Curved glass moulding method and die adopted by the method

A curved glass and forming method technology, which is applied in glass forming, glass reshaping, and other household appliances, etc., can solve the problems of many surface defects, large roughness of concave curved surface and convex curved surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

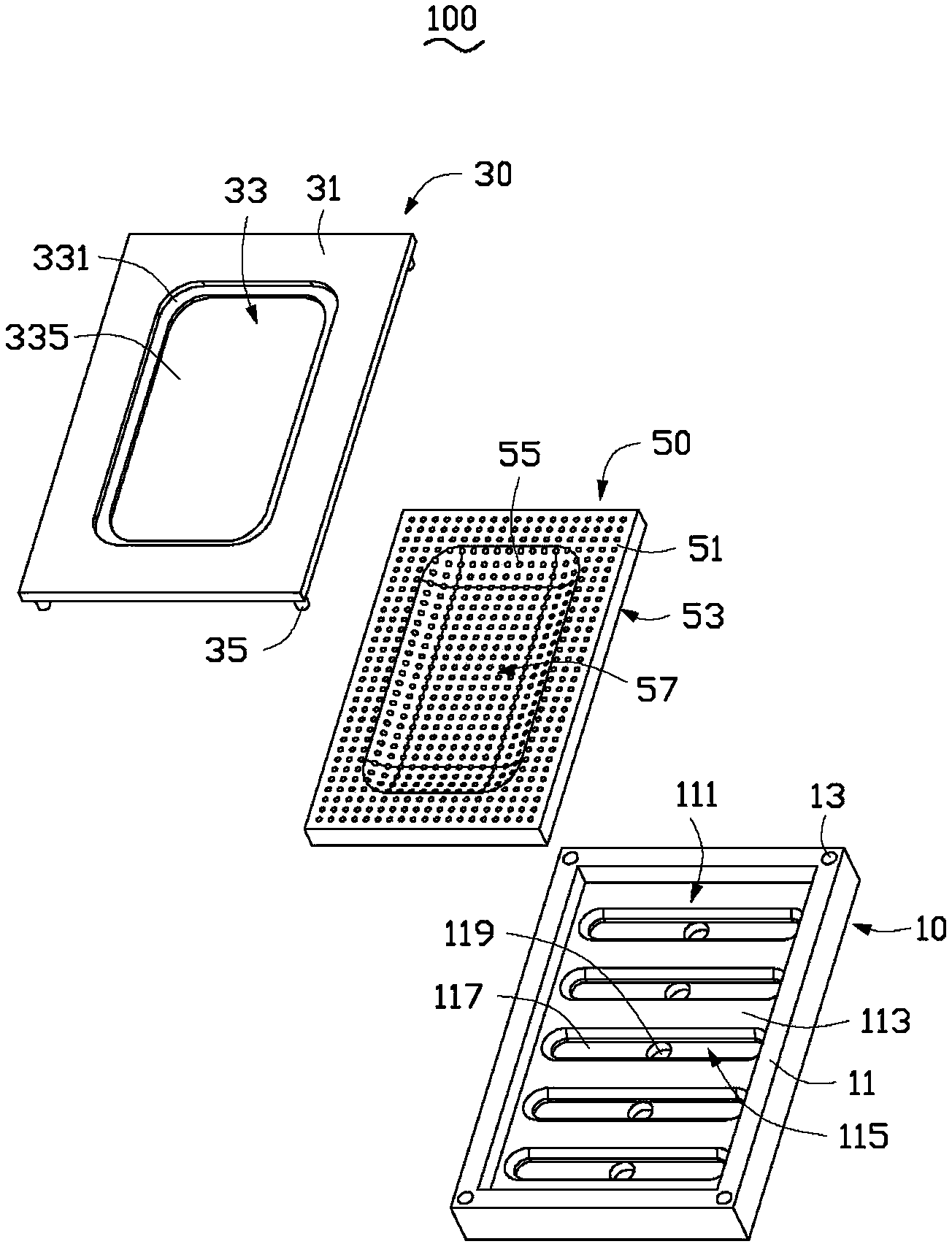

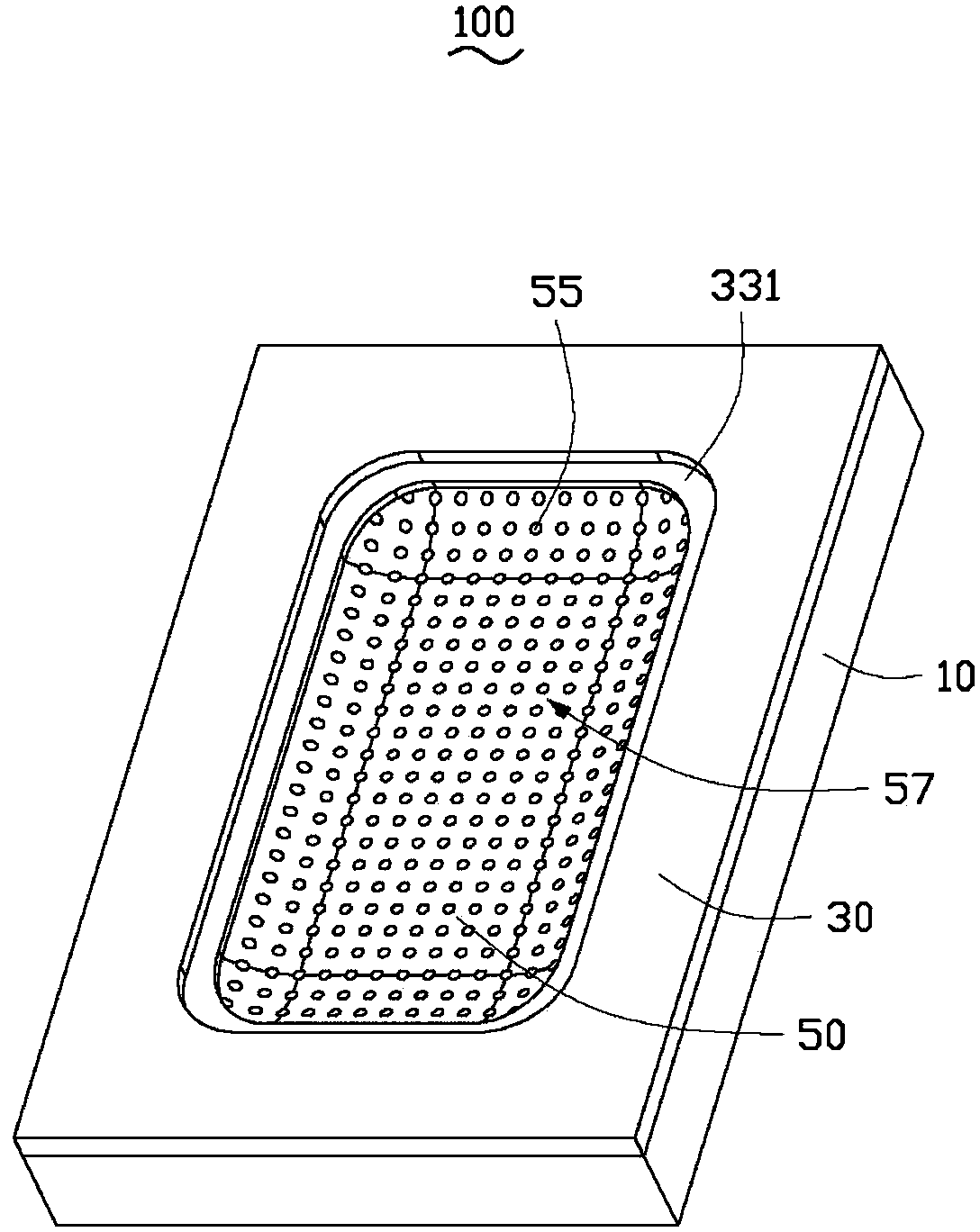

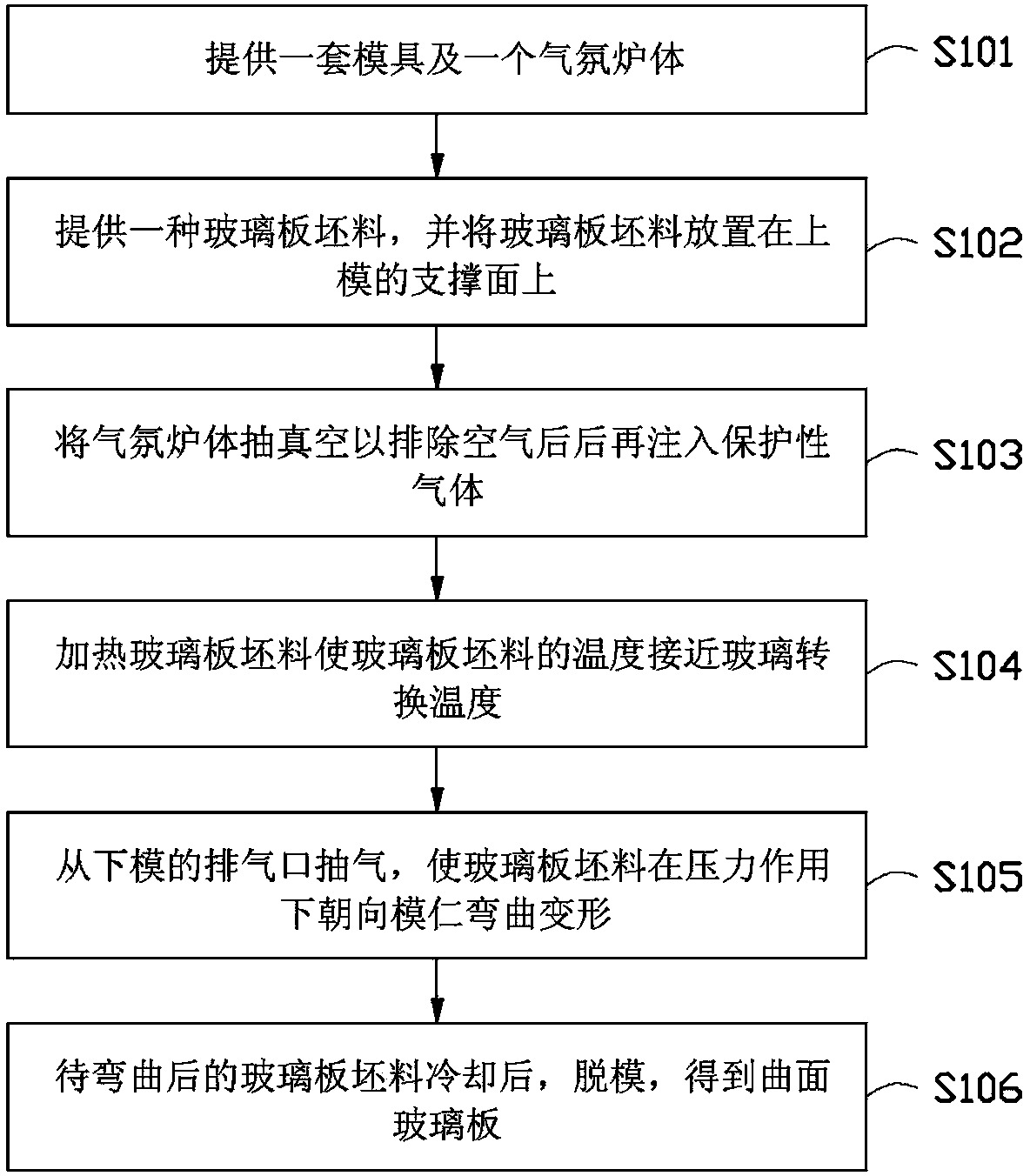

[0017] see figure 1 and figure 2 , in the curved glass forming method of the embodiment of the present invention, the glass plate blank 200 (such as Figure 4 ) shaped into curved glass 300 (eg Figure 6 ). The mold 100 includes a lower mold 10 , an upper mold 30 opposite to the lower mold 10 , and a mold core 50 disposed between the lower mold 10 and the upper mold 30 .

[0018] The lower mold 10 is roughly a cuboid and includes a mounting surface 11 close to the mold core 50 . The mounting surface 11 is recessed inward to form a receiving space 111 suitable for the mold core 50 to accommodate the mold core 50 . The lower mold 10 includes a bottom surface 113 for supporting the core 50 . The bottom surface 113 is recessed to form a plurality of diversion grooves 115 distributed at intervals. The bottom surface 117 of each diversion groove 115 is provided with an exhaust port 119 . The exhaust port 119 communicates with the receiving space 111 . In this embodiment, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com