Crushing bucket

A bucket and shovel mouth technology, which is applied in the field of crushing buckets of composting technology, can solve the problems of the crushing bucket stuck, and the fermented material cannot be crushed and homogenized, so as to reduce material flow, improve equipment efficiency, and reduce logistics cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

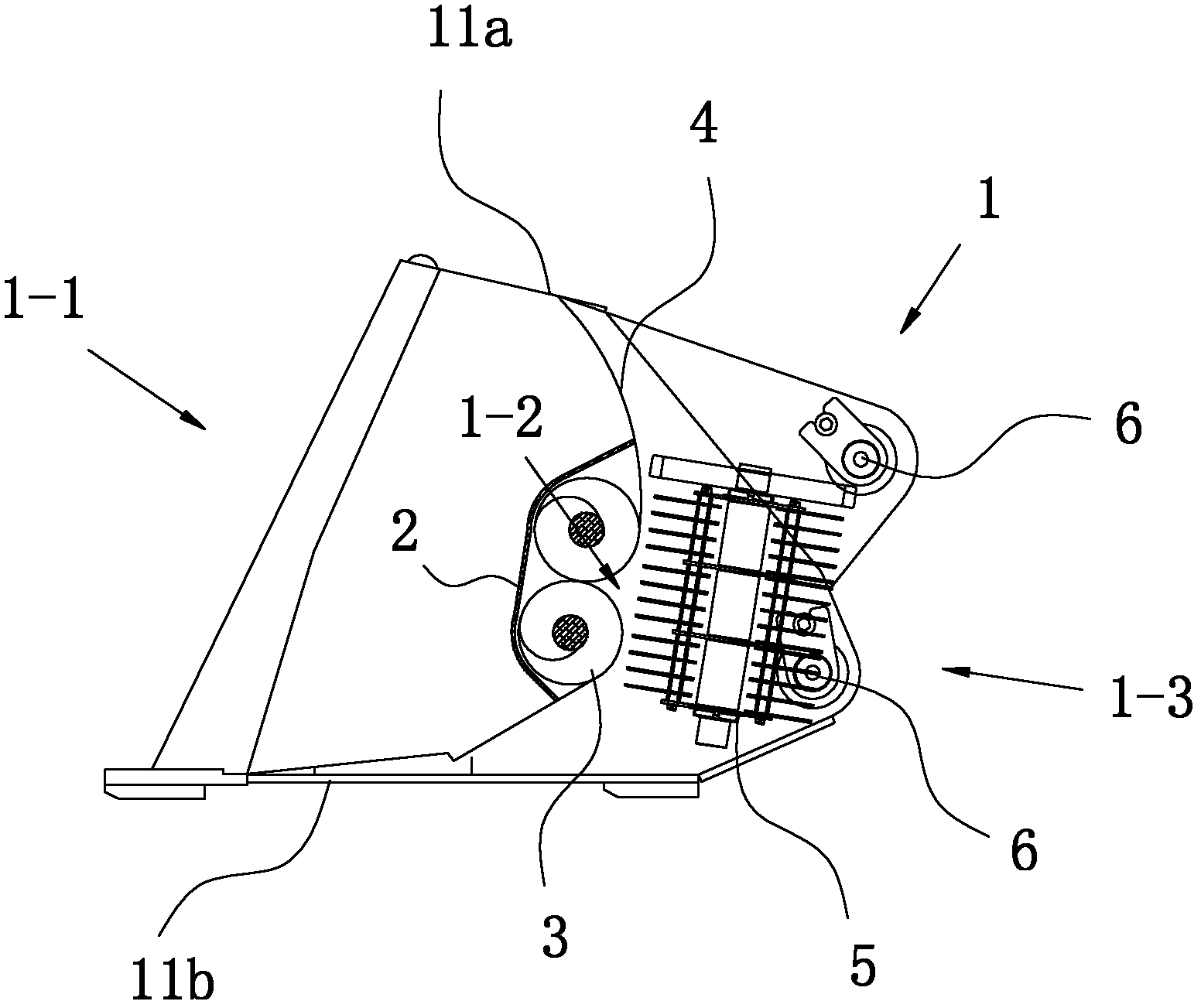

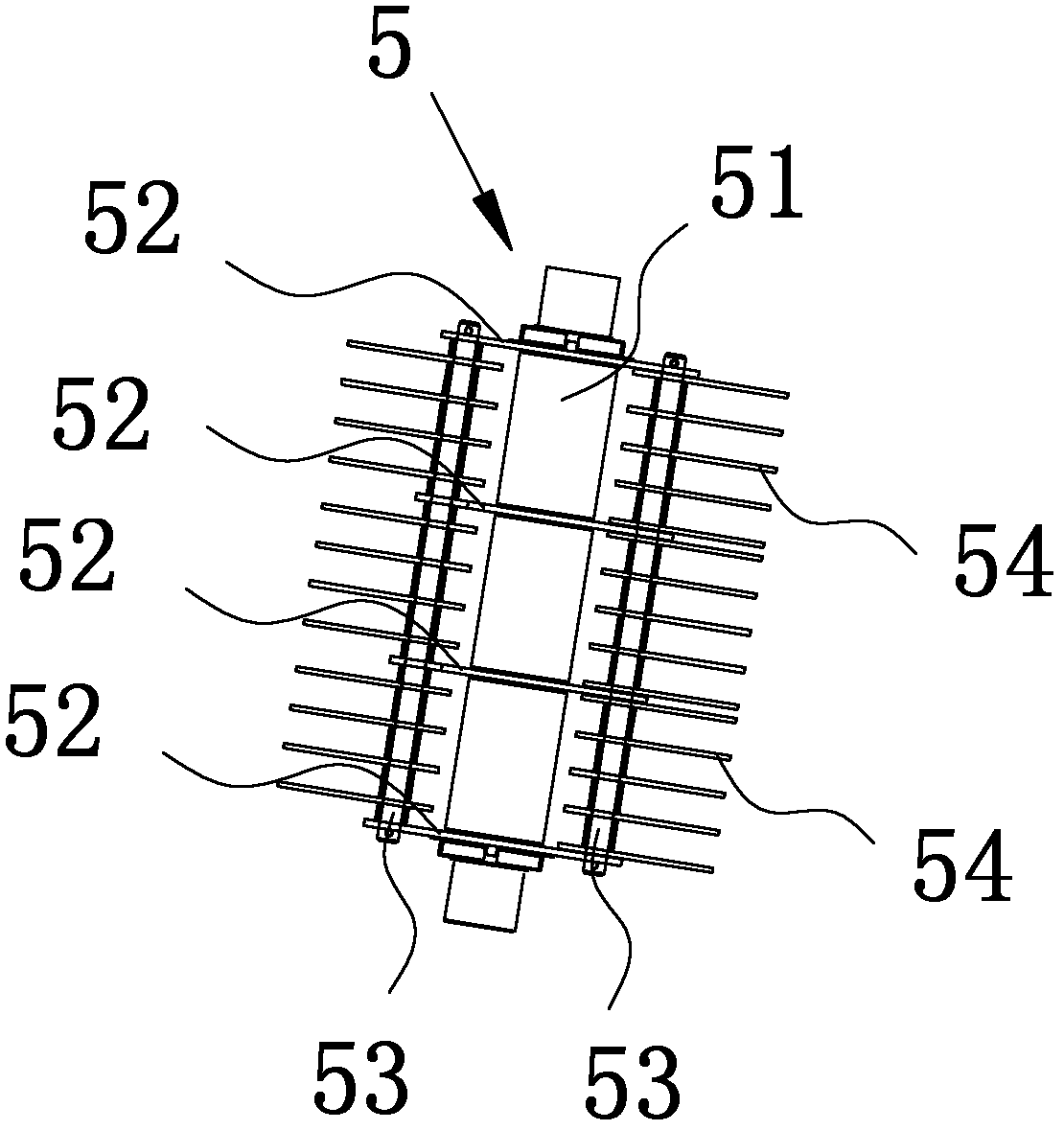

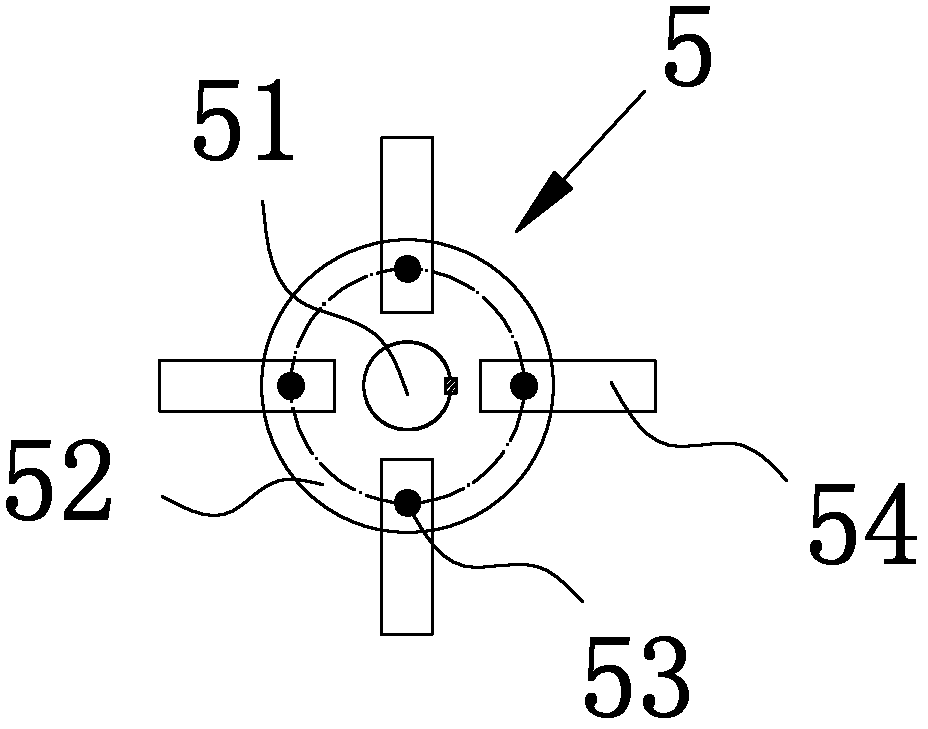

[0026] Such as Figure 1 to Figure 5 As shown, a crushing bucket includes a bucket shell 1 that can be freely mounted on the loader mechanical arm 7 and a shovel opening 1-1 that is located at the front end of the bucket shell 1. The bucket shell 1 The inner cavity is provided with a partition wall 4, which divides the inner cavity of the crushing bucket shell 1 into two cavities; The arc is bent, and the arc is bent in the direction of the rear cavity. When the bucket 1 is vertically lifted by the loader, the lowest point of the arc wall forms a groove along the left wall 12a and the right wall 12b of the casing, and the compost material can be moved by gravity. Under the action, it can slide down into the groove along the arc-shaped wall; the opening 1-2 connecting the front and rear chambers is provided on the partition wall 4, and the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com