Continuous preparation method of high-purity magnesium hydroxide

A magnesium hydroxide, high-purity technology, applied in the fields of inorganic non-metallic materials, metallurgy, and chemical industry, can solve the problems of high concentration of free ammonia, environmental pollution, etc., and achieve the effect of high purity, less investment and large particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

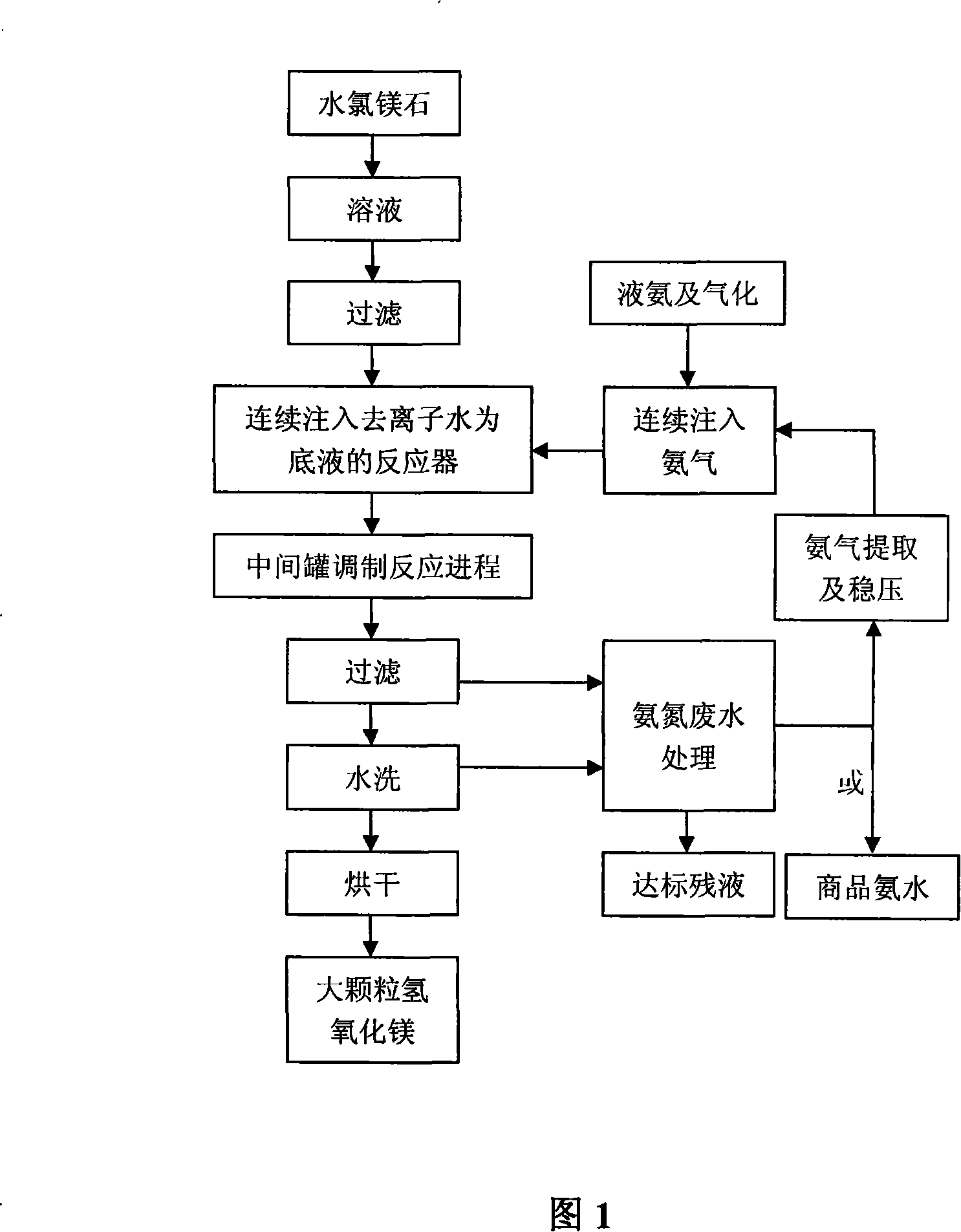

Image

Examples

Embodiment Construction

[0034] (1) preparation concentration is the magnesium chloride solution of 3mol / L:

[0035] Add bischofite to deionized water, stir at room temperature until completely dissolved, and prepare a magnesium chloride solution with a concentration of 3 mol / L; use a filter press to filter the solution to remove impurities;

[0036] (2) Inject the reaction bottom solution

[0037] Inject 15 liters of distilled water into a reactor with an effective volume of 30 liters as the bottom liquid, add 100 g of seed crystals, heat to 85 ° C and keep it warm;

[0038] (3) Inject ammonia gas

[0039] Ammonia gas was continuously injected at a flow rate of 90 L / min.

[0040] (4) inject magnesium chloride solution

[0041] After ammonia gas began to inject 10 minutes, concentration is that the magnesium chloride solution of 3mol / L is continuously injected in the reactor with the flow rate of 40 liters per hour, and the magnesium precipitation reaction begins.

[0042] (5) Product discharge

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com