Exhaust gas treatment device, method for processing exhaust gas, and motor vehicle

A technology for exhaust gas treatment device and motor vehicle, which is applied in the direction of exhaust device, exhaust gas treatment, muffler device, etc., can solve problems such as inability to convert, and achieve the effect of reducing CO2 emission and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

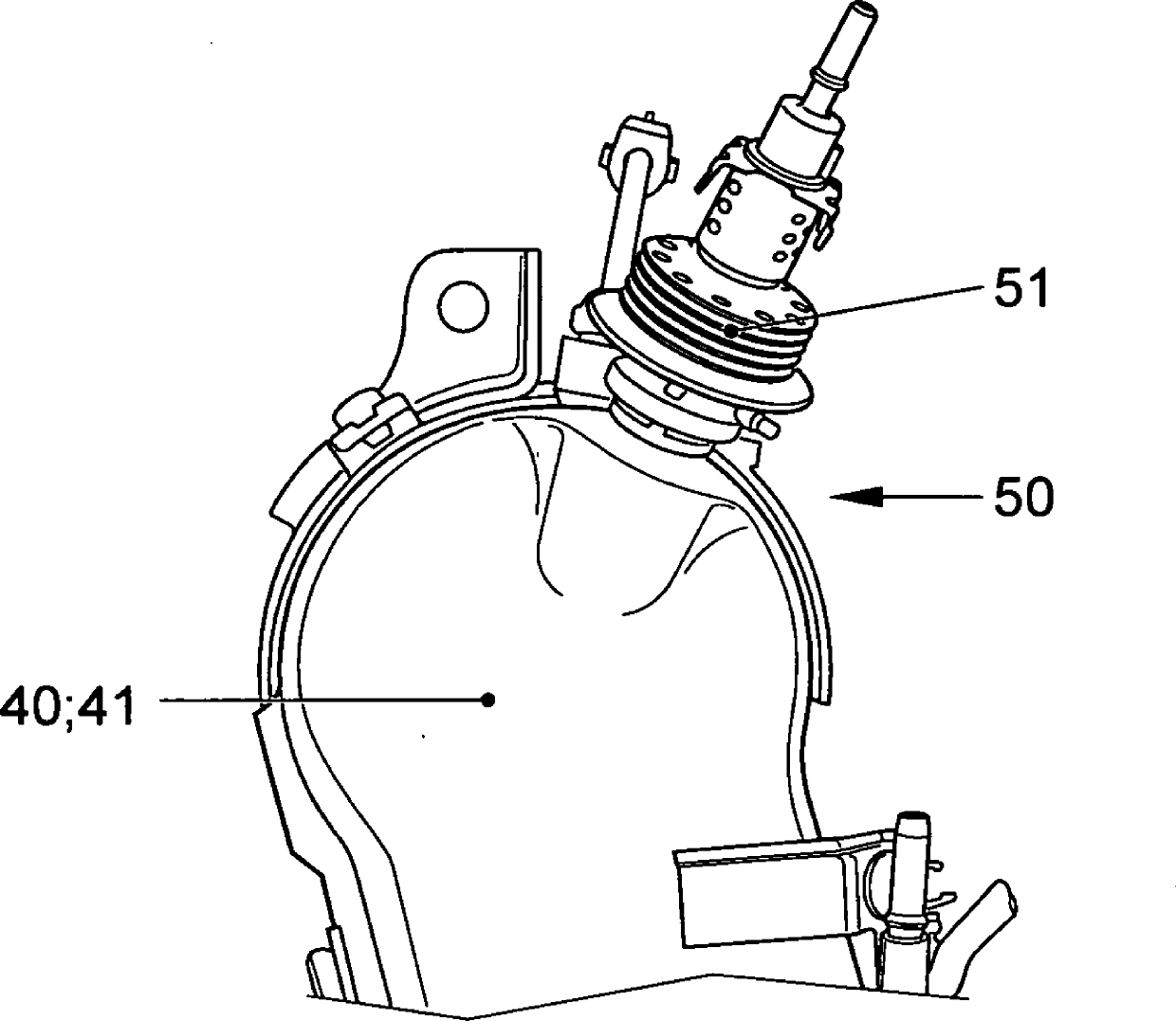

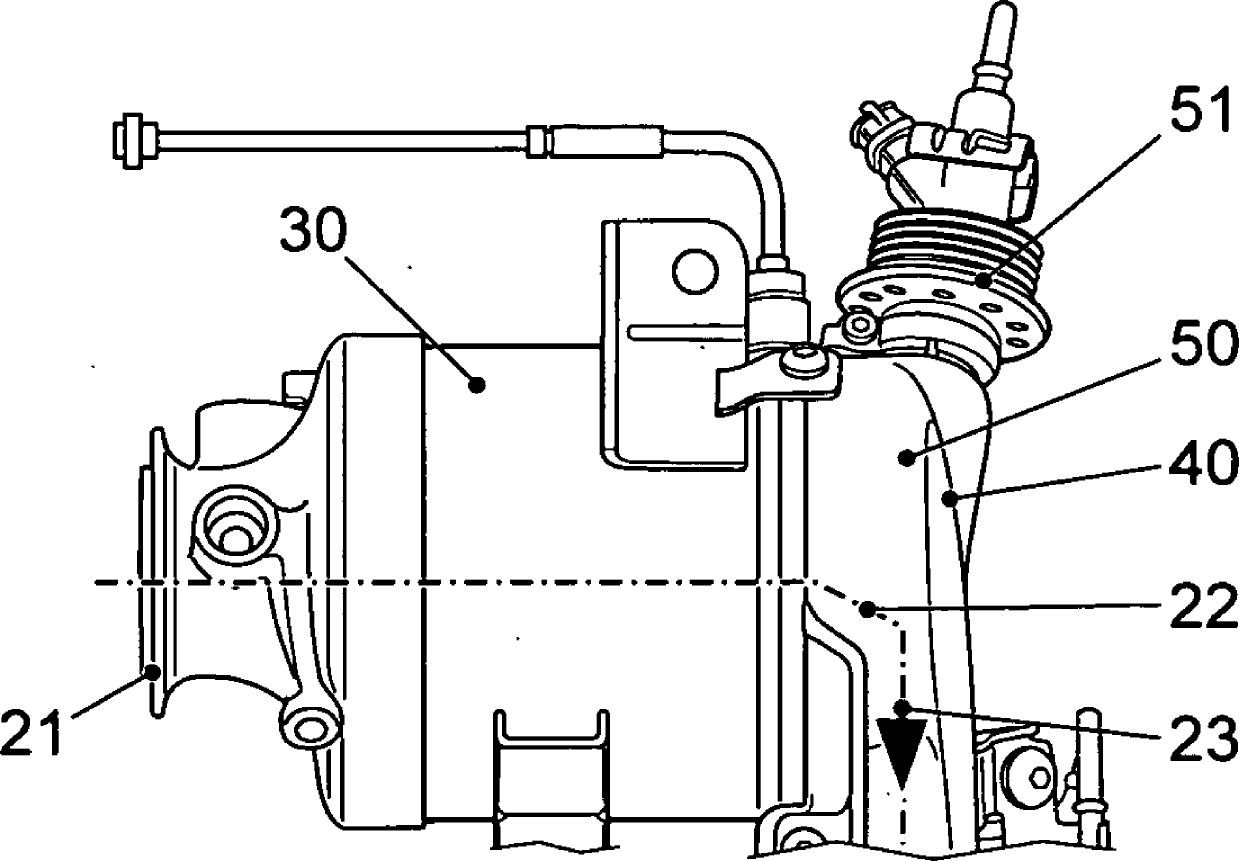

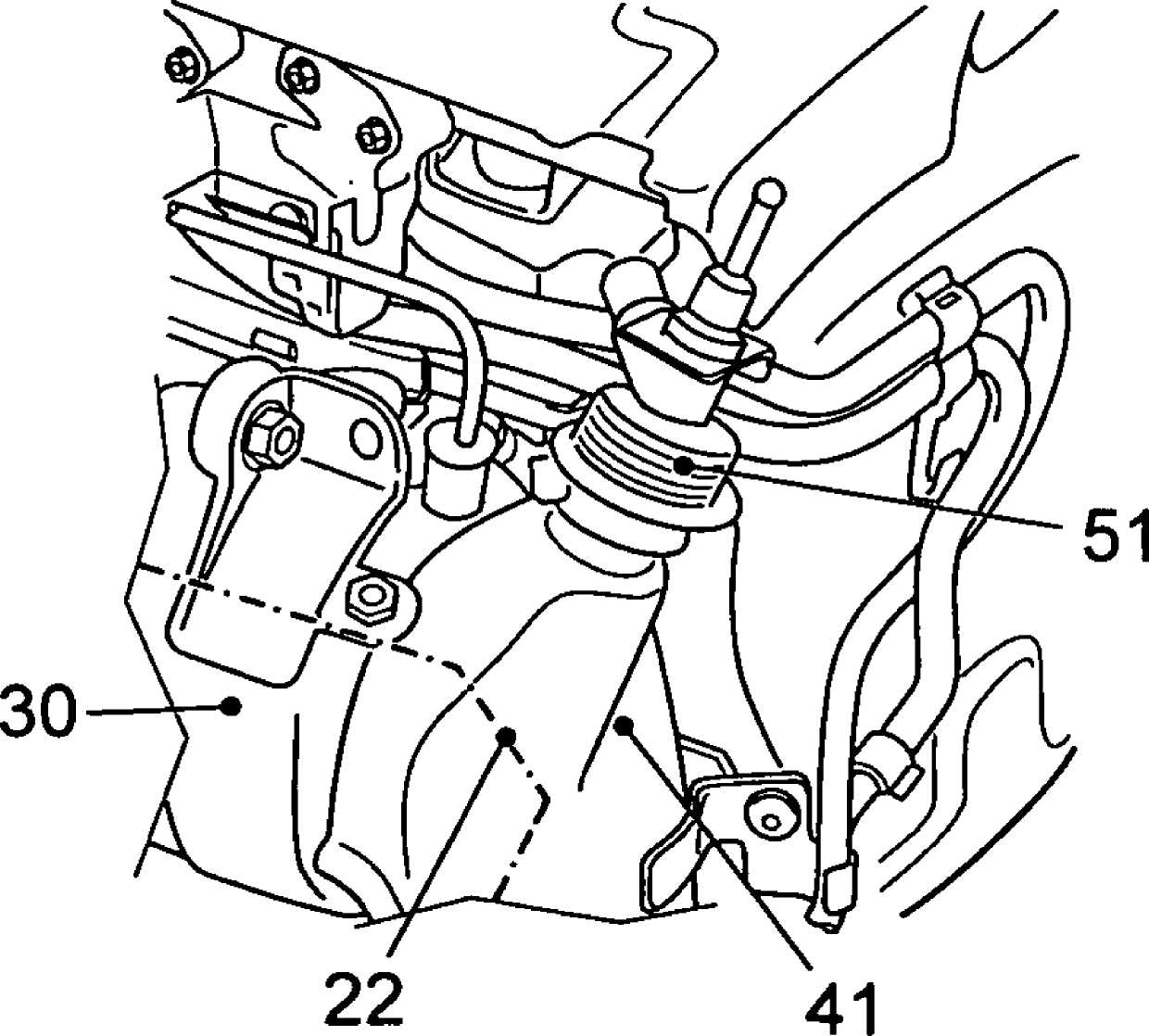

[0037] exist figure 1 A combustion device 10 can clearly be seen in the figure, on the exhaust system 20 of which the oxidation catalyst 30 is arranged on the connecting device 21, and downstream in the exhaust gas flow direction 23 in the exhaust gas system 20 shown in dotted lines The reduction catalytic converter 50 is arranged in the gas line 22 on the connecting module 40 or its housing 41 . The connecting module 40 leads to a particle filter 60 which is likewise arranged in the exhaust gas line 22 .

[0038] That is to say that reduction catalytic converter 50 is arranged on housing 41 of connecting module 40 between oxidation catalytic converter 30 and particle filter 60 .

[0039] In contrast to conventional embodiments, the reduction catalytic converter 50 is thus arranged in a very tight manner on the combustion system 10 or on the connecting device 21 so that the exhaust gas heat produced by the exothermic reaction in the combustion system 10 is used to convert Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com