Enclosed type electrolytic tank and electrolytic system

An electrolytic cell and closed technology, applied in the field of electrolytic cells, can solve the problems of uneven electrode current distribution, poor operating environment of electrolysis workshop, and increase the chance of side reactions, achieve good electrode potential distribution, and reduce the chance of side reactions. , the effect of increasing the limiting current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

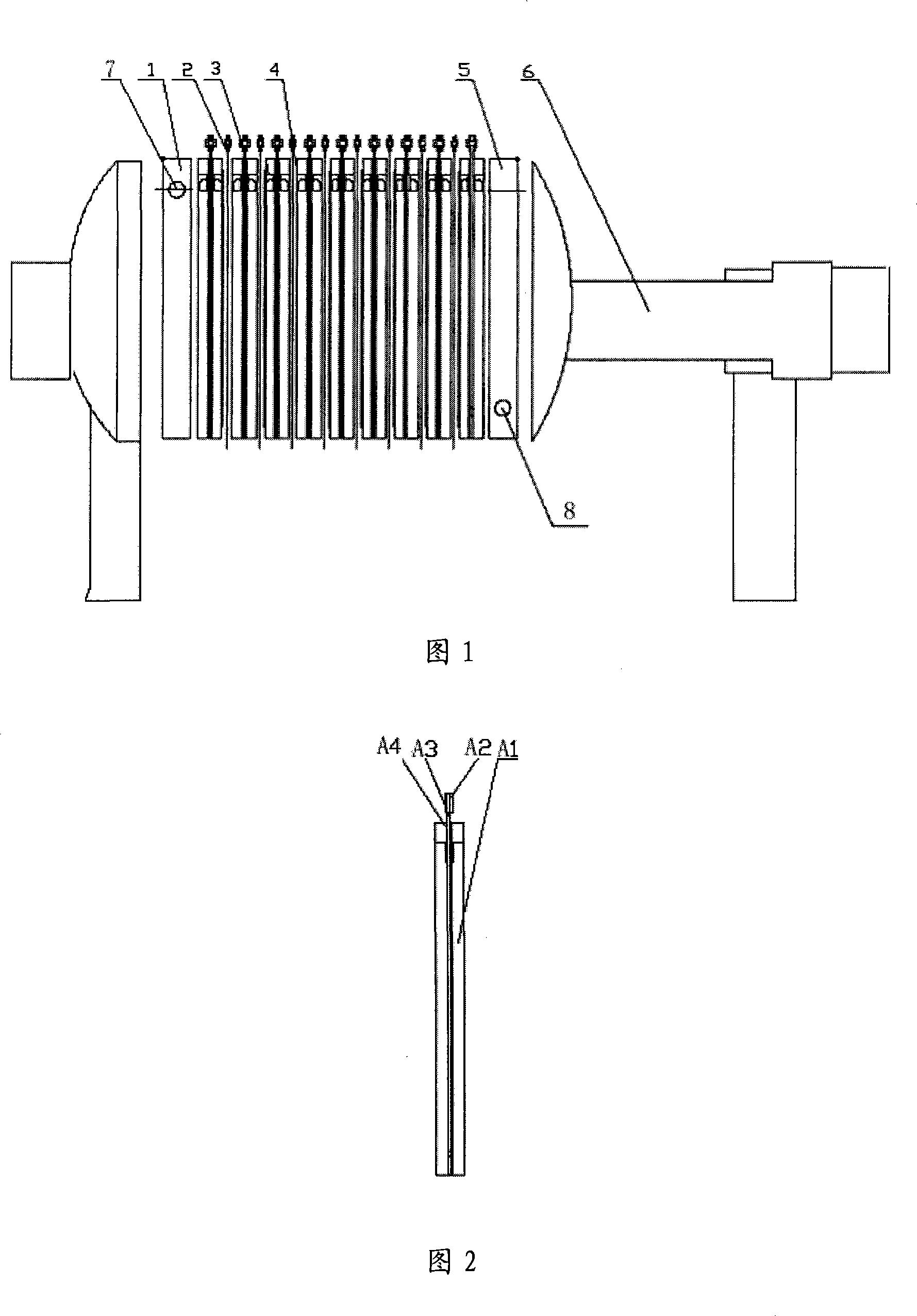

[0029] As shown in FIG. 1, an embodiment of the present invention provides a closed electrolytic cell, which is specifically used for electrowinning various metals, including:

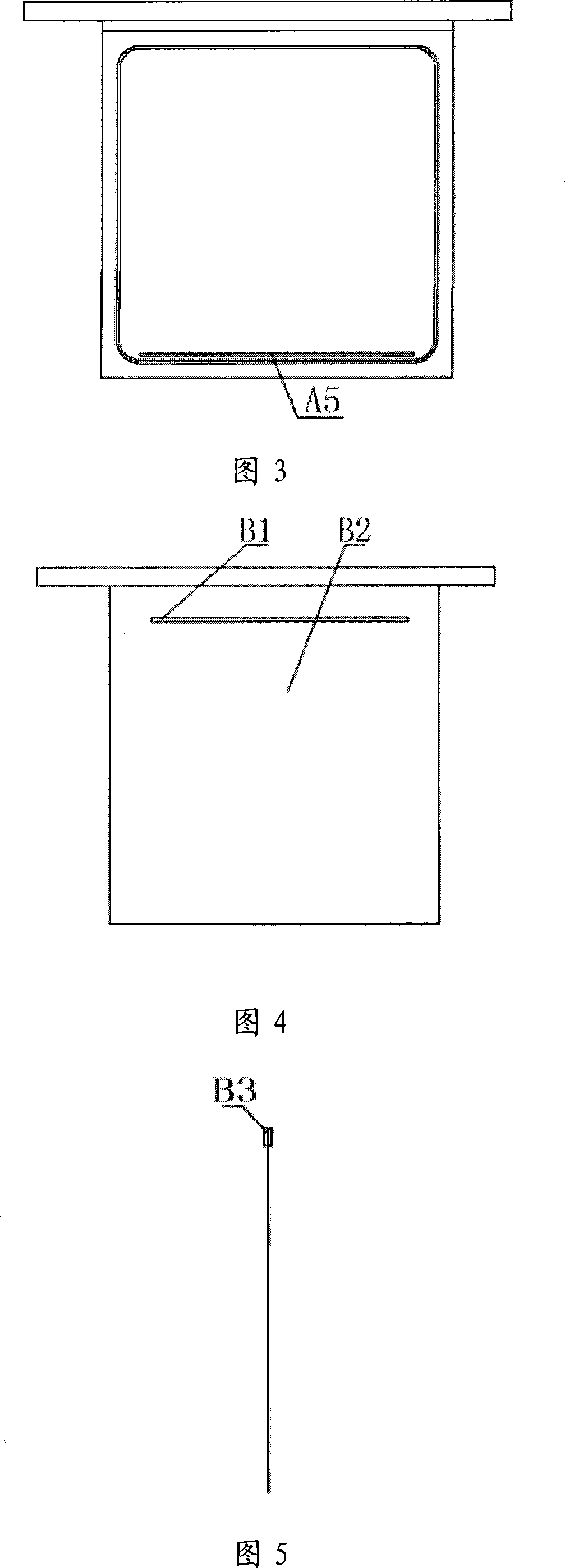

[0030] Two end plates 1, 5, anode assembly 3, cathode assembly 2, seal 4 and pressing device 6; two end plates 1, 5 are provided with liquid flow ports 7, 8, anode assembly 3 and cathode assembly 2 There is a flow through hole correspondingly on the upper part, the anode assembly 3 and the cathode assembly 2 are arranged at intervals between the two end plates 1 and 5, and a pole chamber is formed between the adjacent anode assembly and the cathode assembly. A plurality of anode assemblies and cathode assemblies are arranged, so that a plurality of electrode chambers can be formed, and the distance between the plates of the anode assemblies and the cathode assemblies can be set in the range of 20-100 mm. The anode assembly 3, the cathode assembly 2 and the end plates 1 and 5 are all provided with seals...

Embodiment 2

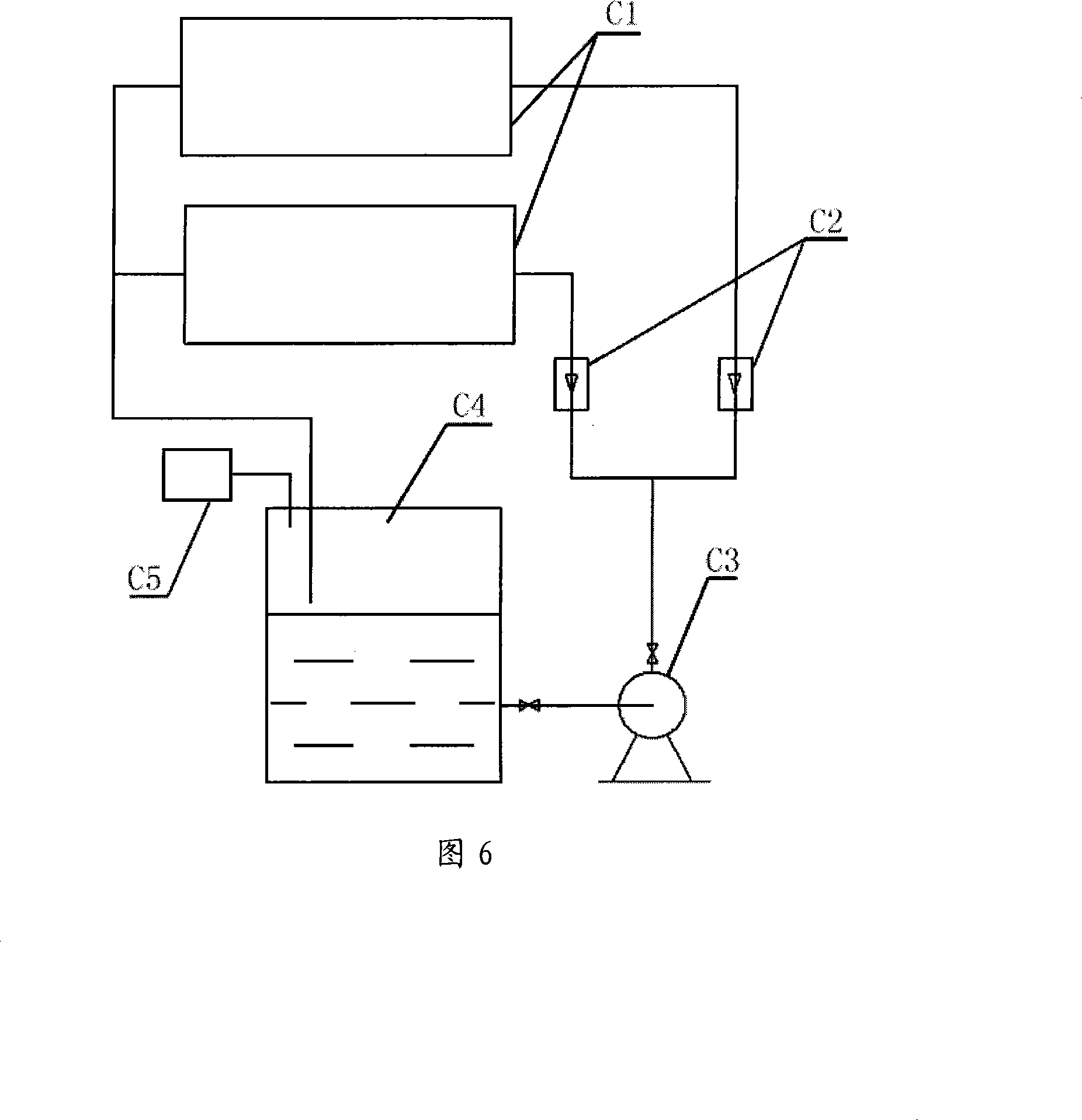

[0039] As shown in FIG. 6 , an embodiment of the present invention further provides an electrolysis system based on the electrolytic cell described in Embodiment 1, the system comprising:

[0040] Using the electrolytic cell C1 described in the first embodiment, the liquid inlet of the liquid inlet end plate of the electrolytic cell C1 is connected to the circulating tank C4 through the pipeline, the flow meter C2, and the circulating pump C3. The solution;

[0041] The liquid outlet of the liquid outlet end plate of the electrolytic cell C1 is directly connected to the circulation tank C4 through a pipeline;

[0042] The circulation tank C4 is provided with a gas absorption device C5, and the gas absorption device C5 processes the gas generated when the electrolysis tank C1 is operated and flows back to the circulation tank C4 through the pipeline.

[0043] In order to ensure the flow rate of the electrolyte, the electrolyte is pressed in from the liquid inlet end plate by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com