Non-vacuum semi-solid mechanically assisted rotary brazing method for magnesium alloy and its composite materials

A composite material and brazing method technology, applied in non-electric welding equipment, welding equipment, welding equipment and other directions, can solve the problems of difficult brazing process, wetting and spreading hindrance of brazing filler metal, over-ablation and erosion of base metal, etc. Ideal engineering significance, overcoming adverse consequences, and the effect of low welding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

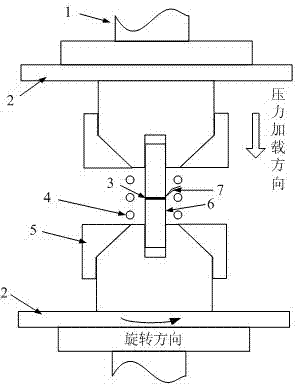

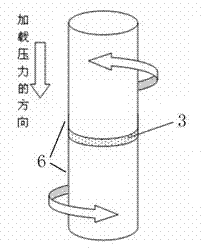

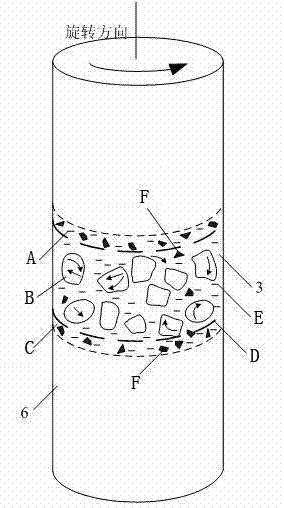

[0034] see figure 1 with Figure 2A, AZ31B magnesium alloy parts 6 to be welded are clamped on the fixture 5, and the gap between the parts to be welded is 500 μm. And place Zn-Sn series brazing filler metal 3 on the welding surface of two pieces to be welded 6, brazing filler metal can be sheet shape, foil shape, coating or be sprayed on the surface to be welded in advance. Use the cylinder 1 to apply pressure to the workpiece 6 to be welded and maintain a constant value. The loading pressure is 0.3 MPa. At the same time, the high-frequency coil 4 is used to heat the workpiece to be welded. The heating temperature is between 350 ° C to melt the solder 3 in the middle layer. Start the rotary platform 2, the rotation mode is double weldment rotation, the rotation direction is opposite, the speed is 300r / min, the temperature is constant during the rotation, and the rotation time is 30 seconds. After the rotation stops, the temperature rises at a certain heating rate, the heati...

Embodiment 2

[0036] see figure 1 with Figure 2B , the AZ91D aluminum alloy to be welded piece 6 is clamped on the fixture 5, and the gap between the welded pieces is 600 μm. And place Zn-Al-Sn solder 3 on the two surfaces to be welded. The solder can be in the form of flakes, foils, coatings or sprayed on the surfaces to be soldered in advance. Use cylinder 1 to apply pressure to the weldment and maintain a constant value, the loading pressure is 0.2MPa, and heat the weldment 6 at the same time, the heating temperature is 360 ° C, so that the middle layer solder 3 is semi-solid. Start the rotating platform 2 device, the rotation method is single weldment rotation, the speed is 300r / min, the temperature is constant during the rotation, and the rotation time is 40 seconds. After the rotation stops, the temperature rises at a certain heating rate, the heating rate is 1°C / s, and it is kept at a predetermined temperature to make the solder dissolve the base metal with a thickness of 20-200 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com