Separated gate type memory embedded into logic circuit and manufacturing method of memory group

A technology of separating gates and manufacturing methods, which is applied in the manufacture of circuits, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve problems such as memory operating speed signal transmission bandwidth limitations, and achieve increased density, small integrated chips, and high operating speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

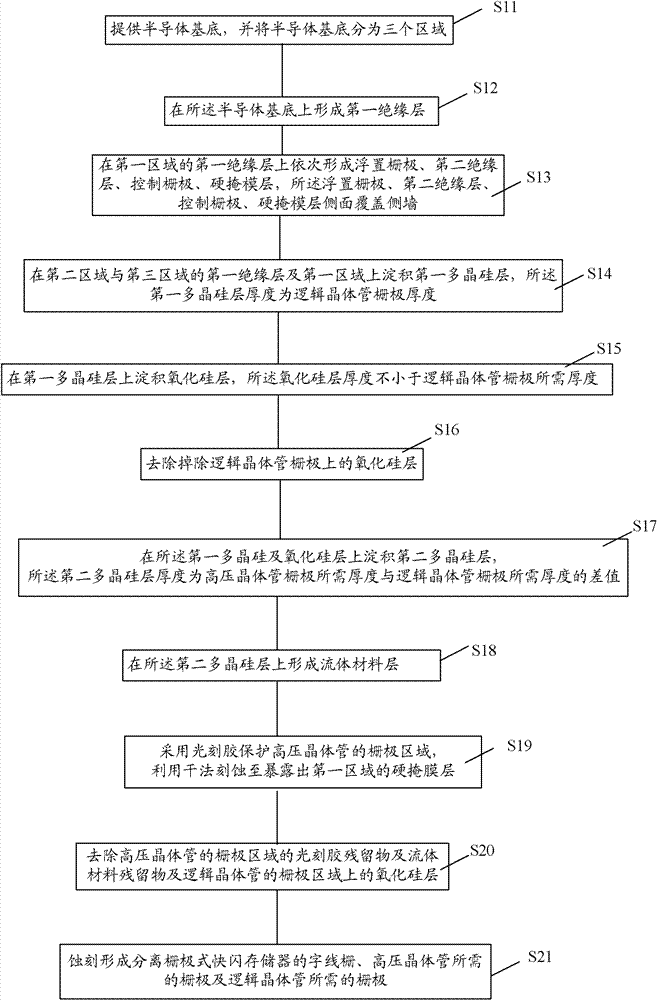

[0082] Figure 15 Shown is a flow chart of a manufacturing method of a split-gate flash memory group embedded with logic circuits according to the second embodiment of the present invention. The group of split-gate flash memories with embedded logic circuits includes a pair of split-gate flash memories with embedded logic circuits of the same size, and each pair of split-gate flash memories with embedded logic circuits includes: Split gate flash memory, high voltage transistors, logic transistors. The fabrication method below takes a pair of split-gate flash memories embedded with logic circuits as an example. Same as the first embodiment, the split-gate flash memory with erase gate and word line gate is still taken as an example.

[0083] Step S11' is executed to provide a semiconductor substrate 11', which includes six regions for forming a pair of identical split-gate flash memories embedded with logic circuits, such as Figure 16 As shown, the six regions are specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com