Rice polishing device

A polishing device and rice technology, applied in grain finishing, grain processing, application, etc., can solve the problems of easy clogging of internal pipes, inability to wet rice, broken rice, etc., improve polishing uniformity, and facilitate installation and disassembly. , to avoid the effect of blocking the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

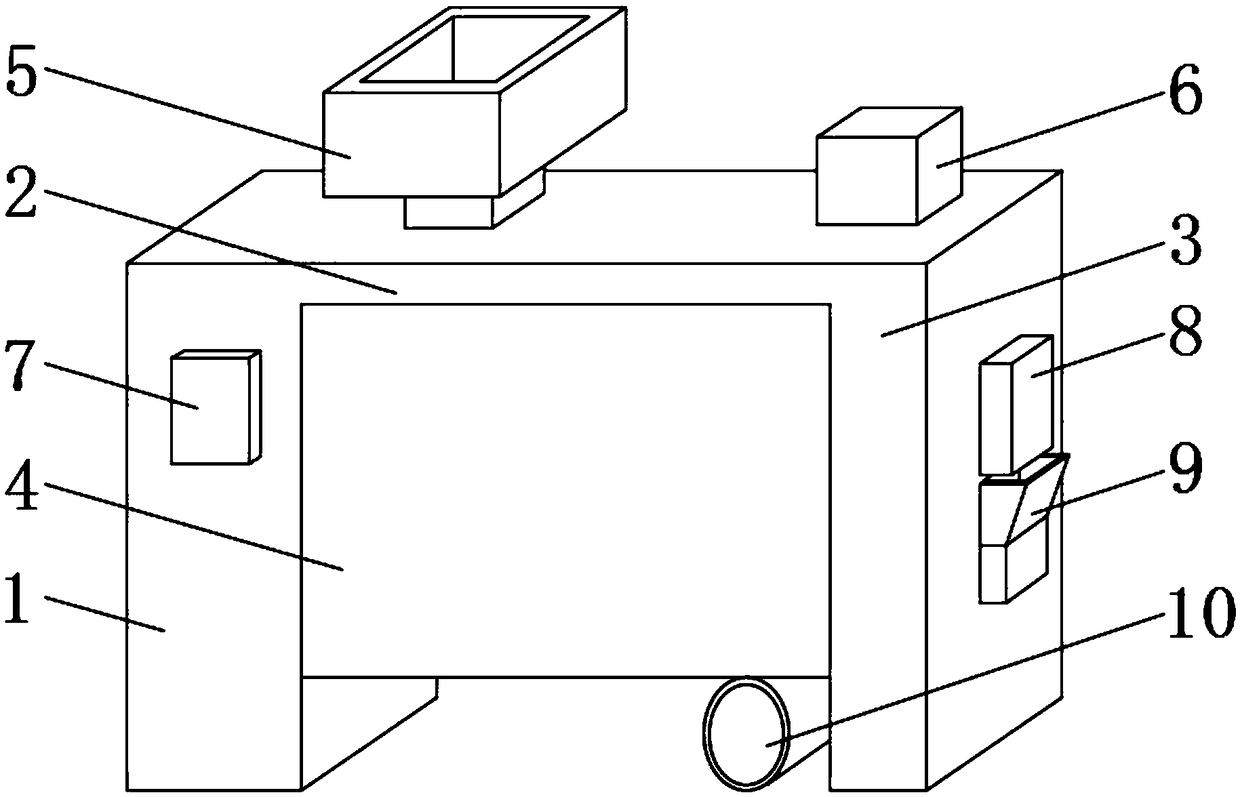

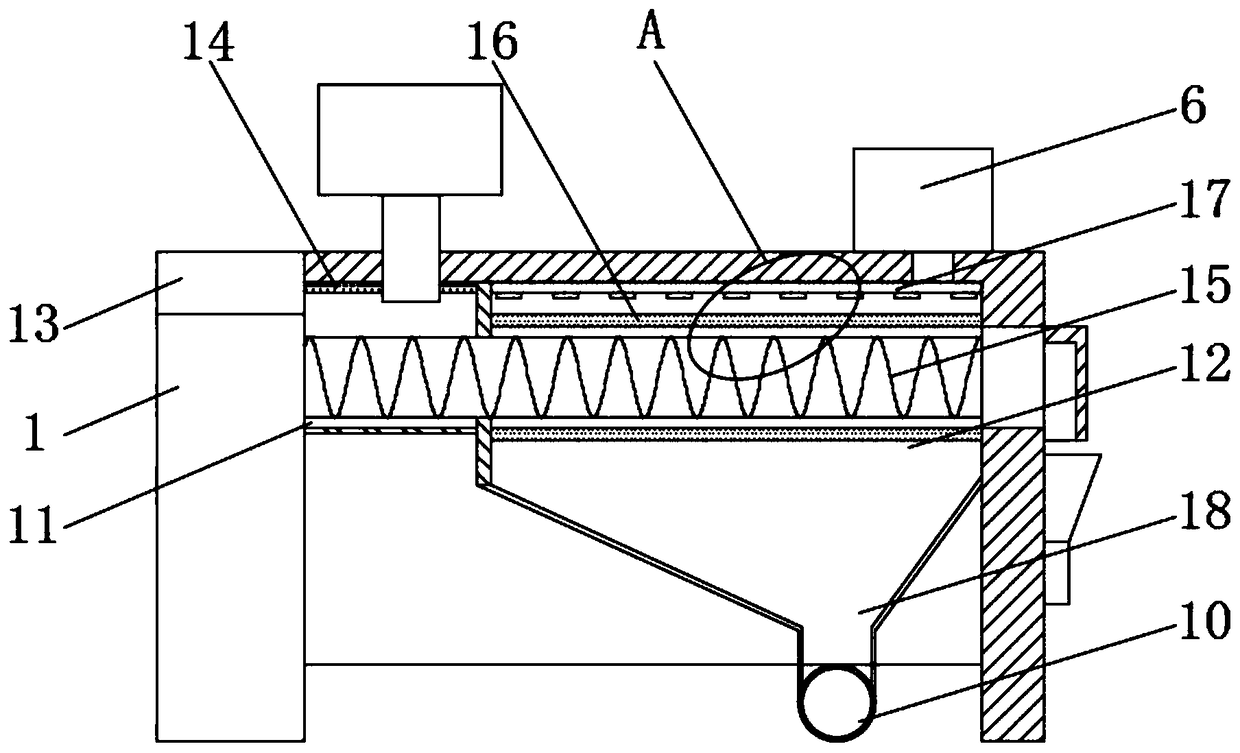

[0025] Such as Figure 1-4 As shown, a rice polishing device comprises a main body box 1 and a top plate 2, the top plate 2 is fixedly installed on the upper end of the main body box 1, the bottom end of the top plate 2 is fixedly installed with a bottom box 3, and the bottom end of the top plate 2 is fixedly installed with a feed The chamber 11 and the polishing chamber 12, and the feeding chamber 11 and the polishing chamber 12 are all located between the main body box 1 and the bottom box 3, the feeding chamber 11 is located on one side of the polishing chamber 12, and the inner top of the feeding chamber 11 is fixedly installed with Water spray plate 14, the upper end of water spray plate 14 is provided with several groups of drainage holes.

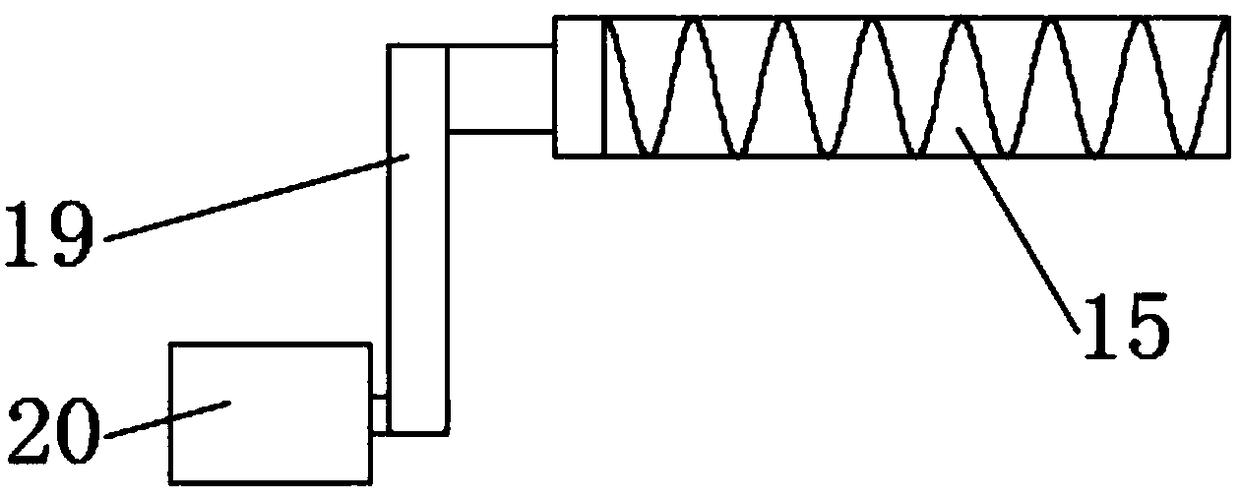

[0026] The inside of the polishing chamber 12 is fixedly equipped with a polishing tube 16, and the inside of the polishing tube 16 is penetrated with a roller 15. Inside the material chamber 11, the outer surface of one side of the...

Embodiment 2

[0032] Such as Figure 1-4 As shown, it includes a main body box 1 and a top plate 2, the top plate 2 is fixedly installed on the upper end of the main body box 1, the bottom end of the top plate 2 is fixedly installed with a bottom box 3, and the bottom end of the top plate 2 is fixedly installed with a feeding chamber 11 and a polishing chamber 12 , and both the feeding chamber 11 and the polishing chamber 12 are located between the main body case 1 and the bottom case 3 , and the feeding chamber 11 is located on one side of the polishing chamber 12 .

[0033] The inside of the polishing chamber 12 is fixedly equipped with a polishing tube 16, and the inside of the polishing tube 16 is penetrated with a roller 15. In the inside of material chamber 11 , the inner top of polishing chamber 12 is fixedly equipped with air duct 17 , and air duct 17 is located at the upper end of polishing pipe 16 , and the bottom end of air duct 17 is connected with several groups of exhaust pipe...

Embodiment 3

[0039] Such as Figure 1-4 As shown, it includes a main body box 1 and a top plate 2, the top plate 2 is fixedly installed on the upper end of the main body box 1, the bottom end of the top plate 2 is fixedly installed with a bottom box 3, and the bottom end of the top plate 2 is fixedly installed with a feeding chamber 11 and a polishing chamber 12 , and the feeding chamber 11 and the polishing chamber 12 are all located between the main body box 1 and the bottom box 3, the feeding chamber 11 is located on one side of the polishing chamber 12, and the inner top of the feeding chamber 11 is fixedly equipped with a water spray plate 14, spraying The upper end of the water plate 14 is provided with several groups of drainage holes.

[0040] The front end of the feeding chamber 11 and the polishing chamber 12 is provided with a front cover 4, and the front cover 4 is fixedly connected with the main body box 1 and the bottom box 3 respectively. The lower end of the polishing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com