Forming method of metal grid electrode

A technology of metal gate and gate, which is applied in the field of formation of metal gate, can solve problems such as the failure of metal gate to work normally and poor performance of metal gate, so as to avoid poor alignment accuracy, prevent height reduction, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The performance of the metal grid formed by the method of the prior art is not good. In severe cases, the reasons why the metal grid cannot work normally are as follows:

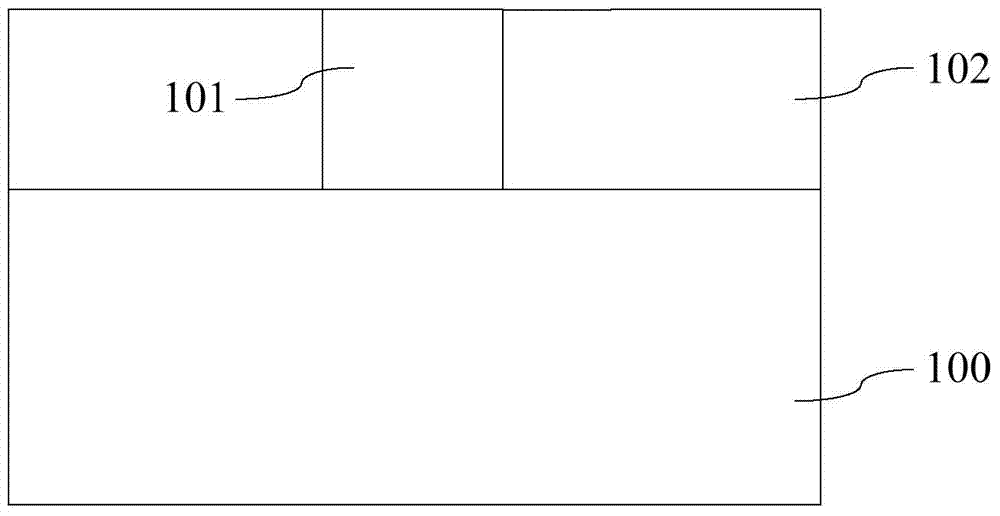

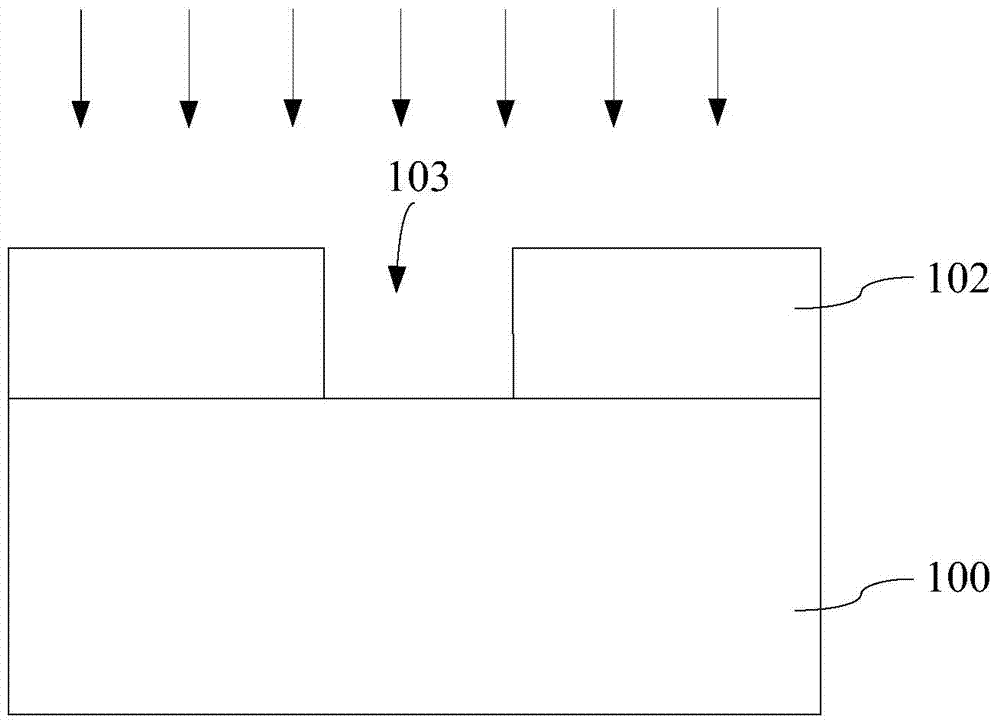

[0044] refer to figure 2 , the dummy gate 101 is removed by etching (refer to figure 1 ), even if the etching selection ratio between the silicon oxide layer 102 and the dummy gate 101 is very different, it will cause the loss of the silicon oxide layer 102, so that the thickness of the silicon oxide layer 102 is reduced, and the gate The depth of the pole groove 103 is also reduced.

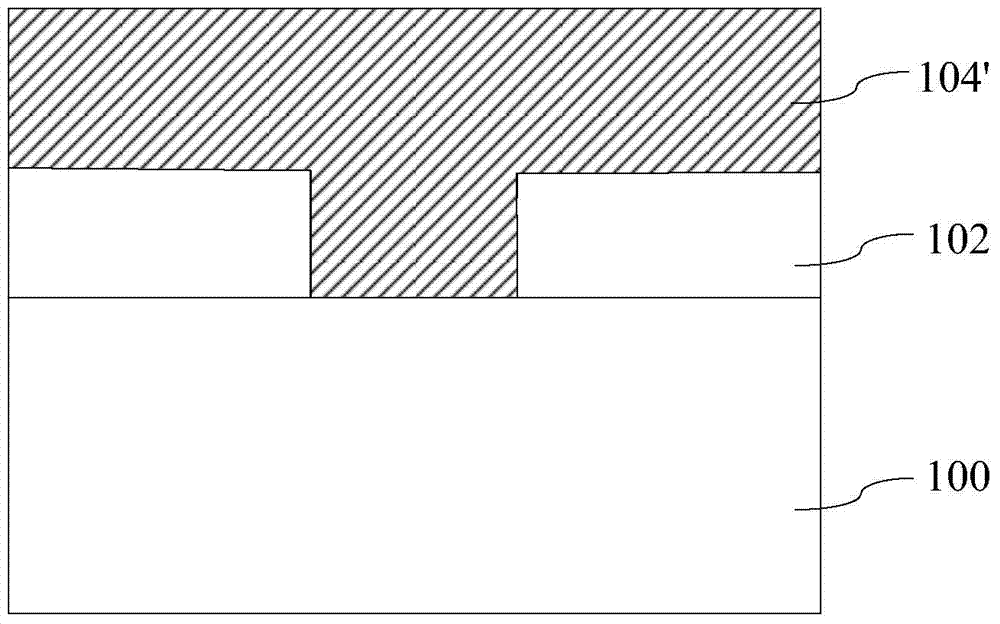

[0045] refer to Figure 4 , using the method of chemical mechanical grinding, so that the aluminum material layer 104' (refer to image 3 ) is equal to the top of the silicon oxide layer 102, limited by the conditions of the chemical grinding equipment, in order to ensure that no aluminum material remains on the surface of the silicon oxide layer 102, more silicon oxide layer 102 will be ground, so that the height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com