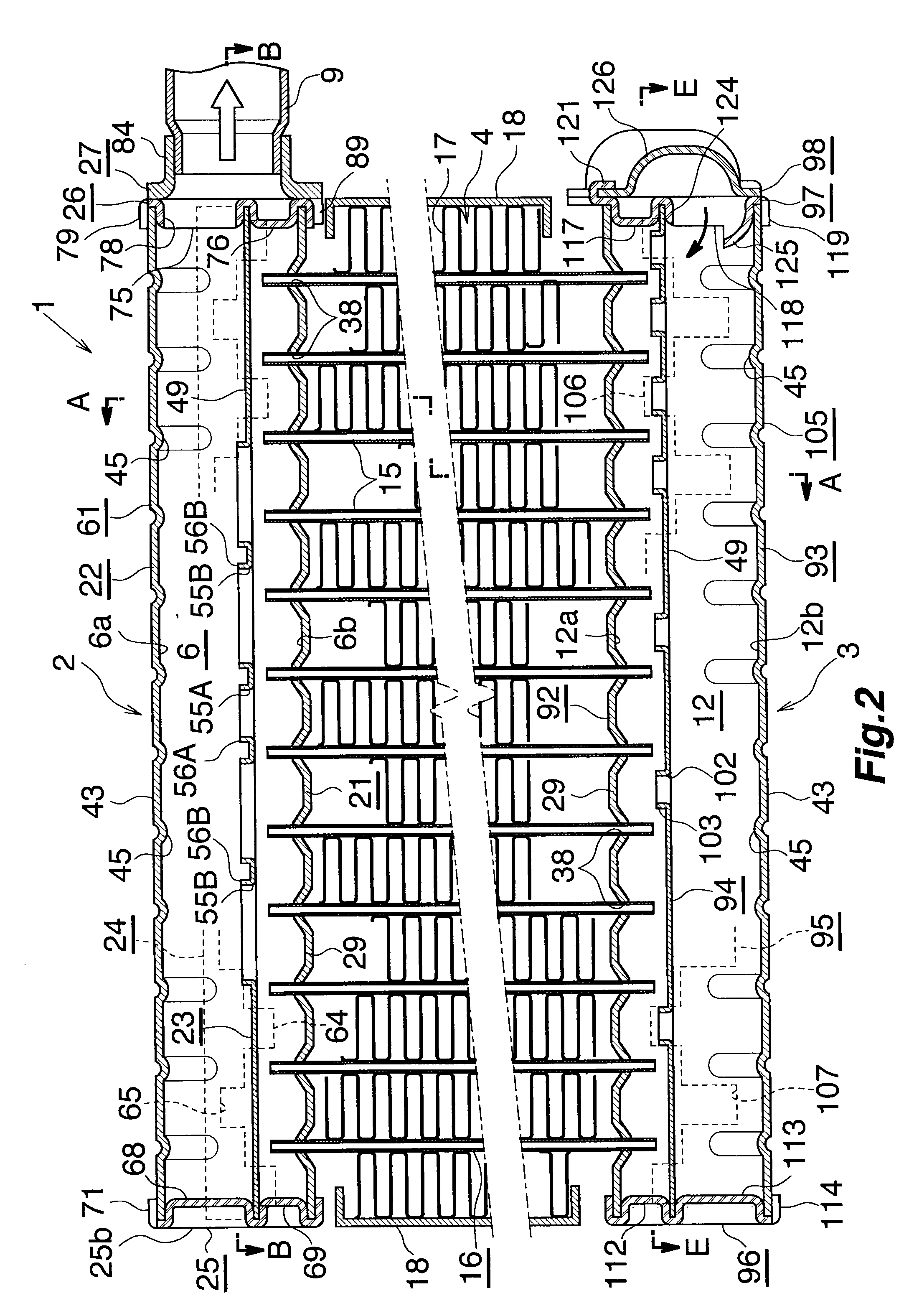

Stacked plate heat exchanger

InactiveUS20090032231A1Sufficient resistance to corrosionReliable joint of brazingCoatingsLaminated elementsPlate heat exchangerEngineering

The stacked plate oil cooler has a first plate and a second plate. Both the first plate and the second plate are made of a three-layered aluminum alloy clad sheet. The second plate is folded at an outer rim to place the brazing material layer on both sides of the second plate. The first and second plates and are stacked alternately and brazed to define a water passage between sacrificial layers and, and to define an oil passage between brazing material layers. The first plate is folded at an outer rim to place the sacrificial layer on a lateral outside of a core assembly to decrease exposure of the brazing material layer to the lateral outside.

Owner:DENSO CORP

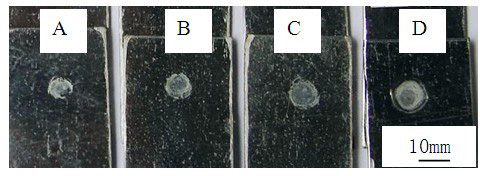

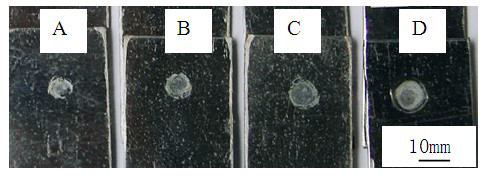

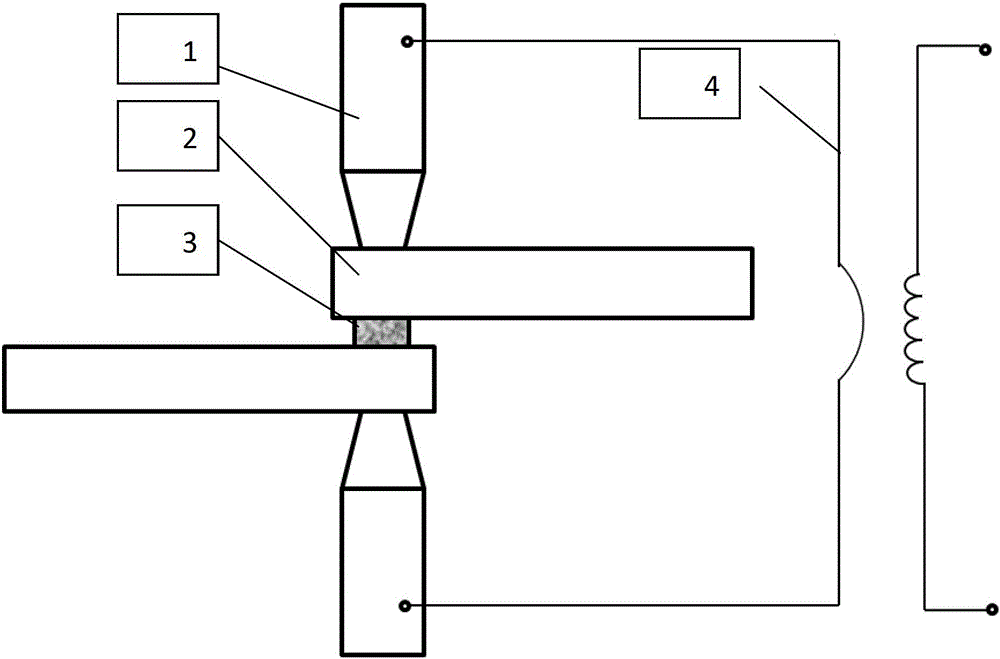

A resistance brazing method for galvanized steel sheets

InactiveCN102275046AFree from destructionExtended service lifeWelding apparatusMaterials scienceElectrical resistance and conductance

A resistance brazing method for galvanized steel sheets relates to the improvement of the resistance spot welding method for galvanized steel sheets. In the present invention, medium-temperature solder such as Zn-Al is placed on the two surfaces to be soldered. The solder can be sheet-like, foil-shaped, plated or sprayed on the surface to be soldered in advance, and the thickness of the solder is 0.05-0.5 mm. The electrode material can be an ordinary Cu-Cr-Zr electrode, and the electrode does not need special treatment. Set the resistance spot welding parameters, the welding current is 7000~14000A, the welding time is 10C~50C, the welding pressure is 0.7KN~5KN, start the resistance spot welding, and then let the weldment cool naturally. The invention can realize the connection without galvanized layer damage and copper pan under the premise that the galvanized steel sheet meets the strength, and improves the service life of the electrode.

Owner:CHONGQING UNIV OF TECH

Heat exchanger

InactiveUS20080223566A1Reliable connectorImprove reliabilityStationary conduit assembliesHeat exchanger casingsEvaporatorEngineering

A heat exchanger used as an evaporator is configured such that two heat exchange tube groups, each composed of a plurality of heat exchange tubes, are provided between a pair of header tanks, while being separated from each other in a front-rear direction. Each of the header tanks includes two header sections. Each header tank includes a first member to which the heat exchange tubes are connected, a second member which is joined to the first member and covers the side of the first member opposite the heat exchange tubes, and a partition plate disposed between the first and second members and having partition portions which divide the interiors of the two header sections into respective upper and lower spaces. Through holes are formed in the partition portions so as to establish communication between the upper and lower spaces of the header sections.

Owner:KEIHIN THERMAL TECH CORP

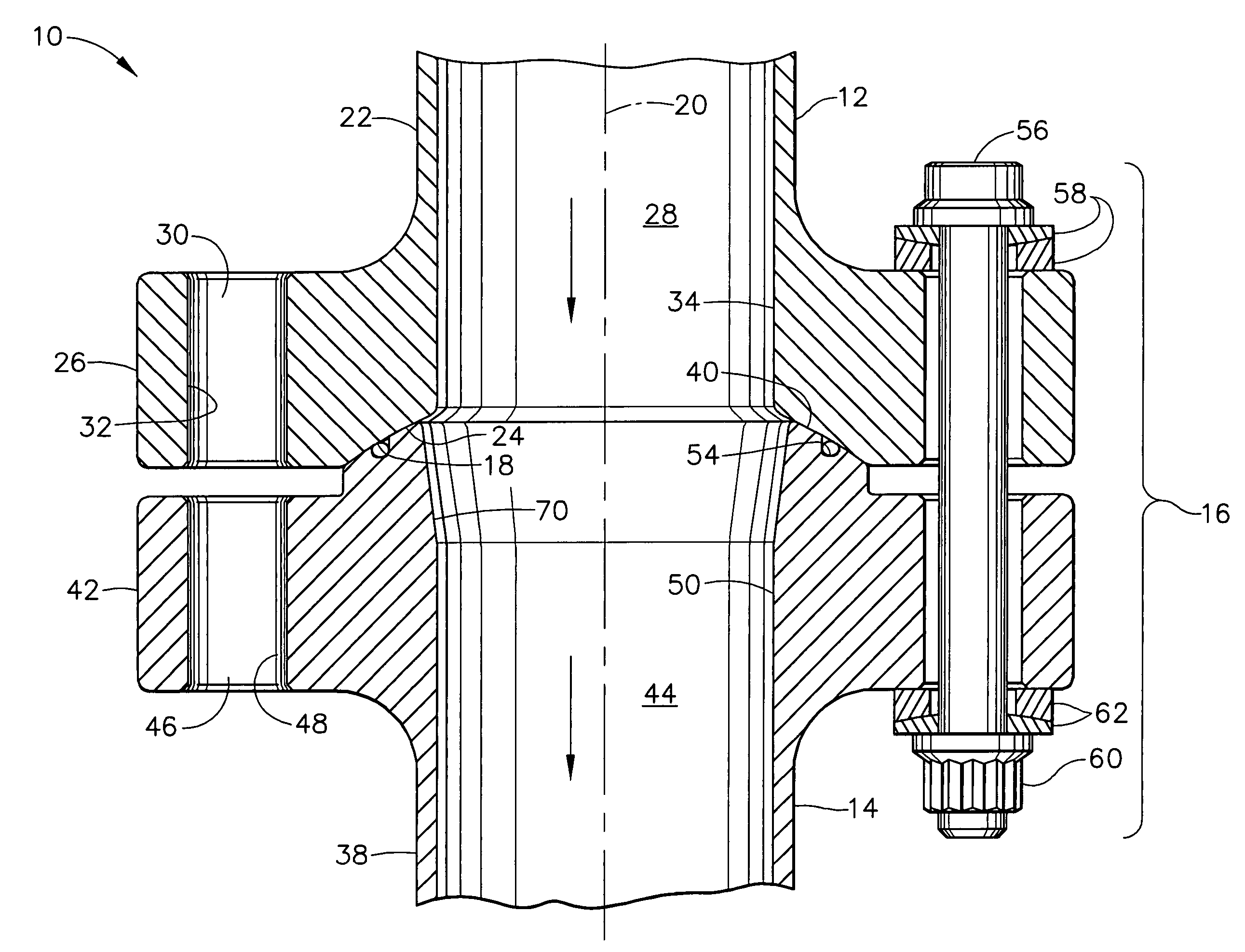

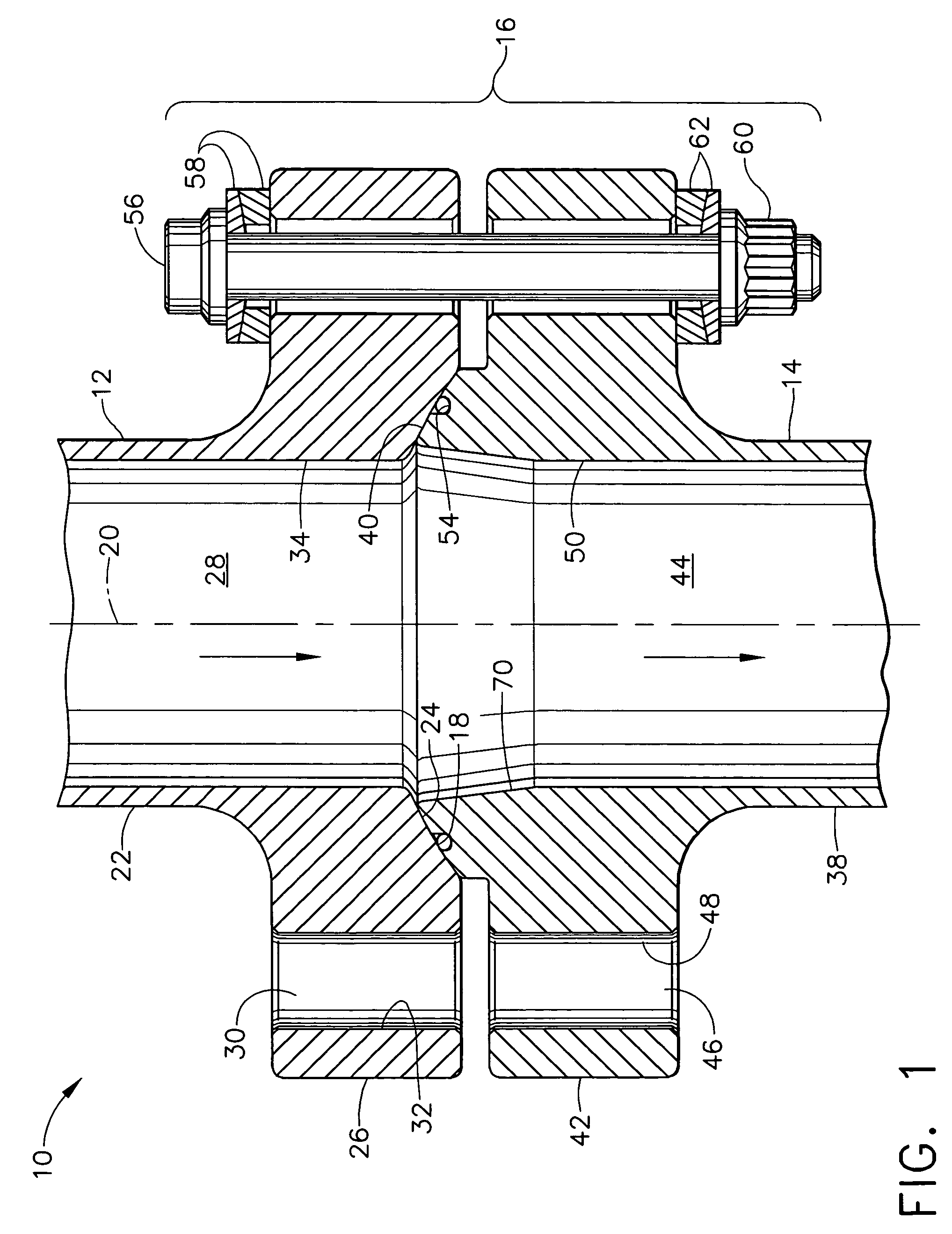

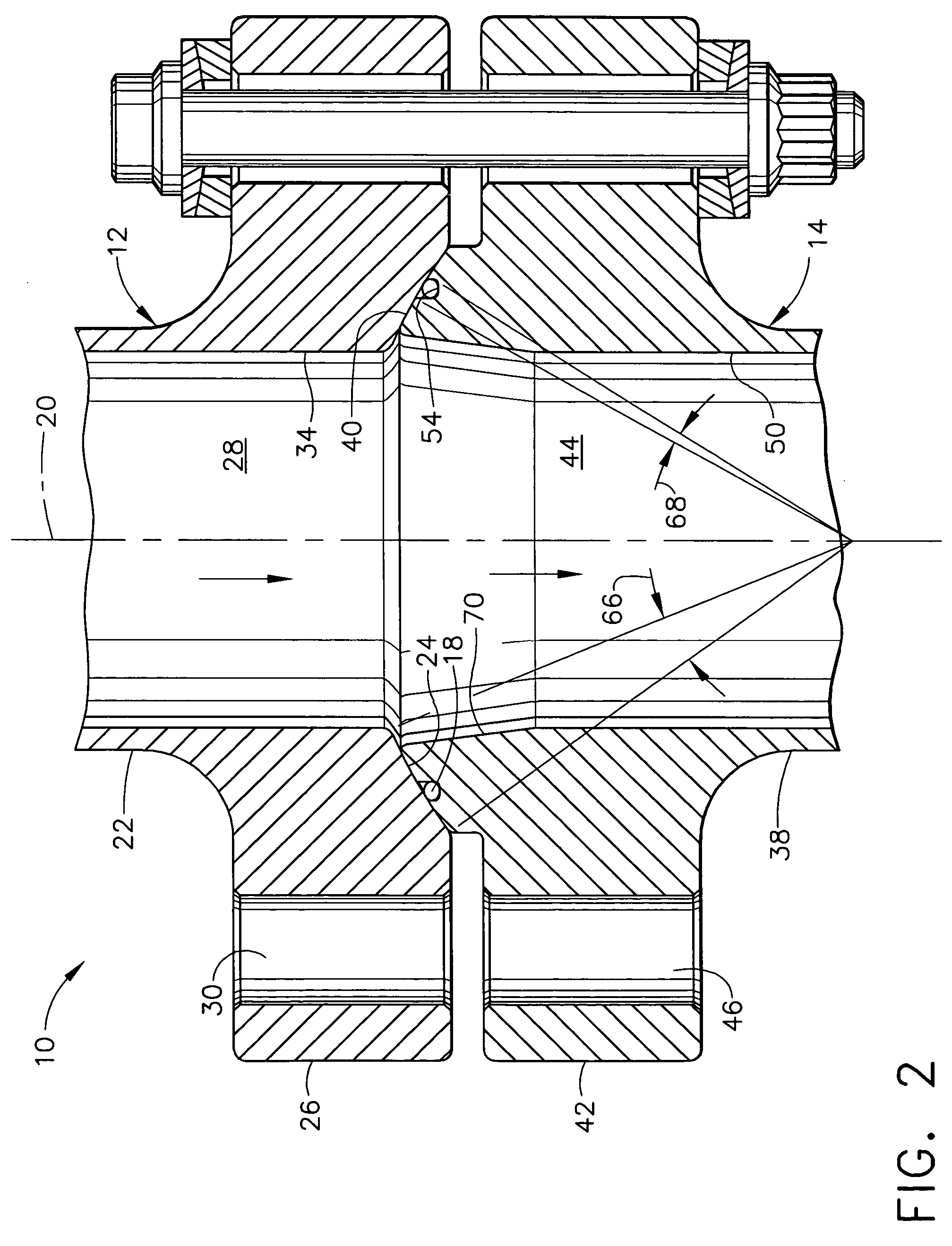

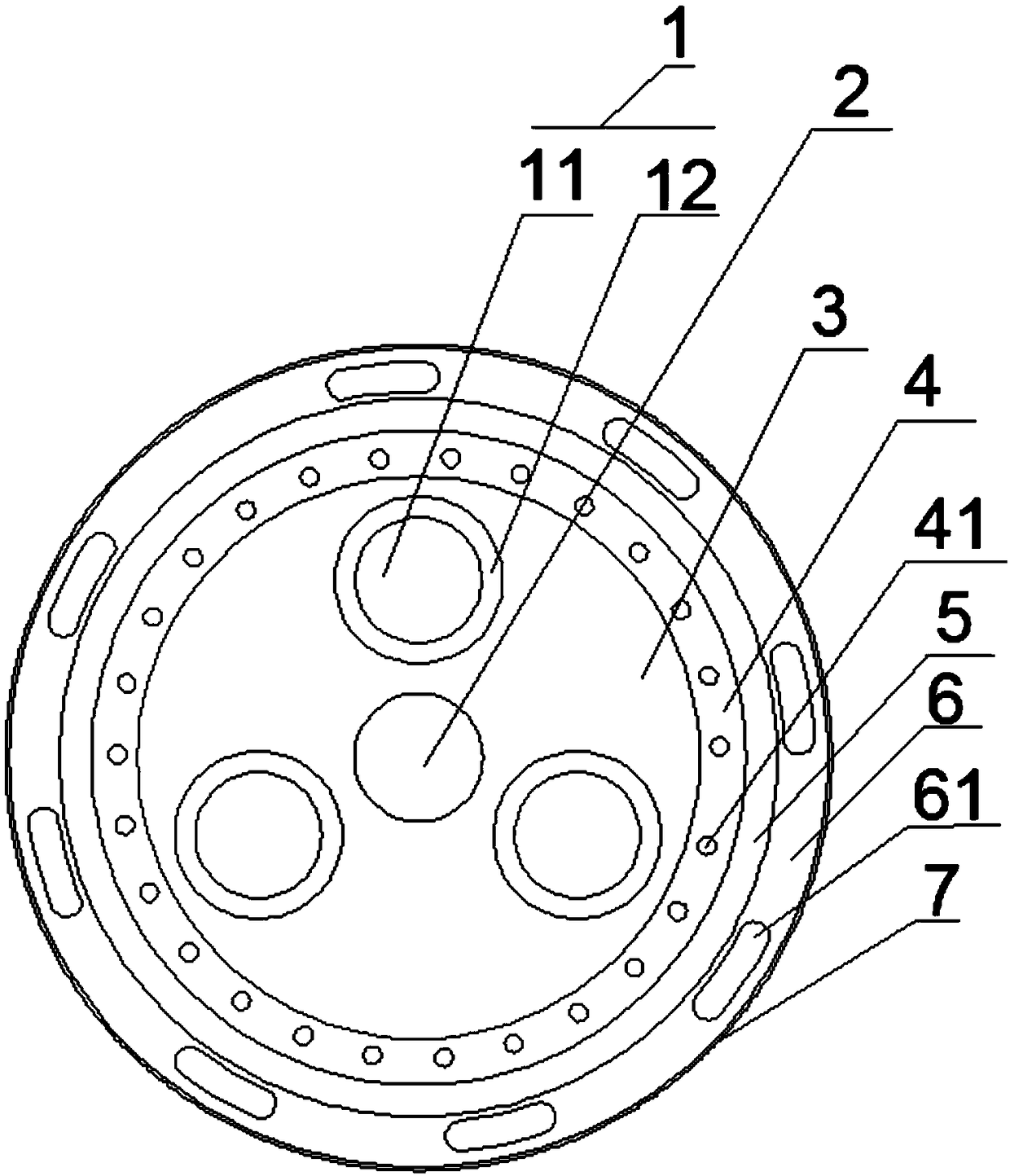

Spherical flange assembly

Owner:AEROJET ROCKETDYNE OF DE

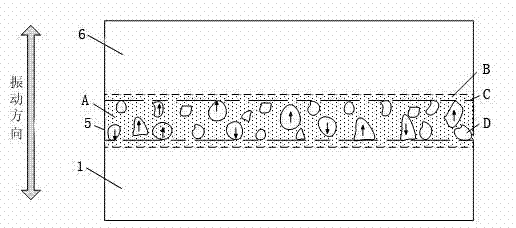

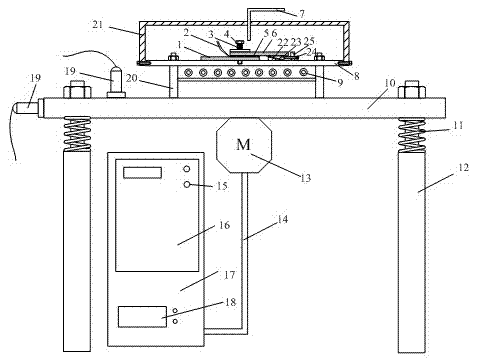

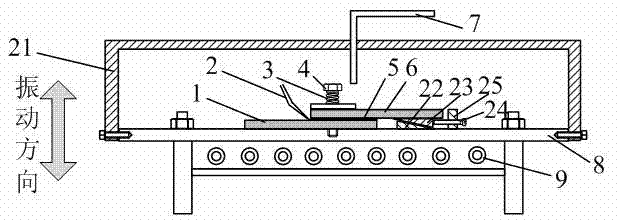

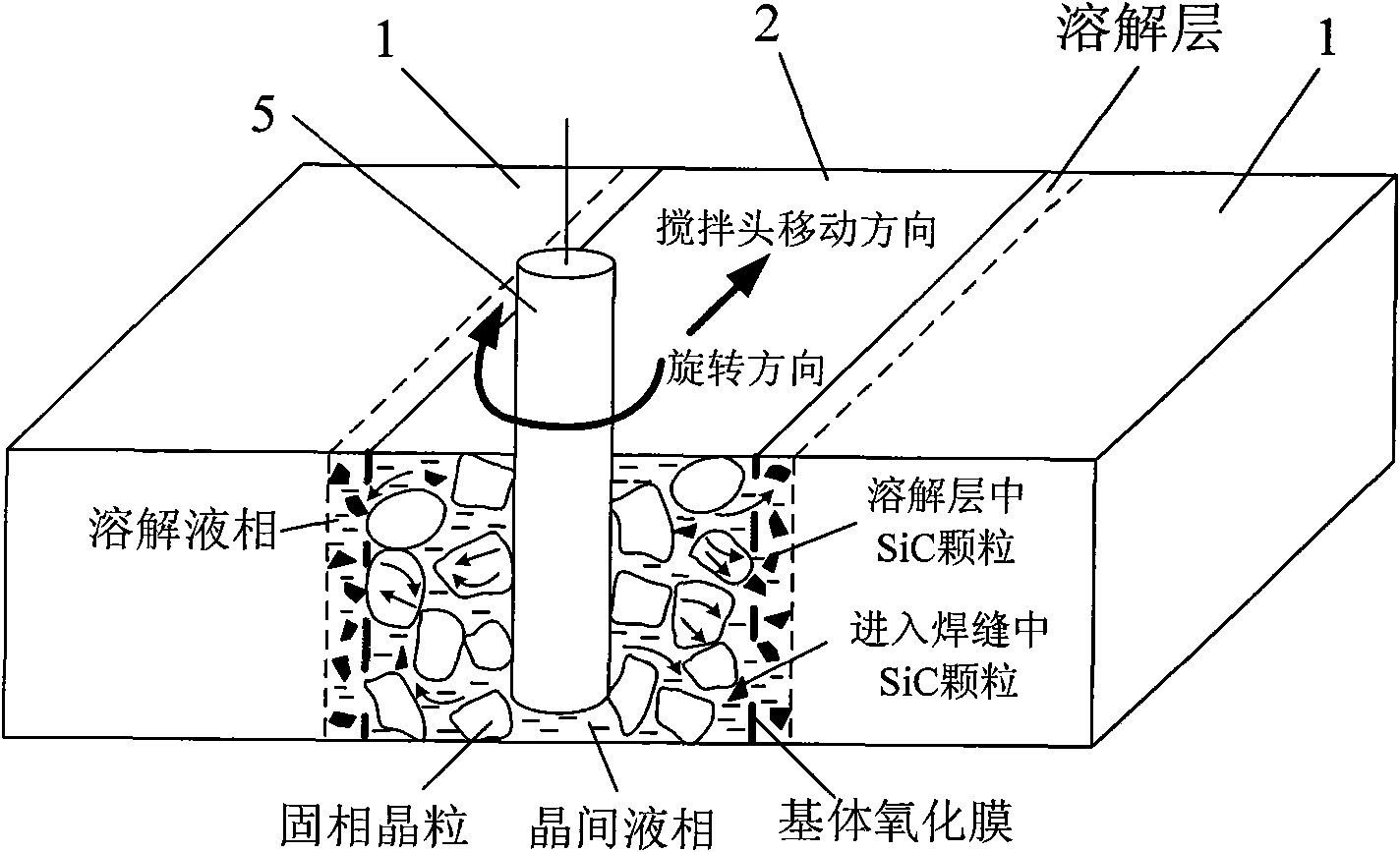

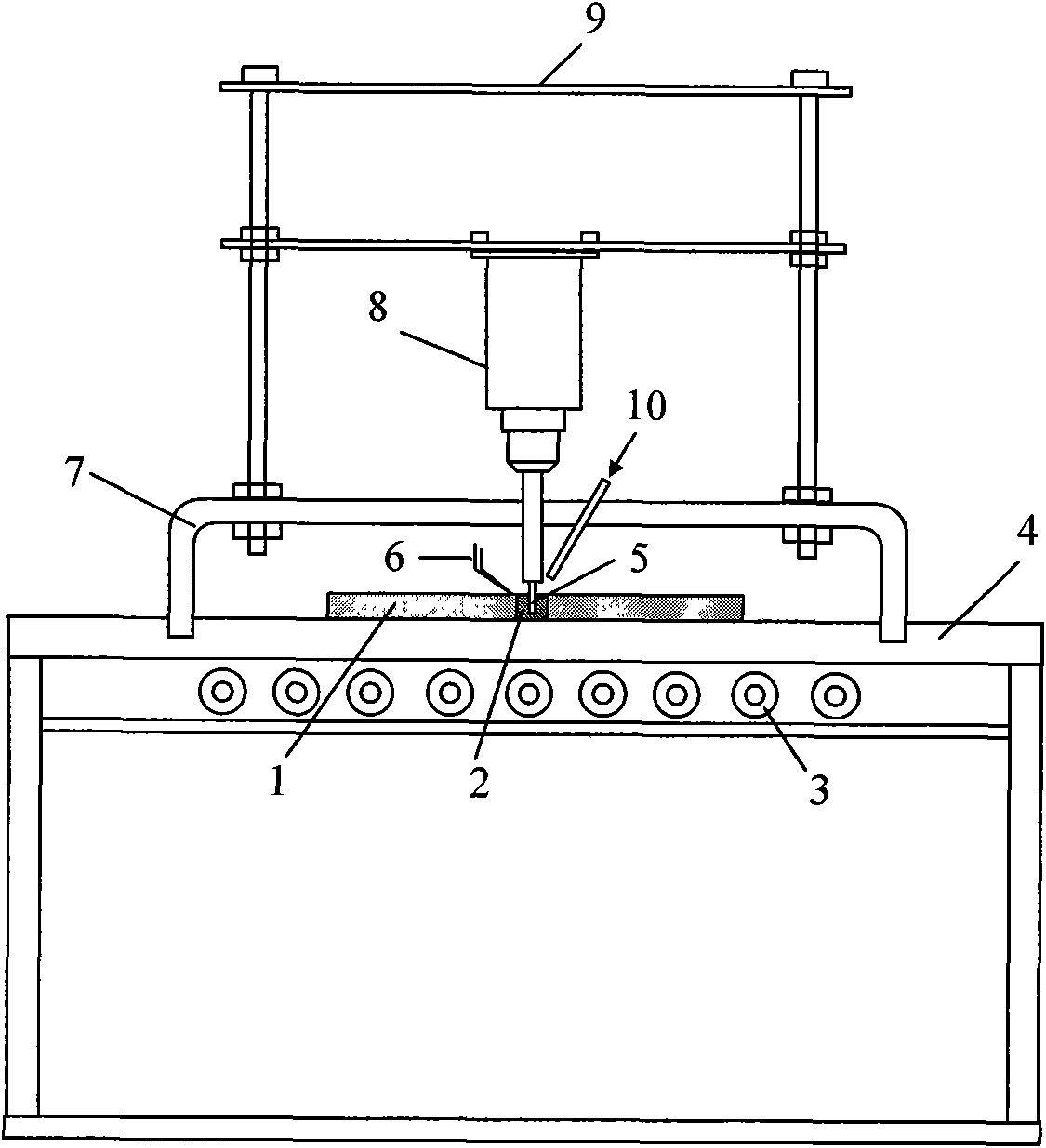

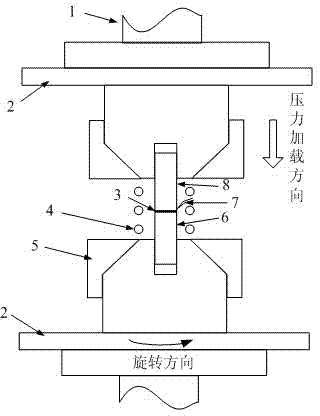

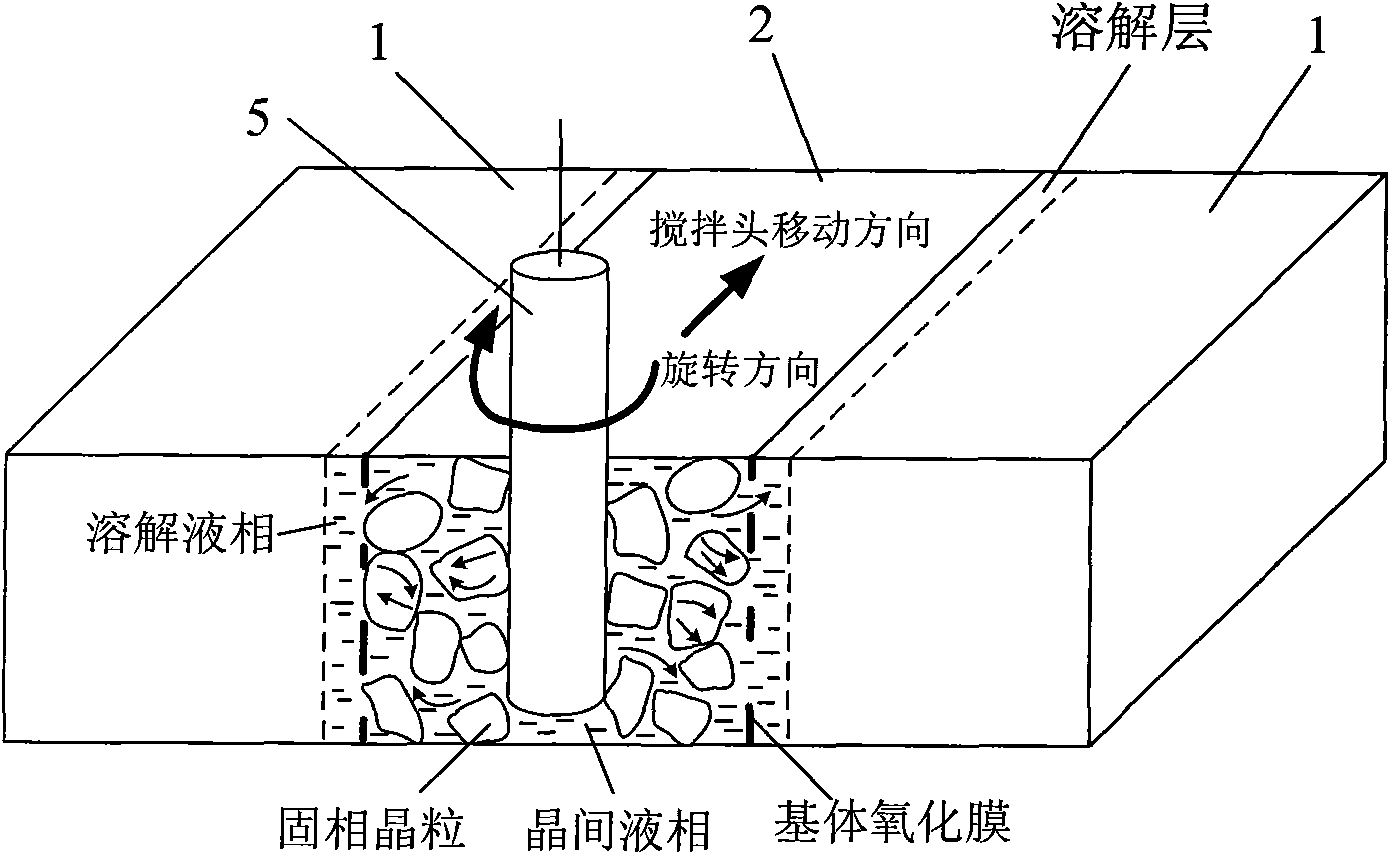

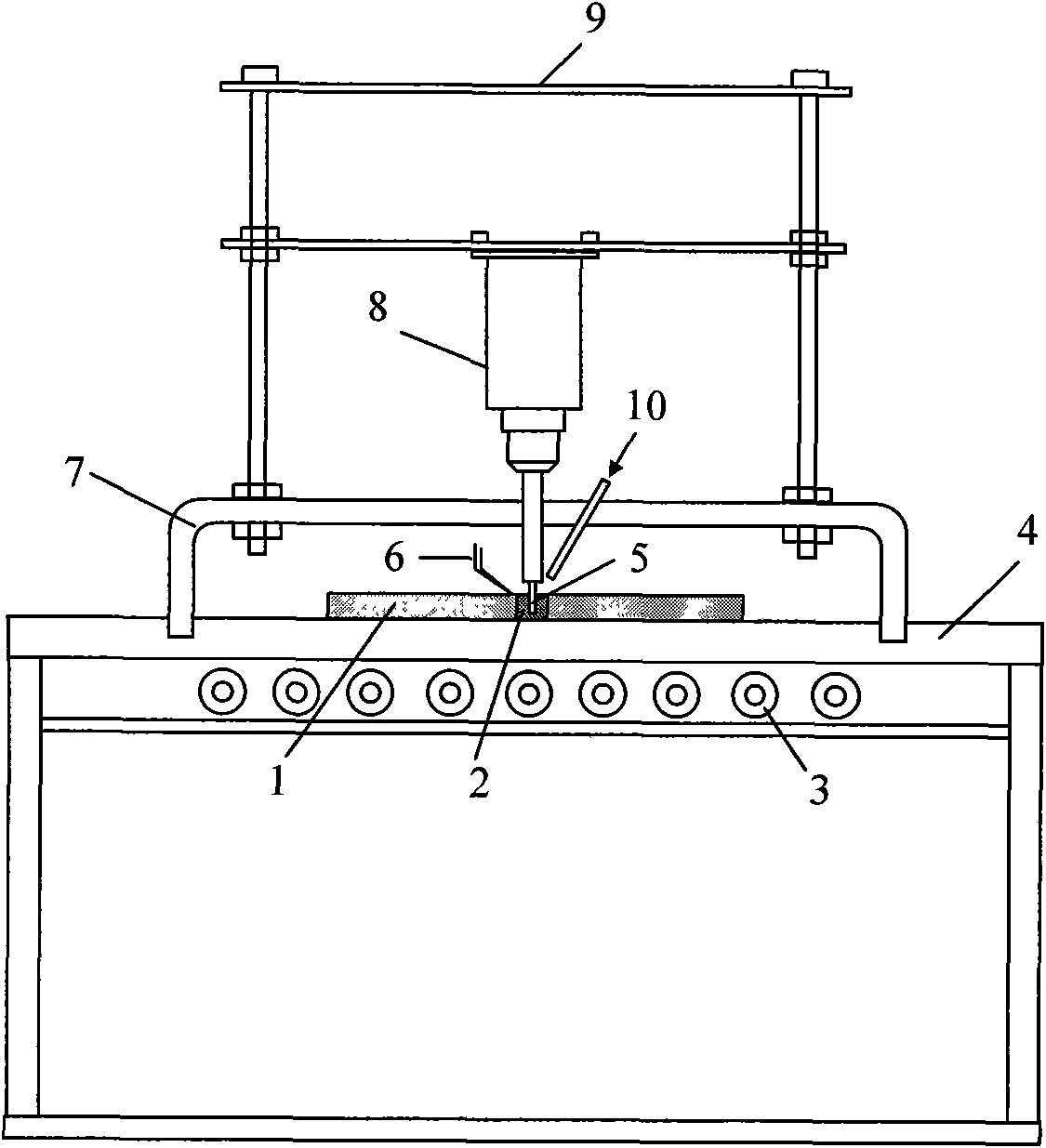

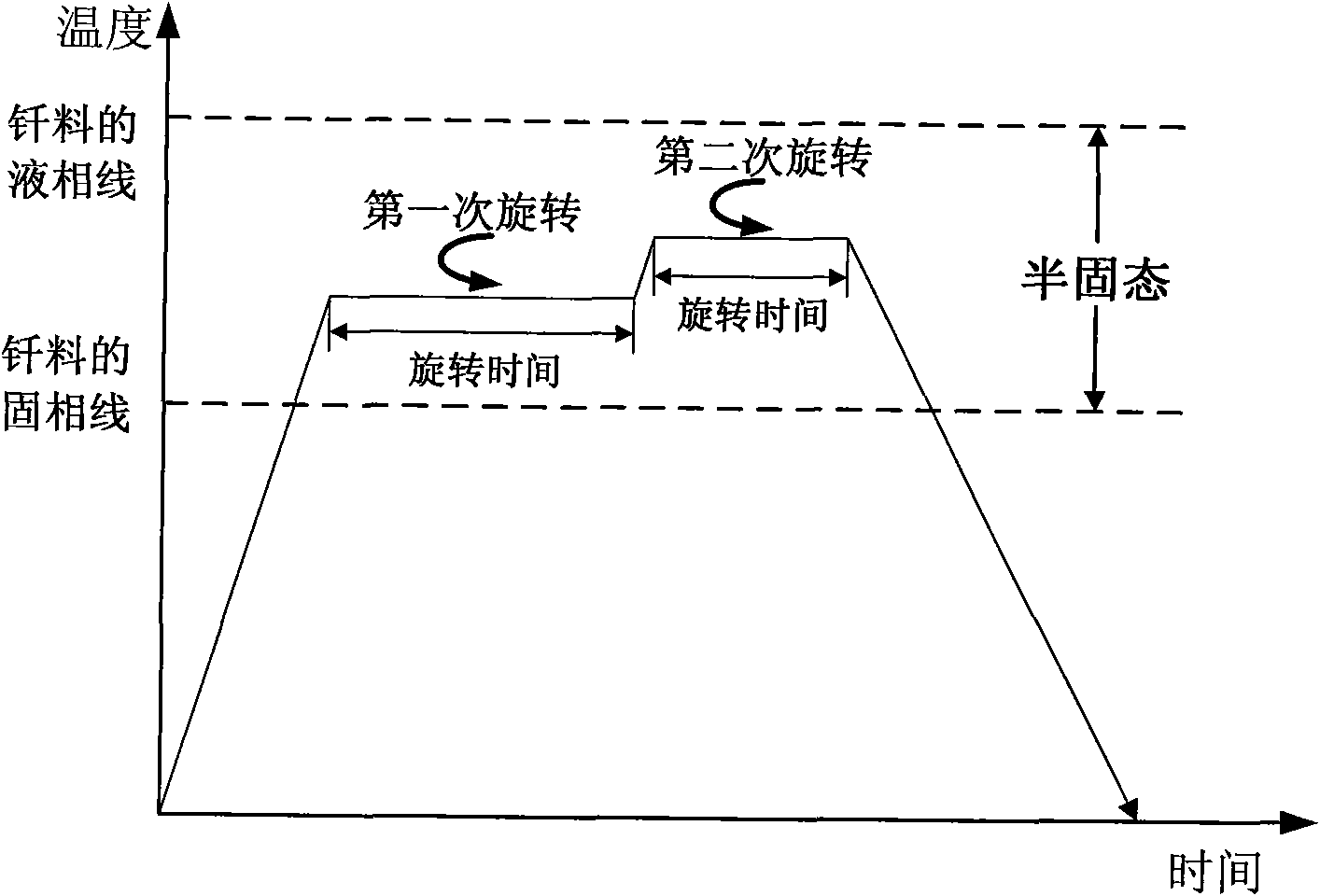

Heterogeneous semi-solid brazing method of aluminum alloy and magnesium alloy assisted by external vibration energy

InactiveCN102266994AAvoid serializationEfficient weldingSoldering apparatusRoom temperatureSemi solid

The invention provides a heterogeneous semi-solid brazing method for an aluminum alloy and a magnesium alloy under assistance of external vibration energy. According to the invention, the method comprises the following steps of: clamping an aluminum alloy weld member and a magnesium alloy weld member on a fixture and placing medium-temperature brazing filler metals of a Zn-Al or Al-Si series on two surfaces to be welded, wherein the brazing filler metals can be of flaky shapes or foil shapes, can be plating layers or can be sprayed on the surfaces to be welded in advance; heating the weld members so that the middle layer of brazing filler metal is in a semi-solid state; adjusting the pressure to be matched with the amplitude of the applied vibration; starting a vibrating device with amplitude of 0.01-2mm, wherein the brazing filler metals vibrate along with the two weld members, and the vibration time is 0.5-3 minutes according to actual requirements; stopping the vibration; and cooling the weld members to room temperature by air, wherein a certain pressure of 0.1-5 Mpa is always applied in the brazing process. According to the invention, high-efficiency, high-quality and economic connection between the aluminum alloy and the magnesium alloy can be realized.

Owner:CHONGQING UNIV OF TECH

Mechanically formed standoffs in a circuit interconnect

InactiveUS6417997B1Low costReliable connectorPrinted circuit assemblingElectrical connection between head and armIntegrated circuit interconnectBonding process

Mechanically formed standoffs in a disk drive integrated circuit interconnect reduces the cost of manufacturing and improves the reliability of the electrical interconnections thereof. Connection pads defined along the interconnect are bonded with bonding pads of a signal producing source and a signal processing source. The standoffs provide mechanical stops during the bonding process, enabling sufficient bonding material to form between bonding areas. The standoffs are mechanically formed with a punch and die assembly either directly through a bonding pad predefined along traces on the interconnect or adjacent the bonding pad. The standoffs formed through the bonding pads are covered with solder or other electrically conductive bonding material.

Owner:WILLIAMS STEPHEN P

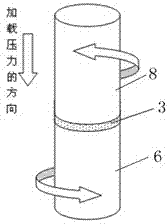

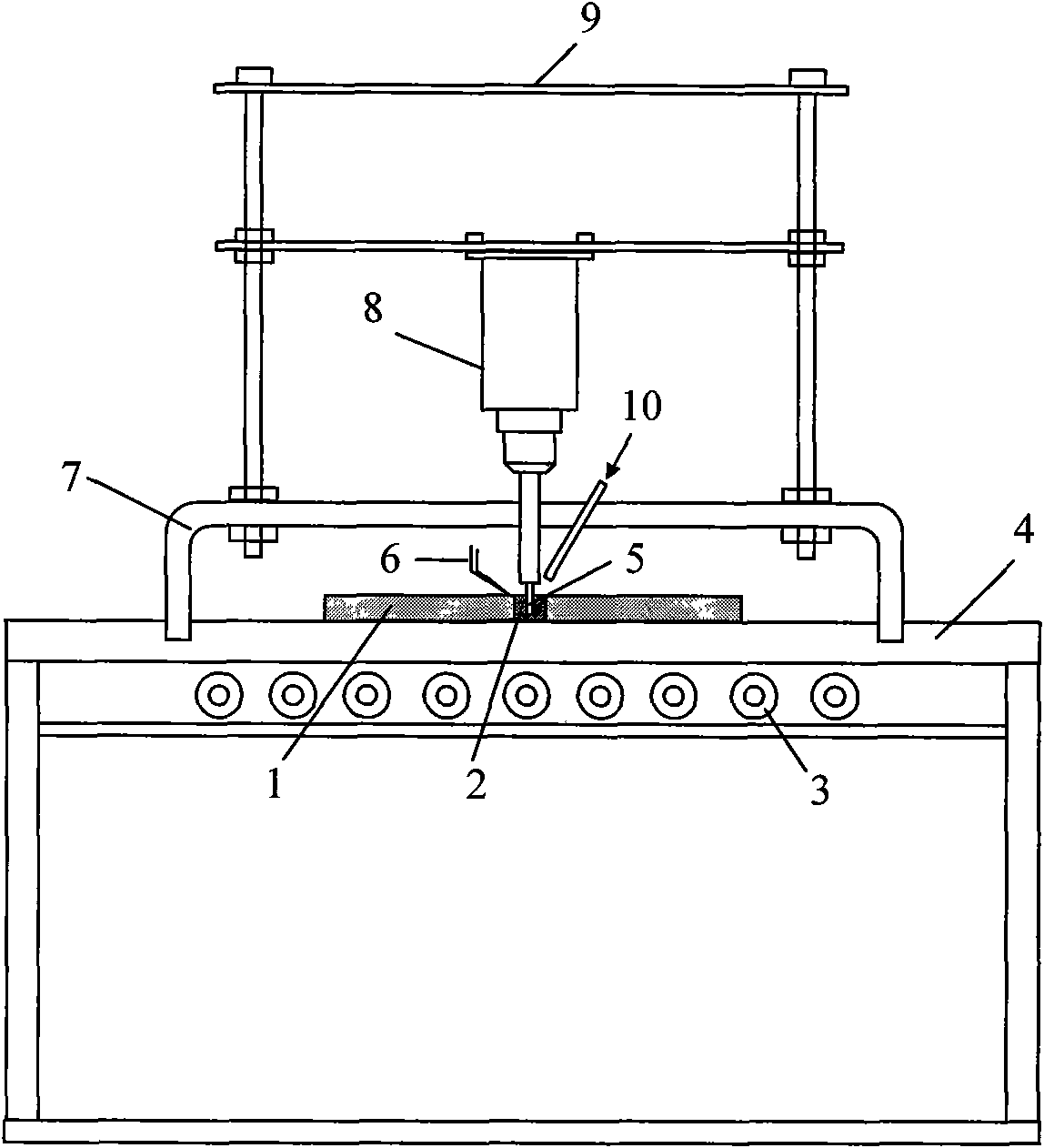

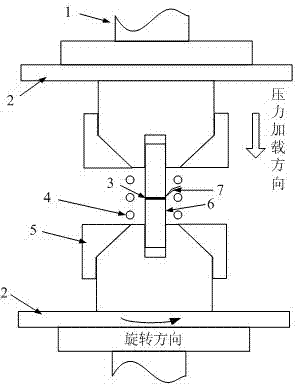

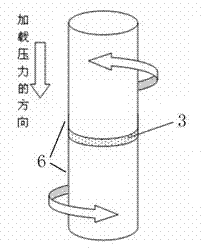

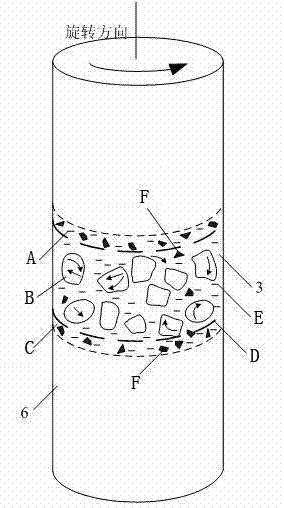

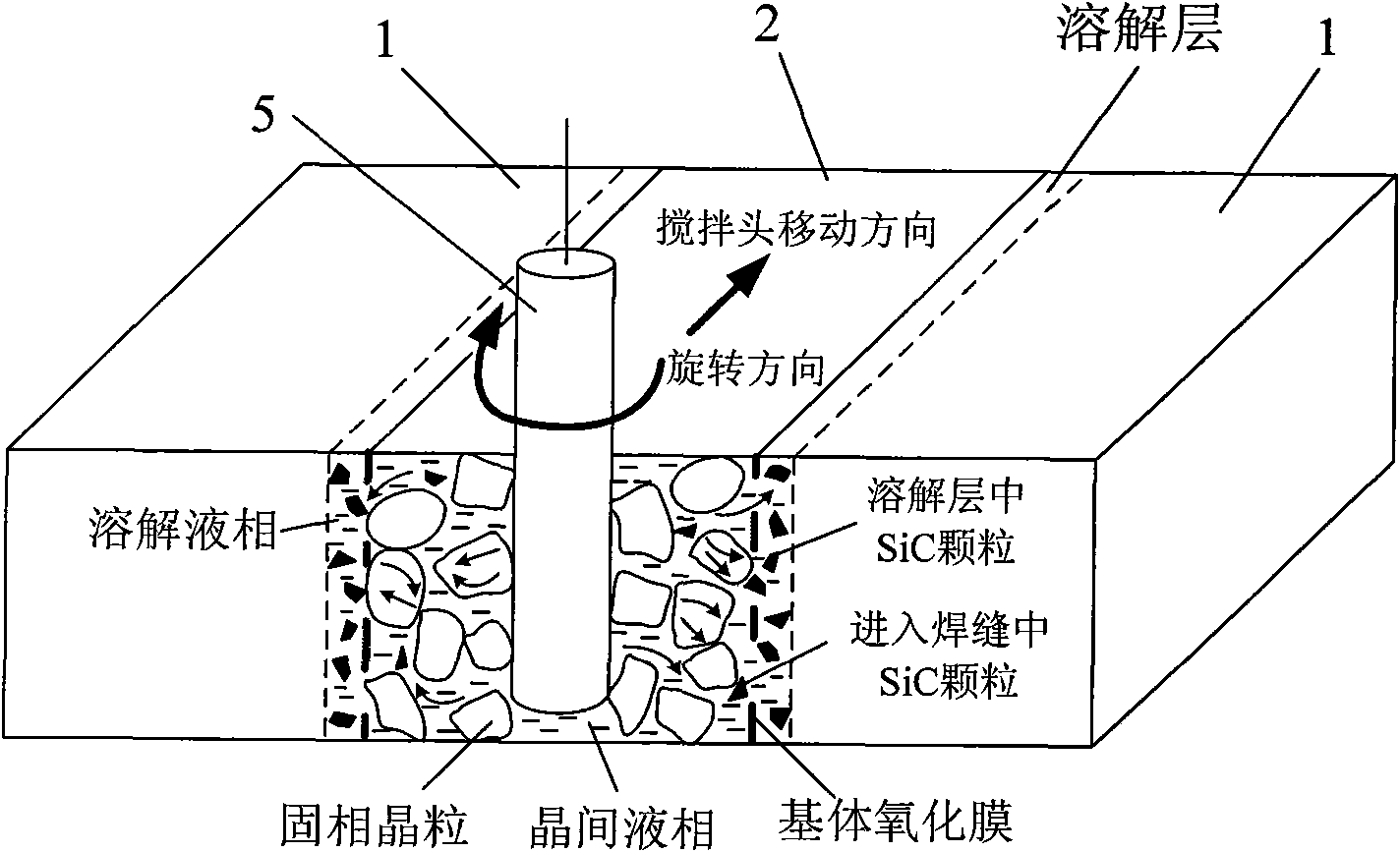

Non-vacuum semi-solid stirring brazing method for aluminum alloy and composite material thereof

The invention provides a semi-solid brazing method for aluminum alloy and a composite material thereof under the assistance of non-vacuum mechanical stirring, which comprises the steps of: mounting a weldment taking the aluminum alloy or the composite material thereof as a base material on a welding platform first; placing intermediate-temperature solder on two surfaces to be welded, heating the weldment to between 390 and 420 DEG C, and ensuring that the solid fraction of the solder is between 50 and 80 percent; staring a rotary sliding device, wherein the rotating speed is between 150 and 300 r / m, the temperature is constant, and the longitudinal movement rate, which is parallel to a welding seam, of a stirring head is between 0.5 and 2 cm / min; stopping the rotary sliding when the stirring head moves to the terminal of the welding seam; increasing the temperature to between 430 and 450 DEG C, performing thermal insulation for 1 to 5 minutes, and ensuring that the solid fraction of the solder is between 10 and 40 percent; restarting the rotary device again, wherein the rotating speed is between 20 and 150 r / m; sliding the stirring head in a reverse direction, wherein the movement speed is between 1 and 2 cm / m; stopping the rotation, when the stirring head moves to the initial end of the welding seam, and lifting the stirring head; and cooling the solder along with a furnace after thermal insulation for 5 to 30 minutes. The method can realize the low-cost, high-efficiency and high-quality welding of the aluminum alloy or the composite material thereof.

Owner:CHONGQING UNIV OF TECH

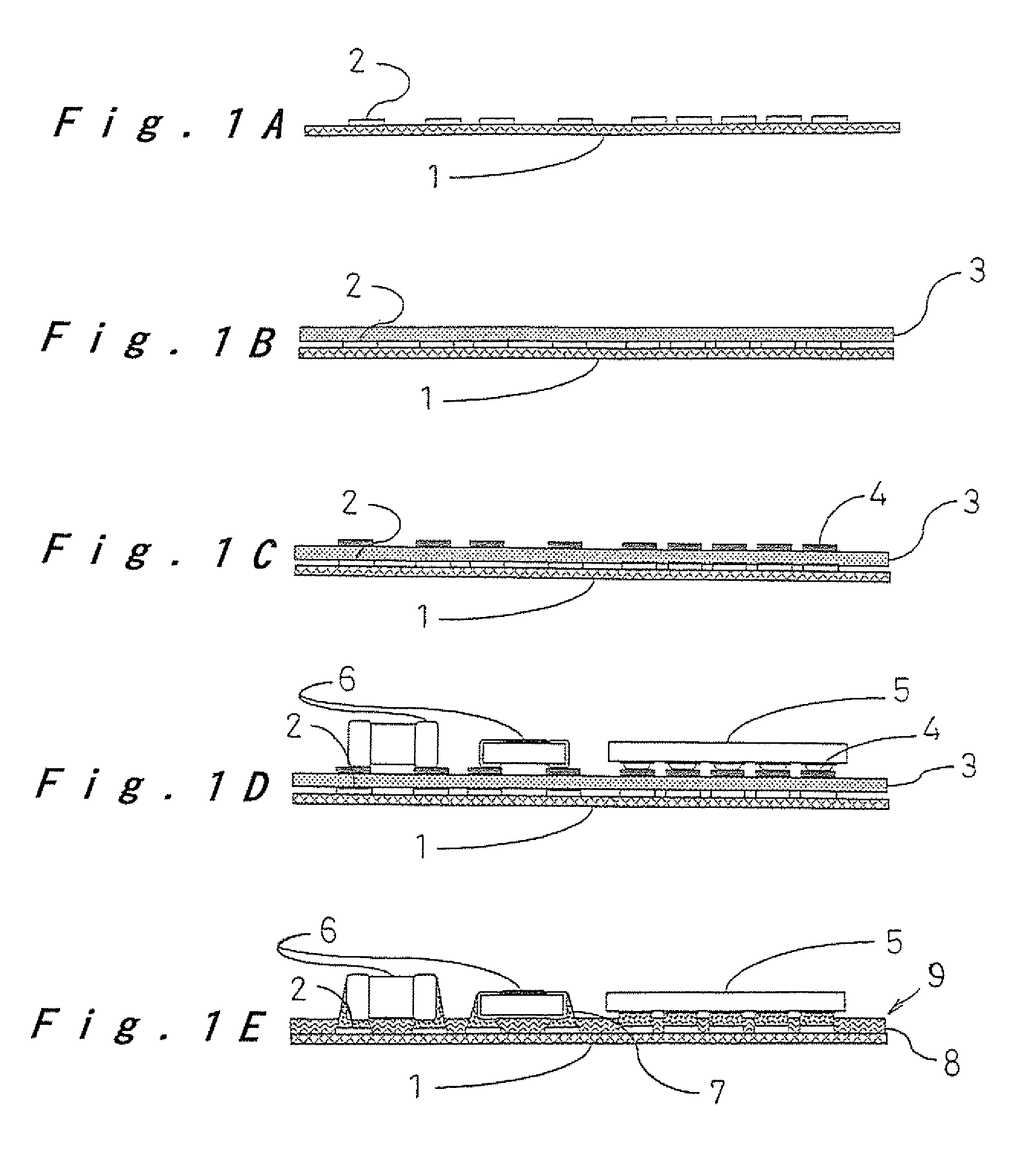

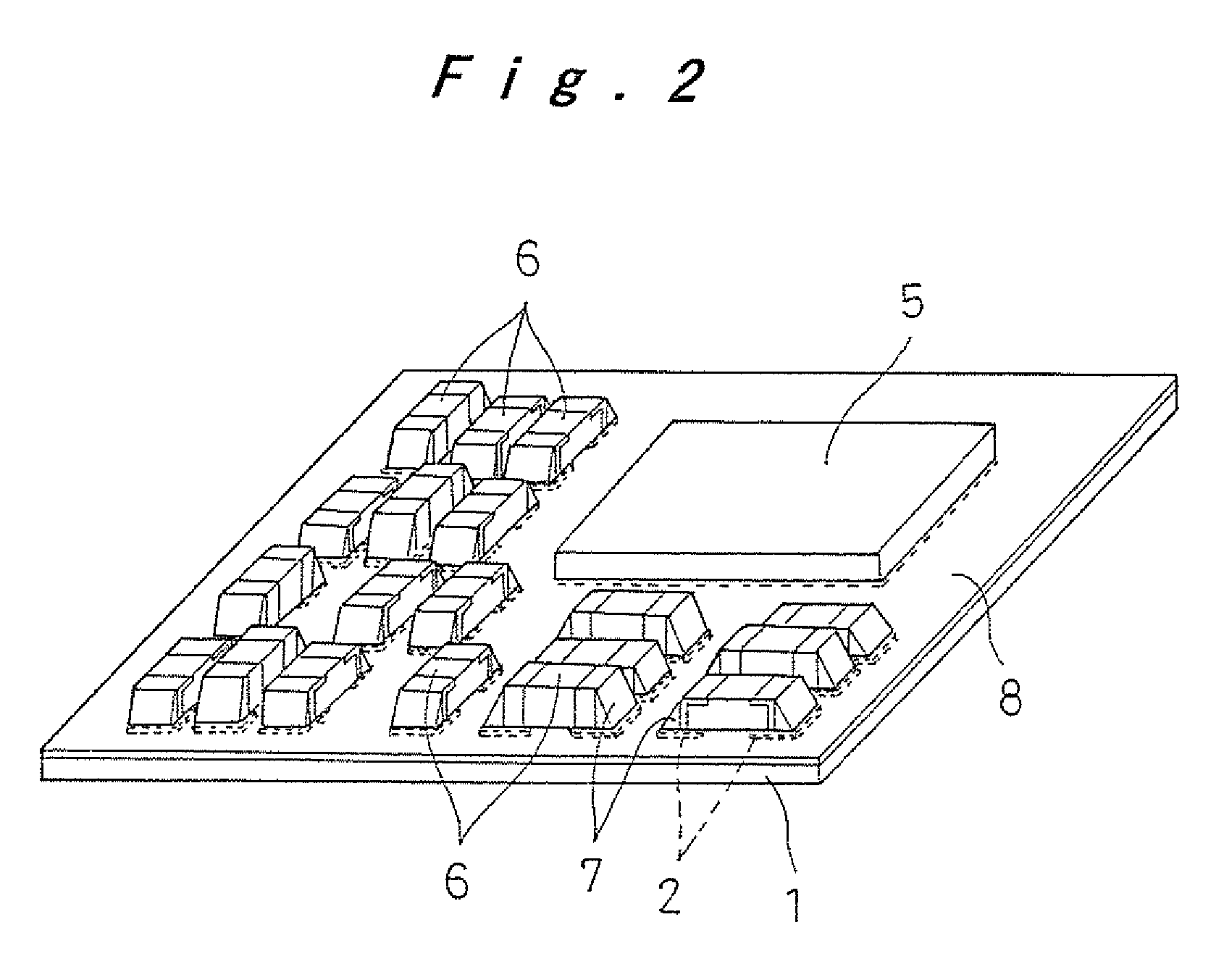

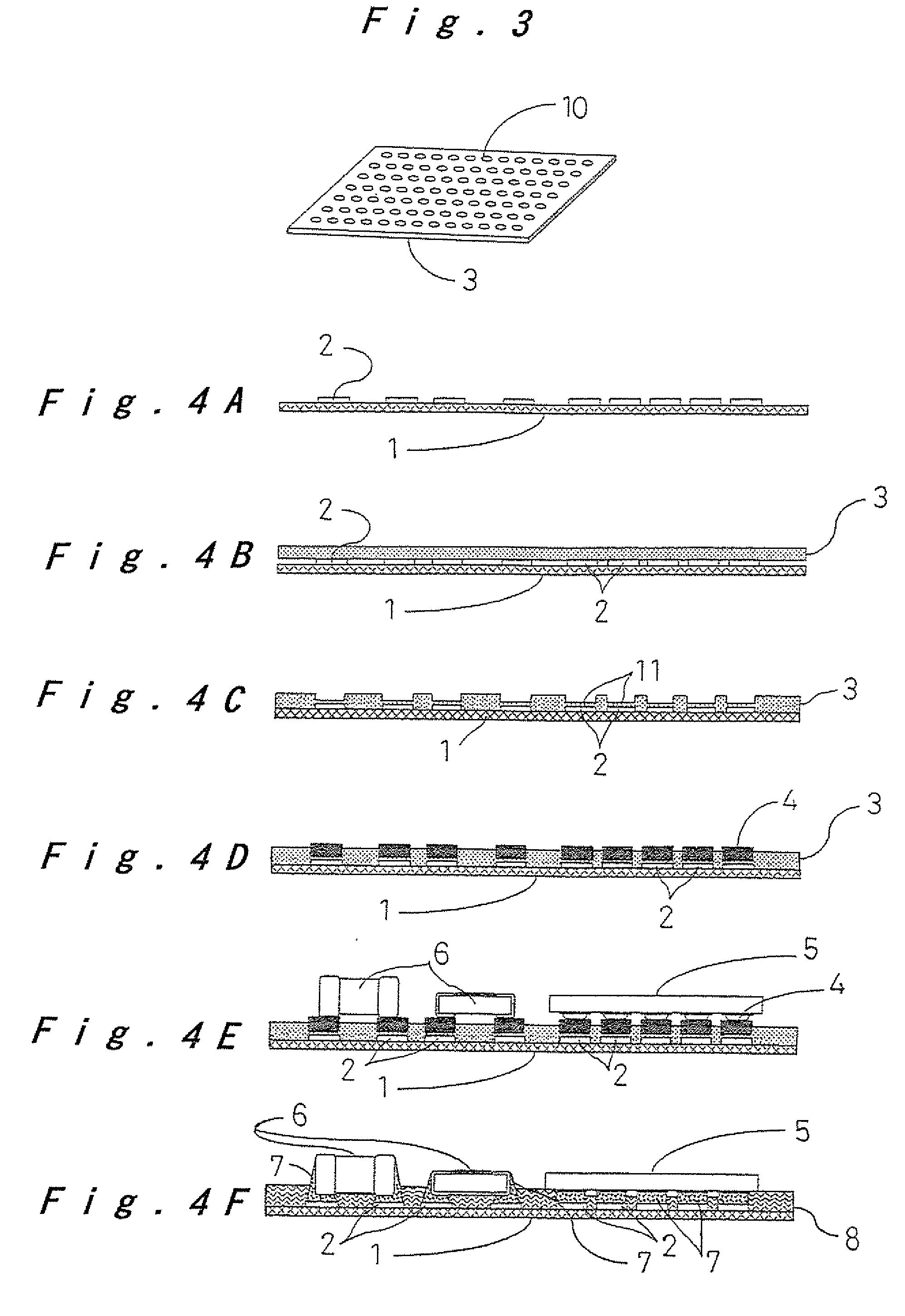

Electronic component mounting method, and circuit substrate and circuit substrate unit used in the method

InactiveUS20070164079A1High joint reliabilityIncrease production capacityPrinted circuit assemblingCooking-vessel materialsProduction rateSurface mounting

An electronic component mounting method comprising: supplying an unhardened reinforcing resin on a circuit substrate; supplying a solder paste on bond areas of the circuit substrate on which electrodes of the electronic components are to be bonded; placing the electronic components on the circuit substrate; and heating and then cooling the circuit substrate with the reinforcing resin, the solder paste, and the electronic components carried thereon. The mounting method enables mounting of components with high joint reliability, while incorporating the conventional surface mount process steps. The method may also be applied to the mounting of smaller electronic components with narrower pitch without deteriorating productivity or mounting quality.

Owner:PANASONIC CORP

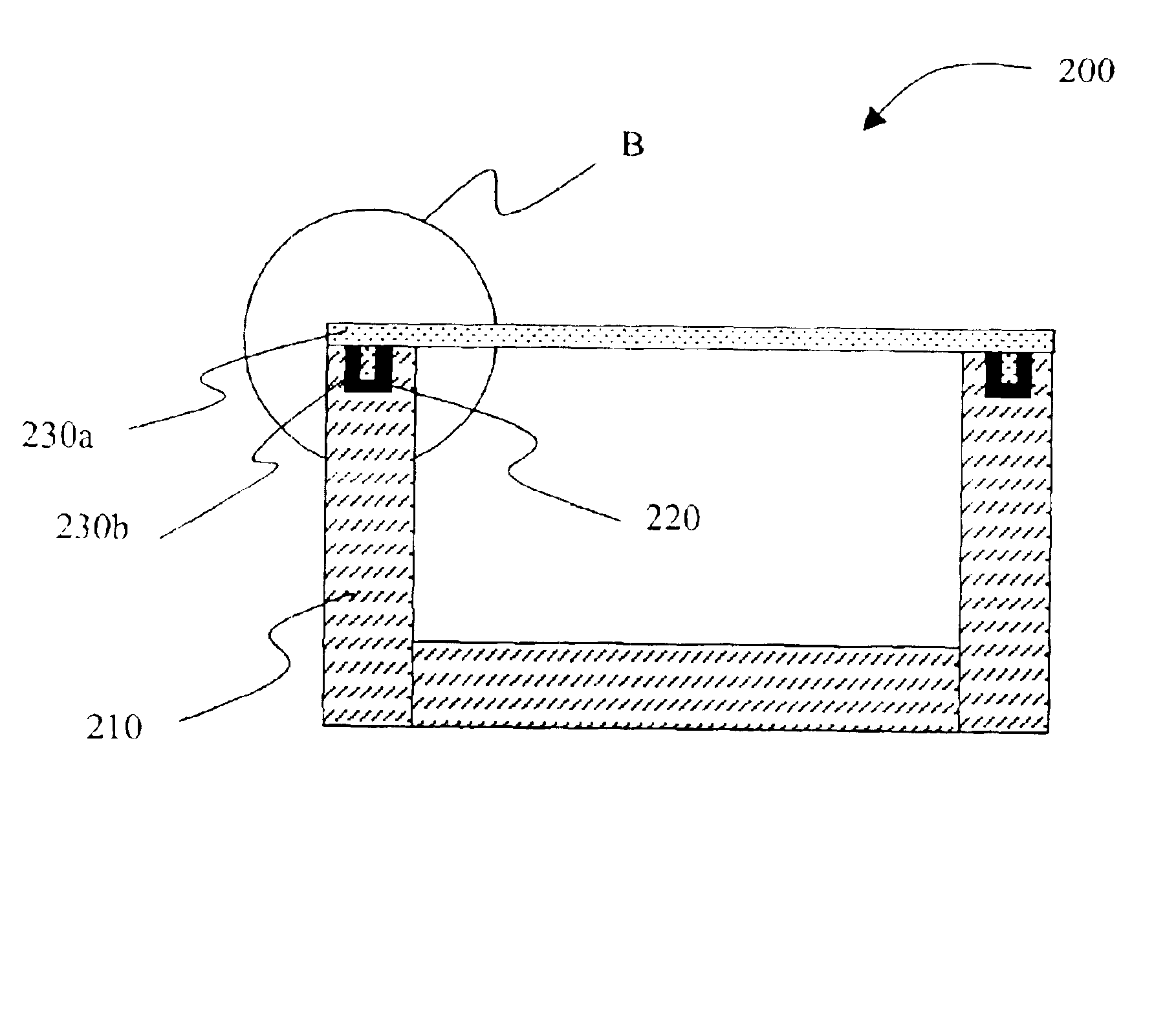

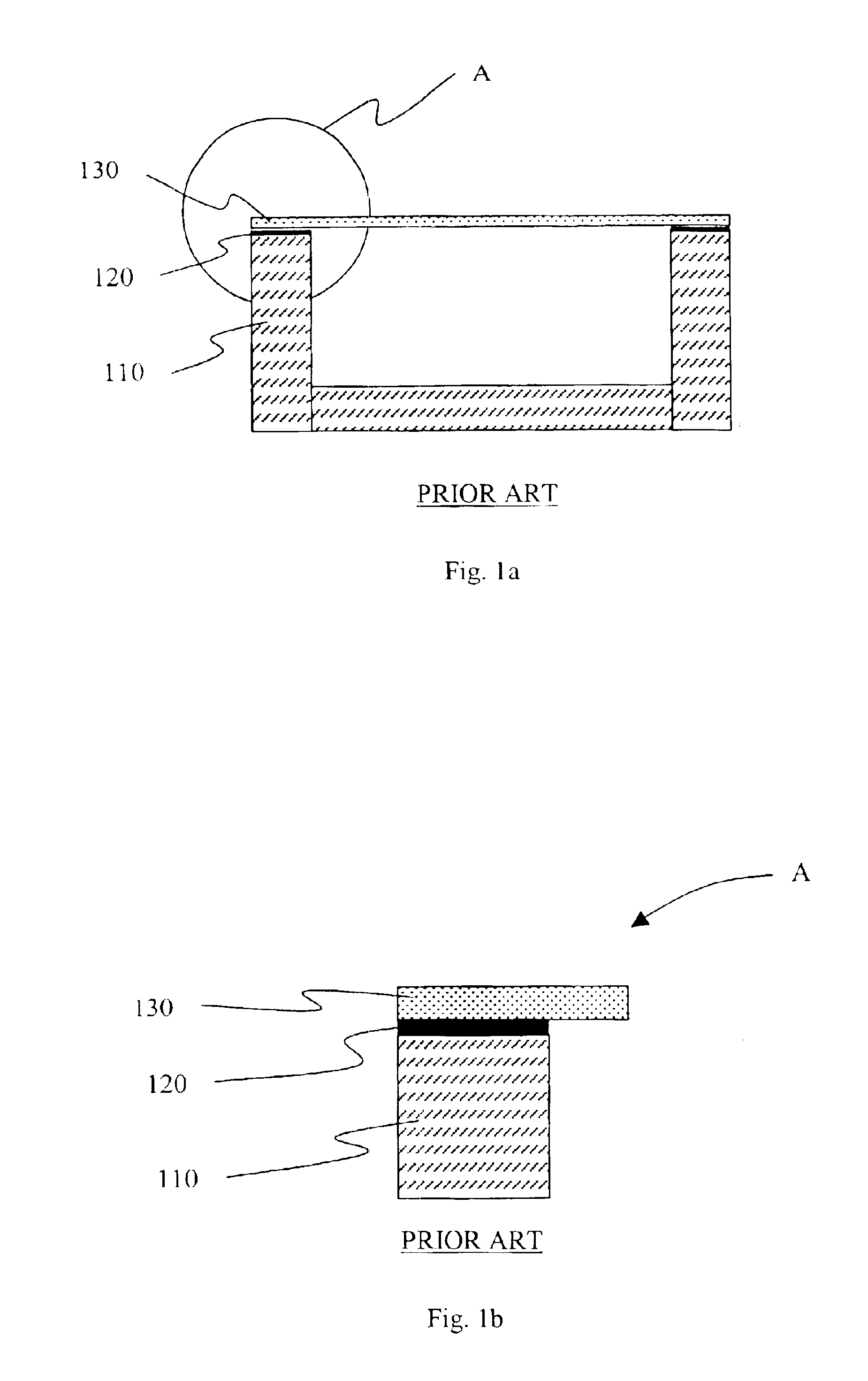

Hermetic seal and a method of making such a hermetic seal

InactiveUS6962338B2Reliable and reliableLow costEngine sealsRemovable lids/coversHermetic sealEngineering

The invention provides a hermetic seal and a method of making a hermetic seal having the steps of providing a first member of a first material having a flange thereon, providing a second member of a second material having a slot thereon for accommodating the flange in said slot such that there is a gap between the slot and the flange, providing a sealant in the slot, and heating the sealant such that the sealant fills at least a portion of the gap between the flange and the slot for forming a hermetic seal therebetween. Advantageously, the slot and flange design of the inventive hermetic seal produces a three-dimensional compressive state of stress thereby providing a joint design of improved reliability.

Owner:LUMENTUM OPERATIONS LLC

Semiconductor device and method for manufacturing thereof

InactiveUS7579677B2Increasing the thicknessAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceThermal expansion

In a power semiconductor device, a joint between the power semiconductor element and frame plated with Ni is composed of a laminated structure comprising, from the power semiconductor element side, an intermetallic compound layer having a melting point of 260° C. or higher, a Cu layer, a metal layer having a melting point of 260° C. or higher, a Cu layer and an intermetallic layer having a melting point of 260° C. or higher. The structure of the joint buffers the stress generated by the secondary mounting and temperature cycle at the bond for the semiconductor element and the frame having a large difference in thermal expansion coefficient from each other.

Owner:RENESAS ELECTRONICS CORP

Leaf seal, in particular for a gas turbine, and method of producing it

A leaf seal for sealing a shaft rotating about an axis, in particular in a gas turbine, includes a plurality of spaced-apart leaves arranged in a concentric circle around the axis and fixed in position by brazing, the leaves having surfaces oriented essentially parallel to the axis. The leaves are brazed to one another via intermediate spacers made of a brazing foil, so that a brazed joint is produced by brazing alloy from the brazing foils. The brazing temperature may be set to an optimum value just above the solidus temperature of the brazing foil, at which partial melting of the brazing foil occurs and penetration of liquid brazing alloy into the gap between the leaves is avoided.

Owner:ANSALDO ENERGIA IP UK LTD

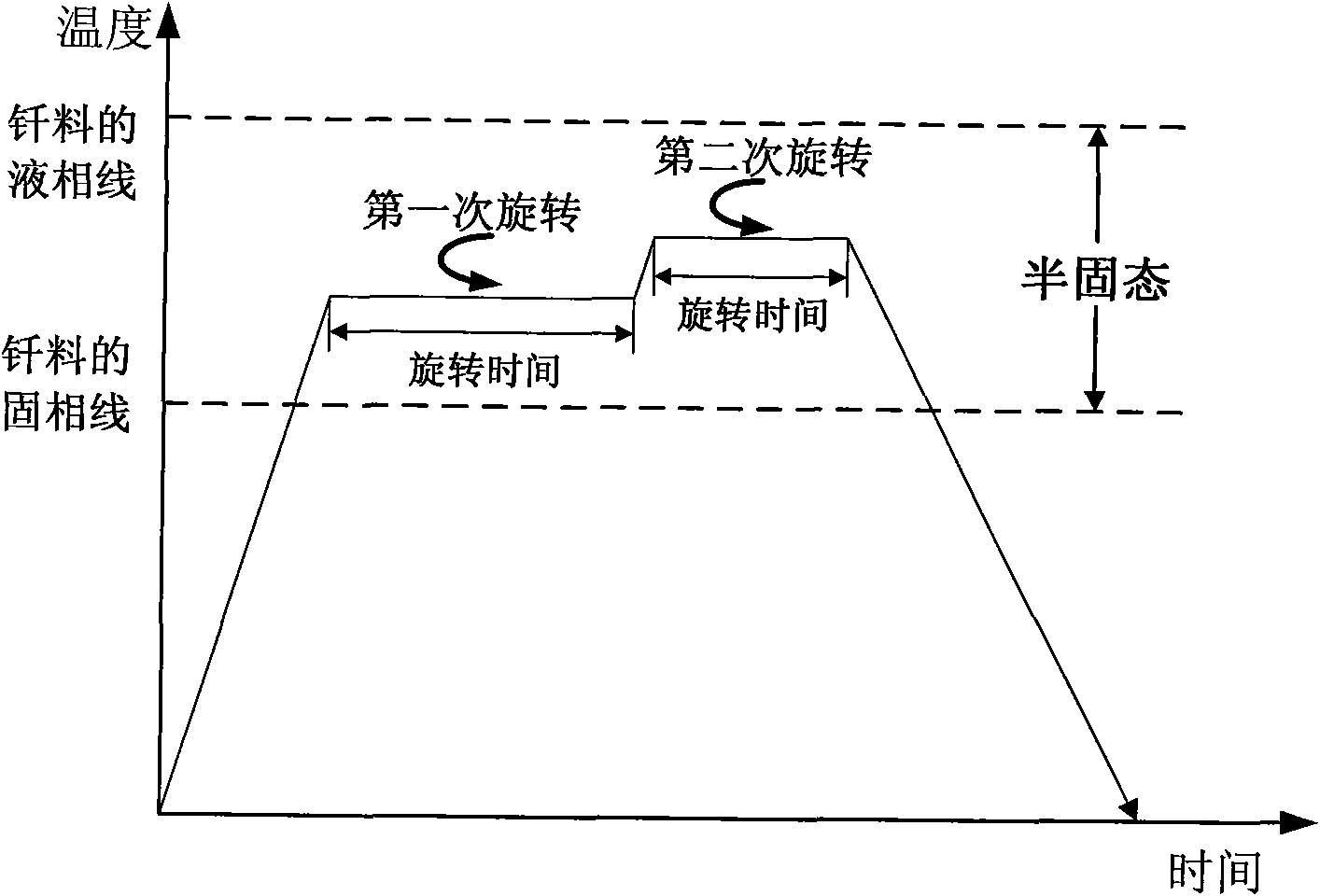

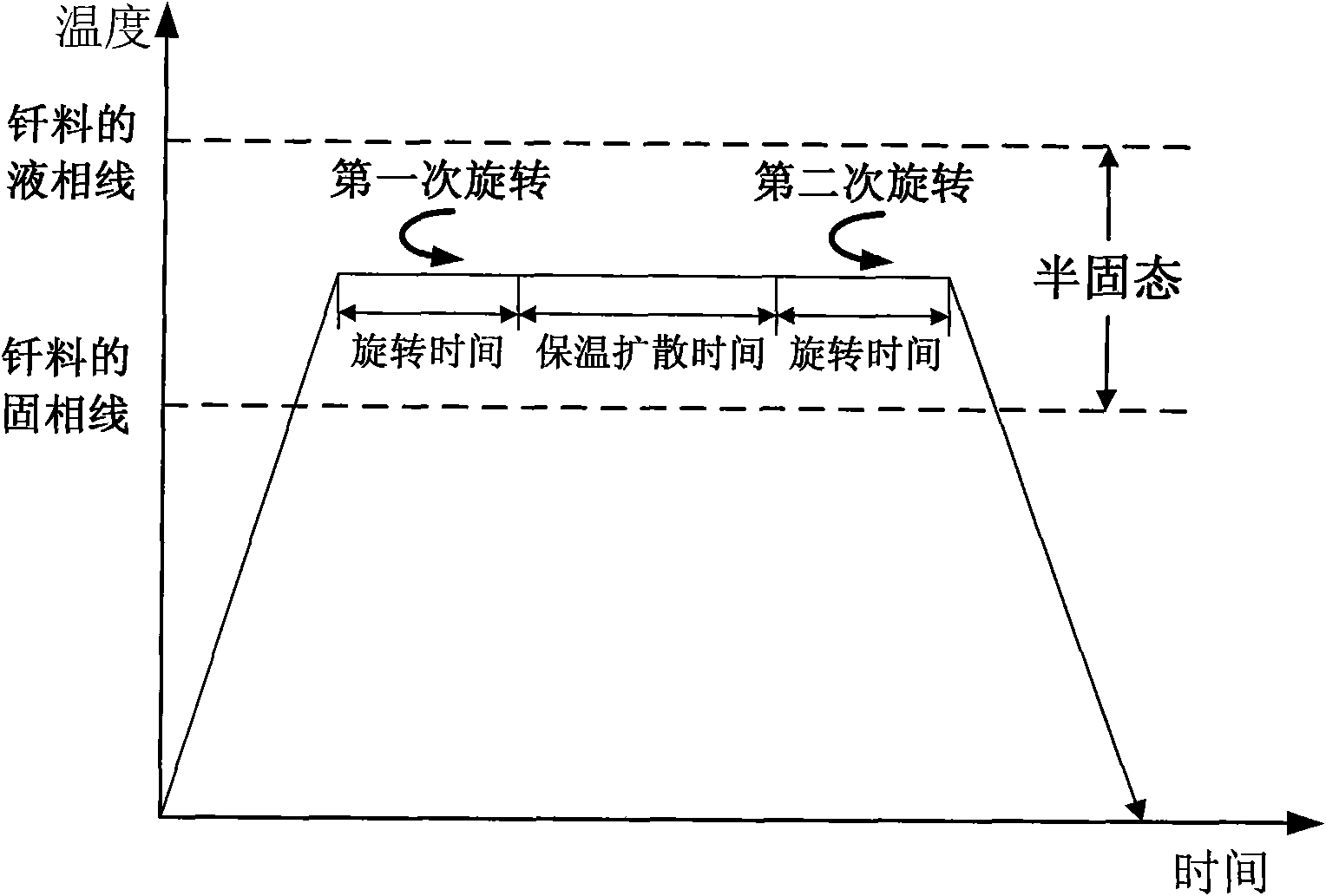

Magnesium alloy and aluminum alloy heterogeneous non-vacuum mechanical forced rotation semi-solid brazing method

InactiveCN102284758ALow costHigh quality weldingSoldering apparatusWelding/soldering/cutting articlesSemi solidMagnesium alloy

The invention relates to a magnesium alloy and aluminum alloy heterogeneous non-vacuum machinery forced rotation semi-solid brazing method; a magnesium alloy weldment and an aluminum alloy weldment are clamped on a clamp, Zn-Sn or Zn-Al-Sn system other brazing materials are arranged on two surfaces to be brazed, the weldments are heated, the heating temperature is between 350DEG C to 450DEG C, simultaneously pressure is increased, the pressure range is 0.1MPa to 1MPa, so that the brazing materials on a middle layer are in a semi-solid state, a rotary device is started, the rotating speed is 65r / min to 1500r / min, the temperature is constant during a rotation process, and the rotation time is 10s to 300s. After the rotation, the temperature rises by a certain rate, the heat is insulated at preset temperature, so that the brazing materials dissolve parent materials with a certain thicknesses, the heat insulating temperature is between 400DEG C to 480DEG C, and the heat insulating time is1min to 5min. Afterwards, pressure is increased, the pressure range is 0.1MPa to 1MPa, the rotary device is started again (secondary rotation), the rotating speed is 65r / min to 600r / min, rotation is stopped after 3s to 60s, and cooling is carried out with a furnace after the heat is insulated for 5 min to 30min. The magnesium alloy and aluminum alloy heterogeneous non-vacuum machinery forced rotation semi-solid brazing method can realize the high-efficiency, high-quality and economic connection of a magnesium alloy and an aluminum alloy.

Owner:CHONGQING UNIV OF TECH

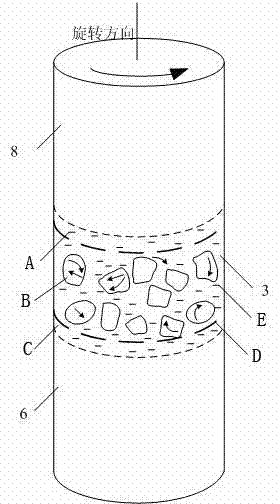

Tubular fitting, tool and method

A method and tools for forming ridges or dimples in tubular members such as copper pipes is provided. A manual tool has a pair of jaws which can be adjustably positioned and has a threaded ram affixed to one of the jaws for rotation. The jaws are adjustable for holding various thicknesses of pipe walls in firm engagement as the ram is manually rotated to form a ridge in the pipe wall. A hydraulic tool is also described for high production requirements.

Owner:SPERKO WALTER J

Anti-vacuum semi-solid states stirring soldering method of magnesium alloy and composite material thereof

The invention provides an anti-vacuum semi-solid states stirring soldering method of magnesium alloy and composite material thereof, which comprises the following steps of: a weldment taking the magnesium alloy or the composite material thereof as a parent metal is arranged and blocked on a welding platform and medium temperature brazing filler metal is put on two surfaces to be welded; the weldment is heated in the temperature of 380 to 430 DEG C to cause that the solid phase ratio of the brazing filler metal is between 50 to 80%; hereupon, a rotational sliding device is started; the rotary speed is 150 to 300 r / m; the temperature is constant; a stirring head is parallel to the longitudinal movement speed of 0.5-2cm / min of a welding line; when the stirring head moves to the terminal of the welding line, the rotational sliding stops; the holding time is 1 to 5 minutes so that the weldment is further dissolved; the rotational device is started again; the rotary speed is 20 to 150 r / m; the stirring head slides in a negative direction; the movement speed is 1 to 2 cm / min. When the stirring head moves to the initial end of the welding line, the rotary stops; the stirring head is lifted; the holding temperature is 5-30 minutes, and a furnace cools. The method can realize the low cost, high efficient, high quality welding of the magnesium alloy and the composite material thereof.

Owner:CHONGQING UNIV OF TECH

Alloy powder and method for synchronously sending powder and welding galvanized steel sheet and AZ91D magnesium alloy based on laser

InactiveCN103252581APrecise control ratioReduce burning lossLaser beam welding apparatusShielding gasMolten bath

The invention discloses an alloy powder and method for synchronously sending powder and welding a galvanized steel sheet and AZ91D magnesium alloy based on laser. A main component of the powder is AlMgxCuZn, wherein x is the mole ratio of Al and Mg, the ratio range is between 0 and 0.4, the size of the powder is 100 meshes to 300 meshes, and a process method which is matched with the alloy powder and method for synchronously sending the powder and welding the galvanized steel sheet and the AZ91D magnesium alloy based on the laser can improve wettability and compatibility between the galvanized steel sheet and AZ91D magnesium alloy. According to the alloy powder and method for synchronously sending the powder and welding the galvanized steel sheet and the AZ91D magnesium alloy based on the laser, the laser is taken as a welding hot source, under the protection of protective gas and the hot effect, a part of the surface of a material to be welded melts, through effective sending of the alloy powder, a stable weld pool is easily obtained, burning loss of alloying elements is reduced, the ratio of the alloying elements in a weld joint can be accurately controlled, a formula for filling the alloying powder is flexible, metallurgy action of weld metal can be remarkably improved, the weld joint without inclusions can be obtained especially aiming at the existence of Zn, a welding surface needs no special cleaning, welding efficiency is high, cost is low, the joint is reliable, and the alloy powder and method for synchronously sending the powder and welding the galvanized steel sheet and the AZ91D magnesium alloy based on the laser has relatively ideal engineering practical significance.

Owner:SHANGHAI UNIV OF ENG SCI

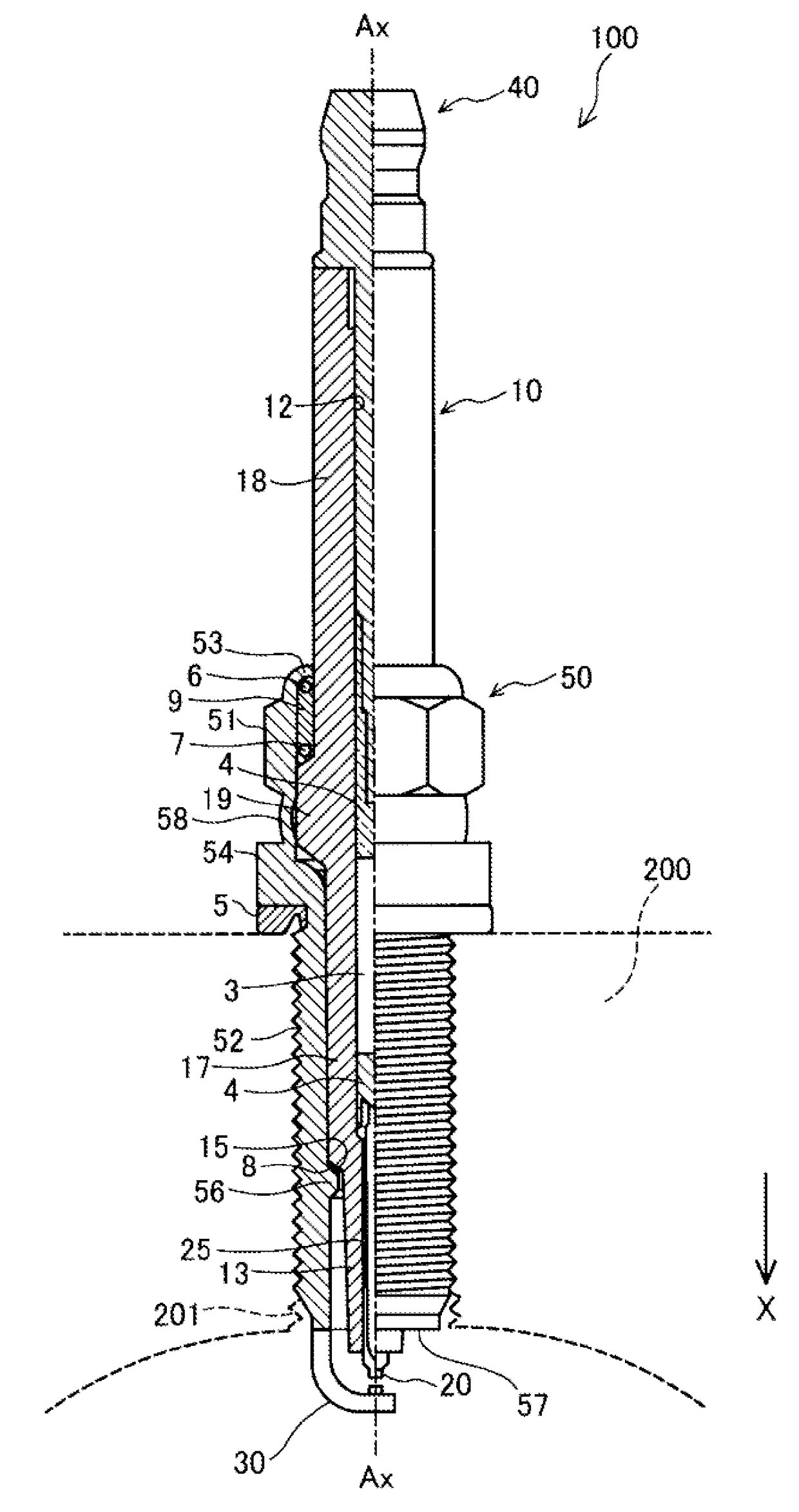

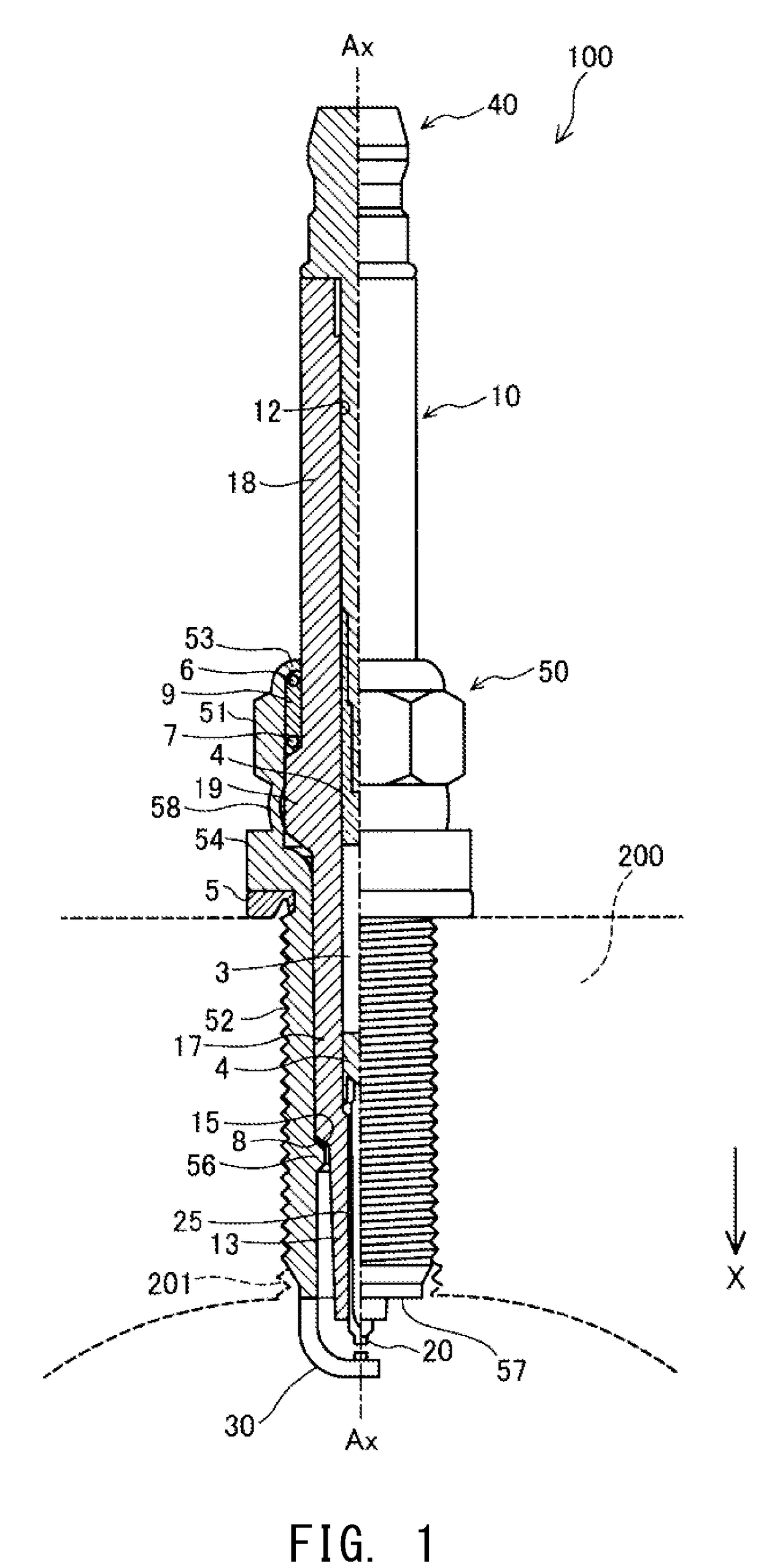

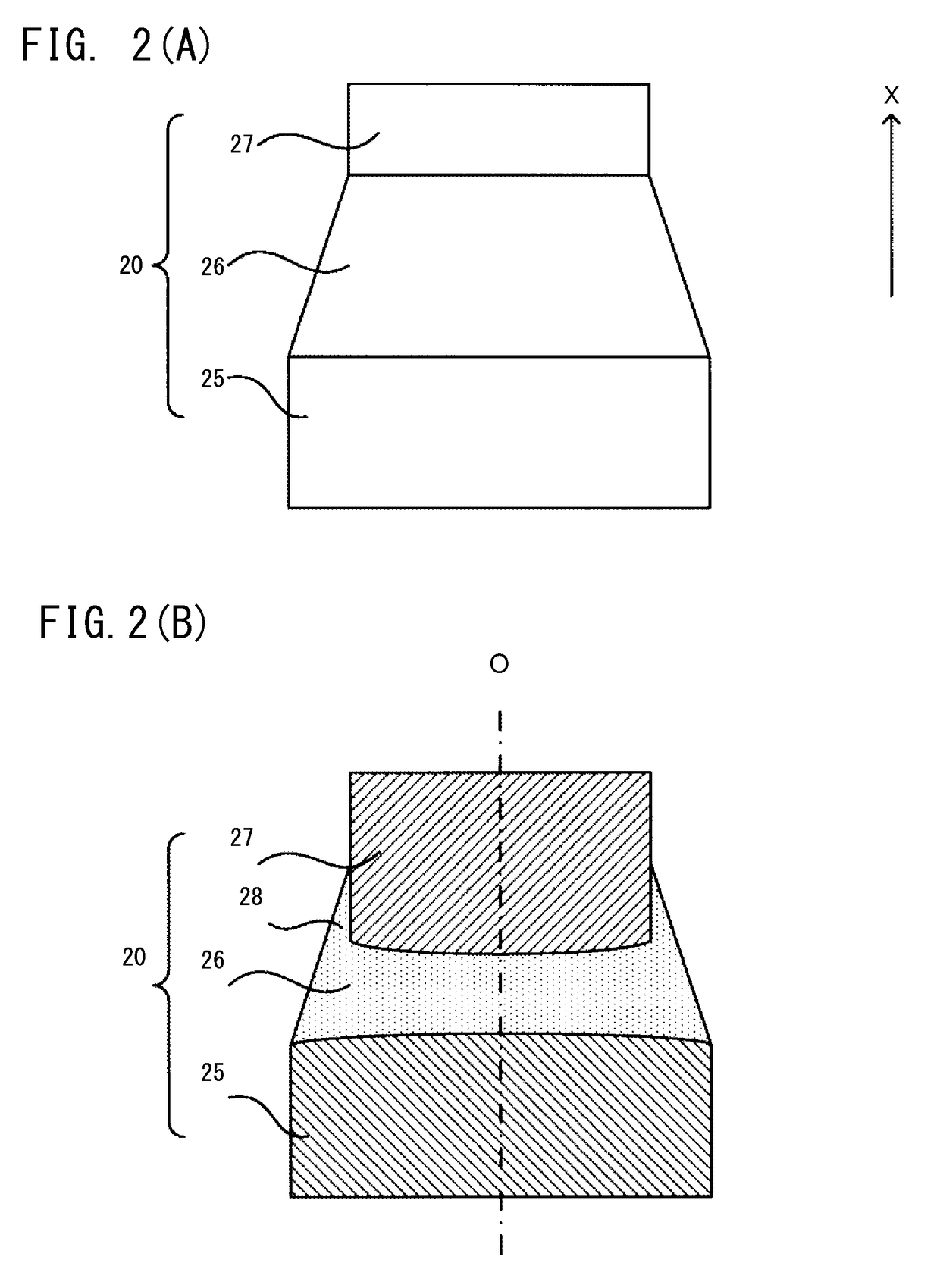

Spark plug

ActiveUS20170125981A1Suppressing formation of oxideInhibit the generation of cracksSparking plugsMetallurgySpark plug

A spark plug including an electrode having a cylindrical precious metal tip welded thereto, the electrode having a melt portion in which the precious metal tip and the electrode base material are melted, wherein the melt portion includes a melt sag over an entire circumference on a side surface of the precious metal tip.

Owner:NGK SPARK PLUG CO LTD

Non-vacuum semi-solid mechanically assisted rotary brazing method for magnesium alloy and its composite materials

InactiveCN102284760ALow costHigh quality weldingSoldering apparatusNon-electric welding apparatusVacuum assistedSemi solid

The invention relates to a non-vacuum semi-solid machine-assisted rotary soldering method for a magnesium alloy and a composite material thereof, which comprises the following steps of: clamping the magnesium alloy and a composite material weldment thereof on a fixture, putting Zn-Sn or Zn-Al-Sn solders and the like on two surfaces to be welded, heating the weldment at the temperature of between 350 and 450 DEG C, and applying pressure of 0.1 to 1MPa to make the solder in an intermediate layer positioned in a semi-solid state; starting a rotating device, rotating at a speed of 65 to 1,500r / min for 10 to 300 seconds, and keeping the temperature constant in the rotating process; raising the temperature at a certain heating rate after rotation is stopped, and preserving heat at the predetermined temperature of between 400 and 480 DEG C for 1 to 5 minutes to make the solder dissolve parent metal with certain thickness; and applying pressure of 0.1 to 1MPa, starting the rotating device again, rotating for the second time at a speed of 65 to 600r / min for 3 to 60 seconds, stopping rotation, preserving heat for 5 to 30 minutes, and cooling with a furnace. By the method, the magnesium alloy and the composite material thereof can be efficiently and economically connected at high quality.

Owner:CHONGQING UNIV OF TECH

Non-vacuum semi-solid stirring brazing method for aluminum alloy and composite material thereof

InactiveCN101596630BAchieve weldingShort welding cycleSoldering apparatusThermal insulationSemi solid

The invention provides a semi-solid brazing method for aluminum alloy and a composite material thereof under the assistance of non-vacuum mechanical stirring, which comprises the steps of: mounting a weldment taking the aluminum alloy or the composite material thereof as a base material on a welding platform first; placing intermediate-temperature solder on two surfaces to be welded, heating the weldment to between 390 and 420 DEG C, and ensuring that the solid fraction of the solder is between 50 and 80 percent; staring a rotary sliding device, wherein the rotating speed is between 150 and 300 r / m, the temperature is constant, and the longitudinal movement rate, which is parallel to a welding seam, of a stirring head is between 0.5 and 2 cm / min; stopping the rotary sliding when the stirring head moves to the terminal of the welding seam; increasing the temperature to between 430 and 450 DEG C, performing thermal insulation for 1 to 5 minutes, and ensuring that the solid fraction of the solder is between 10 and 40 percent; restarting the rotary device again, wherein the rotating speed is between 20 and 150 r / m; sliding the stirring head in a reverse direction, wherein the movementspeed is between 1 and 2 cm / m; stopping the rotation, when the stirring head moves to the initial end of the welding seam, and lifting the stirring head; and cooling the solder along with a furnace after thermal insulation for 5 to 30 minutes. The method can realize the low-cost, high-efficiency and high-quality welding of the aluminum alloy or the composite material thereof.

Owner:CHONGQING UNIV OF TECH

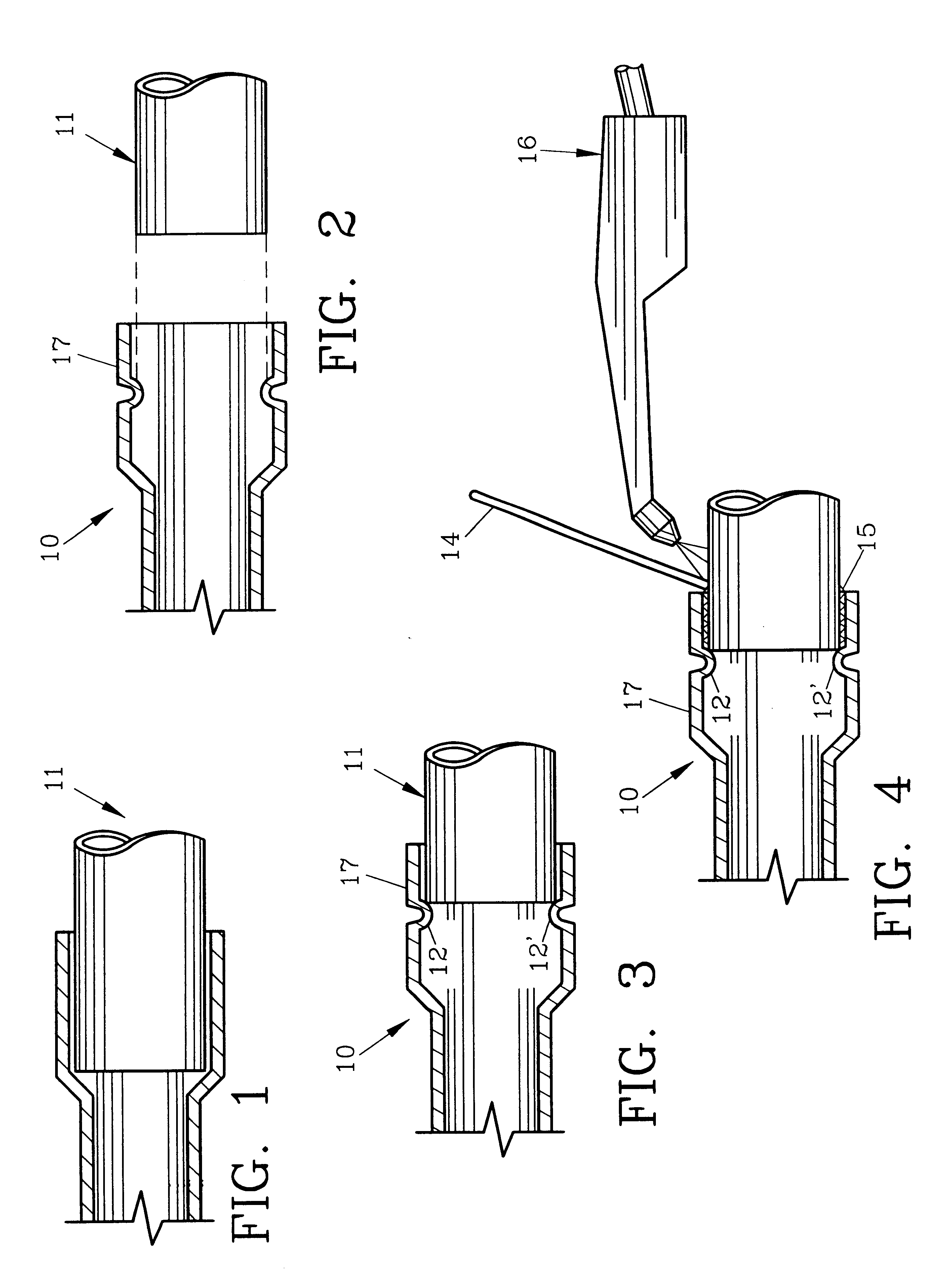

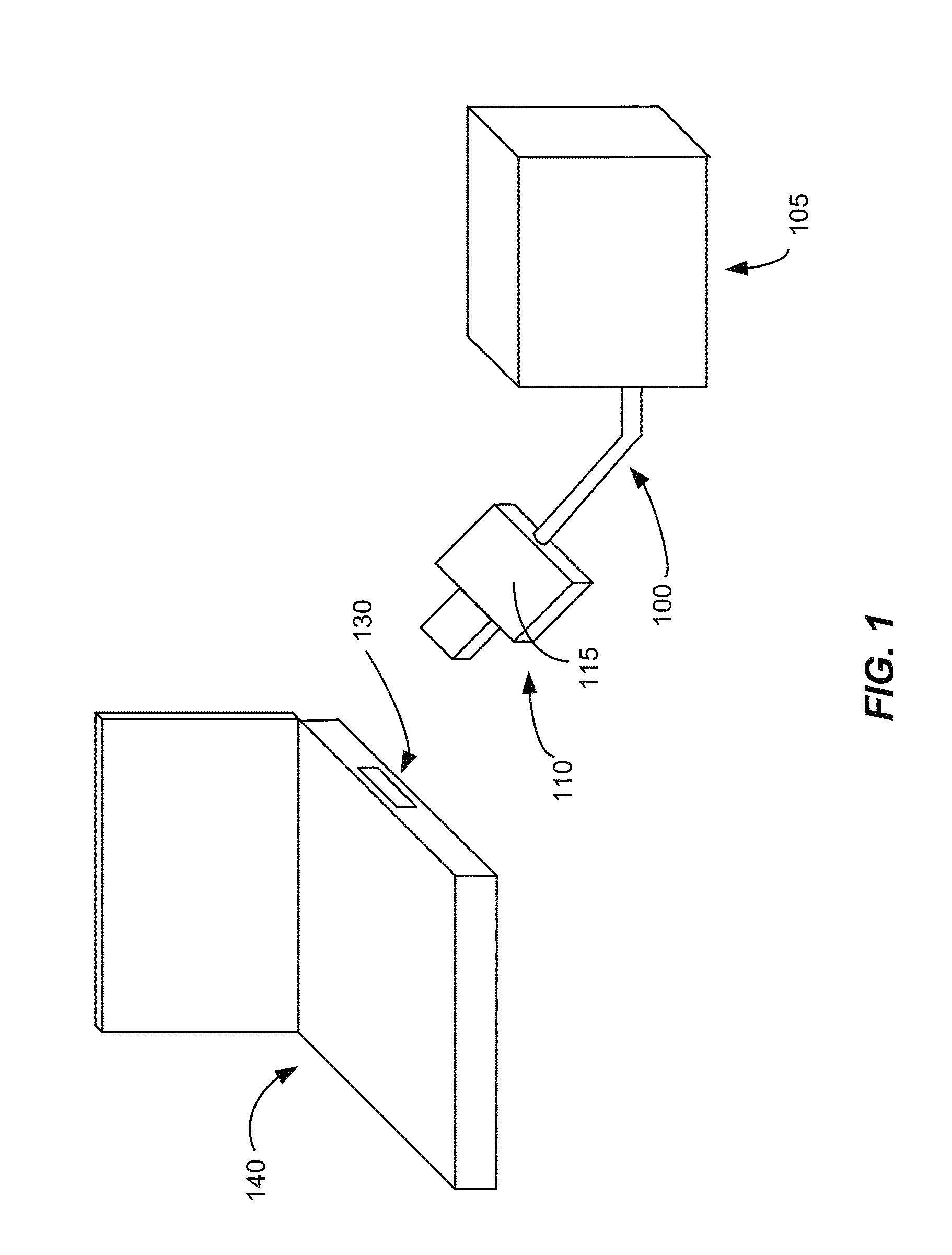

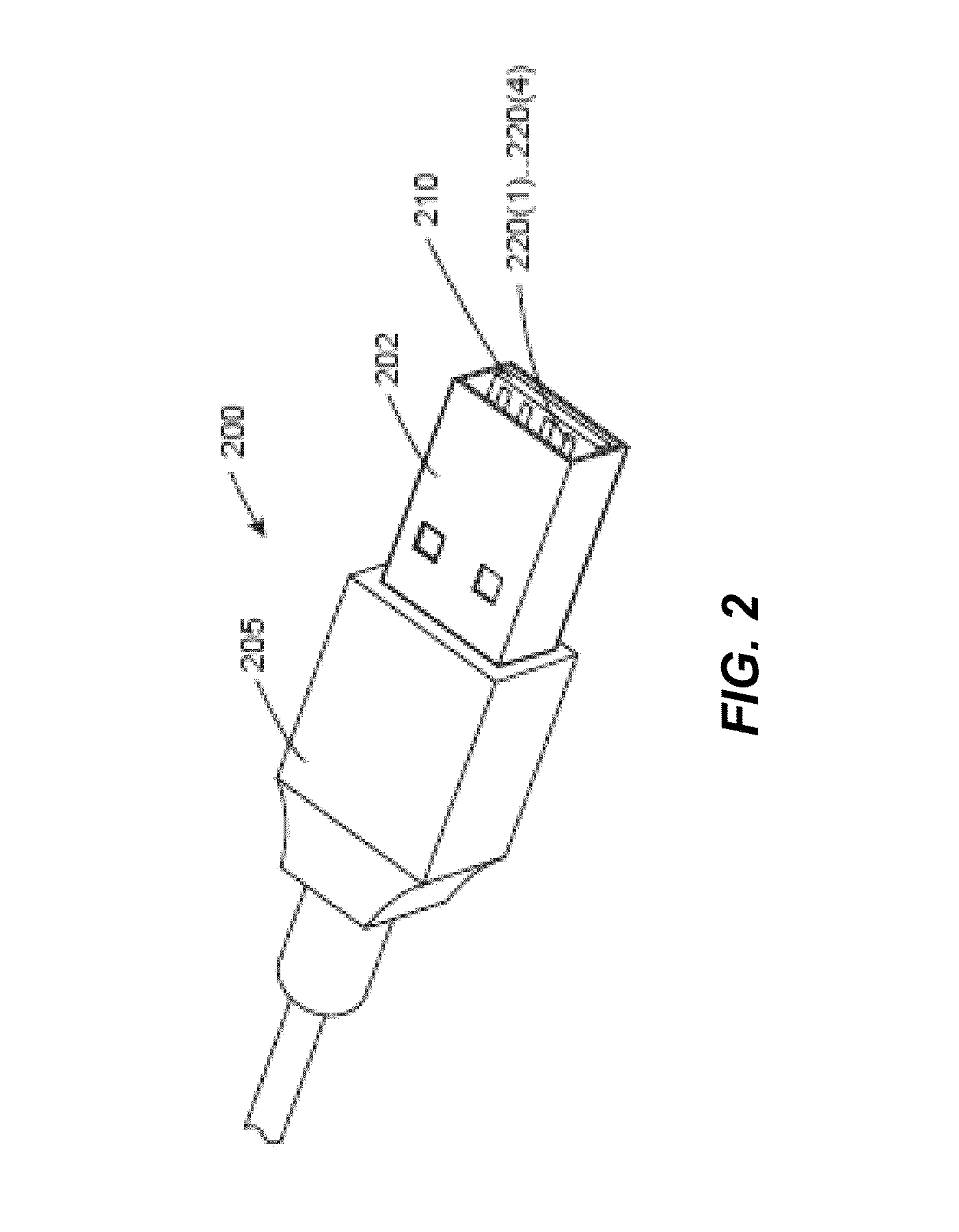

Method for improving connector enclosure adhesion

InactiveUS8926337B2Evenly distributedSmall geometryLine/current collector detailsCouplings bases/casesEngineeringImproved method

An improved method is employed to attach an enclosure to a connector body having relatively small geometry. One or more bonding channels are disposed in the outside surface of the connector body. During assembly of an enclosure over the connector body, a bonding material is distributed within the bonding channels and subsequently cured. The bonding channels and the bonding material are designed to employ capillary wicking to aid in the distribution of the bonding material within the bonding channels.

Owner:APPLE INC

A kind of process method for filling spot welding stainless steel high-entropy alloy powder and a kind of high-entropy alloy powder filling spot welding stainless steel

InactiveCN103252568BIncrease contact resistanceGood welding performanceResistance welding apparatusElectrical resistance and conductanceHigh entropy alloys

The invention discloses a technique method for filling spot welding stainless steel high-entropy alloy powder and for filling spot welding stainless steel with high-entropy alloy powder. According to the technique method for filling the spot welding stainless steel high-entropy alloy powder and for filling the spot welding stainless steel with the high-entropy alloy powder, the high-entropy alloy powder is mainly composed of AlFeCuCoNiTiCrx, wherein the x is molar ratio of the Al to the Cr and is between 0 to 0.3, and the size of the powder is 100-300 meshes. When high-entropy alloy powder media are used as a filling layer, the contact resistance of a stainless steel material which are different to weld at the early welding stage is improved, resistance heat is used as a welding heat source, partial melting of the surface of the material to be welded is achieved under the protection of protective air and under the action of the resistance heat, an oxidation film can be broken under the impact effect of proper electrode pressure, refining of the high-entropy alloy powder media can be achieved on the interface of the material to be welded, a molten core and a single face-centered cubic tissue are formed on the interface, and then the strength and the corrosion resistance of a connector are improved. The technique method for filling the spot welding stainless steel high-entropy alloy powder and for filling the spot welding stainless steel with the high-entropy alloy powder has the advantages that welding can be achieved under the thermal compensation condition, the flexibility is strong, and ideal engineering significance is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

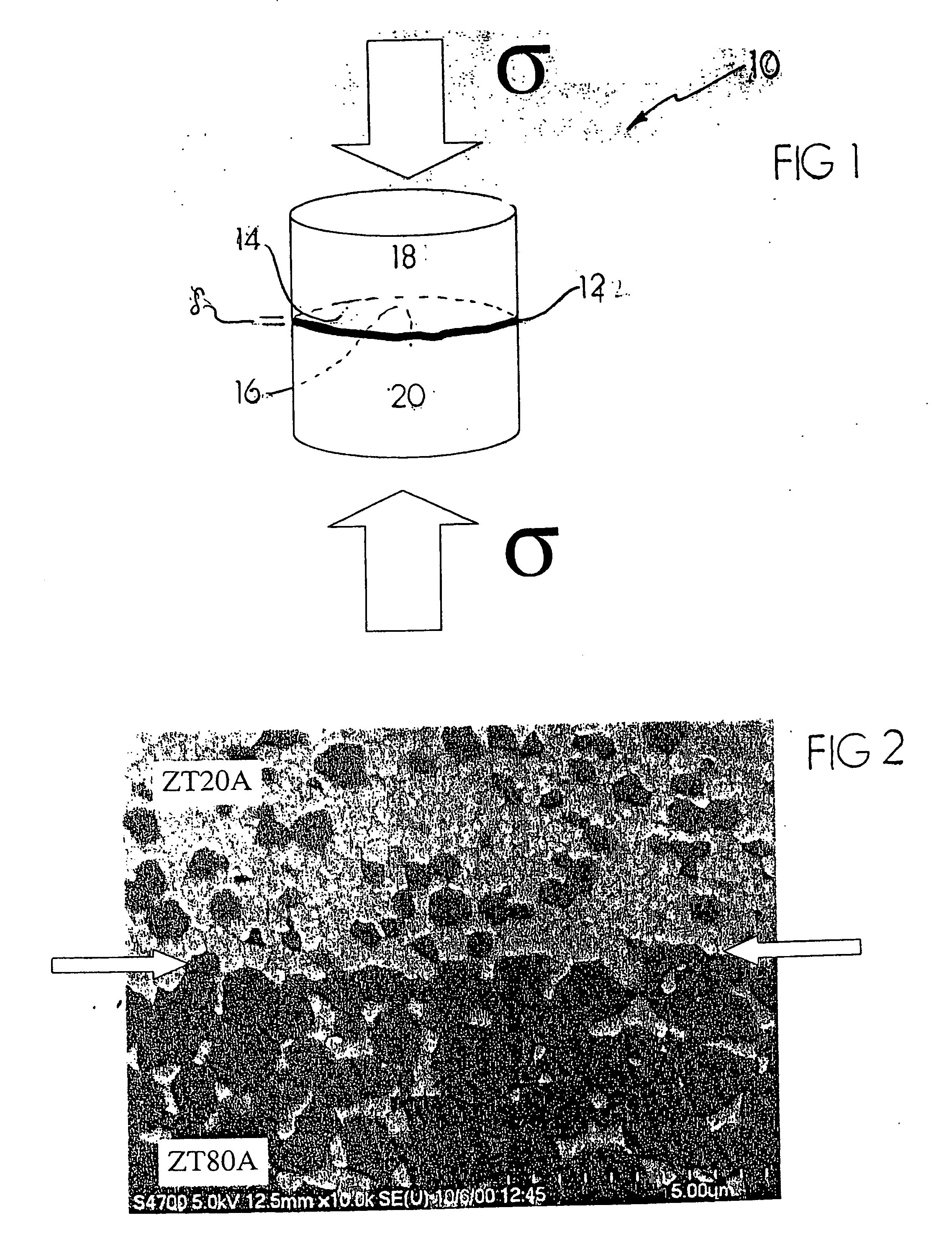

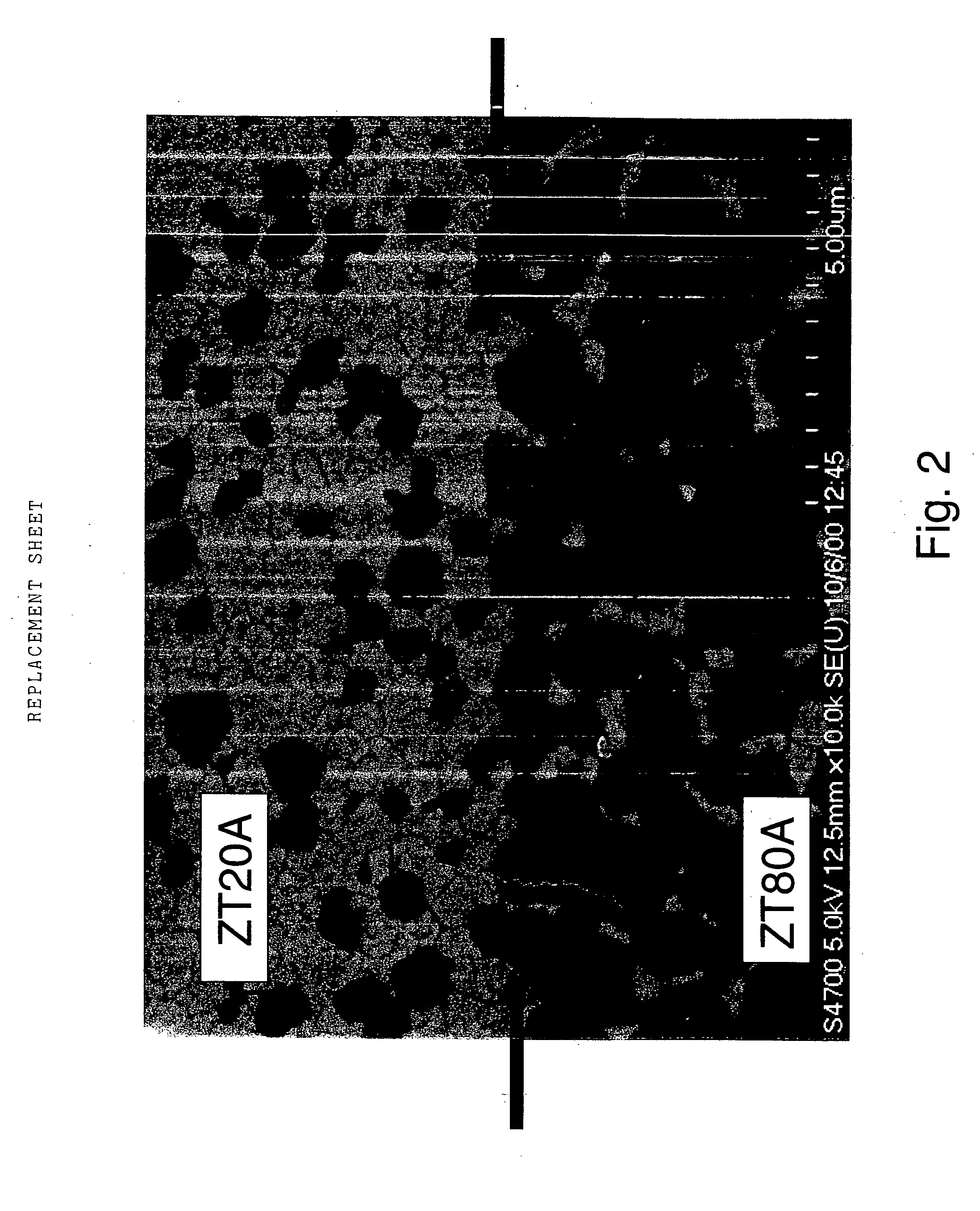

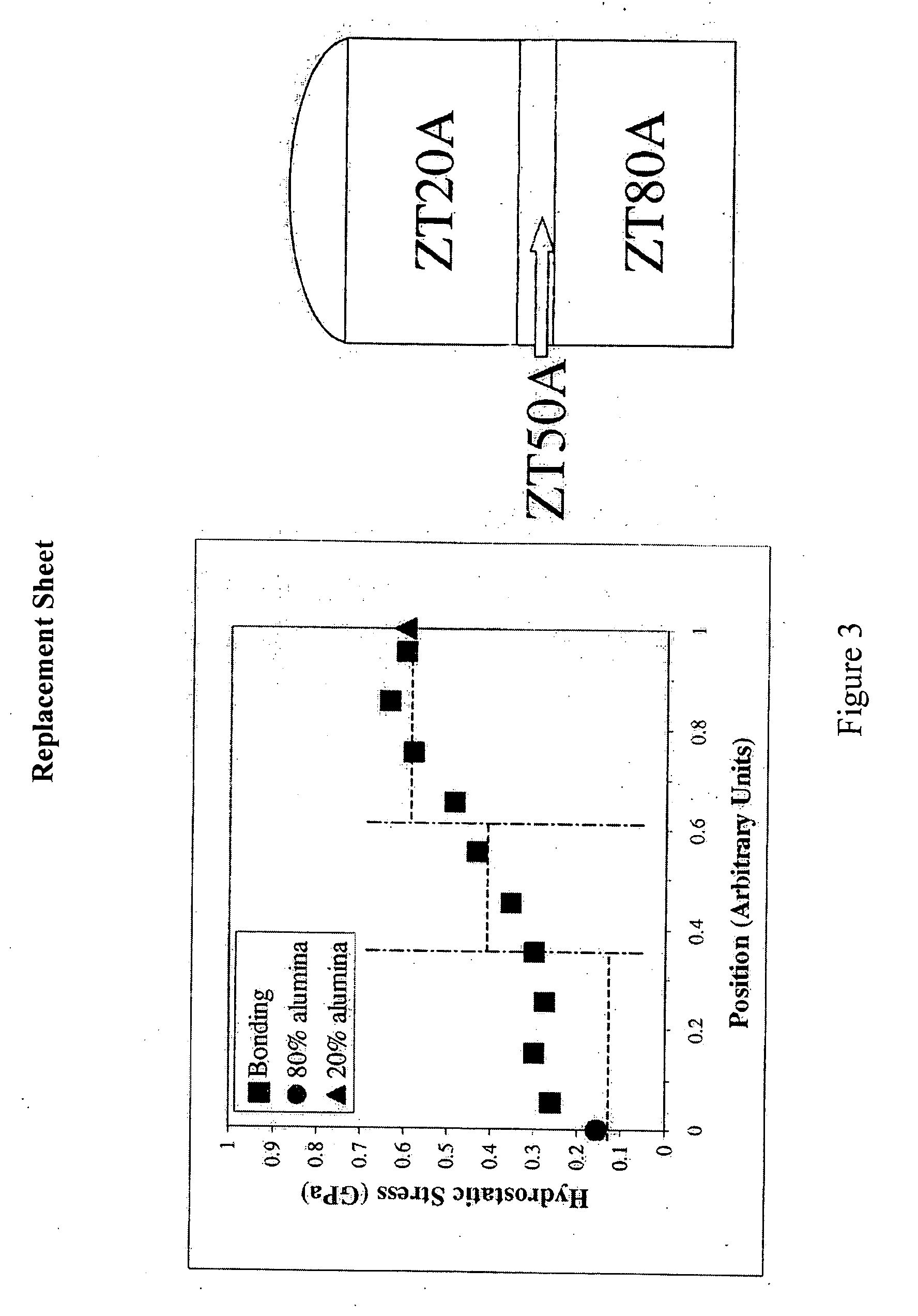

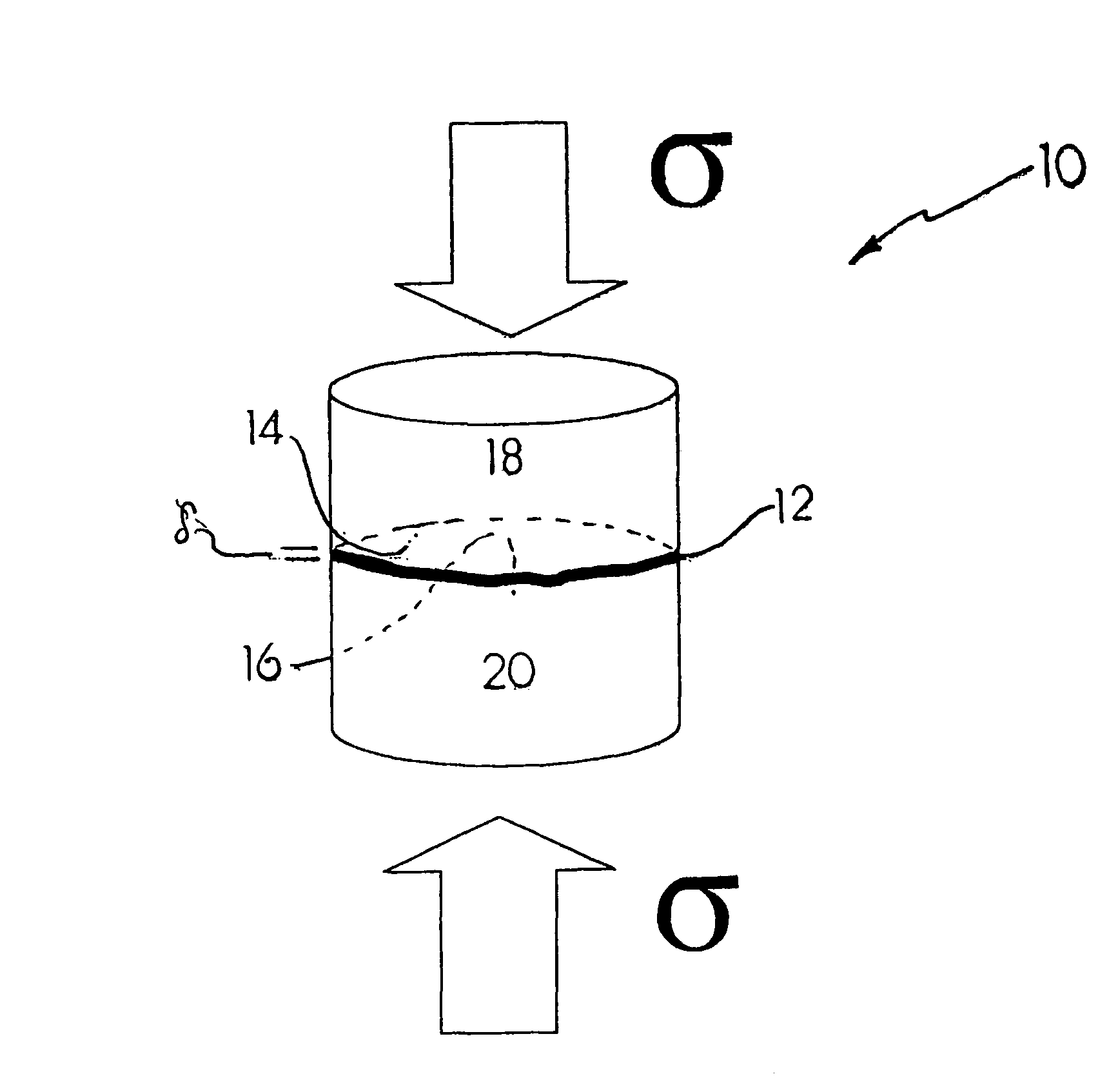

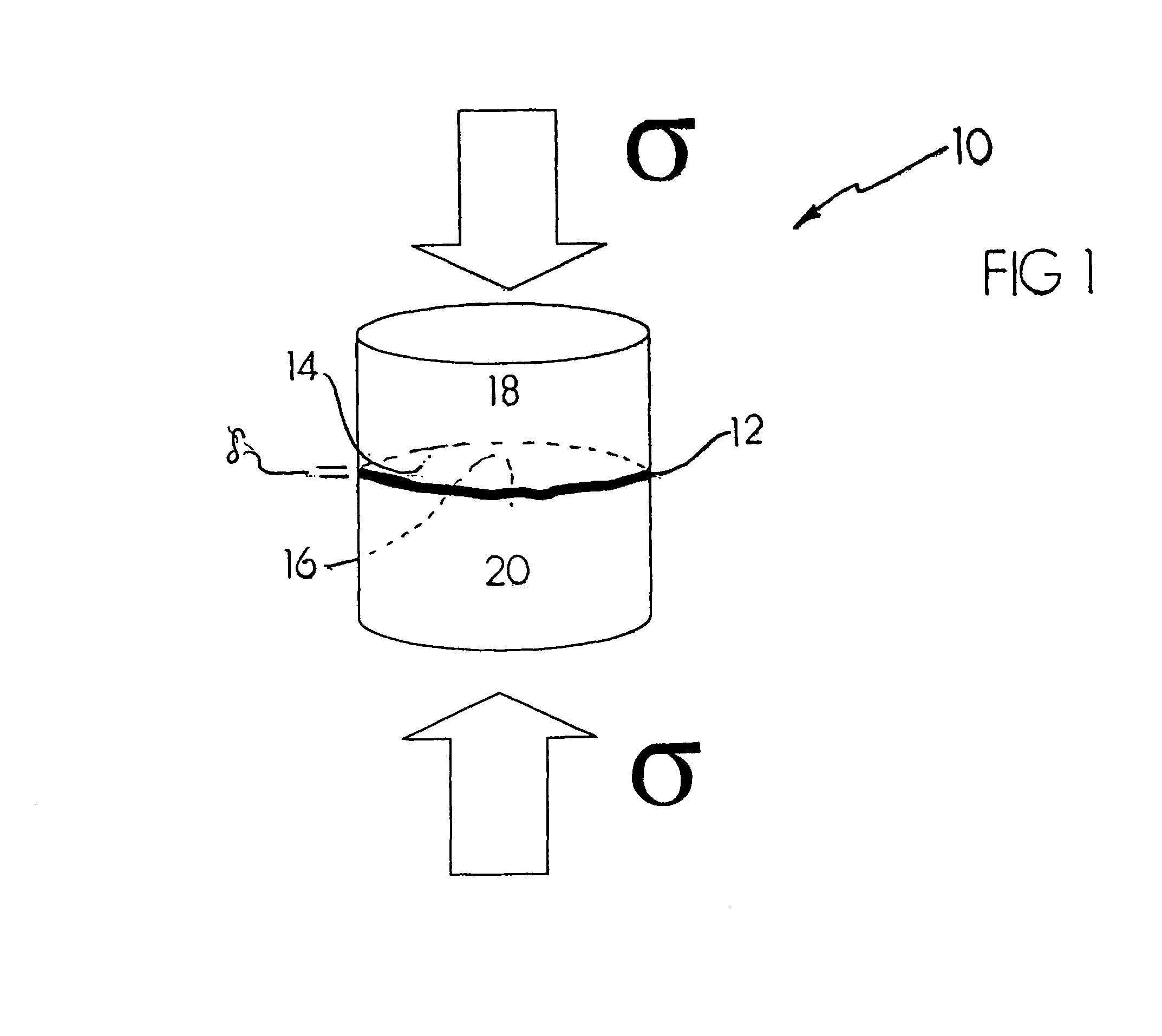

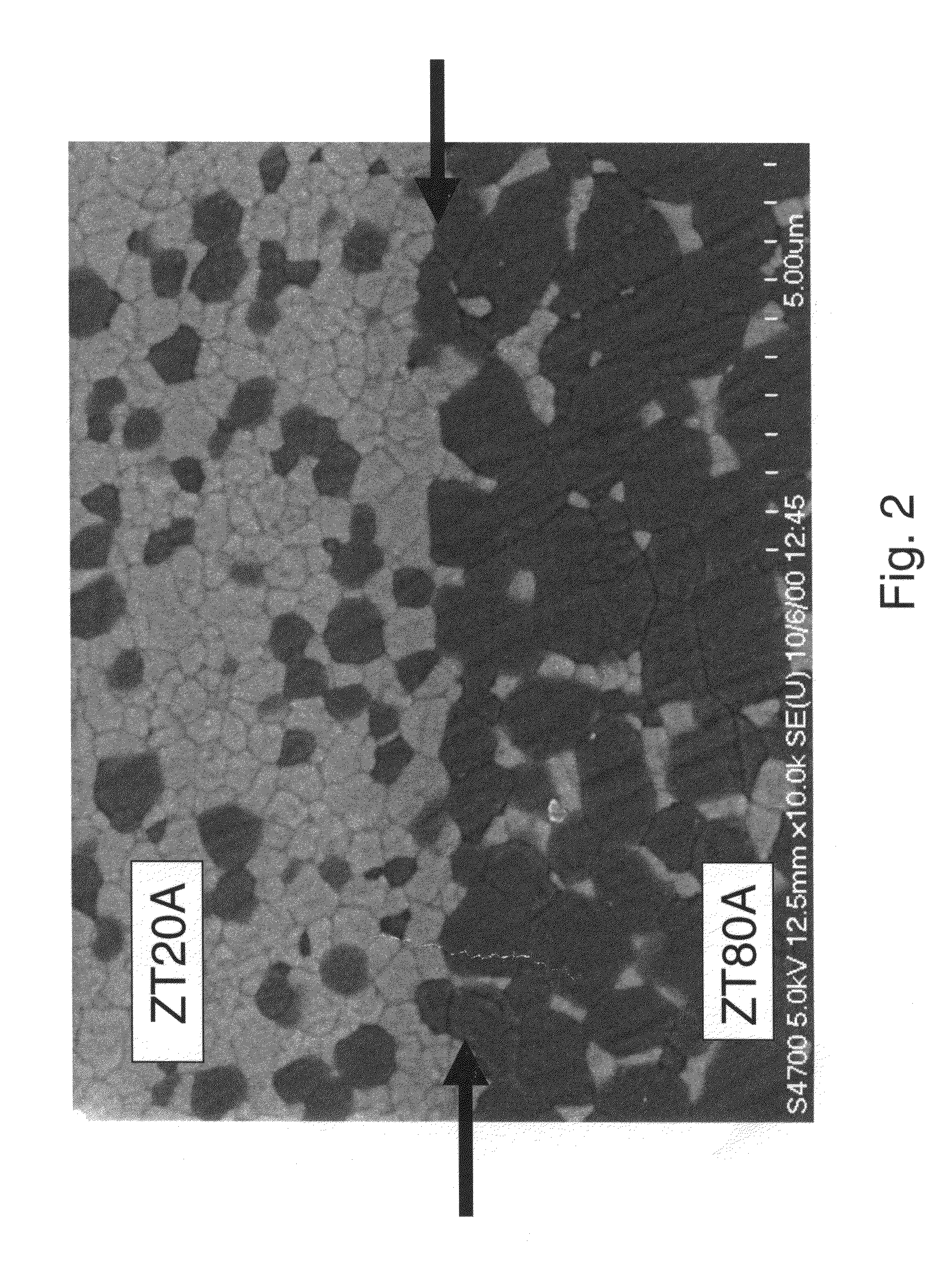

Joining of advanced materials by plastic deformation

InactiveUS20070187464A1Reliable and reliableSame porosityCooking-vessel materialsLaminationPorosityGrain Boundary Sliding

A method for utilizing plastic deformation resulting from grain boundary sliding with or without a novel joint compound that leads to the joining of advanced ceramic materials, intermetallics, and cermets. A joint formed by this approach is as strong as or stronger than the materials joined. The method does not require elaborate surface preparation or application techniques. The method also allows for the formation of transparent joints between two subunits of a construct joined via plastic deformation. The method can be used to tailor residual stresses and maintain native porosity.

Owner:UCHICAGO ARGONNE LLC

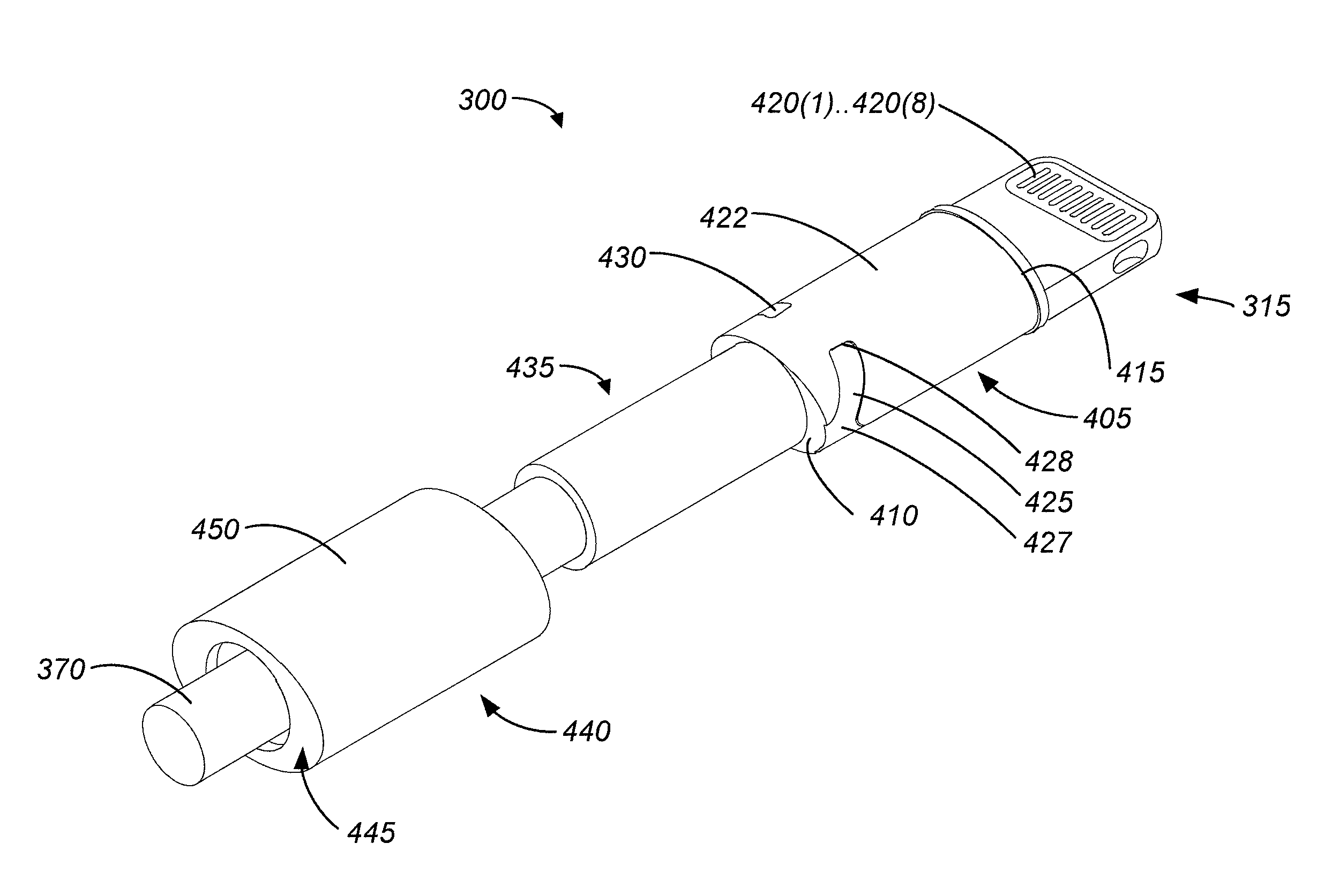

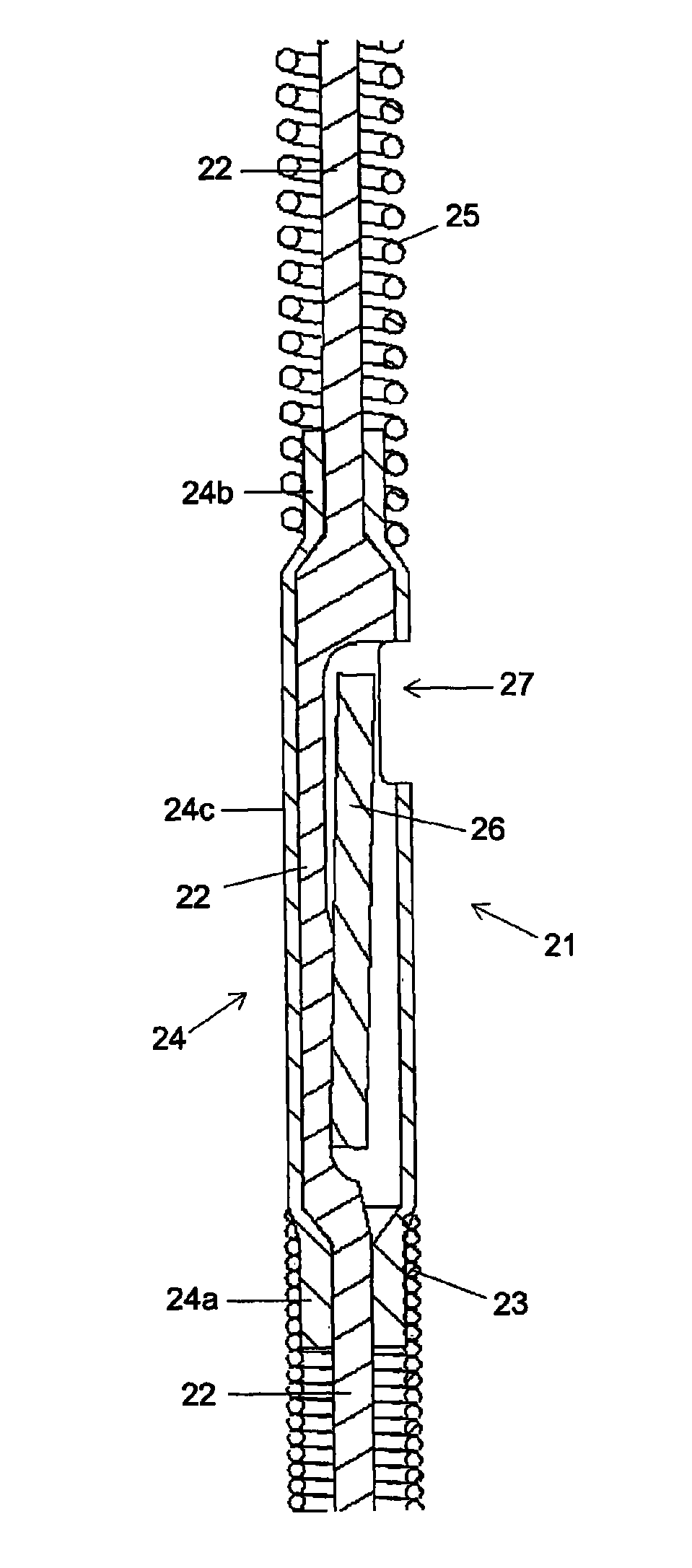

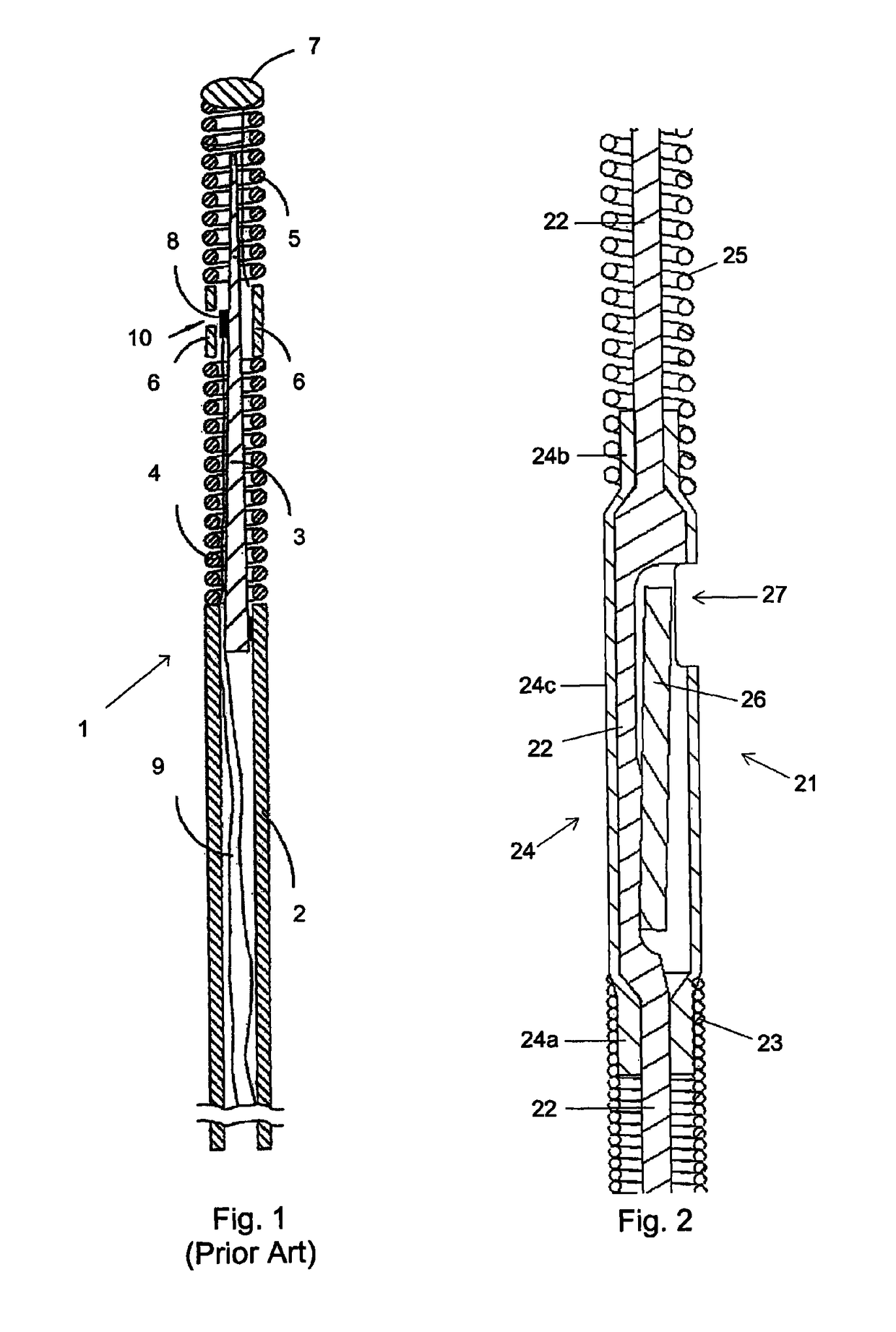

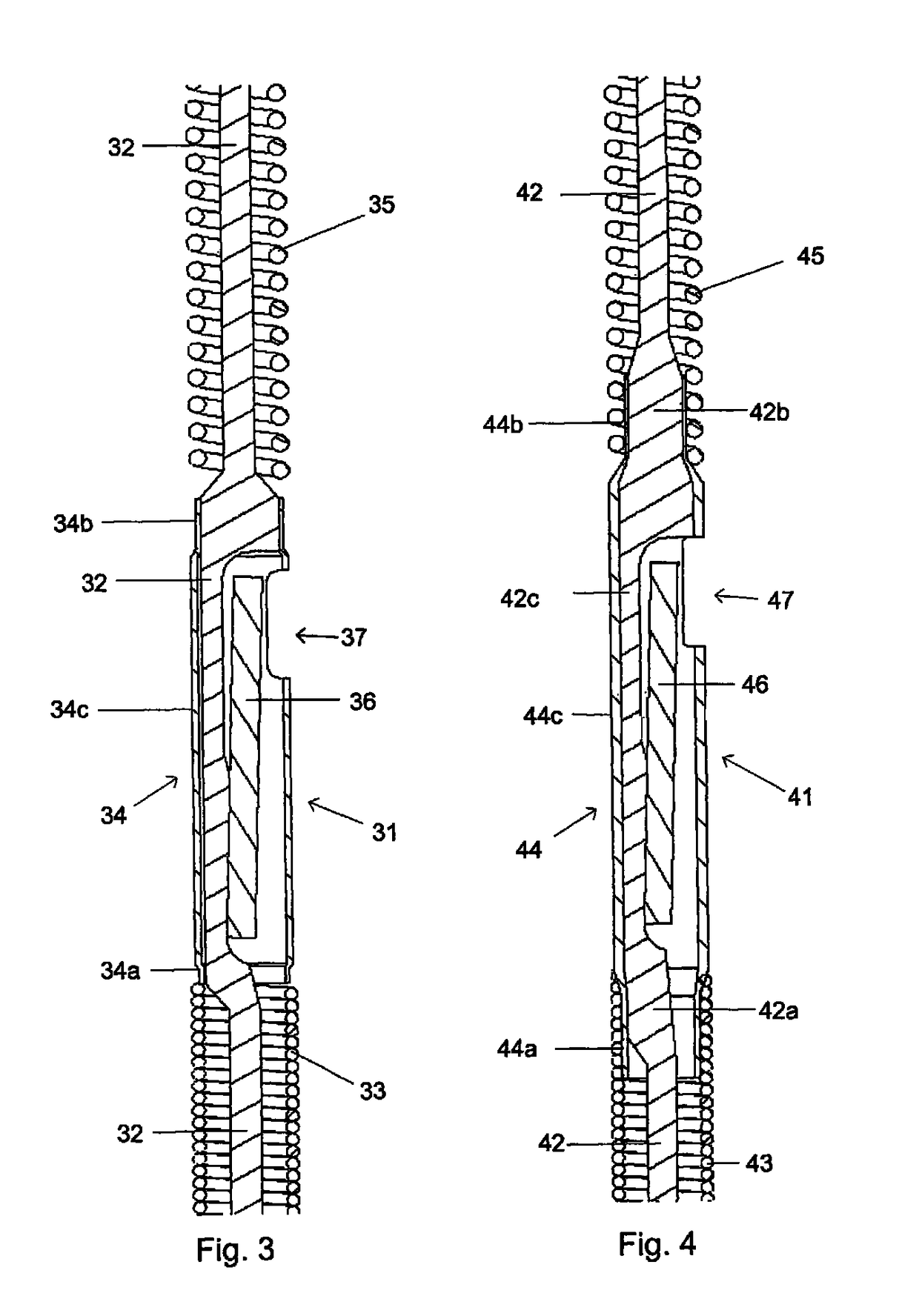

Sensor and guide wire assembly

ActiveUS9949647B2Firmly attachedBulky attachmentGuide wiresDiagnostic recording/measuringEngineeringLiving body

The invention relates to a sensor and guide wire assembly (21) for intravascular measurements of physiological variables in a living body, comprising a core wire (22), a first coil (23), a jacket (24), and a second coil (25). The jacket (24) comprises a first end portion (24a), which is crimped onto the core wire (22) and over which a portion of the first coil (23) is threaded, and a second end portion (24b), which is crimped onto the core wire (22) and over which a portion of the second coil (25) is threaded.

Owner:ST JUDE MEDICAL COORDINATION CENT

Joining of advanced materials by plastic deformation

InactiveUS7722731B2Improve mechanical propertiesImprove toughnessCooking-vessel materialsLaminationPorosityGrain Boundary Sliding

A method for utilizing plastic deformation resulting from grain boundary sliding with or without a novel joint compound that leads to the joining of advanced ceramic materials, intermetallics, and cermets. A joint formed by this approach is as strong as or stronger than the materials joined. The method does not require elaborate surface preparation or application techniques. The method also allows for the formation of transparent joints between two subunits of a construct joined via plastic deformation. The method can be used to tailor residual stresses and maintain native porosity.

Owner:UCHICAGO ARGONNE LLC

Equipment part having luminous visible side

ActiveUS20160062022A1Reliable connectorHigh melting pointMechanical apparatusLamination ancillary operationsComposite filmEngineering

The present invention relates to an equipment part, in particular for a motor vehicle, comprising a carrier (1), a composite film (2), and a light source (3). The composite film (2) is disposed on the carrier (1) and forms the visible side (4) of the equipment part. The composite film (2) comprises a light-conducting layer (5), a scatter layer (6), and two paint layers (7, 8), so that light rays (9) generated by the light source (3) can be coupled into the composite film, and the visible side (4) of the equipment part is extensively illuminated with the aid of the composite film (2). The present invention further comprises a method for the production of such an equipment part.

Owner:LISA DRAXLMAIER GMBH

Novel tensile special cable

PendingCN109119194AGuaranteed electrification effectSafety protectionPlastic/resin/waxes insulatorsClimate change adaptationElectrical conductorIsolation layer

The invention discloses a novel tensile special cable, and the cable comprises at least one conductor unit, a tensile cable and a filling layer. The conductor unit comprises a cable core and a split-phase insulating isolation layer, wherein the split-phase insulating isolation layer is set around the cable core. The tensile cable is located at the center of the cable, and the filling layer is disposed outside the tensile cable. The conductor units are arranged around the tensile cable, and are distributed in the filling layer. One side, far from the tensile cable, of the filling layer is provided with a fireproof isolation layer, and one side, far from the tensile cable, of the fireproof isolation layer is provided with a reinforcing layer. One side, far from the fireproof isolation layer,of the reinforcing layer is provided with an impact-resistant layer, and one side, far from the reinforcing layer, of the impact-resistant layer is provided with an outer protection sheath. The reinforcing layer comprises a flame-retardant oxygen isolating layer and an armored layer wrapping the flame-retardant oxygen isolating layer in an annular manner.

Owner:GUIZHOU XINSHUGUANG CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com