Non-vacuum semi-solid stirring brazing method for aluminum alloy and composite material thereof

A technology of composite materials and brazing methods, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of semi-solid connection technology that have not been reported, and achieve the effects of overcoming adverse consequences, reliable joints, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

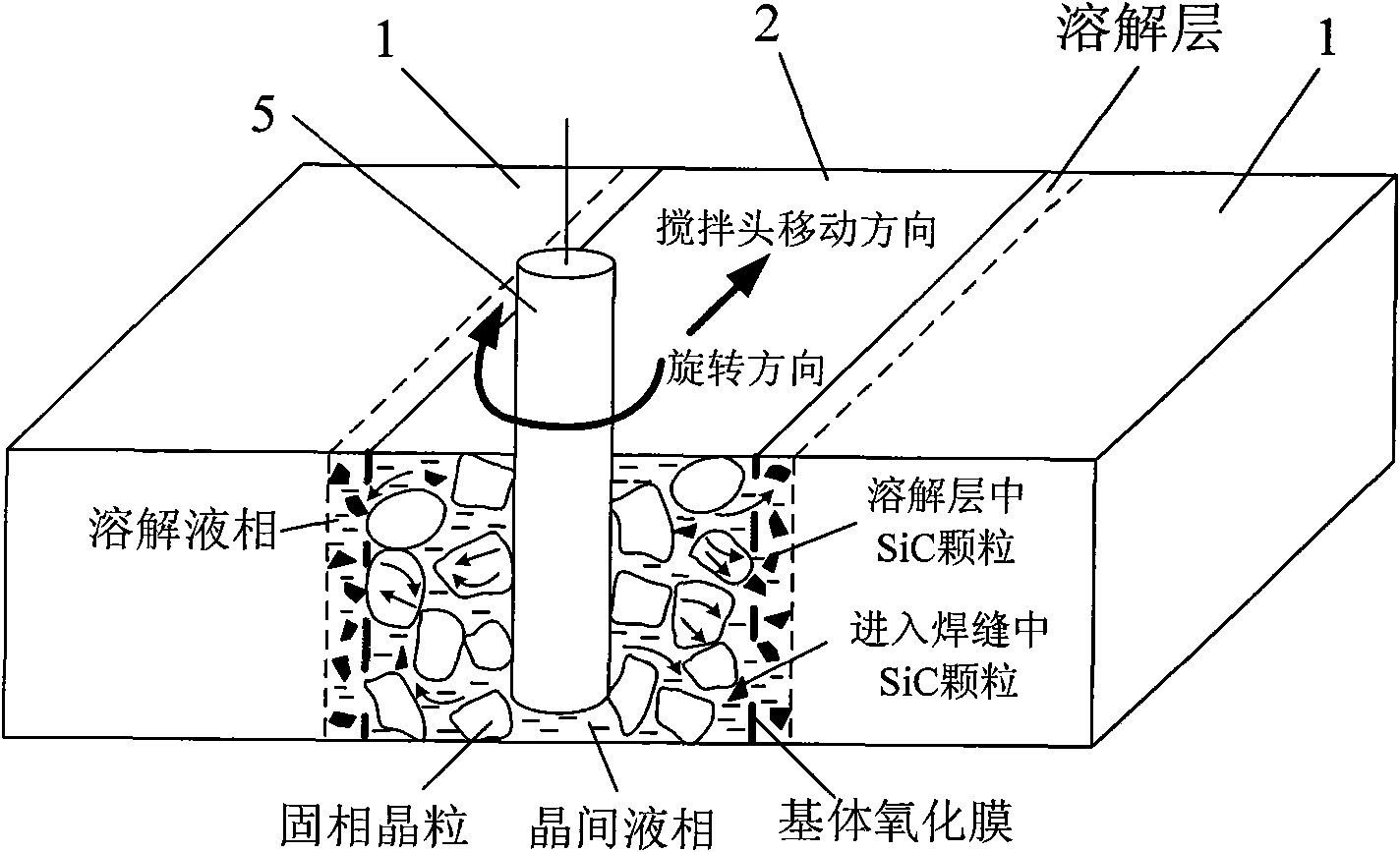

Method used

Image

Examples

Embodiment 1

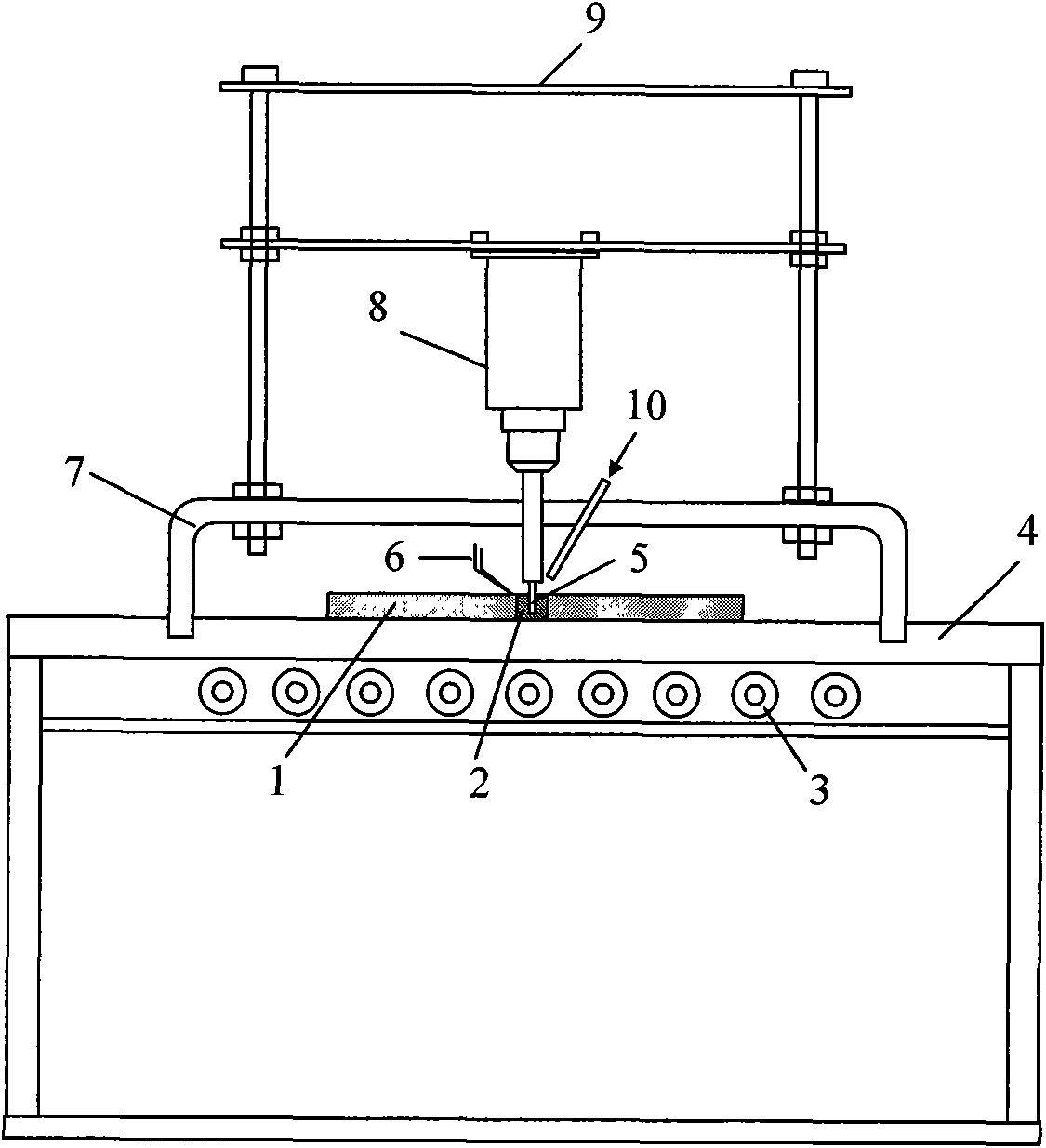

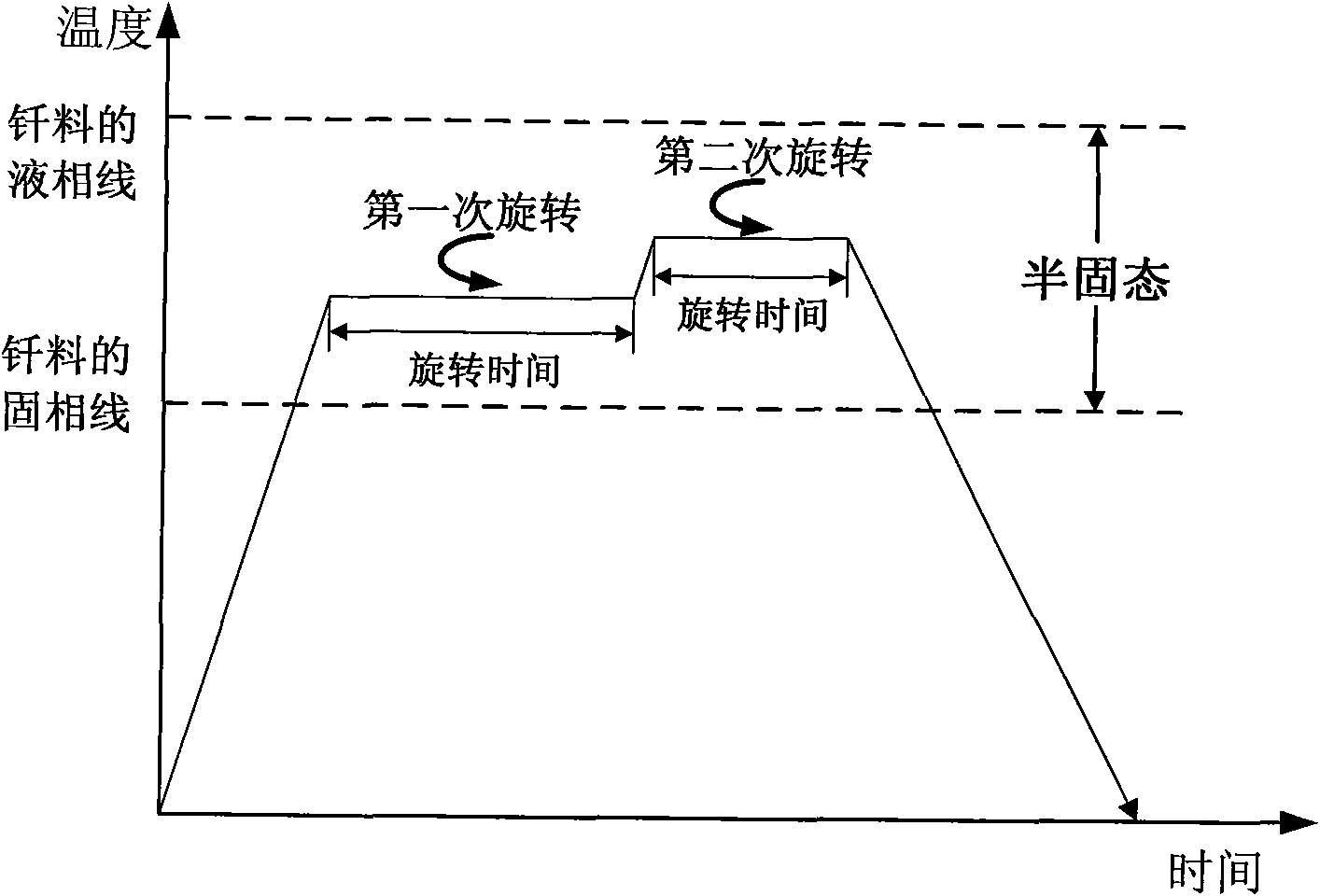

[0034]Embodiment 1: The aluminum-based composite material weldment 1 is installed and clamped on the welding platform 4 and Zn-Al medium-temperature solder 2 is placed on the two surfaces to be welded. The solder 2 can be in the form of a sheet, a square column, a coating or sprayed on it in advance. surface to be welded. The weldment is heated by the resistance heater 3, and the heating temperature is between 390-420° C., such as 390° C., 400° C., 410° C., 420° C., so that the solder 2 is partially melted. Then start the rotary slide device, the track type sliding platform 7 drives the stirring head 5 to move, and the rotating motor 8 installed on the motor support 9 drives its rotation, and the rotational speed is 150-300 rev / min, such as 150 rev / min, 180 rev / min. rev / min, 200 rev / min, 230 rev / min, 250 rev / min, 280 rev / min or 300 rev / min, the temperature is constant during the rotation, the longitudinal moving speed of the stirring head 5 parallel to the weld seam is 0.5 -2...

Embodiment 2

[0035] Example 2, the second embodiment of the present invention is based on the first embodiment, after one rotation, the holding temperature is between 430-440°C, such as 430°C, 435°C, 440°C, and the holding time In 2-5 minutes, the solder 2 in the middle is further melted. Subsequently, start the rotating slide device again (secondary rotation), the rotation speed is 100-150 rpm, such as 100 rpm, 120 rpm, 150 rpm, the stirring head slides in the opposite direction, and the moving speed is 1-1.5 cm / min. When the stirring head moves to the initial end of the weld, stop the rotation, lift the stirring head, keep warm for 15-30 minutes, such as 15 minutes, 22 minutes, 27 minutes, 30 minutes, and cool with the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com