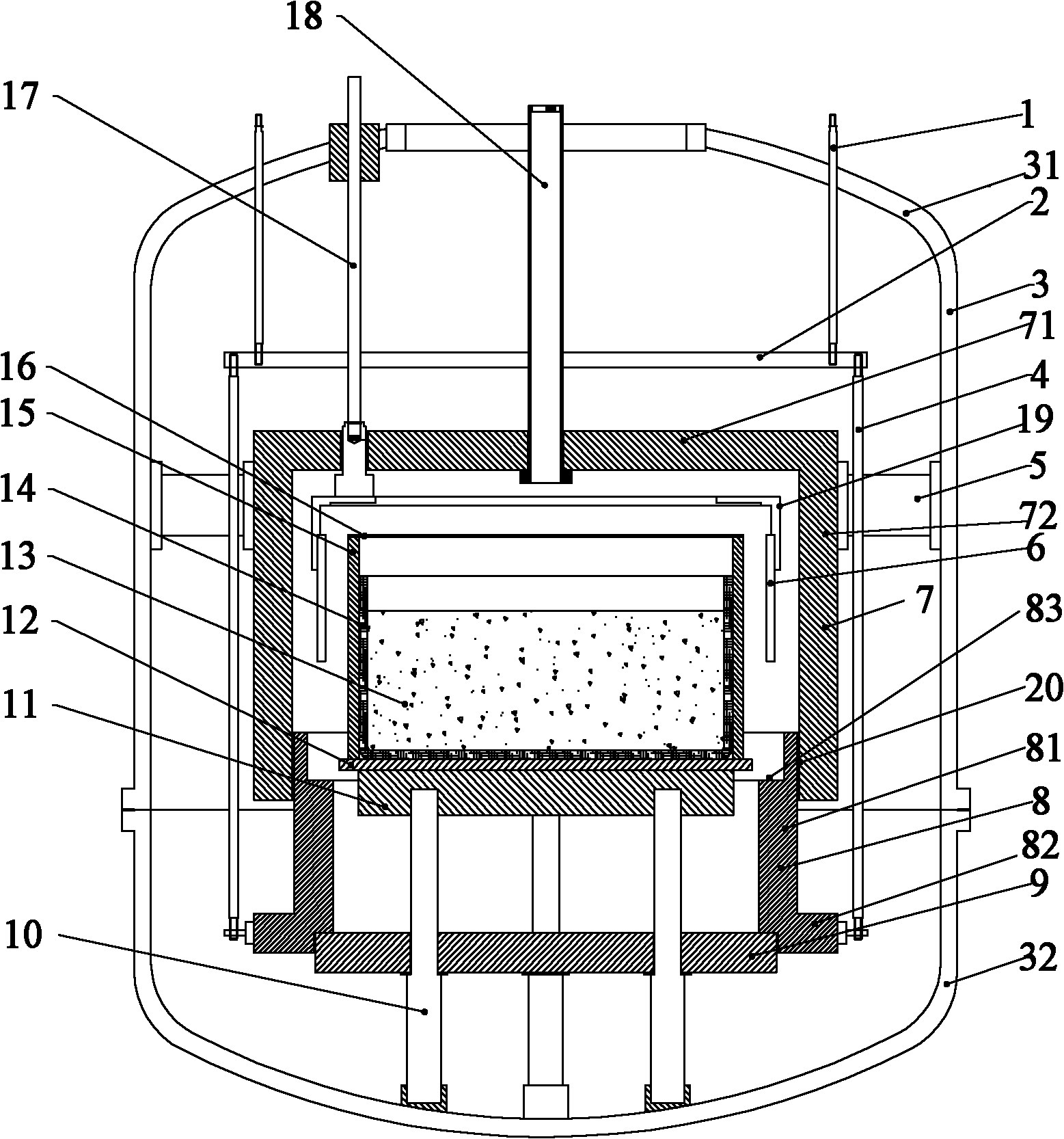

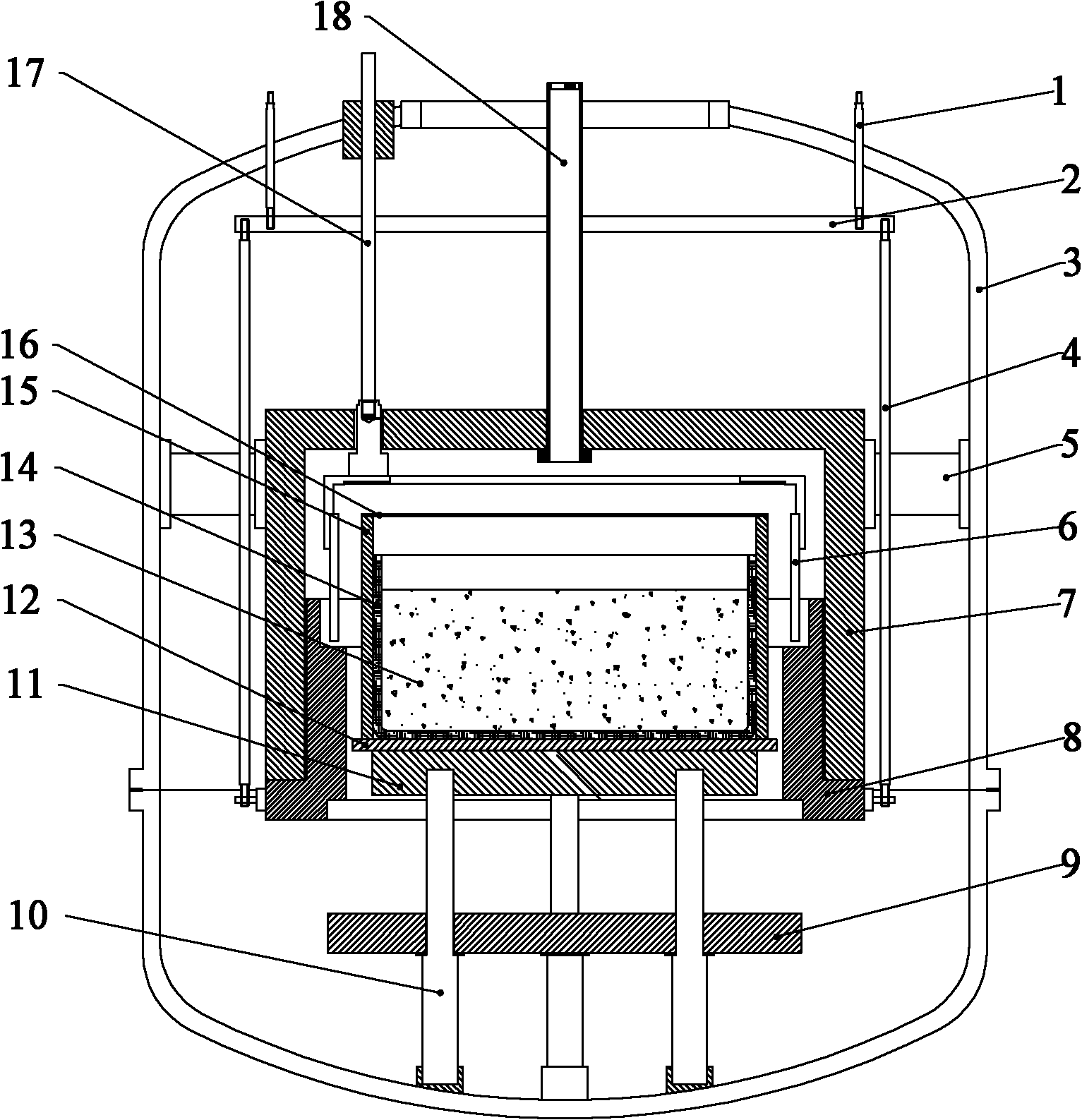

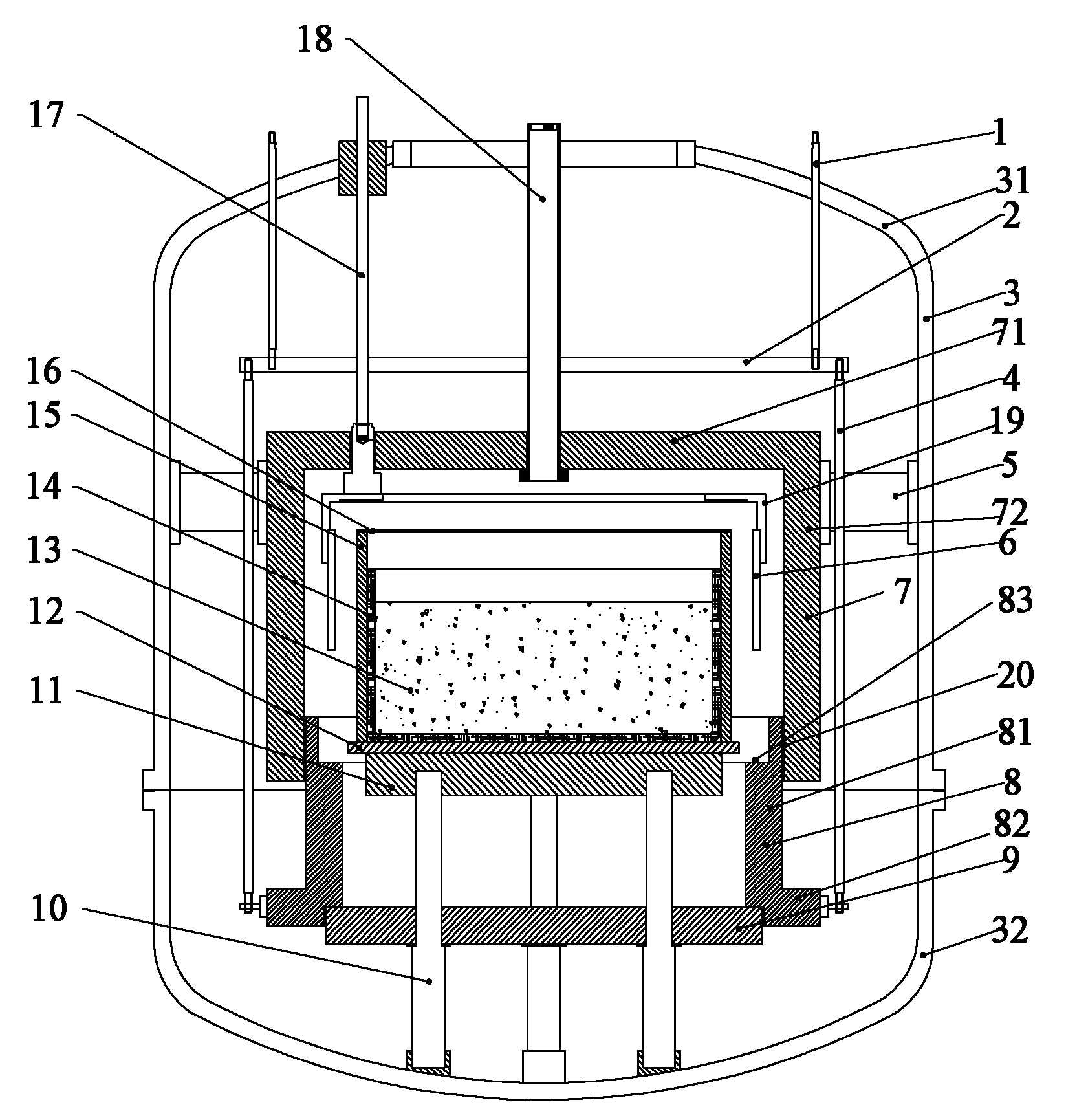

Thermal field structure of polysilicon ingot casting furnace

A technology of polysilicon ingot casting furnace and thermal field, which is applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., and can solve problems affecting the crystallization quality of polycrystalline silicon ingots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The general idea of the technical solution of the present invention is: the thermal insulation cage body is composed of an upper thermal insulation body, a lower thermal insulation body and a thermal insulation bottom plate to form a sealed thermal field chamber, and the lower thermal insulation body can slide up and down relative to the upper thermal insulation body through a lifting mechanism. During the lifting process of the lower insulation body, due to the high and low temperature difference in the thermal field chamber, a vertical temperature gradient field is formed on the crystallization surface of silicon. By controlling heat dissipation and heating, silicon can be oriented and crystallized, and its crystallization is solidified. The process is effectively controlled to improve the quality of the polysilicon ingot, and at the same time shorten the whole process time, reduce the energy consumption in the crystallization process, and increase the unit production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com