Rubber base and manufacturing method thereof

A rubber bearing and rubber technology, which is applied in the direction of building components, shock absorbers, and shockproof, can solve the problems of prone to partial steel plates, poor support flatness, and easy to have partial plates on steel plates, etc., to achieve reliable process assurance, flatness, etc. Good degree and uniform exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

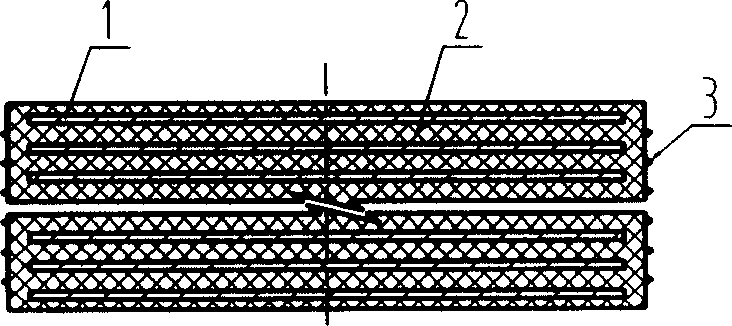

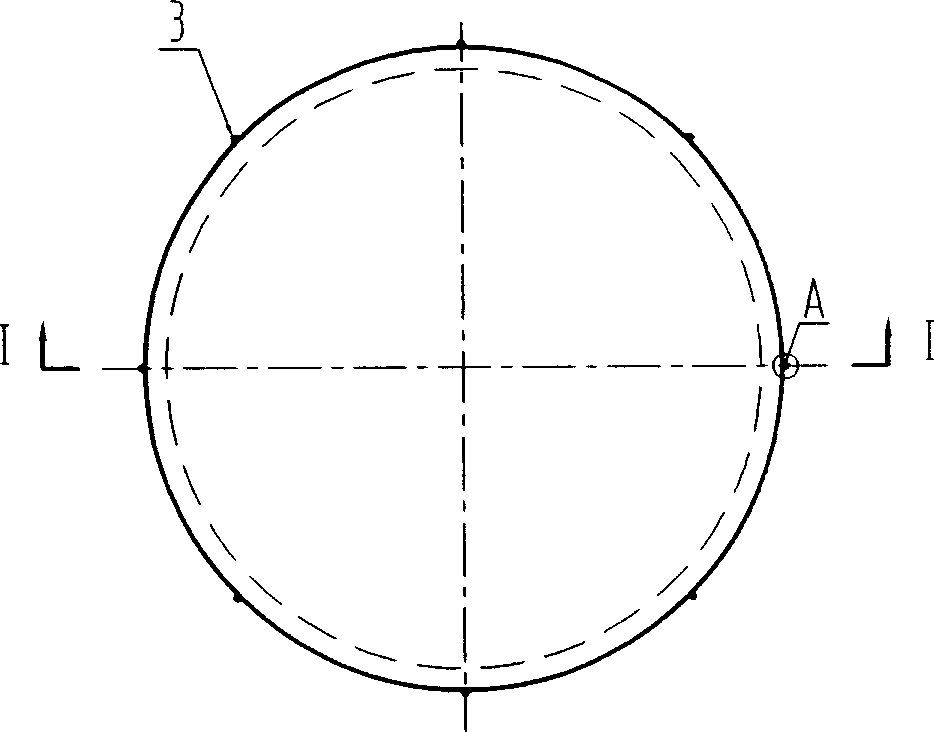

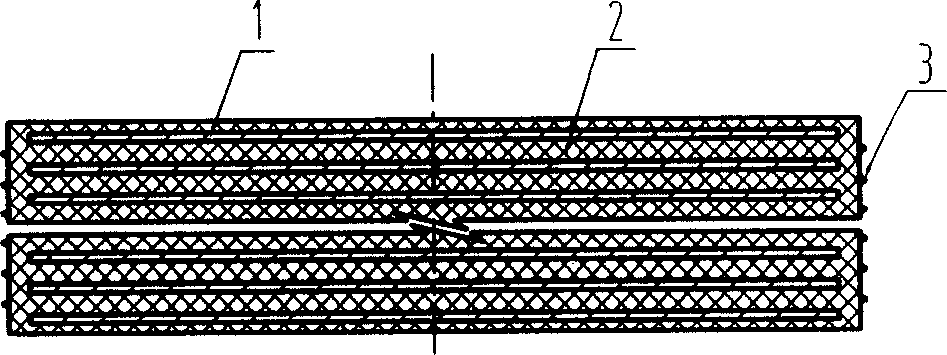

[0038] Embodiment 1: A cylindrical rubber bearing, which is a cylinder-shaped bearing formed by sequentially laminating M layers of rubber and M-1 layers of stiffened steel plates and vulcanized, including stiffened steel plates 1, elastic rubber vulcanized into one Body 2, there is a protective rubber layer on the side of the support, and there are N evenly distributed small protrusions 3 on the surface of the protective rubber layer on the longitudinal side of the support. The shape of the small protrusions 3 is a combination of a hemisphere and a cylinder Body shape (referring to Fig. 9), its maximum diameter is 0.1~10mm, length is 1~100mm, the value range of M, N is: M=2~10, N=10~200.

[0039] As a transformation of Embodiment 1 of the present invention, the shape of the rubber support can also be a cuboid or a cube (see image 3 , Figure 4 ), the shape of the small protrusion on it also can be the combination shape (referring to Fig. 10) of conical body and cylinder.

Embodiment 2

[0040] Embodiment two: a kind of square rubber bearing (referring to Figure 5 , Figure 6 ), which is a square support formed by vulcanizing successive lamination of M layer rubber, M-1 layer stiffening steel plate and connecting steel plates on the upper and lower bottom surfaces, including stiffening steel plate 1 and elastic rubber body 2 vulcanized into one, located on the upper , the upper and lower connecting steel plates 5 on the lower bottom surface 1 , there are 4 through holes in the middle of the support, and there are 4 high-purity lead cores in the holes. 1 , there are protective rubber layers on the four longitudinal sides of the support, and there are N evenly distributed small protrusions 3 on the surface of the protective rubber layer on the longitudinal sides of the support. The maximum diameter is 0.1-10mm, the length is 1-100mm, and the value ranges of M and N are: M=2-10, N=10-200.

Embodiment 3

[0041] Embodiment three: a kind of square rubber bearing (referring to Figure 7 , Figure 8 ), which is a cube support formed by sequentially laminating and vulcanizing the M layer of rubber, the M-1 layer of stiffening steel plate and the connecting steel plates on the upper and lower bottom surfaces, including the stiffening steel plate 1 and the elastic rubber body 2 vulcanized into one, located on the upper and lower The upper and lower connecting steel plates 5 on the lower bottom surface 2 , there is a through hole in the middle of the support, and a high-purity lead core 4 is placed in the hole 2 There are protective rubber layers on the four longitudinal sides of the support, and there are N evenly distributed small protrusions 3 on the surface of the protective rubber layer on the longitudinal sides of the support. The shape of the small protrusions 3 is cylindrical (see Figure 17), The maximum diameter is 0.1-10mm, the length is 1-100mm, and the value ranges of M ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com