Novel tensile special cable

A special cable and tensile technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of impact, poor impact resistance and compression performance, easy damage to the cable core, etc., so as to reduce the influence of self-weight and improve fire resistance. , to ensure the effect of power-on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, not all of them.

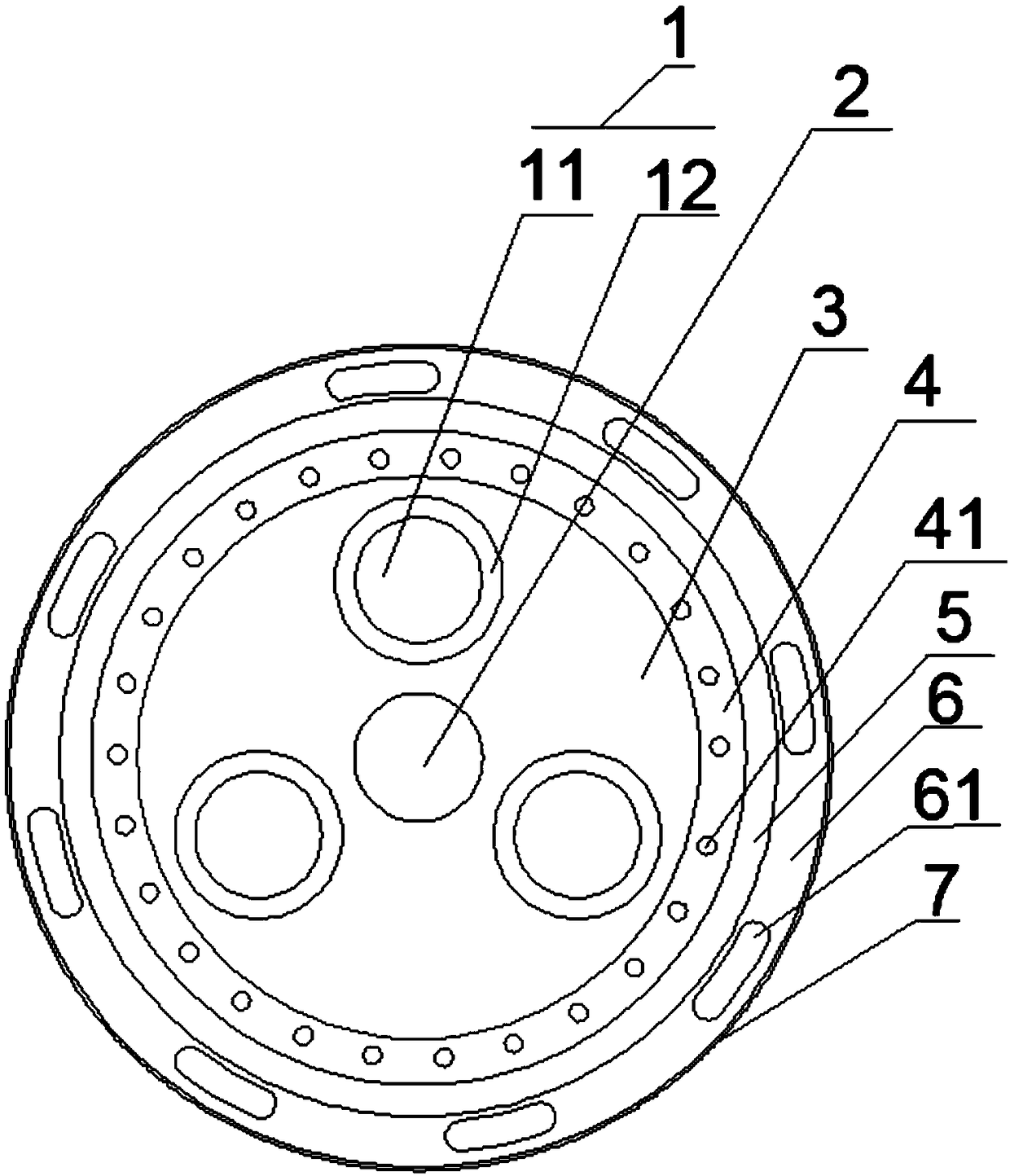

[0027] refer to figure 1 , a new type of tensile special cable, comprising at least one conductor unit 1, a tension cable 2 and a filling layer 3, the conductor unit 1 includes a cable core 11 and a phase-separated insulating layer 12, and the phase-separated insulating layer 12 is surrounded and arranged outside the cable core 11;

[0028] The tension cable 2 is located at the center of the cable, the filling layer 3 is arranged outside the tension cable 2, and the conductor unit 1 is distributed around the tension cable 2 in the filling layer 3, and the filling layer 3 is far away from the tension cable. One side of the cable 2 is provided with a fireproof isolation layer 4, and the side of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com