Edge bonding belt special for grouting for high-speed railway II type track board

A track plate and edge banding technology, which is used in tracks, track laying, track maintenance, etc., can solve problems such as uneven exhaust, large workload, and complicated processes, and achieve good air permeability, sealing performance, and good sealing performance. and air permeability, the effect of overcoming construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

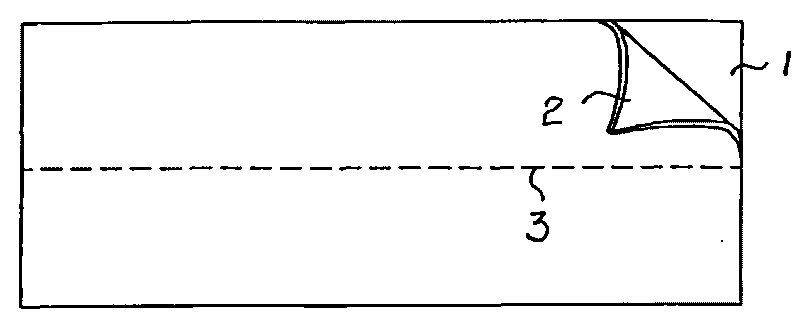

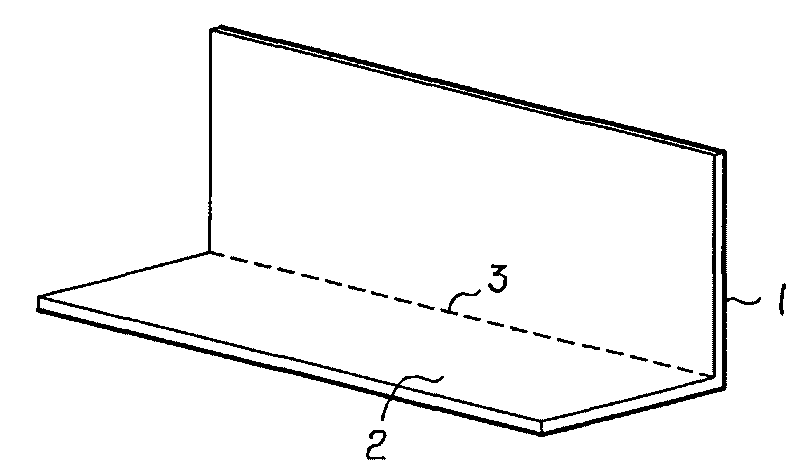

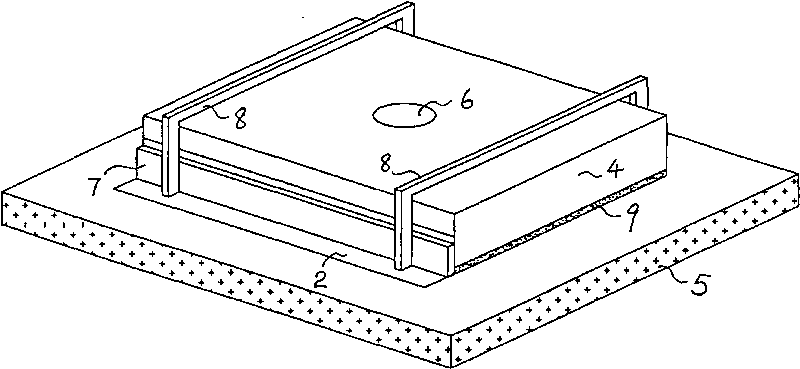

[0022] A special grouting edge band for high-speed rail type II track slabs, used to seal the mortar between the high-speed rail type II track slabs and the concrete base plate 5, which includes at least one layer of waterproof and breathable layer 1 on the inside and at least one layer on the outside The sealed air-permeable layer 2, the waterproof air-permeable layer 1 and the sealed air-permeable layer 2 are bonded together. The waterproof and air-permeable layer 1 is a soft thin layer with waterproof and air-permeable properties, and the sealed and air-permeable layer 2 is made of a soft material with a certain thickness and good air permeability.

[0023] The waterproof and breathable layer 1 is 30g / m2 in weight 2 -200g / m 2 spunbond fabric.

[0024] The sealing air-permeable layer 2 is a felt cloth with a thickness of 0.2 mm to 60 mm.

[0025] The spunbond cloth an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com