Oxygen sensor and air/fuel ratio control system

一种氧传感器、控制系统的技术,应用在燃料喷射控制、电气控制、发动机控制等方向,能够解决空燃比控制精度下降、误差、影响控制的参数等问题,达到提高输出精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

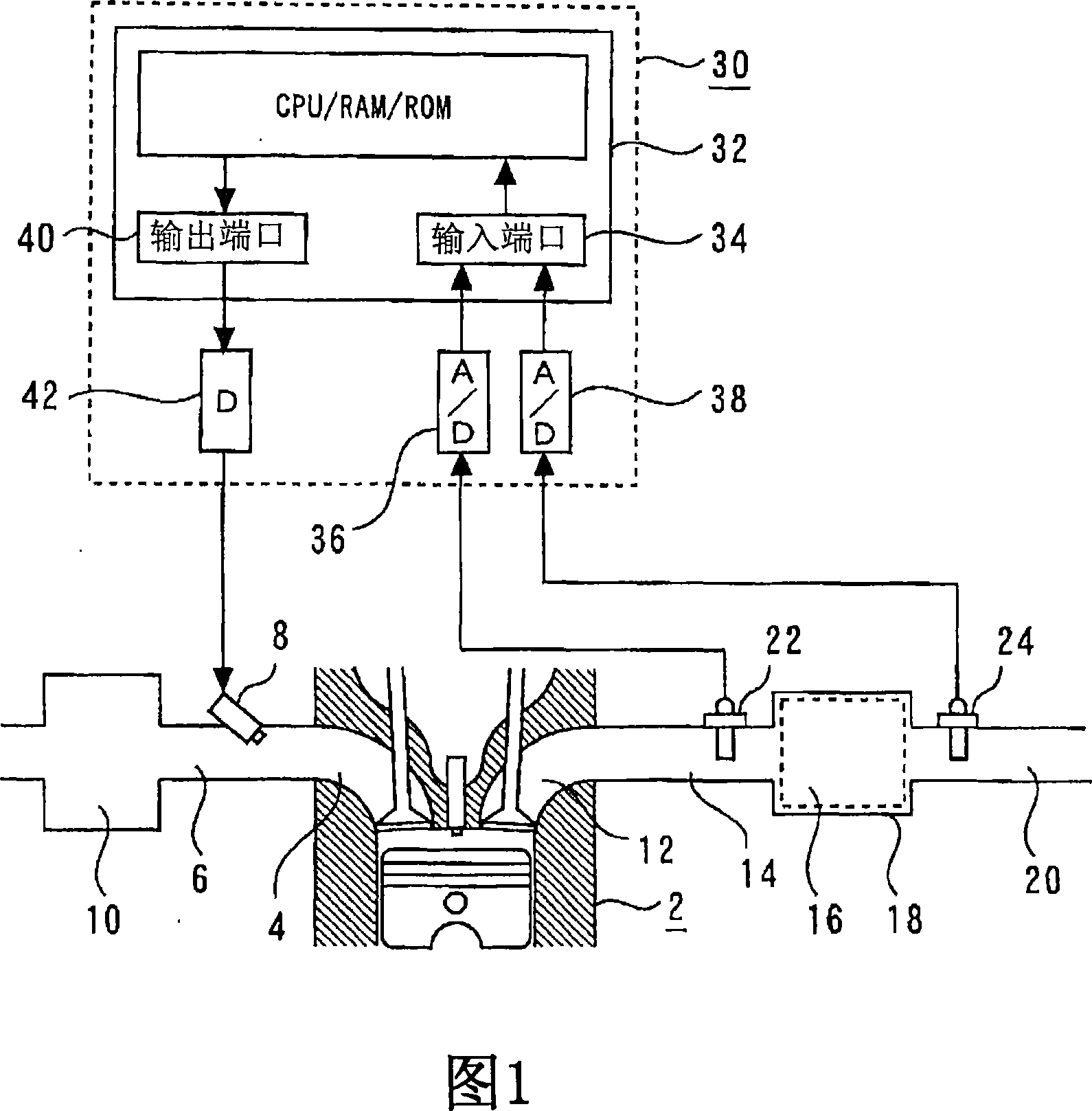

[0122] FIG. 1 is a schematic diagram for explaining a system according to Embodiment 1 of the present invention.

[0123] As shown in FIG. 1 , the system of Embodiment 1 includes an internal combustion engine 2 . An intake branch pipe 6 is connected to the intake port 4 of each cylinder of the internal combustion engine 2 . A fuel injection valve 8 is provided on the intake branch pipe 6 . Also, the intake branch pipe 6 is connected to a common buffer tank 10 .

[0124] On the other hand, the exhaust ports 12 of the respective cylinders of the internal combustion engine 2 are connected to a common exhaust manifold 14 . The exhaust manifold 14 is connected to a catalytic converter 18 with a built-in three-way catalyst 16 . The catalytic converter 18 is connected to a muffler (not shown) through an exhaust pipe 20 . The upstream side sensor 22 is arranged on the exhaust manifold 14 , that is, upstream of the three-way catalyst 16 . The upstream sensor 22 is a so-called glob...

Embodiment approach 2

[0153] The configuration of the system used in Embodiment 2 is the same as that of the system described in Embodiment 1. However, the control device 30 is based on the output V of the downstream side sensor 24 24 The target voltage at the time of deviation is calculated, and two target voltages Vref1 and Vref2 are stored. FIG. 4 is a graph for explaining the relationship between the output of the downstream sensor 24 and the two target voltages Vref1 and Vref2 in the second embodiment of the present invention.

[0154] As shown in FIG. 4 , in the downstream side sensor 24, in a low-concentration atmosphere, the output characteristic of the air-fuel ratio when the air-fuel ratio is changed from rich to lean is hysteresis. That is, the output of the downstream side sensor 24 differs when the air-fuel ratio changes from rich to lean and when the air-fuel ratio changes from lean to rich. Specifically, when the air-fuel ratio is switched from rich to lean, the output abrupt chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com