Lithium supplementing diaphragm of lithium ion battery

A lithium-ion battery and lithium-replenishing technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as actual capacity attenuation, etching of negative electrode active layers, etc., to improve efficiency, avoid side reactions, and reduce production. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

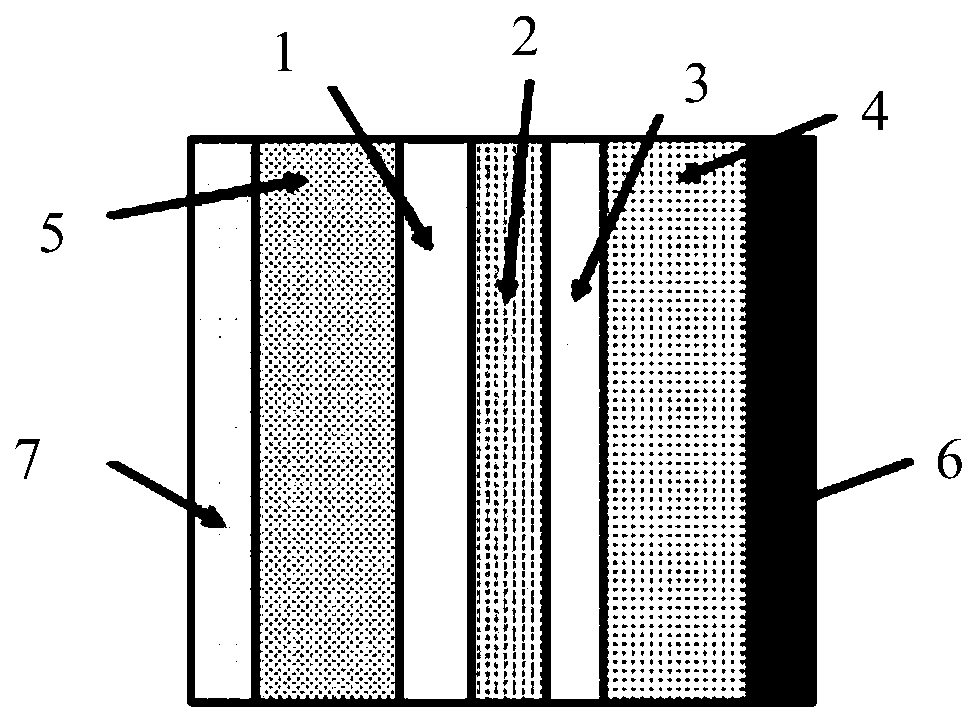

[0037] A lithium-replenishing diaphragm for a lithium-ion battery, the lithium-replenishing diaphragm includes a plurality of mutually superimposed diaphragm layers, a metal lithium layer is provided on the diaphragm layer, and a protective layer is also provided above the metal lithium layer .

[0038] The diaphragm layer is a single-layer polypropylene diaphragm with a thickness of 20 μm. The protective layer is LiPON with a thickness of 10nm. The thickness of the metallic lithium layer was 3 μm.

[0039] The preparation method of described lithium supplement diaphragm, comprises the steps:

[0040] (1) Place the diaphragm layer in the vacuum chamber, the horizontal distance between the evaporation lithium source and the diaphragm layer is 40cm, and vacuumize until the vacuum degree of the chamber reaches 3*10 -4Below Pa, turn on the cooling water circulation system to ensure that the temperature of the diaphragm layer is controlled at 20-30°C. The physical form of the ev...

Embodiment 2

[0045] A lithium-replenishing diaphragm for a lithium-ion battery, the lithium-replenishing diaphragm includes a plurality of mutually superimposed diaphragm layers, a metal lithium layer is provided on the diaphragm layer, and a protective layer is also provided above the metal lithium layer .

[0046] The diaphragm layer is a single-layer polypropylene diaphragm with a thickness of 20 μm. The protective layer is made of Al with a thickness of 10nm. The thickness of the metallic lithium layer was 3 μm.

[0047] The preparation method of described lithium supplement diaphragm, comprises the steps:

[0048] (1) Place the diaphragm layer in the vacuum chamber, the horizontal distance between the evaporation lithium source and the diaphragm layer is 40cm, and vacuumize until the vacuum degree of the chamber reaches 3*10 -4 Below Pa, and turn on the cooling water circulation system to ensure that the temperature of the diaphragm layer is controlled at 20-30°C. The physical form...

Embodiment 3

[0051] A lithium-replenishing diaphragm for a lithium-ion battery, the lithium-replenishing diaphragm includes a plurality of mutually superimposed diaphragm layers, a metal lithium layer is provided on the diaphragm layer, and a protective layer is also provided above the metal lithium layer .

[0052] The separator layer is a single-layer PP coated with alumina, with a thickness of 40 μm. The protective layer is LiPON with a thickness of 10nm. The thickness of the metallic lithium layer was 3 μm.

[0053] The preparation method of described lithium supplement diaphragm, comprises the steps:

[0054] (1) Place the diaphragm layer in the vacuum chamber, the horizontal distance between the evaporation lithium source and the diaphragm layer is 30cm, and vacuumize until the vacuum degree of the chamber reaches 3*10 -4 Below Pa, and turn on the cooling water circulation system to ensure that the temperature of the diaphragm layer is controlled at 20-30°C. The physical form of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com