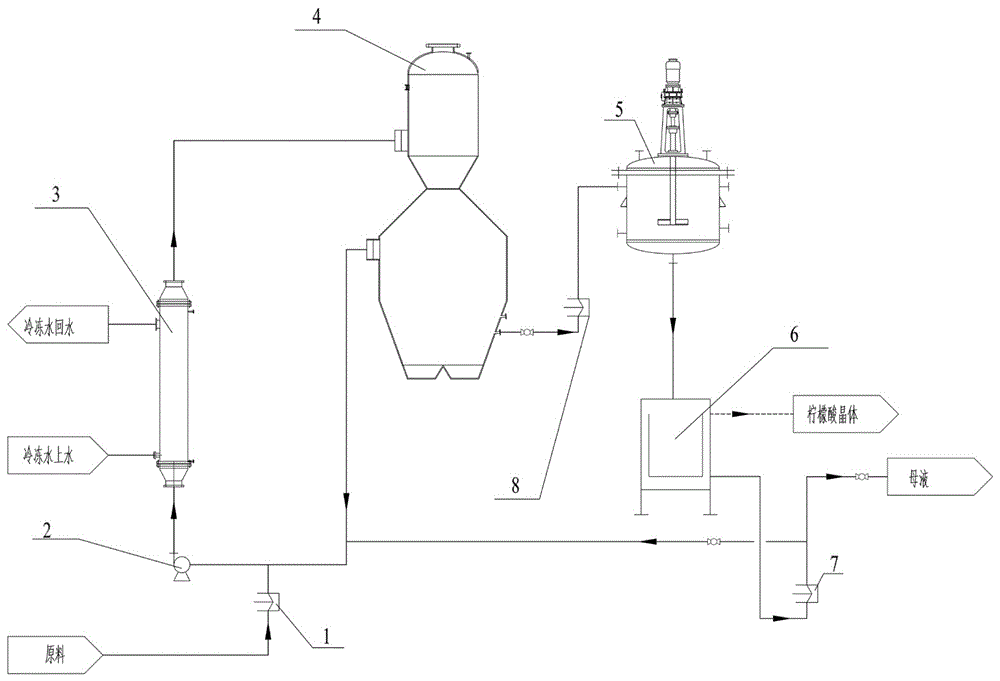

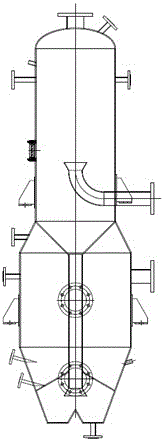

Citric acid continuous cooling crystallization system and method thereof

A technology of cooling crystallization and citric acid, which is applied in the directions of heat exchange cooling crystallization, crystallization separation, solution crystallization, etc., can solve the problems of uneven particle size distribution of citric acid monohydrate crystal products, increased equipment and manual operations, and impact on product production costs. , to ensure continuity and stability, shorten cooling time, and improve the quality of crystal products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment is used to illustrate the citric acid monohydrate crystal provided by the present invention and its production method.

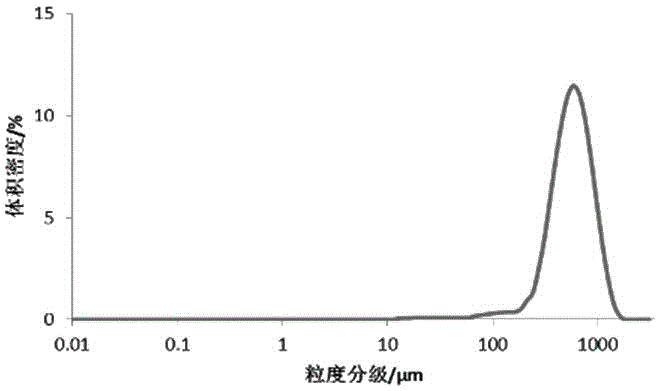

[0065] The citric acid solution is heated and concentrated to 55°C through two-effect heat exchange, and the acidity of citric acid is 98g / 100ml, and then the citric acid concentrate is transported to the continuous cooling crystallization system for cooling and crystallization, and the temperature difference between the citric acid concentrate and the cooling medium is kept at 5°C, the circulation rate is 60 times the feed amount, maintain the temperature of the citric acid feed liquid in the crystallizer at 10°C, and keep the solid content of the citric acid crystal slurry in the crystallizer at 15%, circulate and cool in the crystallizer for 4 hours and pass through the outlet The material is discharged from the feed port, and the monohydrate citric acid crystal slurry is transported to the centrifuge for solid-liquid separation to o...

Embodiment 2

[0067] This embodiment is used to illustrate the citric acid monohydrate crystal provided by the present invention and its production method.

[0068] The citric acid solution is heated and concentrated to 60°C through two-effect heat exchange, and the acidity of citric acid is 105g / 100ml, and then the citric acid concentrate is transported to the continuous cooling crystallization system for cooling and crystallization, and the temperature difference between the citric acid concentrate and the cooling medium is kept at 8°C, the circulation rate is 100 times of the feed amount, maintain the temperature of the citric acid feed liquid in the crystallizer at 12°C, and keep the solid content of the citric acid crystal slurry in the crystallizer at 20%, circulate and cool in the crystallizer for 8 hours and pass through the outlet The material is discharged from the feed port. After the discharge, the monohydrate citric acid crystal slurry is transported to the centrifuge for solid-...

Embodiment 3

[0070] This embodiment is used to illustrate the citric acid monohydrate crystal provided by the present invention and its production method.

[0071] The citric acid solution is heated and concentrated to 65°C through two-effect heat exchange, and the acidity of citric acid is 109g / 100ml, and then the citric acid concentrate is transported to the continuous cooling crystallization system for cooling and crystallization, and the temperature difference between the citric acid concentrate and the cooling medium is maintained at 10°C, the circulation rate is 80 times the feed amount, maintain the temperature of the citric acid feed liquid in the crystallizer at 17°C, and keep the solid content of the citric acid crystal slurry in the crystallizer at 25%, circulate and cool in the crystallizer for 8 hours and then pass through the outlet The material is discharged from the feed port. After the discharge, the monohydrate citric acid crystal slurry is transported to the centrifuge fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com