Patents

Literature

134results about How to "Precise pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

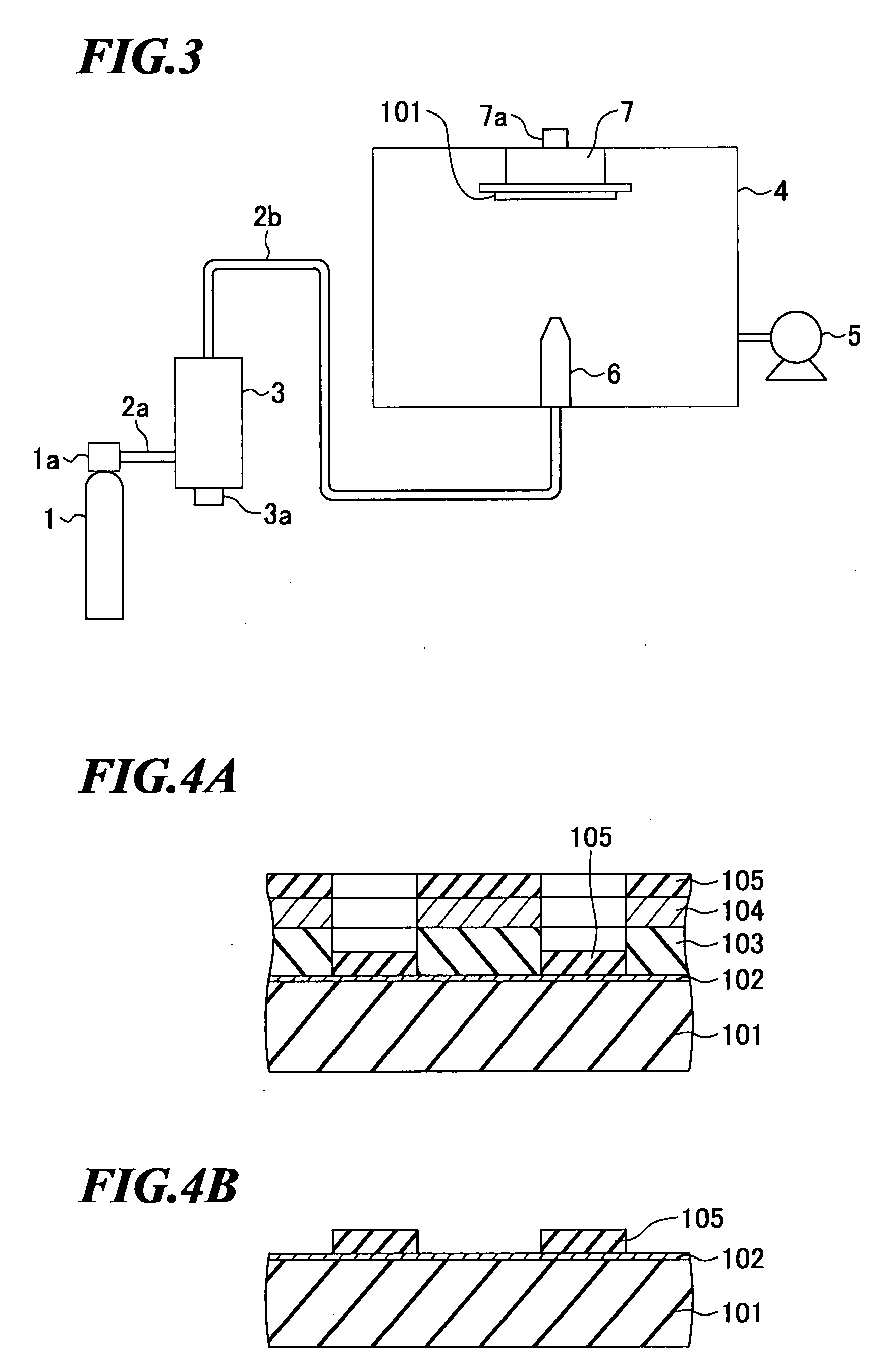

Method and system for the localized deposit of metal on a surface

ActiveUS20170226636A1Desired patternPrecise patternPolycrystalline material growthSemiconductor/solid-state device manufacturingControl mannerCrystal growth

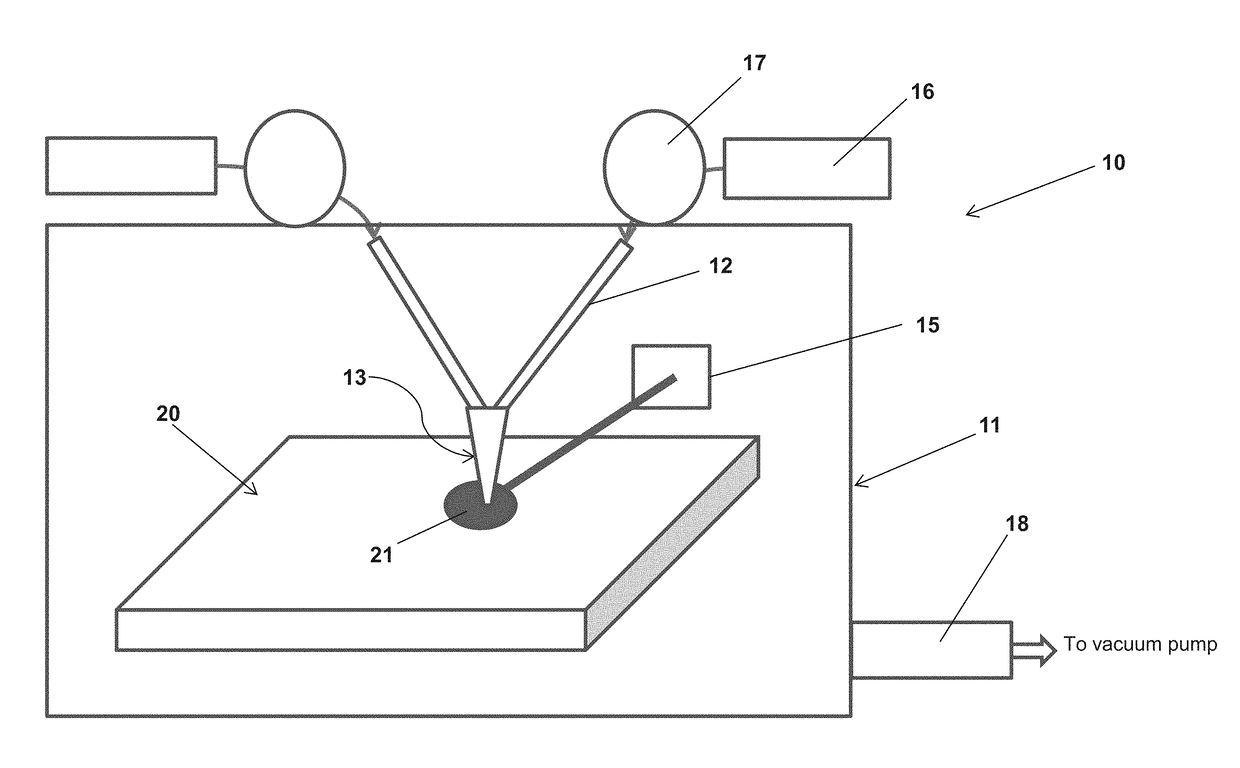

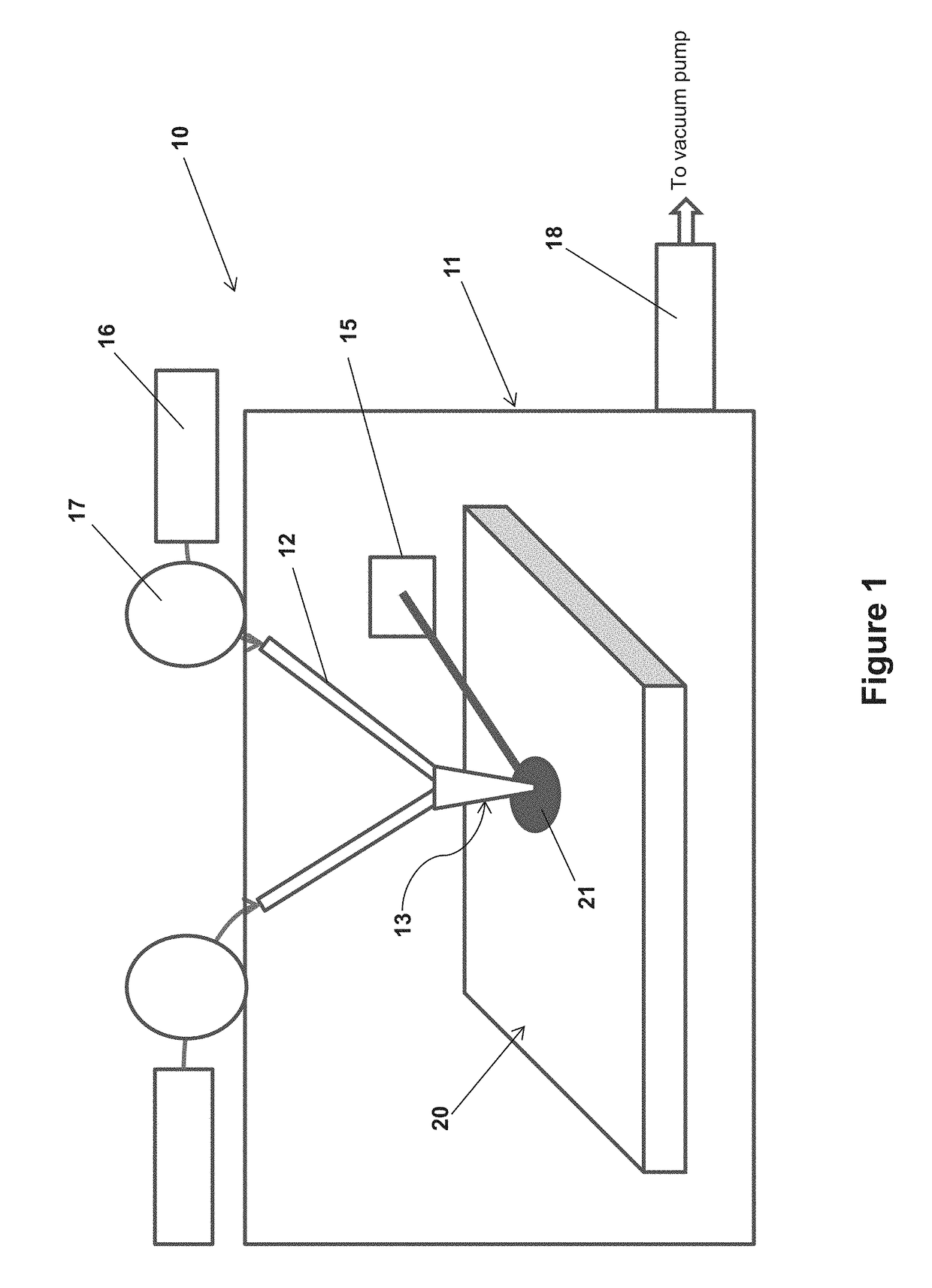

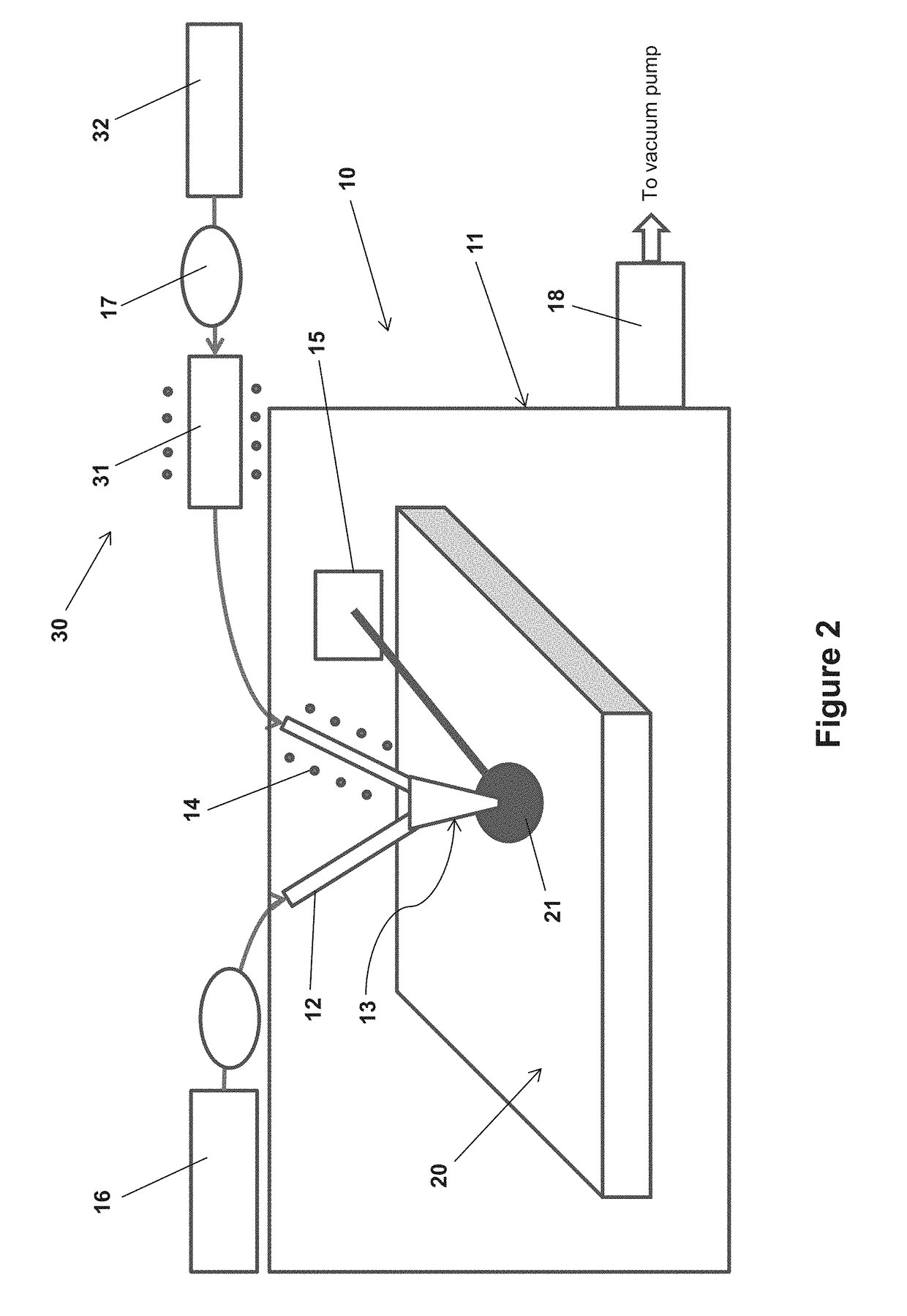

The present disclosure is directed to a method and system for the localized deposition of a metal layer on a surface. The method involves introducing at least two gaseous reactants to a substrate surface that is locally heated by a laser. The surface is heated to a temperature at which the gaseous reactants undergo a reaction that results in metal crystal growth on the substrate surface. The reaction is maintained for a desired period of time and under desired conditions to produce a localized deposit of a metal layer on the heated zone of the substrate. In some embodiments, the gas outlets and the laser may be moved in a controlled manner so that a metal layer may be deposited in a desired pattern on the substrate surface.

Owner:ILLINOIS TOOL WORKS INC

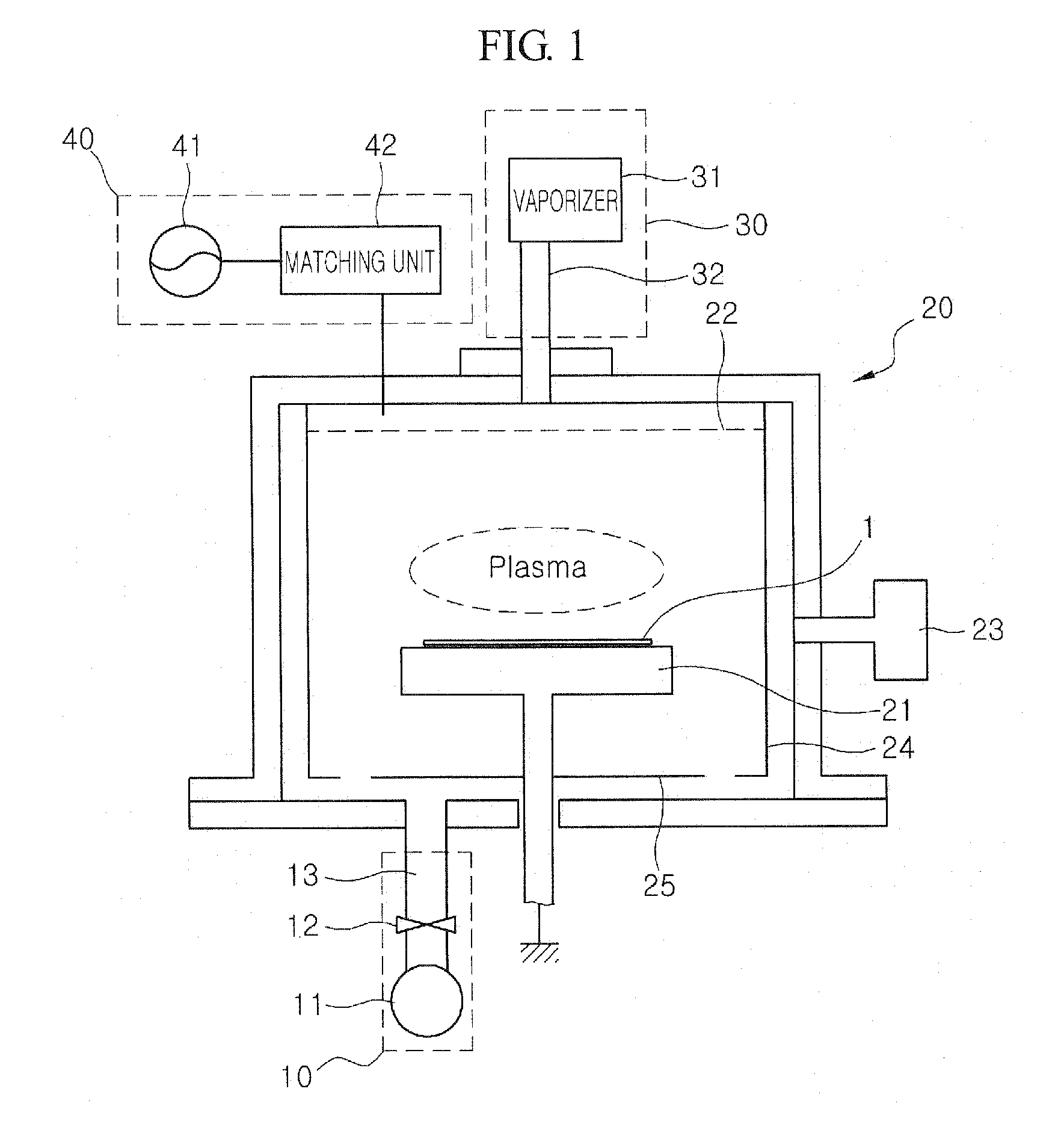

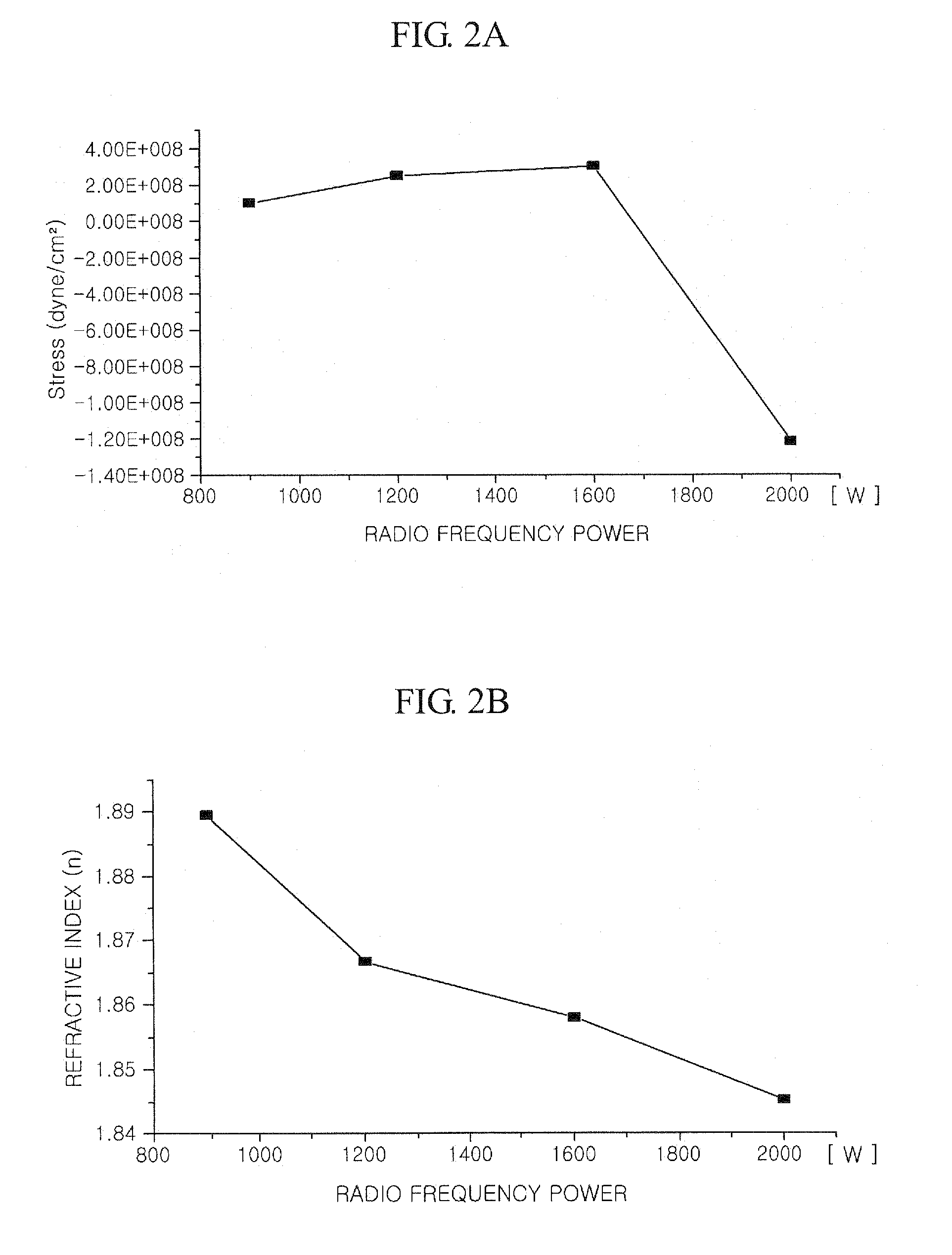

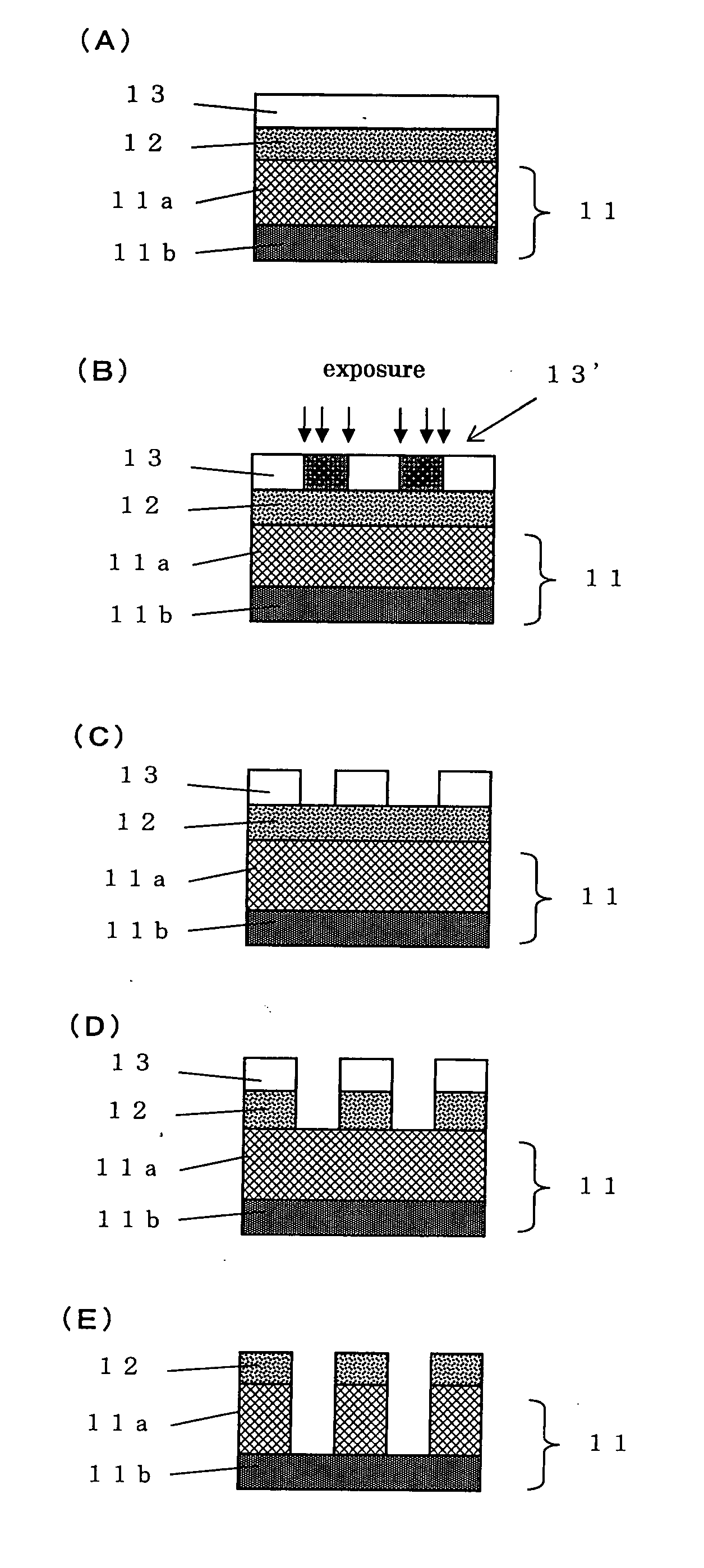

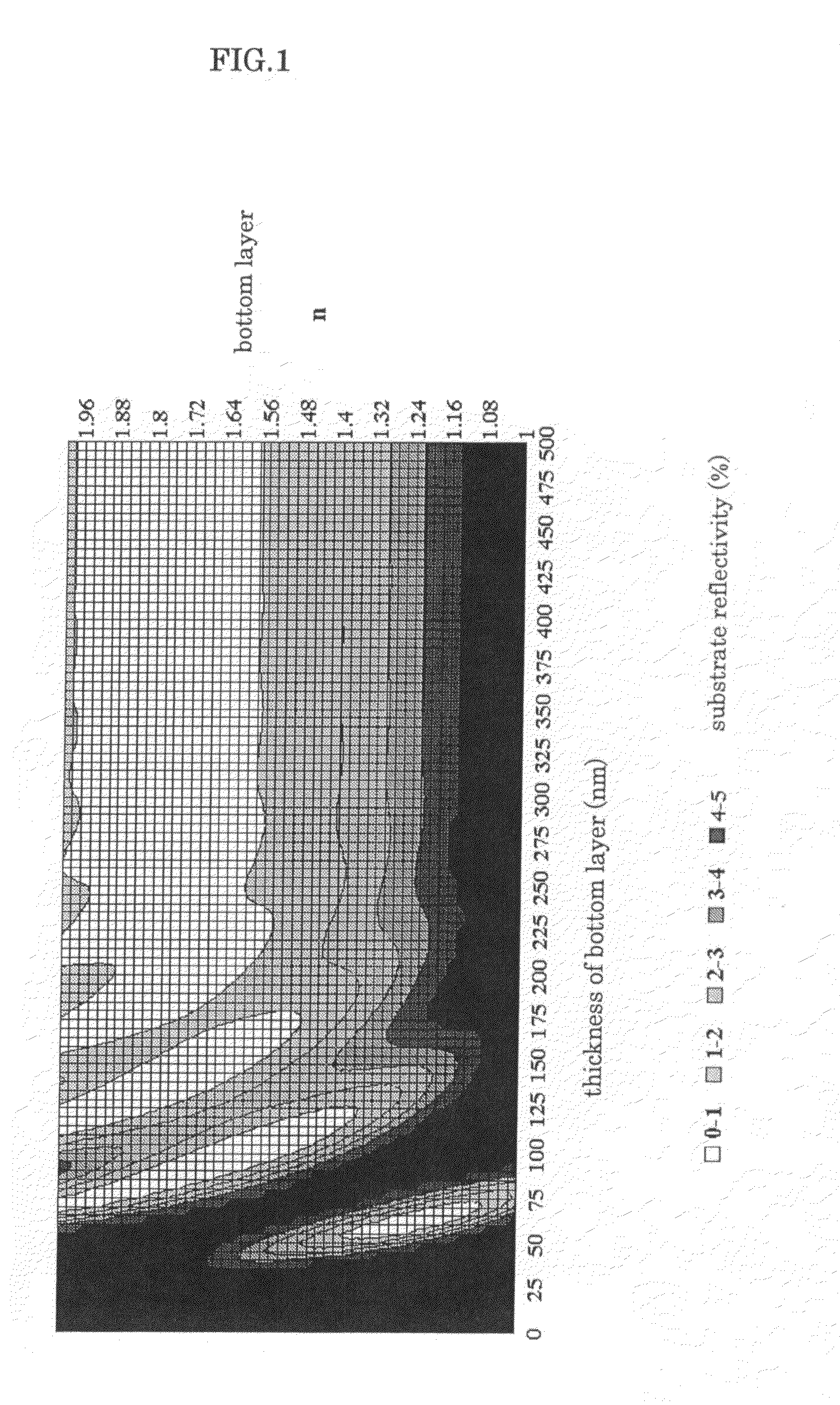

Method of forming amorphous carbon film and method of manufacturing semiconductor device using the same

InactiveUS20080293248A1Better controllableLight absorption coefficient is lowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRefractive indexDiffuse reflection

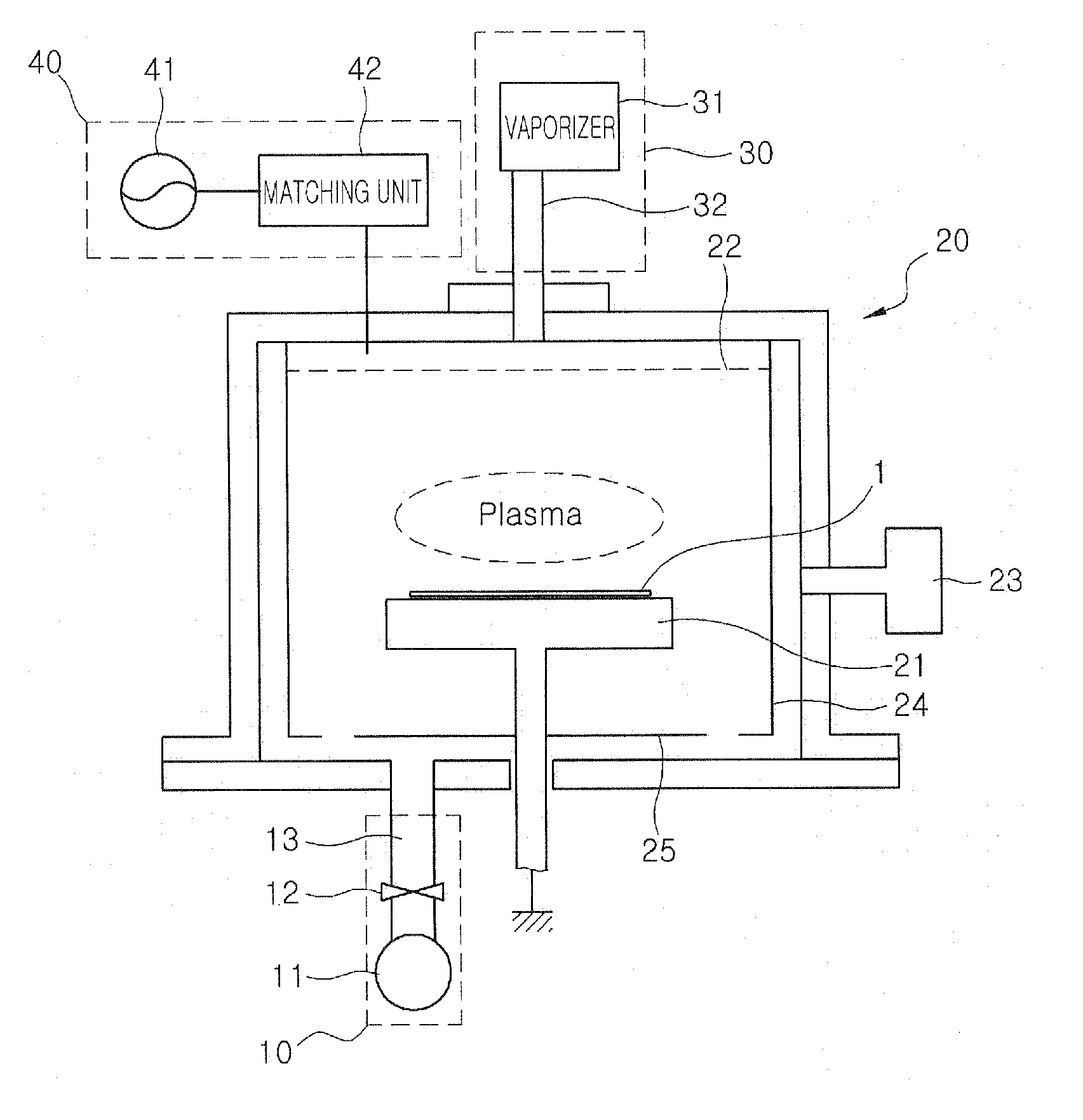

The present invention relates to a method of forming an amorphous carbon film and a method of manufacturing a semiconductor device using the method. An amorphous carbon film is formed on a substrate by vaporizing a liquid hydrocarbon compound, which has chain structure and one double bond, and supplying the compound to a chamber, and ionizing the compound. The amorphous carbon film is used as a hard mask film.It is possible to easily control characteristics of the amorphous carbon film, such as a deposition rate, an etching selectivity, a refractive index (n), a light absorption coefficient (k) and stress, so as to satisfy user's requirements. In particular, it is possible to lower the refractive index (n) and the light absorption coefficient (k). As a result, it is possible to perform a photolithography process without an antireflection film that prevents the diffuse reflection of a lower material layer.Further, a small amount of reaction by-product is generated during a deposition process, and it is possible to easily remove reaction by-products that are attached on the inner wall of a chamber. For this reason, it is possible to increase a cycle of a process for cleaning a chamber, and to increase parts changing cycles of a chamber. As a result, it is possible to save time and cost.

Owner:TES CO LTD

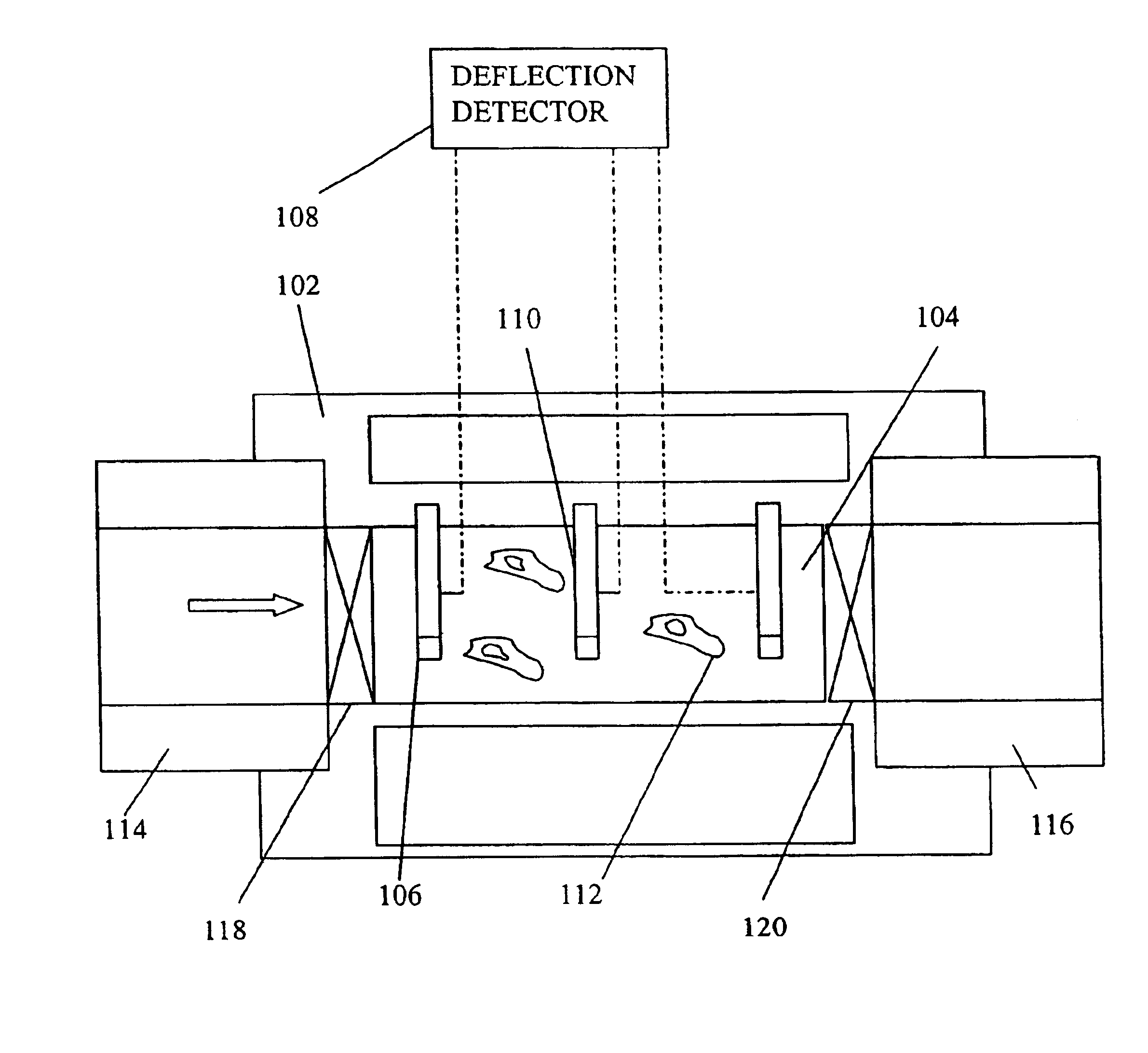

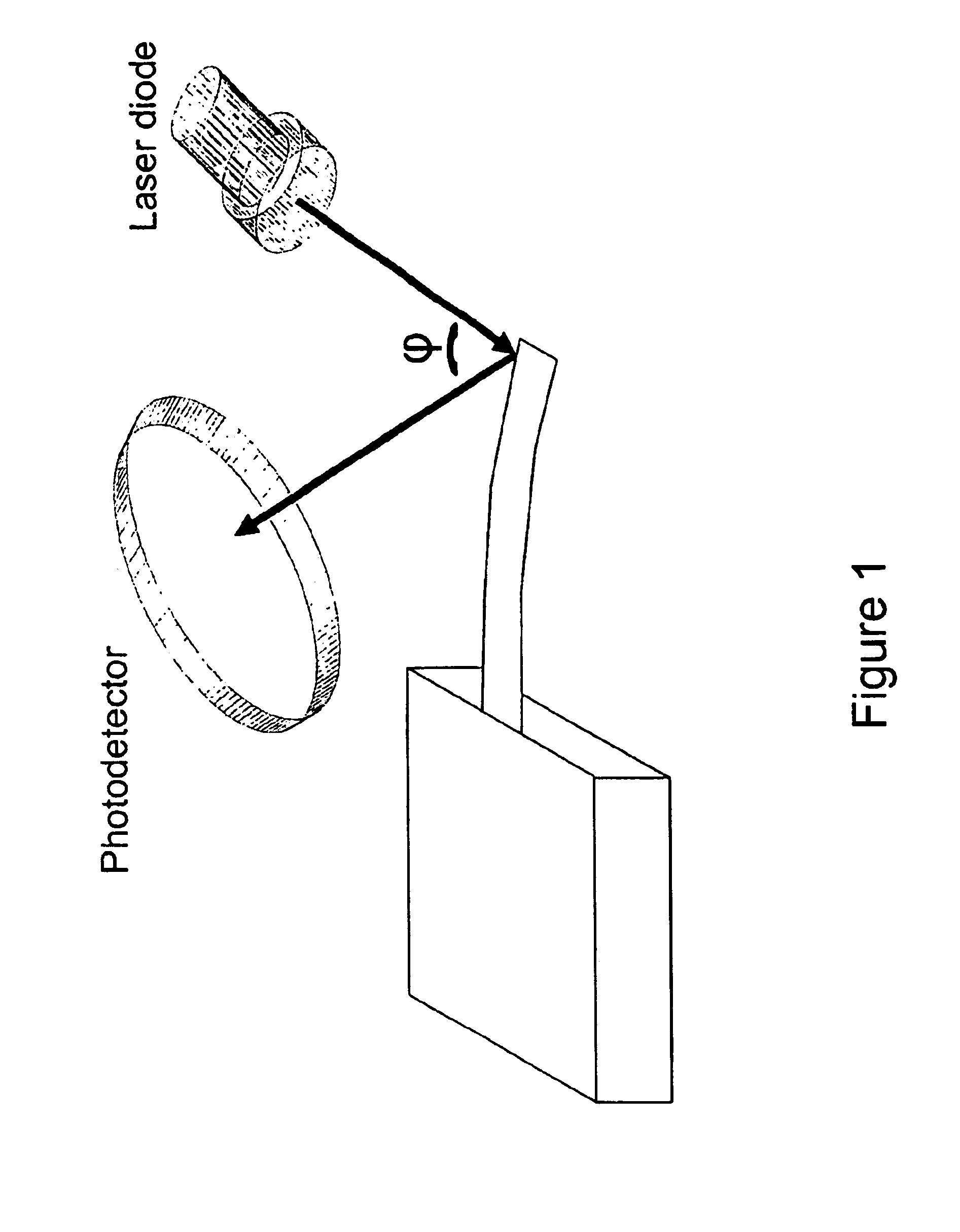

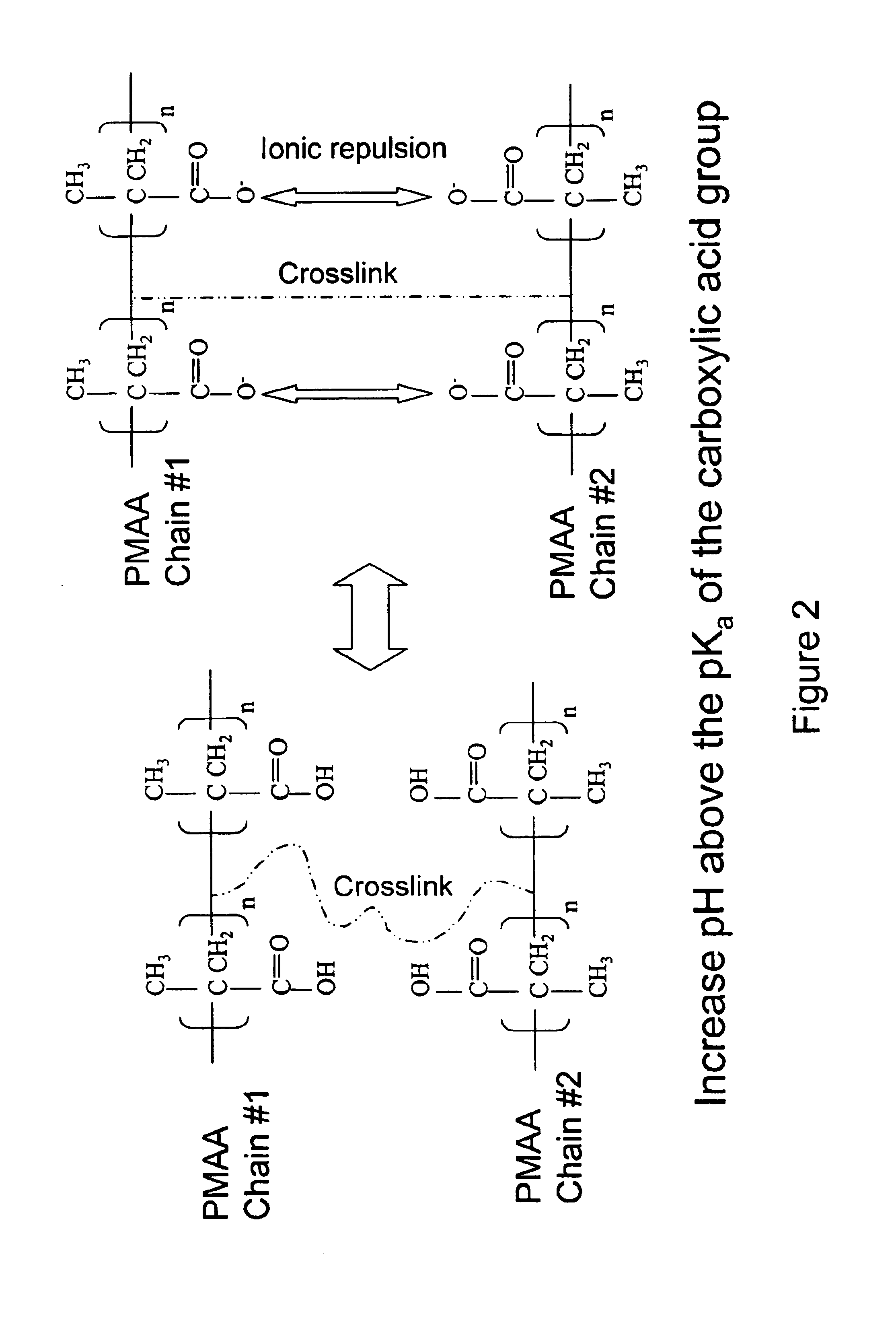

Microscale sensor element and related device and method of use

InactiveUS6935165B2Simple integrationFacilitate creationMaterial nanotechnologyMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringPolymer

A monitoring apparatus useful in detecting viability of biological cells. A substrate defines a microscopic chamber. One or more microcantilevers extend from the substrate into the chamber. A detector is operatively connected to the microcantilevers for sensing a state of deformation thereof. On each microcantilevers is deposited a layer of an environmentally sensitive hydrogel polymer having a configuration changing in accordance with presence of an environmental parameter.

Owner:PURDUE RES FOUND INC

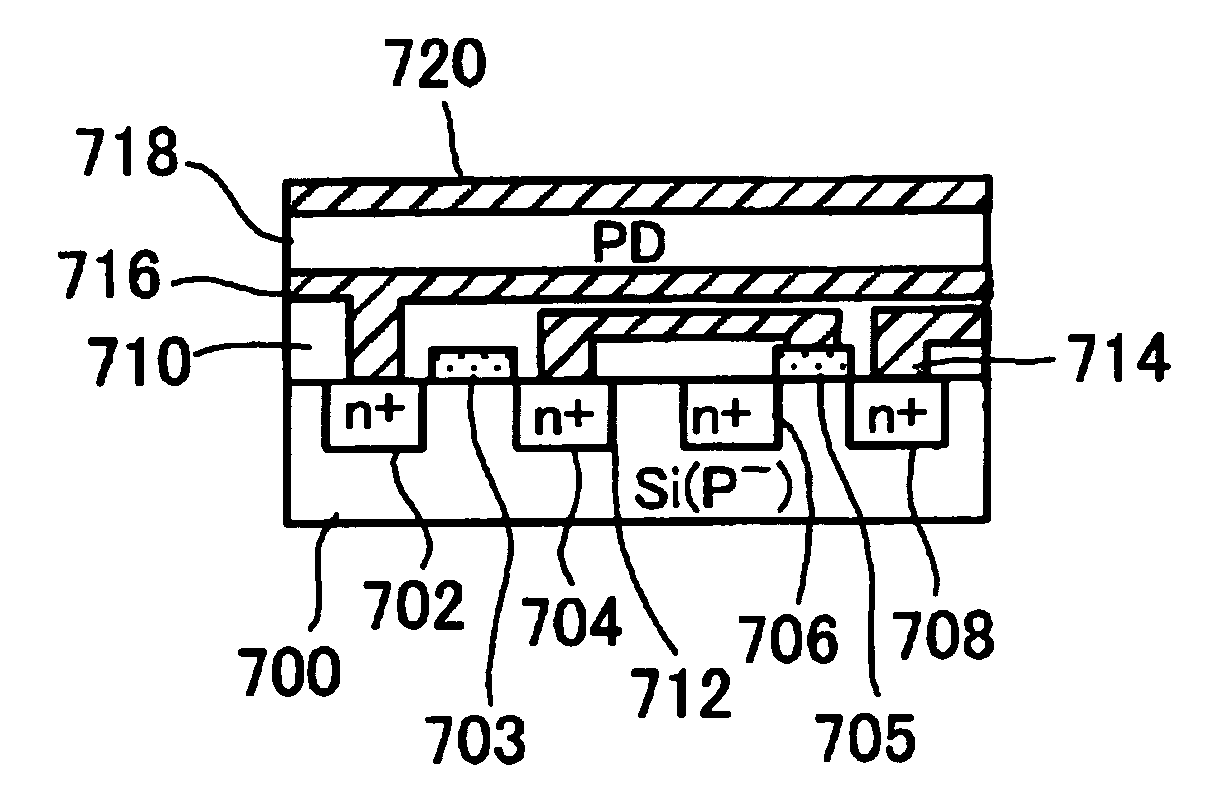

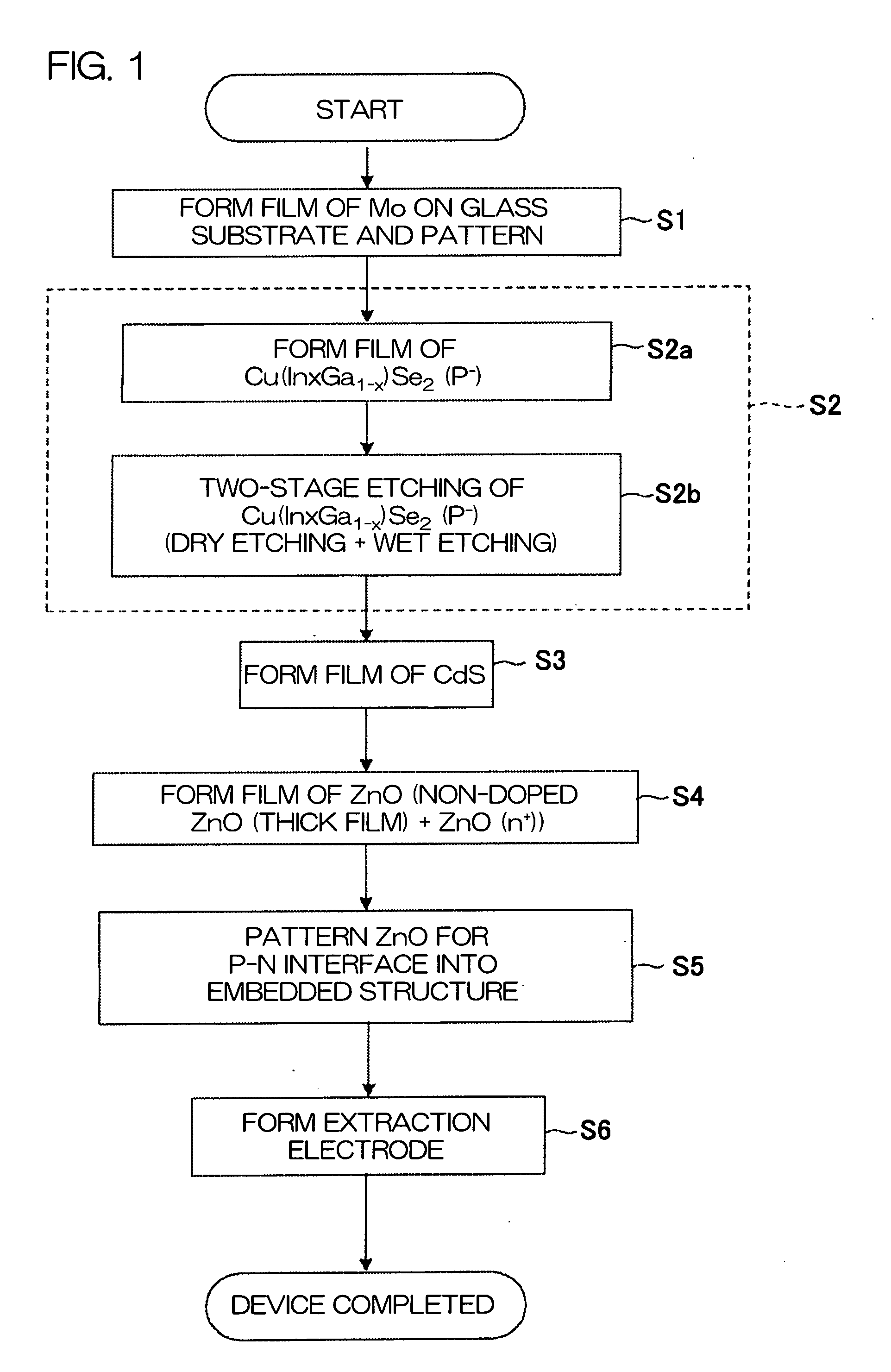

Method for Manufacturing Photoelectric Converter and Photoelectric Converter

InactiveUS20090217969A1Reduce currentPrecise patternFinal product manufactureSolid-state devicesPhotolithographyPhotoelectric conversion

Disclosed is a method for manufacturing a photoelectric converter wherein a lower electrode layer, a compound semiconductor thin film having a chalcopyrite structure which serves as a light absorptive layer and a light-transmitting electrode layer that are laminated to form layers are each patterned by photolithography, thereby minimizing damages to the crystals of the compound semiconductor thin film.

Owner:ROHM CO LTD

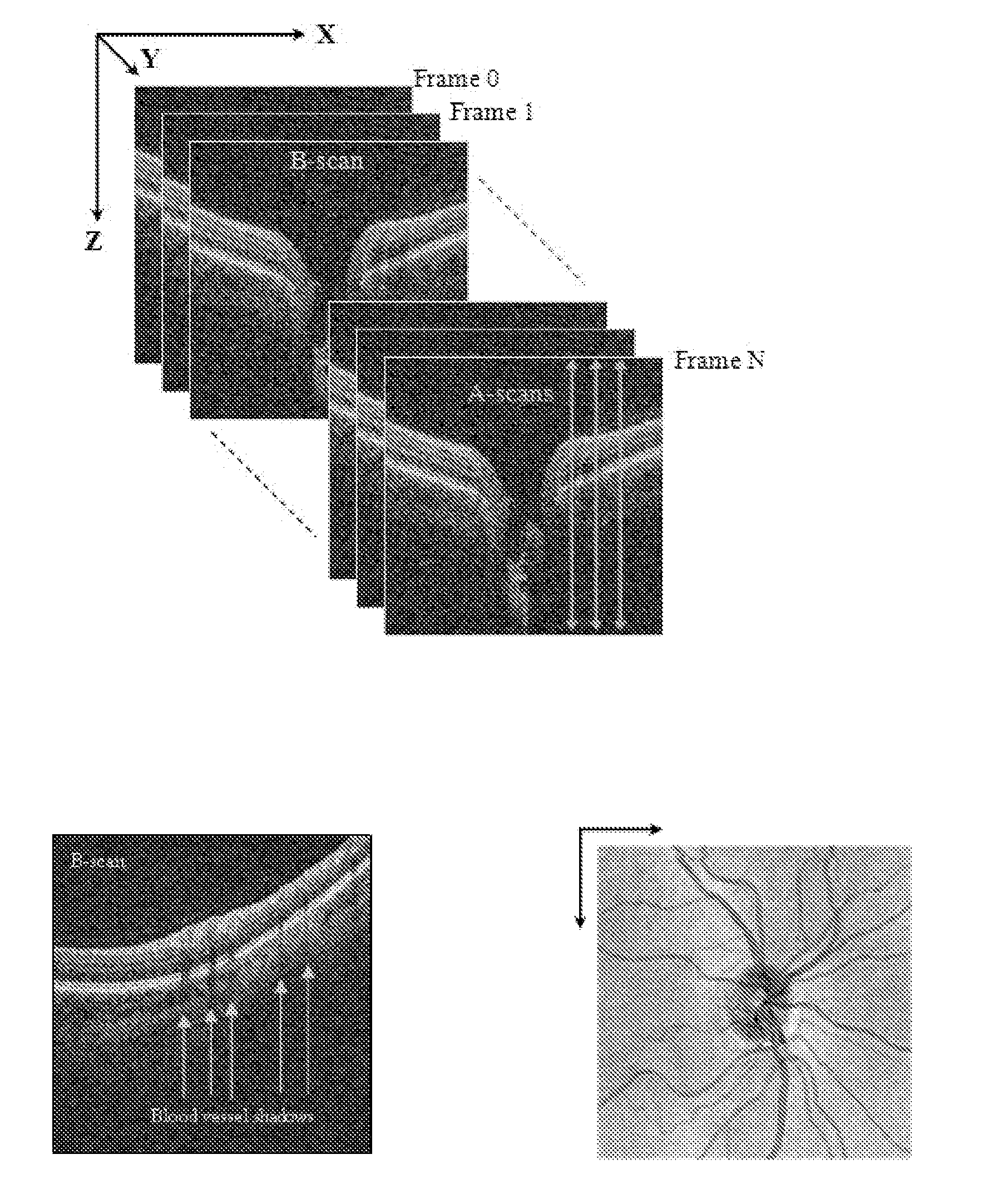

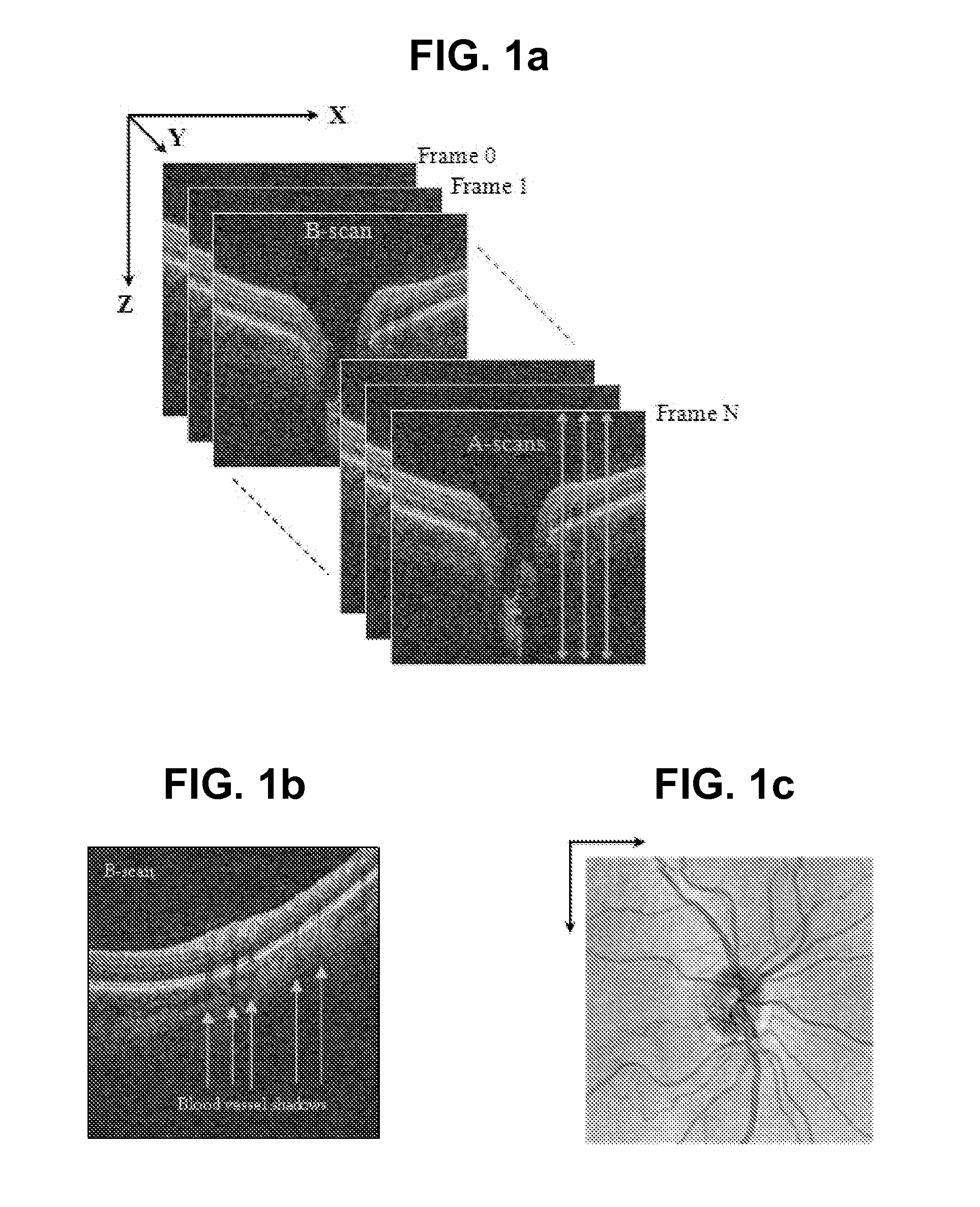

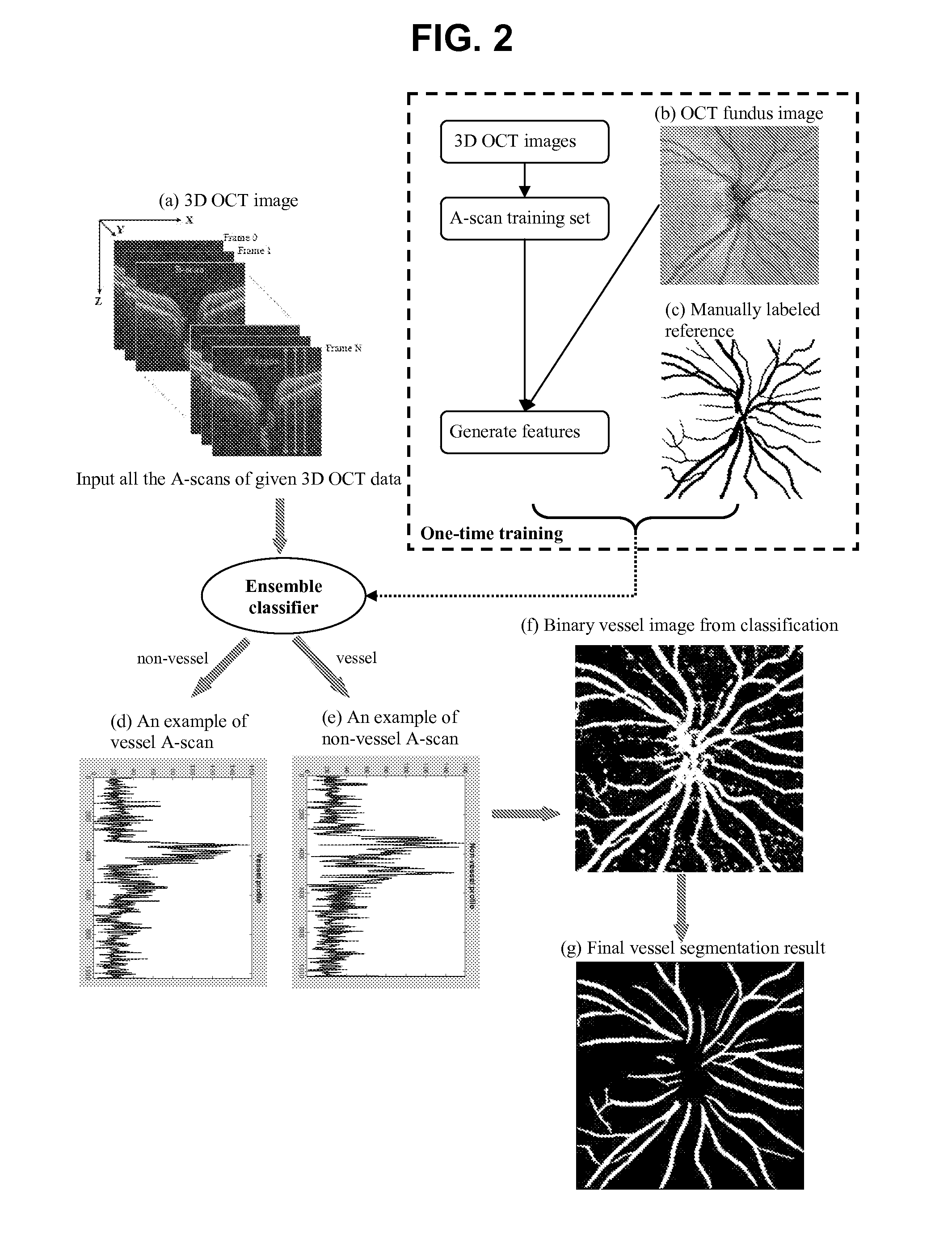

Blood vessel segmentation with three dimensional spectral domain optical coherence tomography

ActiveUS20120213423A1Precise patternImage enhancementImage analysisStudy methodsRetinal image registration

In the context of the early detection and monitoring of eye diseases, such as glaucoma and diabetic retinopathy, the use of optical coherence tomography presents the difficulty, with respect to blood vessel segmentation, of weak visibility of vessel pattern in the OCT fundus image. To address this problem, a boosting learning approach uses three-dimensional (3D) information to effect automated segmentation of retinal blood vessels. The automated blood vessel segmentation technique described herein is based on 3D spectral domain OCT and provides accurate vessel pattern for clinical analysis, for retinal image registration, and for early diagnosis and monitoring of the progression of glaucoma and other retinal diseases. The technique employs a machine learning algorithm to identify blood vessel automatically in 3D OCT image, in a manner that does not rely on retinal layer segmentation.

Owner:UNIVERSITY OF PITTSBURGH

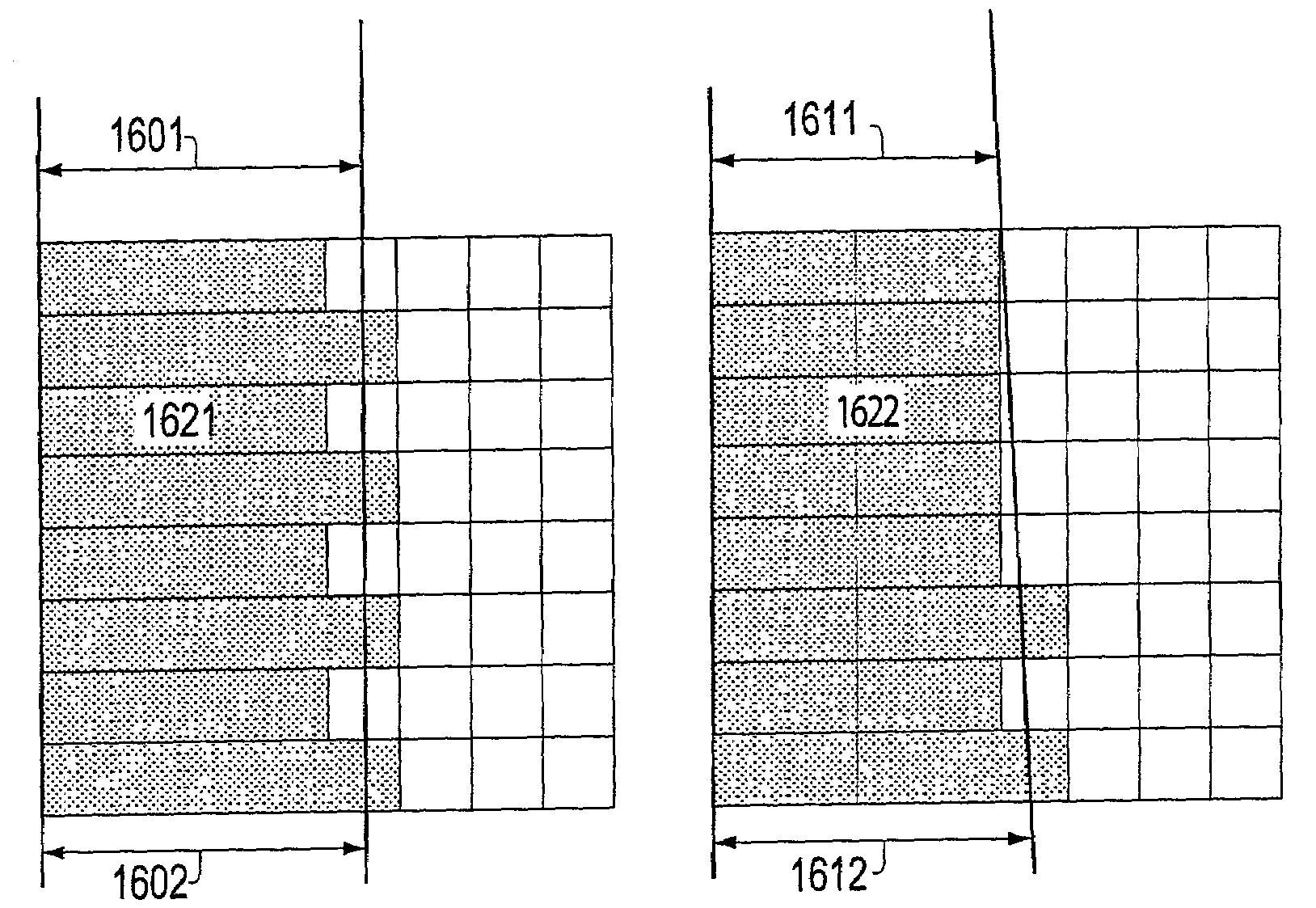

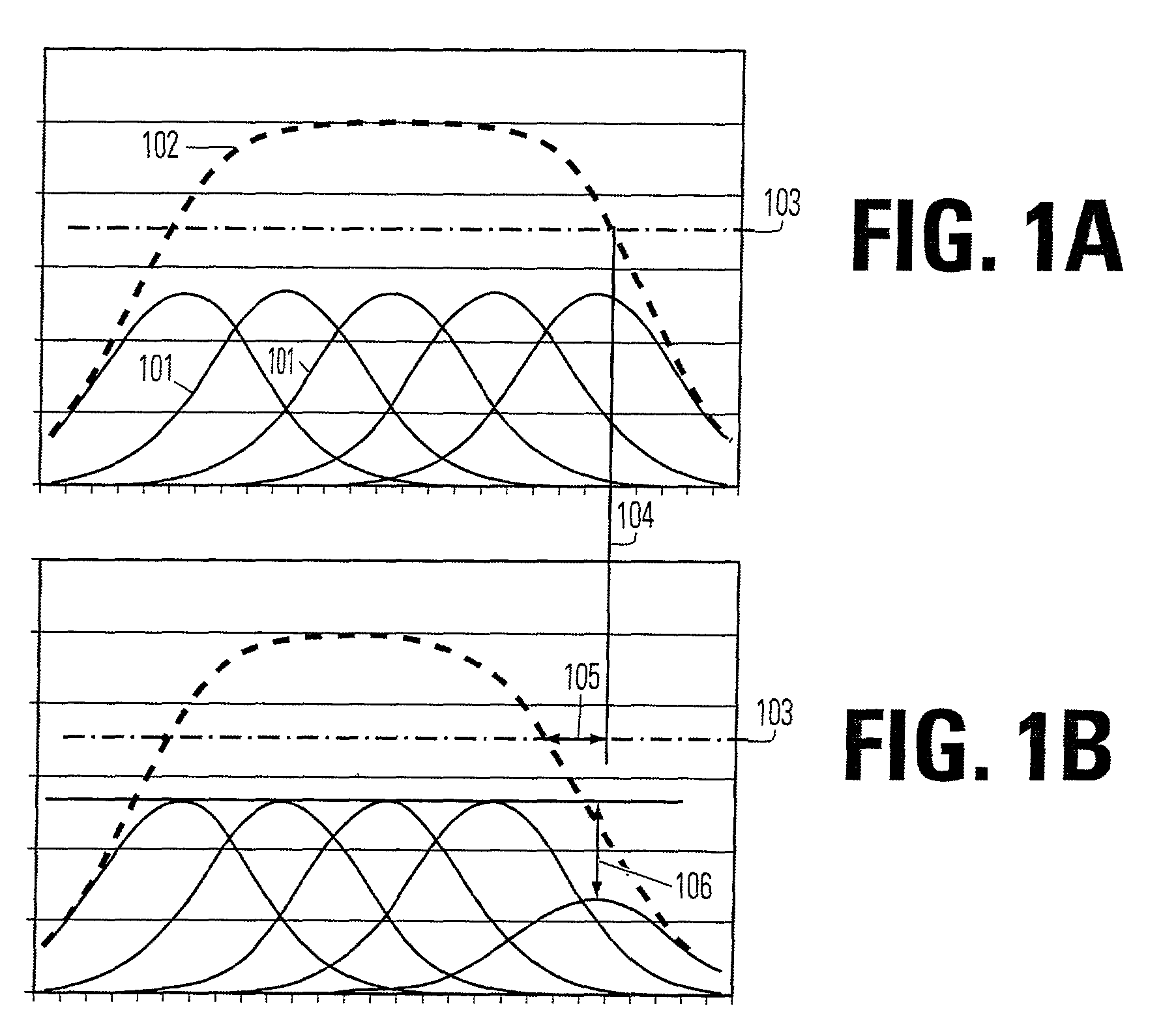

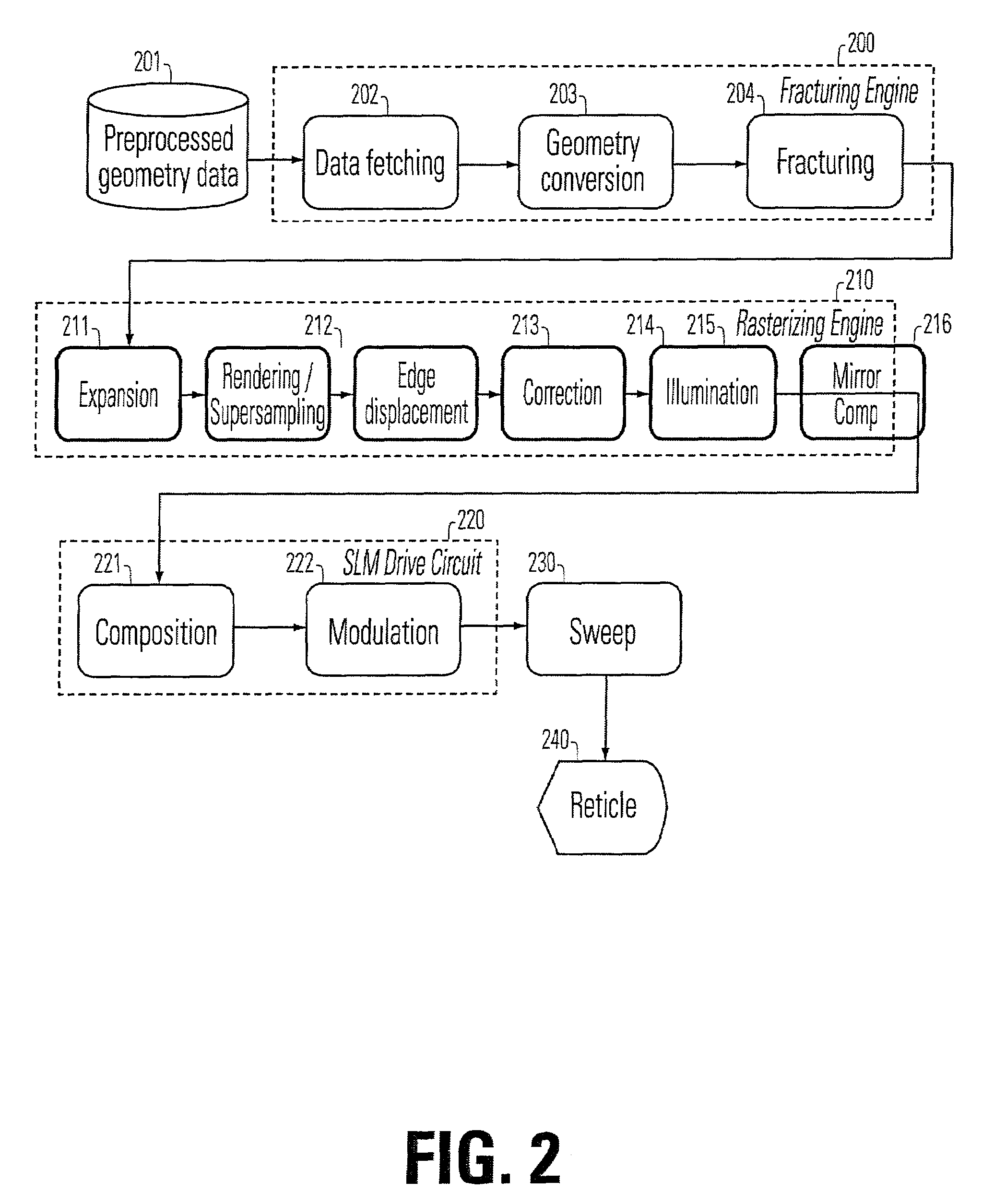

Graphics engine for high precision lithography

InactiveUS7302111B2Good compensationSignificant processingDigitally marking record carriersSemiconductor/solid-state device manufacturingGraphicsComputer vision

The present invention includes a method to use a phase modulating micromirror array to create an intensity image that has high image fidelity, good stability through focus and good x-y symmetry. Particular aspects of the present invention are described in the claims, specification and drawings.

Owner:MICRONIC LASER SYST AB

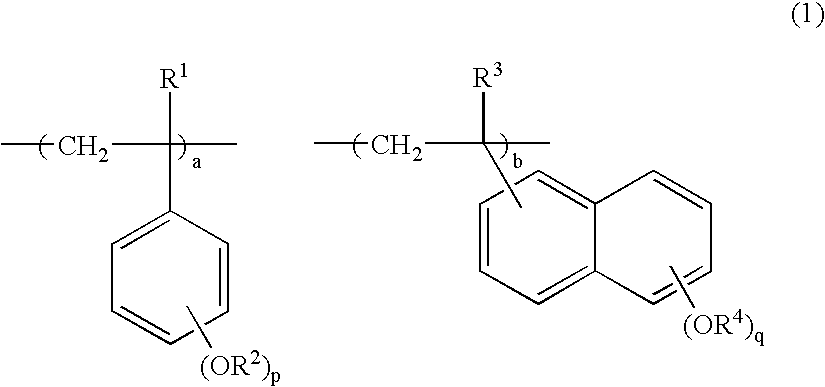

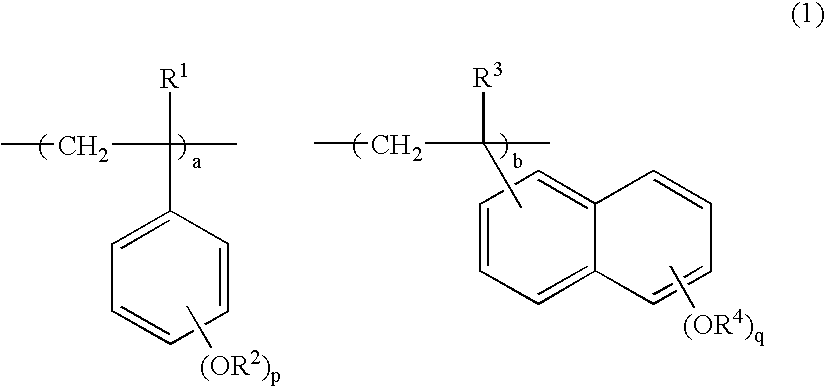

Novel polymer, positive resist composition and patterning process using the same

InactiveUS20080020289A1Increase contrastGood pattern profileX-ray/infra-red processesPhotosensitive materialsResistImage resolution

There is disclosed a polymer comprising: at least, a repeating unit of substitutable hydroxy styrene and a repeating unit of substitutable hydroxy vinylnaphthalene which are represented by the following general formula (1). There can be provided a polymer suitable as a base resin of a positive resist composition, in particular, a chemically amplified positive resist composition that can exhibit higher resolution than conventional positive resist compositions, that provides excellent pattern profiles after being exposed and that exhibits excellent etching resistance; a positive resist composition and a patterning process that use the polymer.

Owner:SHIN ETSU CHEM IND CO LTD

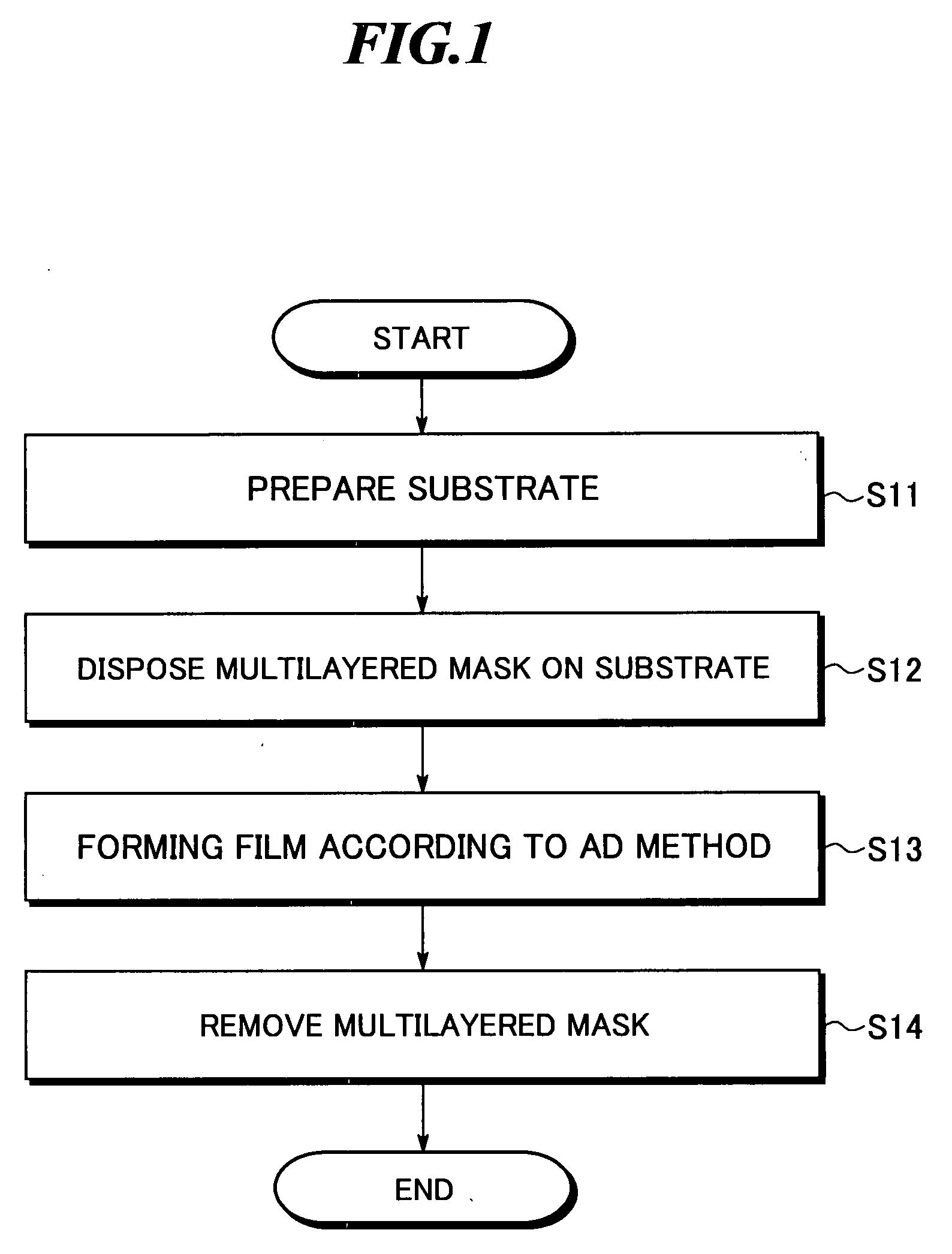

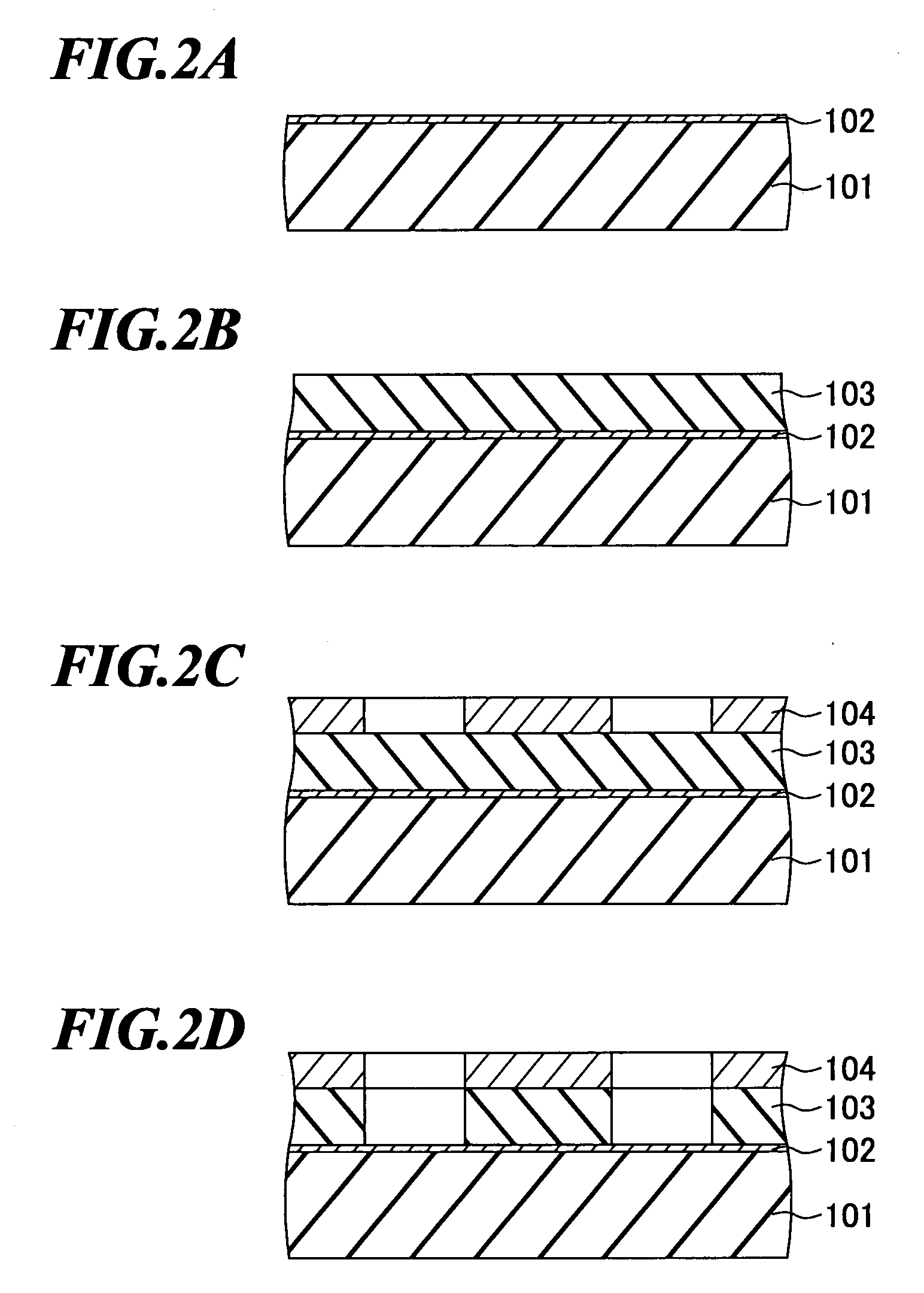

Method of manufacturing patterned film

InactiveUS20070202252A1Stable removalInhibition of attachmentPiezoelectric/electrostrictive device manufacture/assemblyFinal product manufactureSoft materialsMultiple layer

A method of manufacturing a patterned film by which an accurately patterned film is formed when film formation is performed by using the AD method. The method includes the steps of: (a) disposing a multilayered mask containing at least one soft mask layer formed of a soft material and at least one hard mask layer formed of a hard material on a substrate or an electrode formed on the substrate; (b) spraying powder formed of a brittle material toward the substrate, on which the multilayered mask has been disposed, and allowing the powder to collide with an under layer to deposit the powder thereon, thereby forming a brittle material layer; and (c) removing the multilayered mask after step (b).

Owner:FUJIFILM CORP

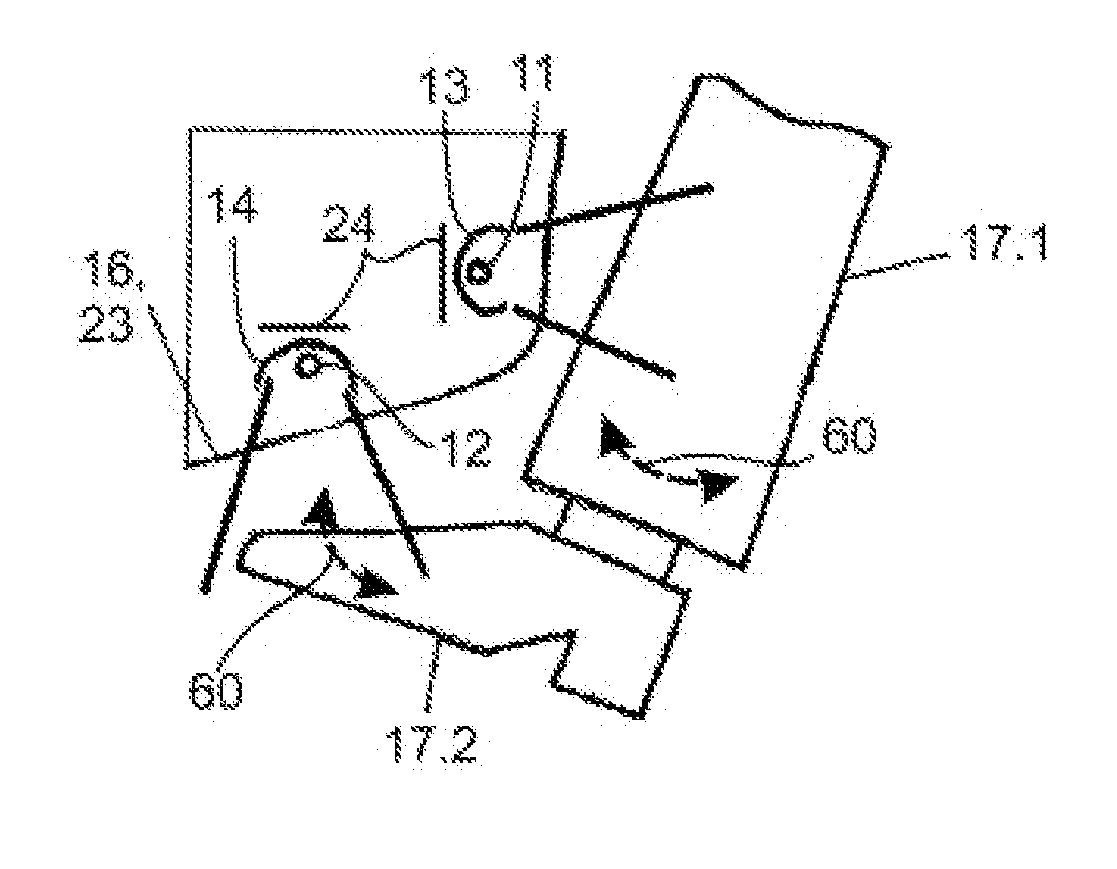

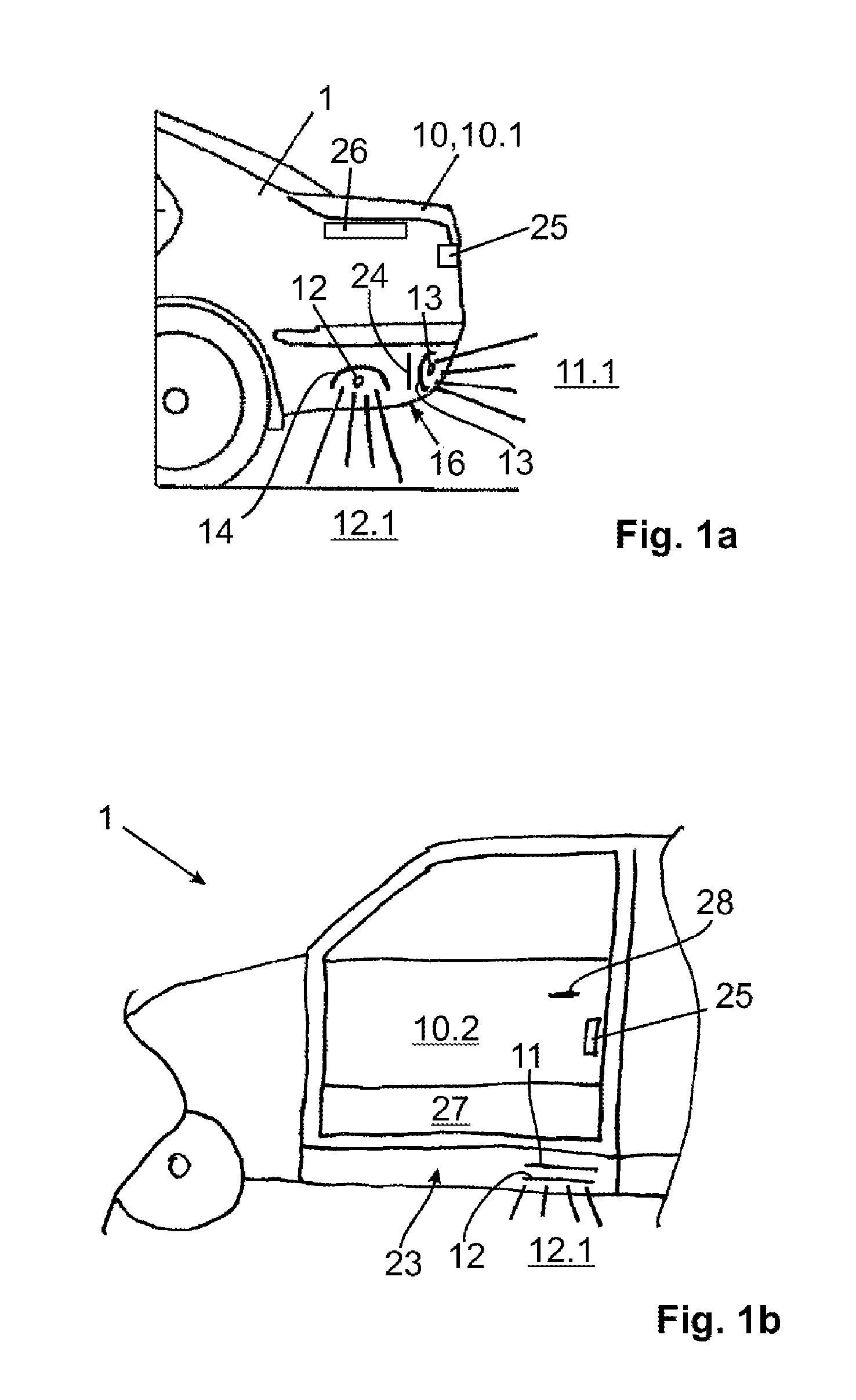

Virtual switch and method for operating same

InactiveUS20120319502A1Easy to measurePrecise patternBoards/switchyards circuit arrangementsAnti-theft devicesEngineeringVirtual switch

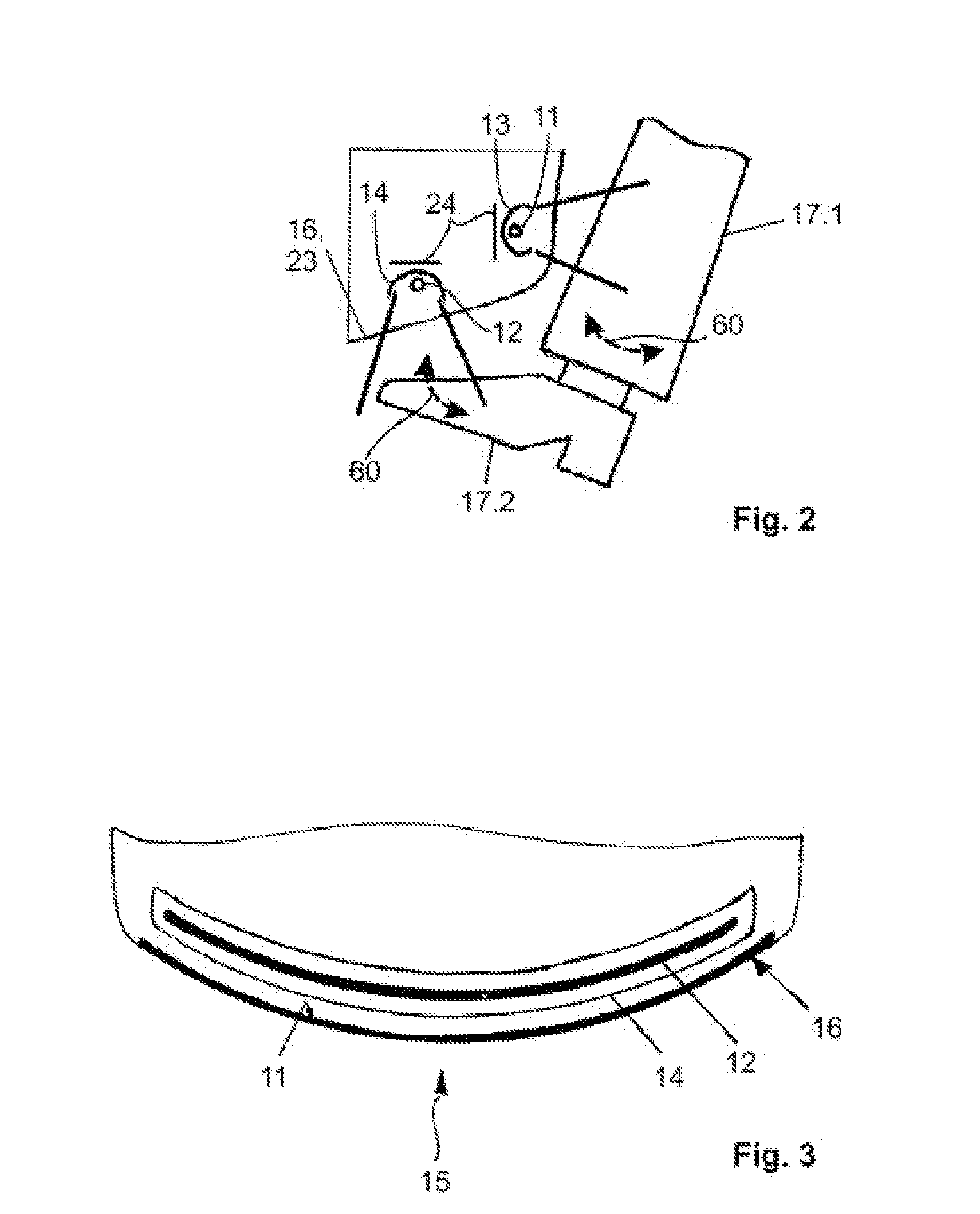

The invention relates to a method for actuating a virtual switch (50) by means of a sensor system (17.2) which detects an actuation of the switch (50), the sensor system (17.2) having at least two non-contact sensors (11, 12). The method comprises the following steps: a) starting the method, b) monitoring at least one sensor (11), starting a first timer (11.2) for a first period (11.3) if the first sensor (11) is activated (by an approaching object), d) starting a second timer (12.2) for a second period (12.3) if the second sensor (12) is activated (by an approaching object) and the first period (11.3) is not yet exceeded, and e) actuating the virtual switch (50) if at least one sensor (11, 12) is deactivated and the second period (12.3) is not yet exceeded, some of steps a) to e) proceeding simultaneously or chronologically.

Owner:HUF HULSBECK & FURST GMBH & CO KG

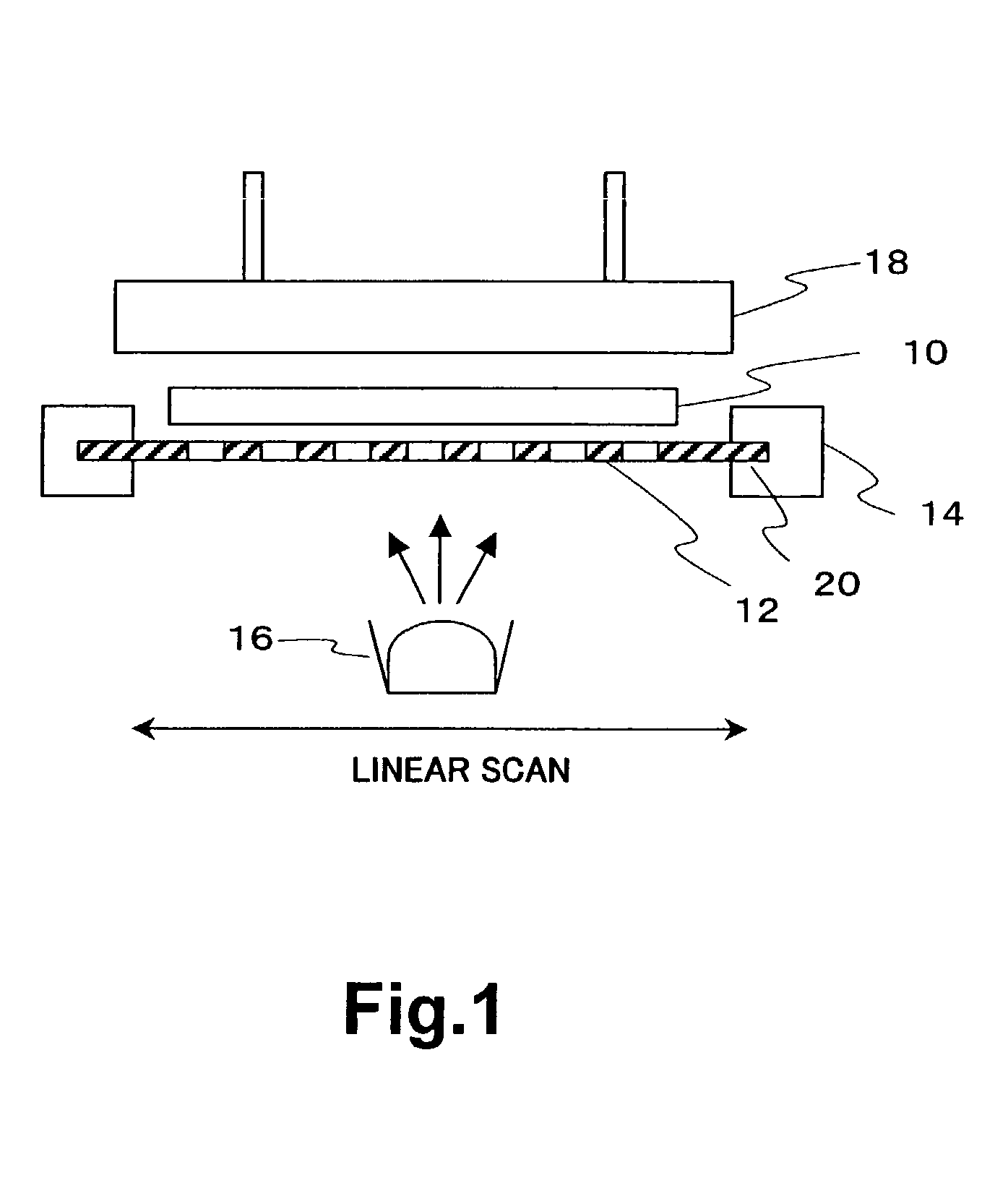

Additive manufacturing system for manufacturing a three dimensional object

InactiveUS20160332386A1High resolution and accuracyImprove accuracyManufacturing platforms/substrates3D object support structuresRadiationMechanical engineering

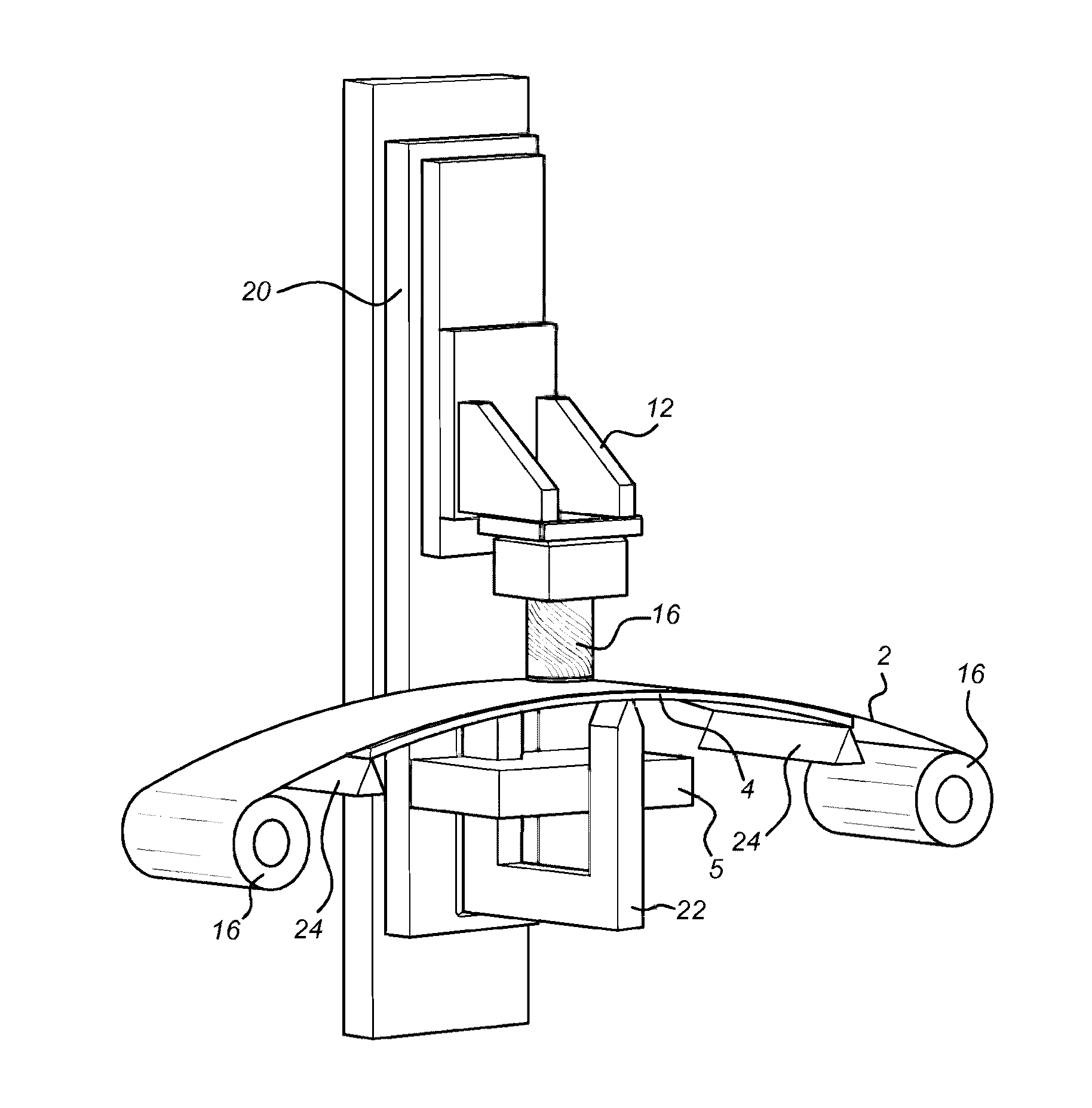

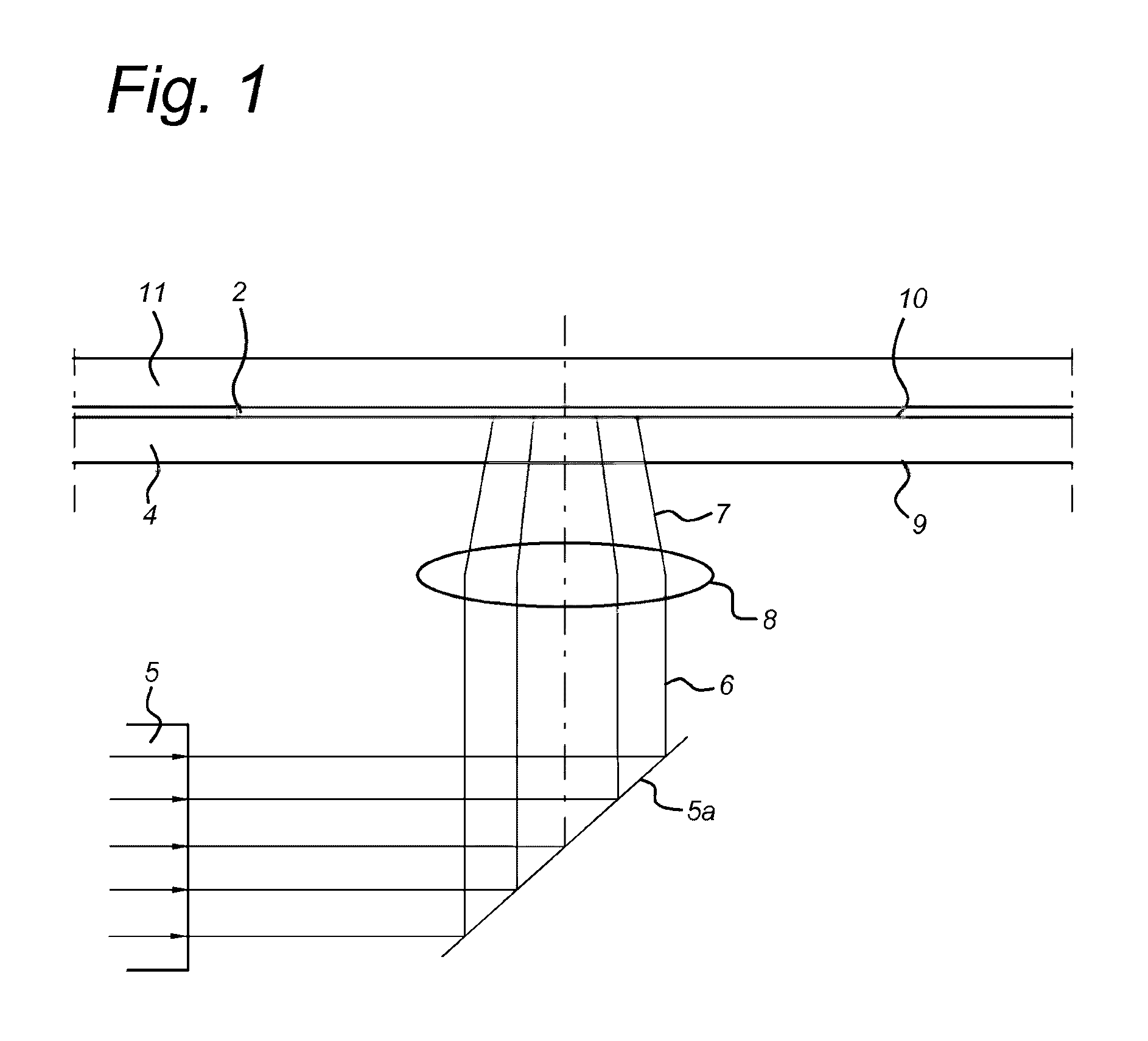

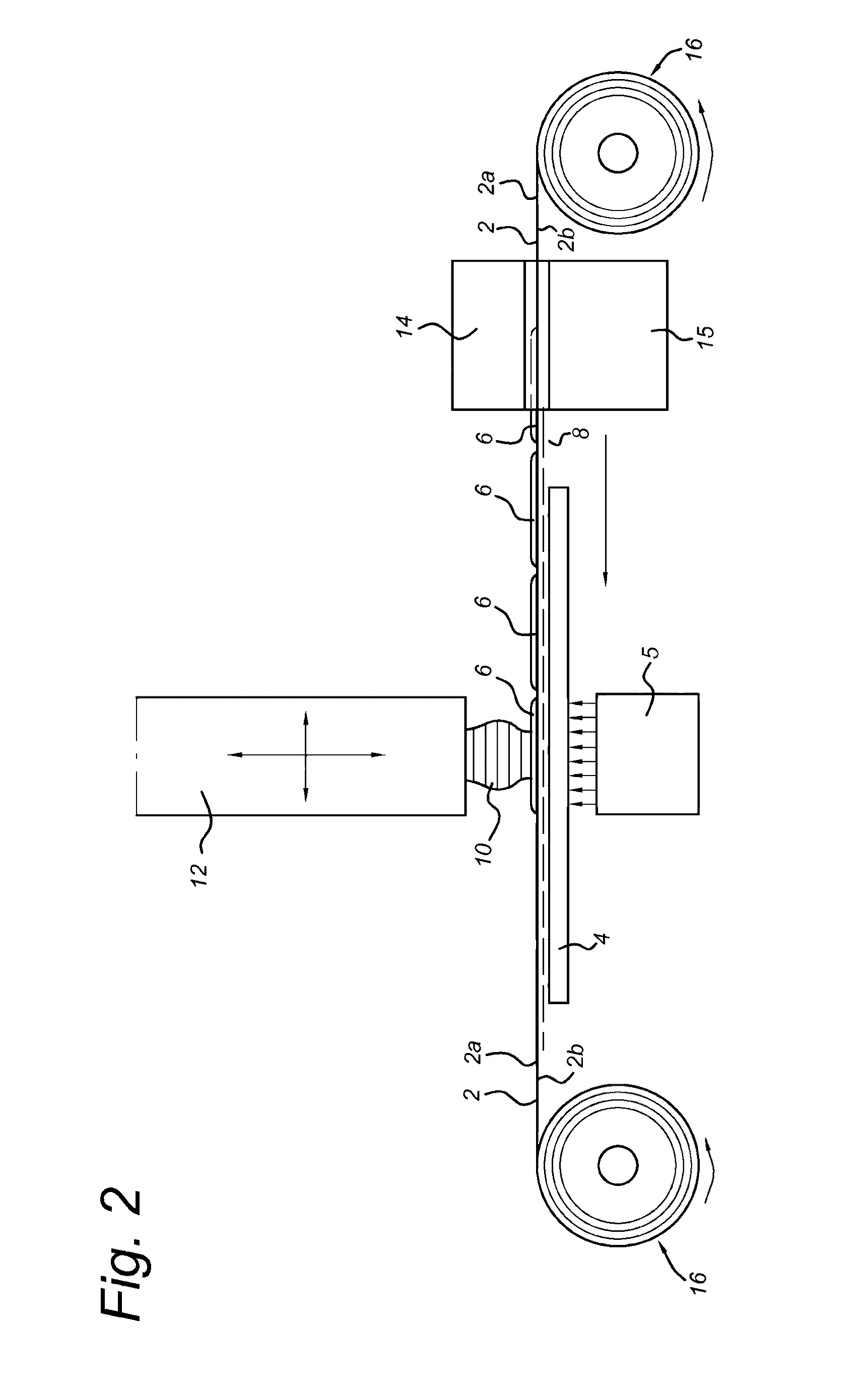

Additive manufacturing system for manufacturing a three dimensional object (10). A resin depositor (14) is present for depositing a layer of curable resin (6) on a first side (2a) of a foil substrate (2). The foil substrate (2) is supported by a transparent support plate (4), and a radiation source (5) is disposed for radiation curing the resin layer (6). A stage (12) is configured to hold a stacked arrangement of one or more cured resin layers representing at least in part the three dimensional object (10) and a positioning system is provided for relative positioning the foil substrate (2) and the stage (12). A masking screen (8) disposed substantially parallel to the resin layer (6) is present for blocking at least in part incident radiation on the resin layer (6) in correspondence with a cross sectional slice of the object (10).

Owner:ADMATEC EURO

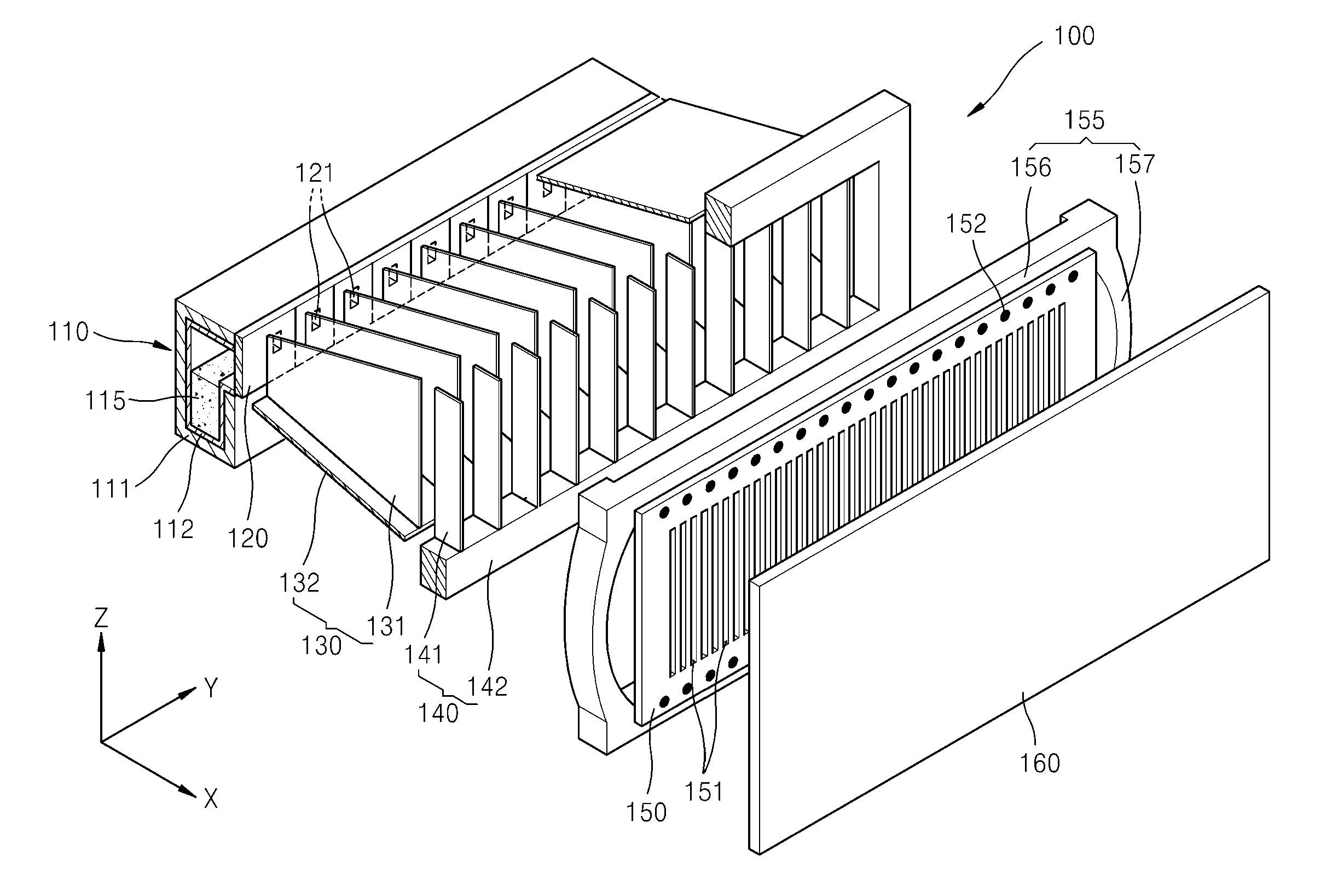

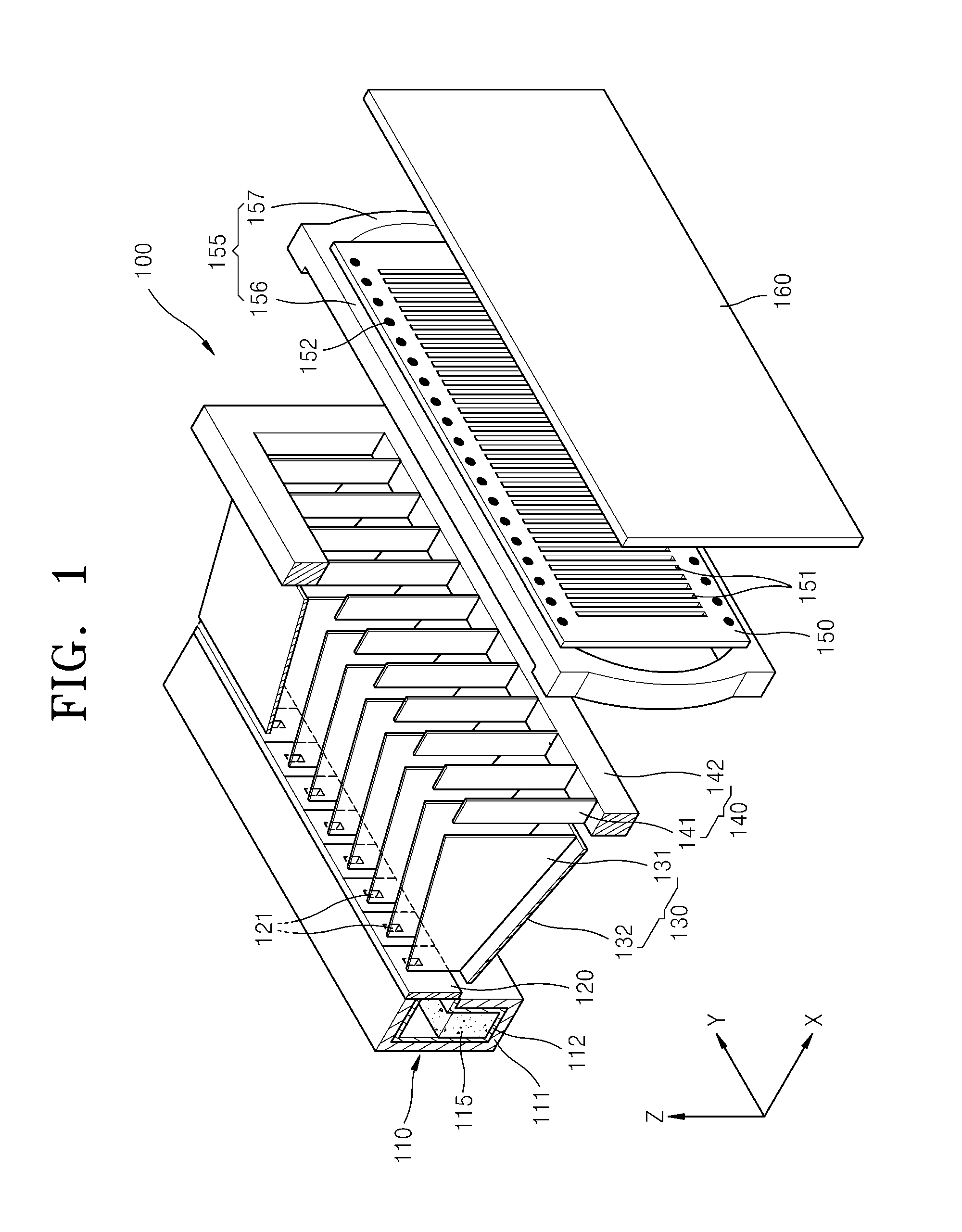

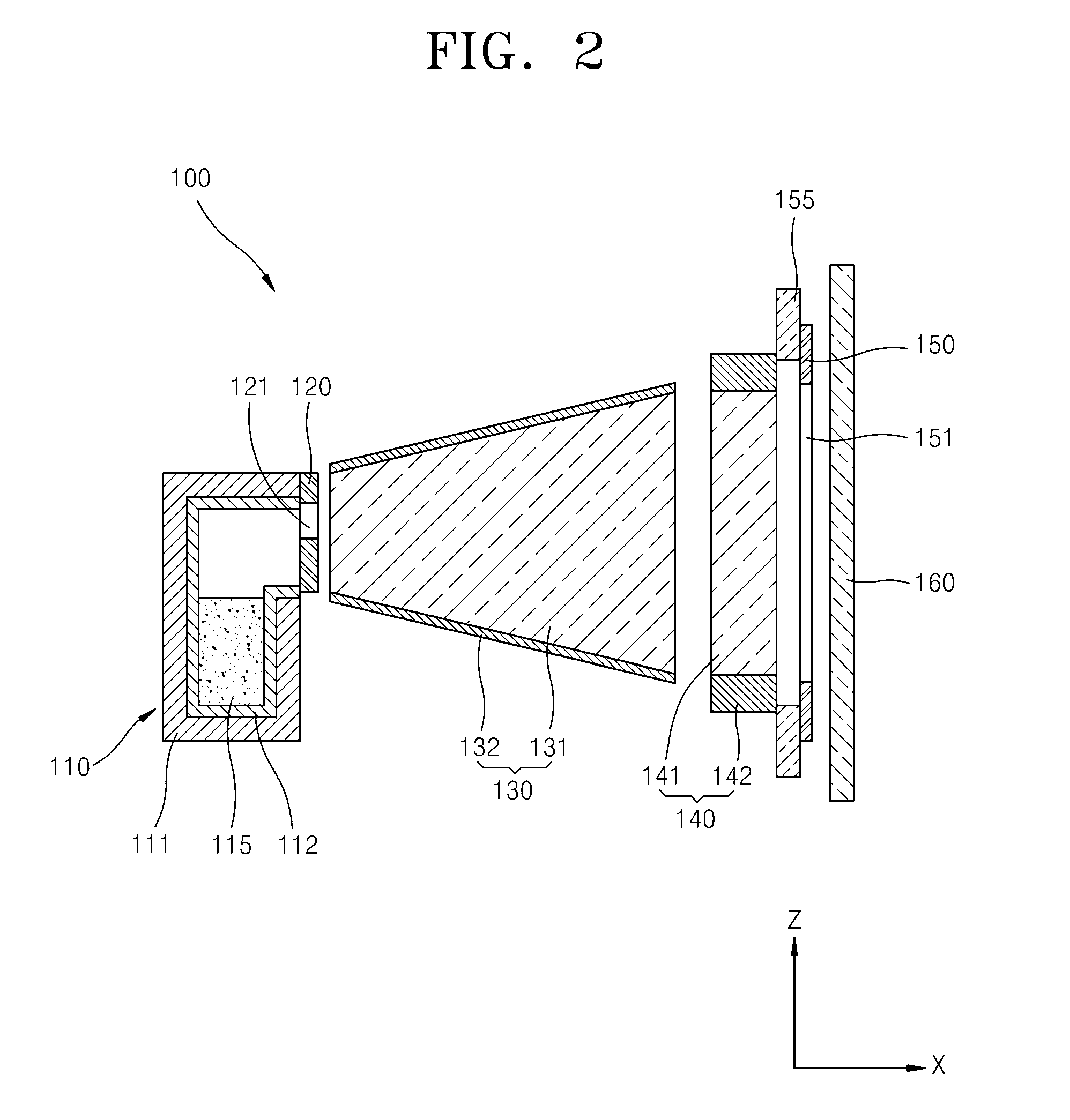

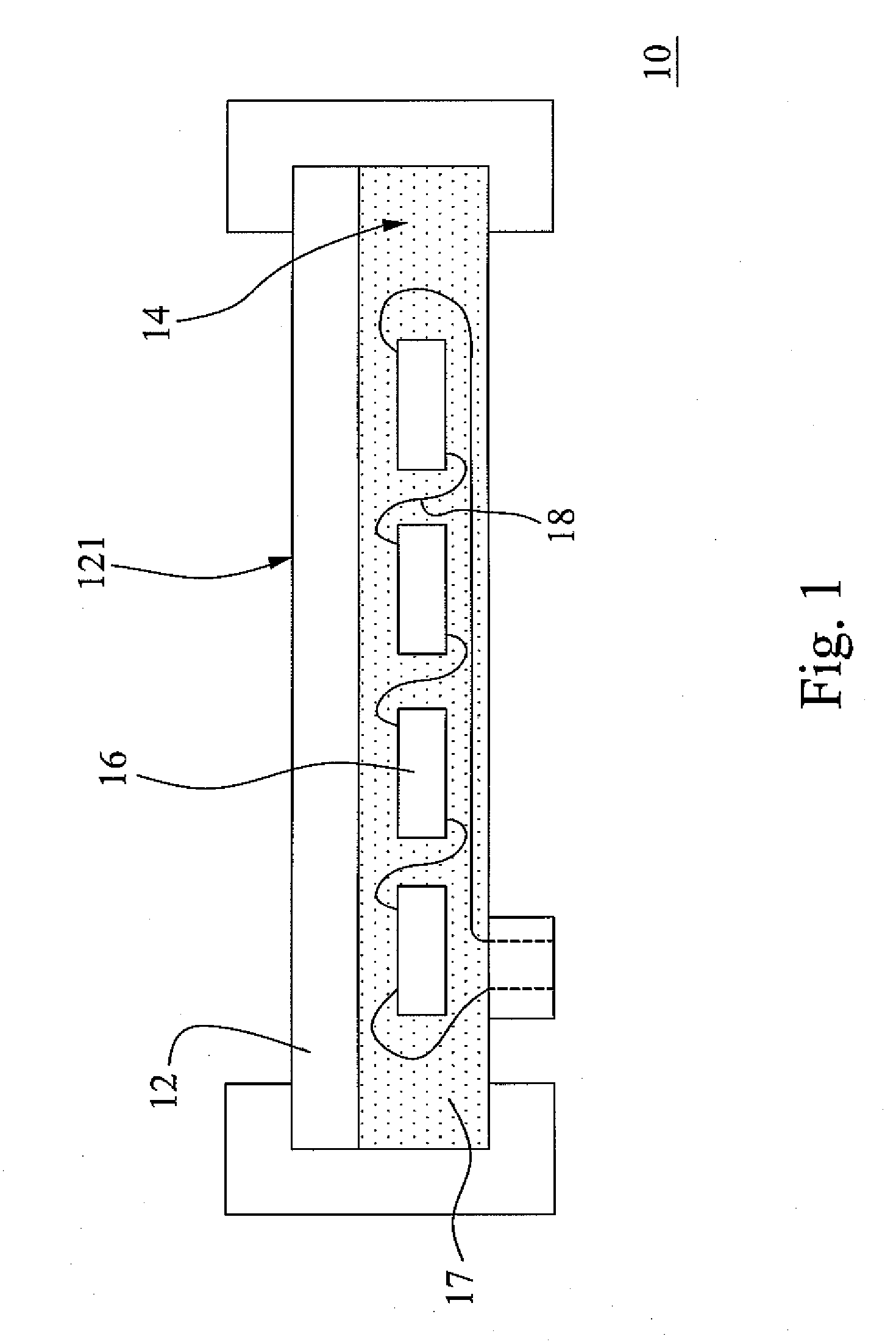

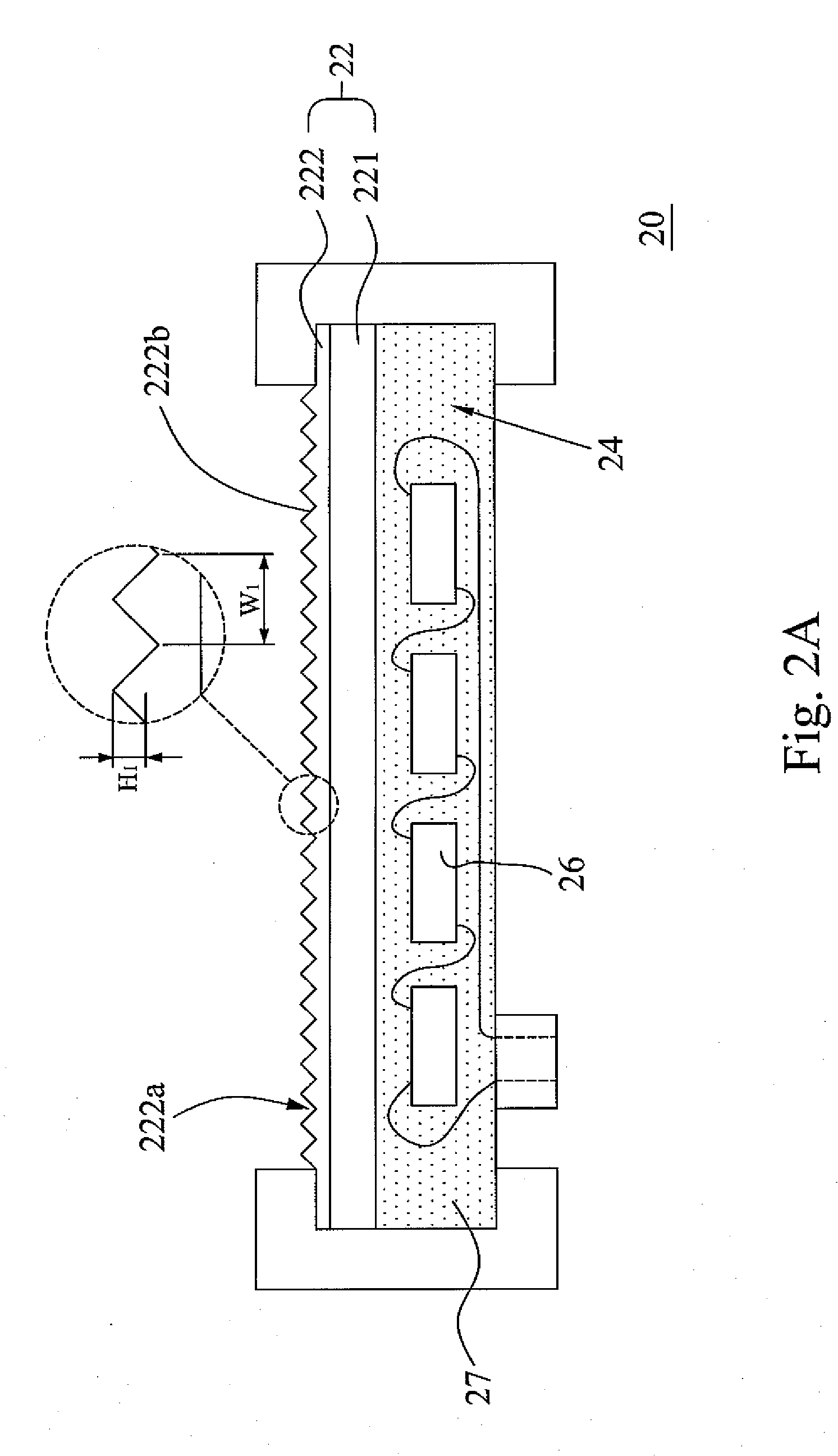

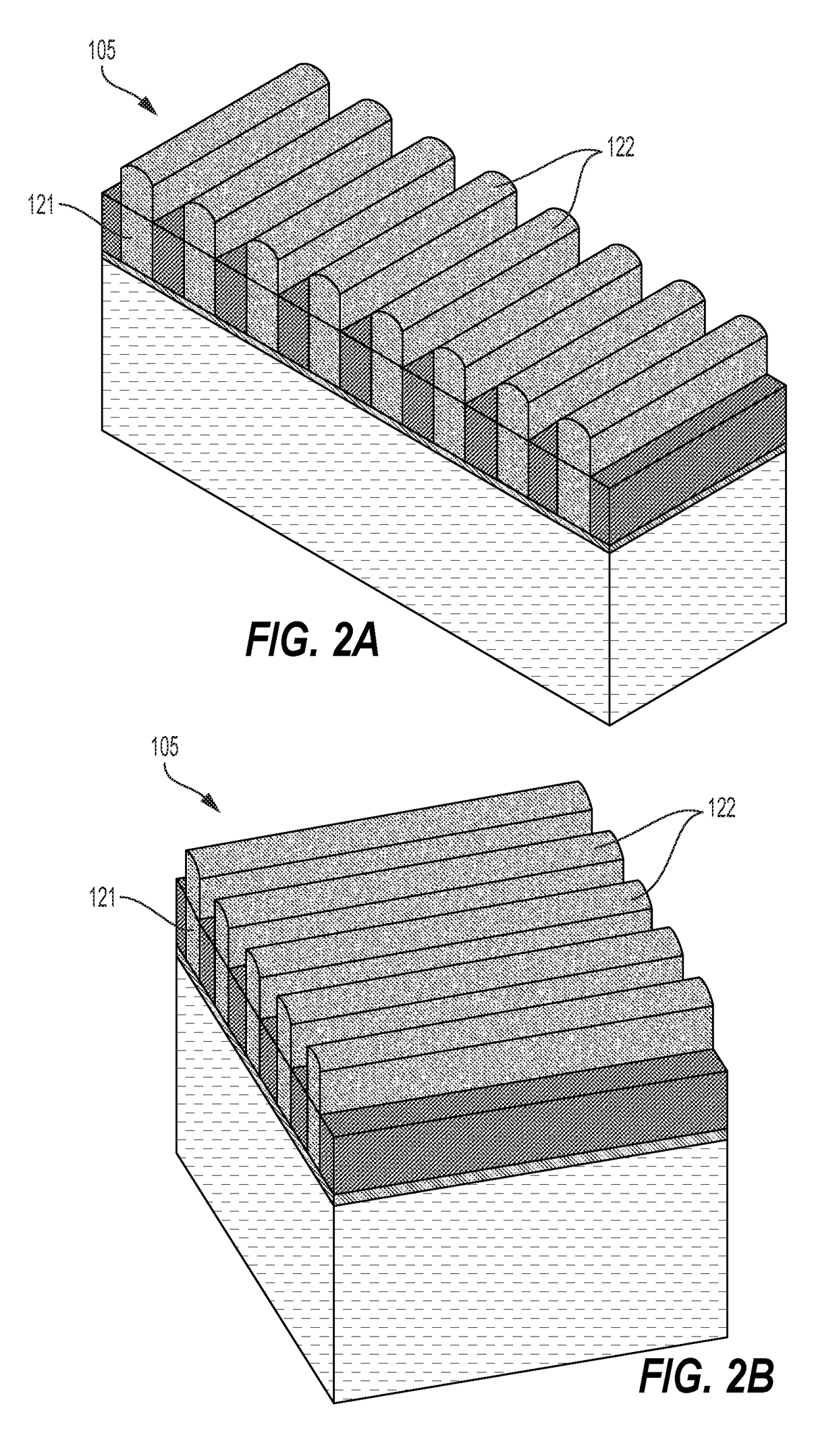

Thin film deposition apparatus

A thin film deposition apparatus capable of forming a precise deposition pattern on a large substrate includes a deposition source; a first nozzle disposed at a side of the deposition source having a plurality of first slits; a second nozzle disposed opposite to the first nozzle having a plurality of second slits; and a second nozzle frame bound to the second nozzle so as to support the second nozzle. The second nozzle frame includes two first frame portions spaced apart from each other and disposed in a direction in which the plurality of second slits are arranged, and two second frame portions each connecting the two first frame portions to each other, wherein the second frame portions are curved in the direction in which the plurality of second slits are arranged, so as to form arches.

Owner:SAMSUNG DISPLAY CO LTD

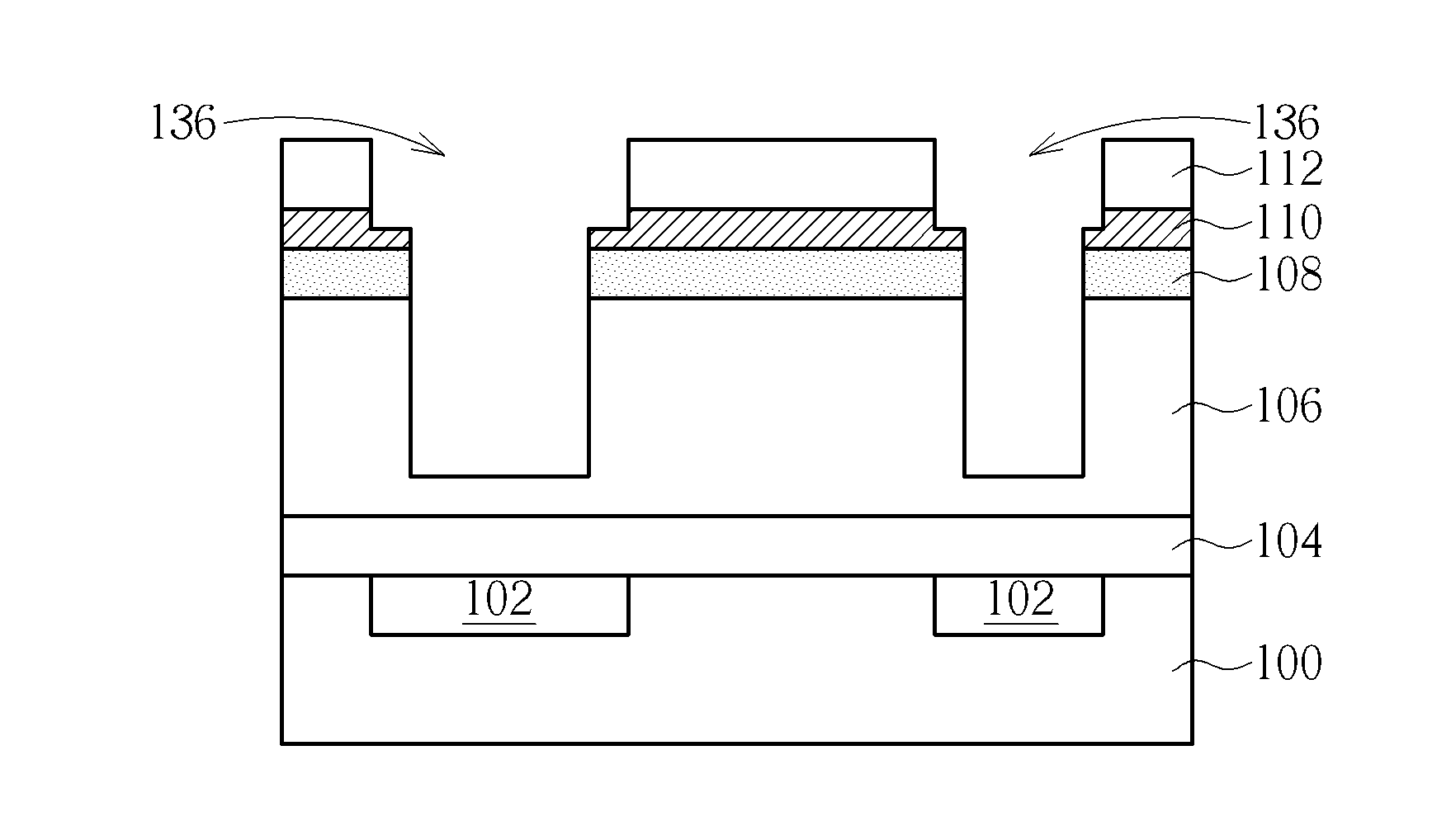

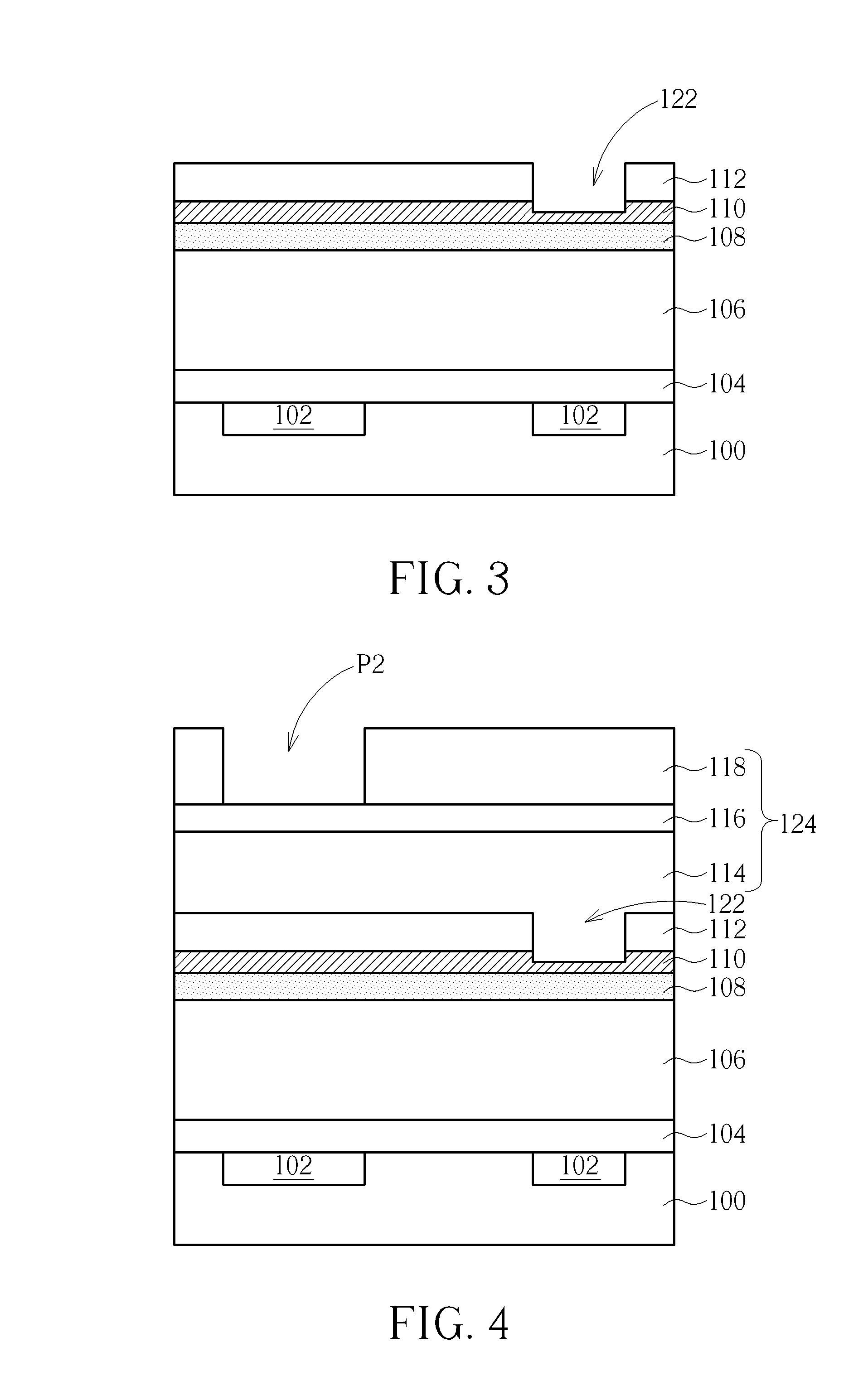

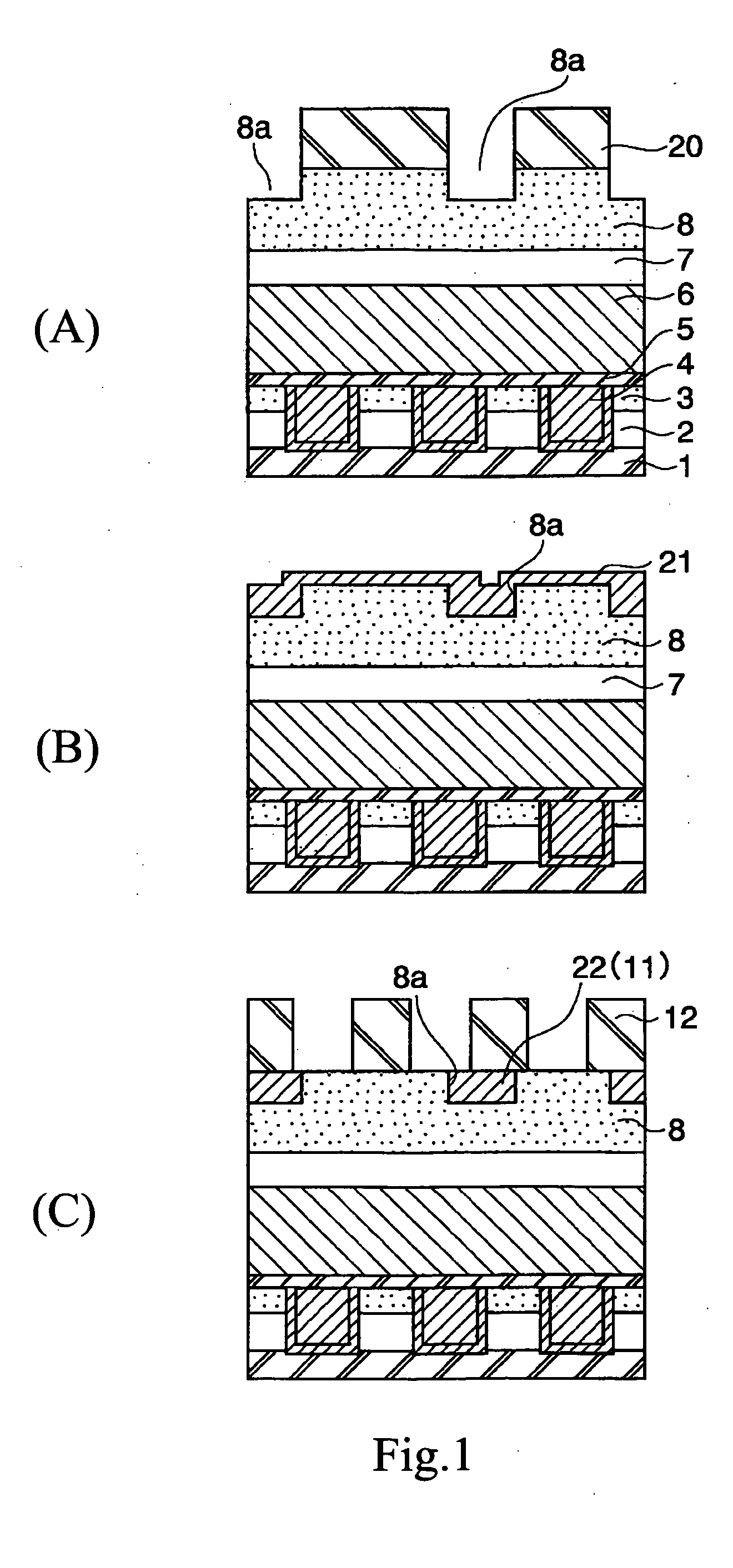

Method of manufacturing dual damascene structure

ActiveUS20130337650A1Improve integrityPrecise patternSemiconductor/solid-state device manufacturingDielectric layerMetal

A method for fabricating a dual damascene structure includes the following steps. At first, a dielectric layer, a dielectric mask layer and a metal mask layer are sequentially formed on a substrate. A plurality of trench openings is formed in the metal mask layer, and a part of the metal mask layer is exposed in the bottom of each of the trench openings. Subsequently, a plurality of via openings are formed in the dielectric mask layer, and a part of the dielectric mask layer is exposed in a bottom of each of the via openings. Furthermore, the trench openings and the via openings are transferred to the dielectric layer to form a plurality of dual damascene openings.

Owner:UNITED MICROELECTRONICS CORP

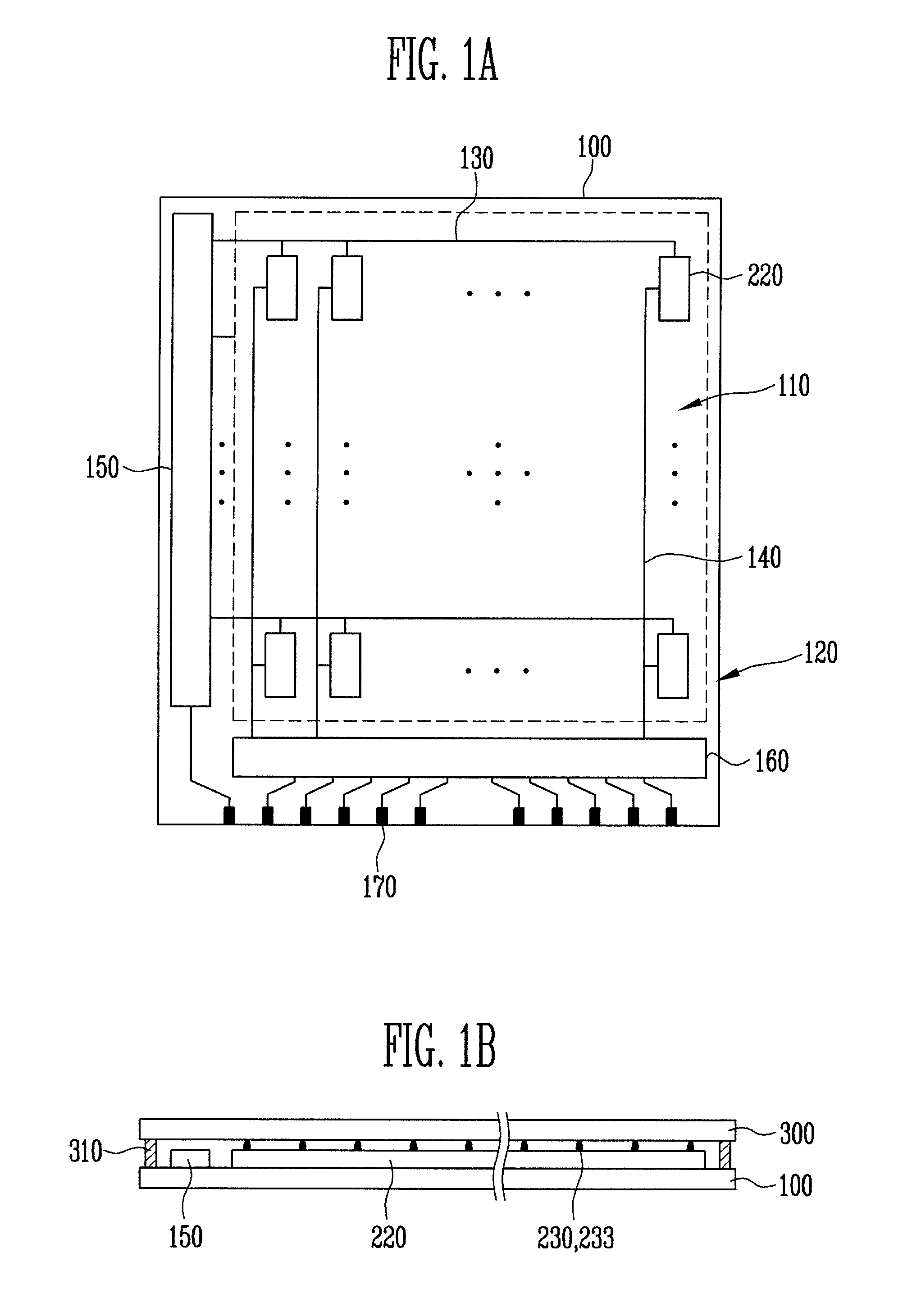

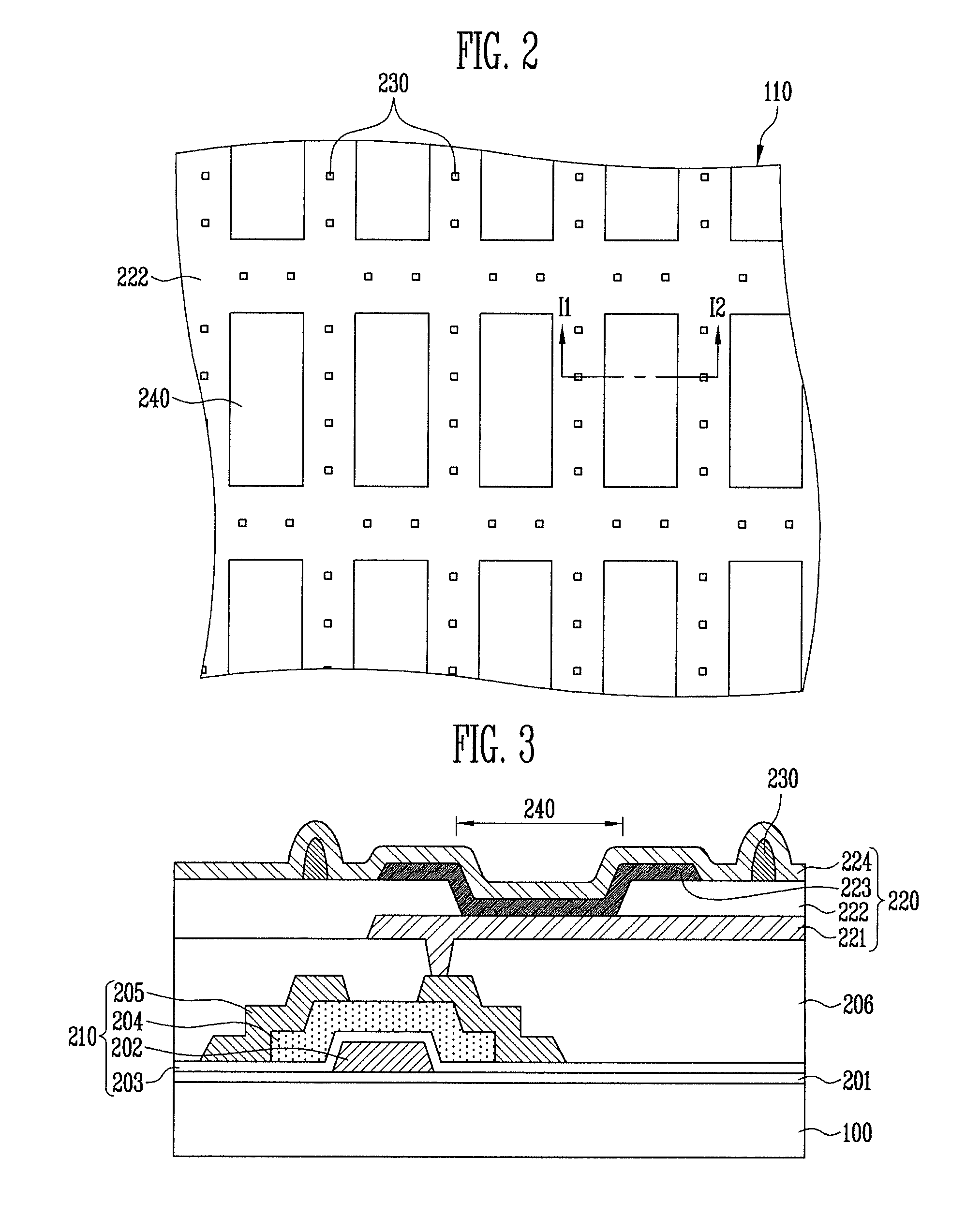

Organic light emitting display device

ActiveUS20100207107A1Reducing and avoiding external appearance defectEvenly supportedSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

An organic light emitting display device includes: a first substrate; a plurality of organic light emitting diodes on the first substrate; a plurality of spacers spaced apart from each other on sides of light emitting regions corresponding to the plurality of organic light emitting diodes; and a second substrate facing the first substrate and spaced apart from the first substrate at an interval by the plurality of spacers.

Owner:SAMSUNG DISPLAY CO LTD

Alignment method, method for manufacturing a semiconductor device, substrate for a semiconductor device, electronic equipment

InactiveUS20050161836A1Precise patternImprove performanceTransistorSemiconductor/solid-state device detailsDevice materialEngineering

Aspects of the invention can provide an alignment method that is preferably applicable when manufacturing equipments by liquid-phase processing. The alignment method in a device manufacturing process can include forming of a functional film on a substrate by liquid-phase processing, forming an alignment mark on the substrate on which the functional film is formed so as to make a pattern of the alignment mark appear on a film that is formed after forming the functional film, and aligning the film that is formed after forming the functional film by using the alignment mark.

Owner:SEIKO EPSON CORP

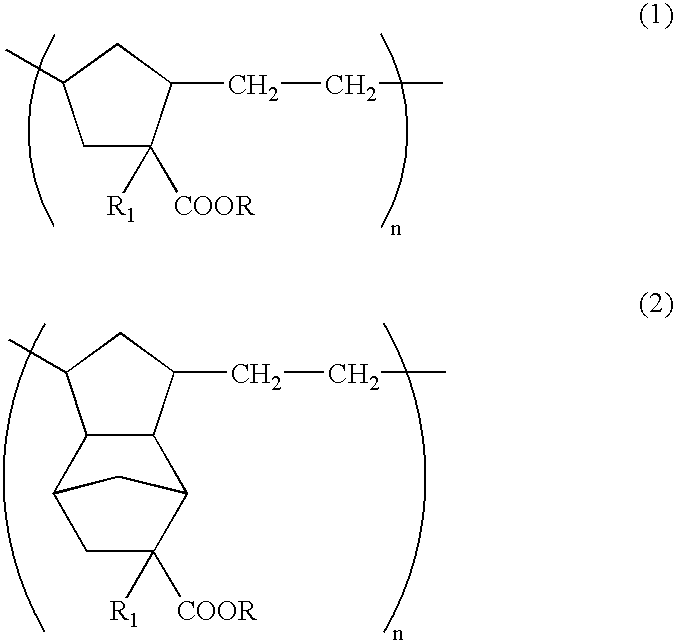

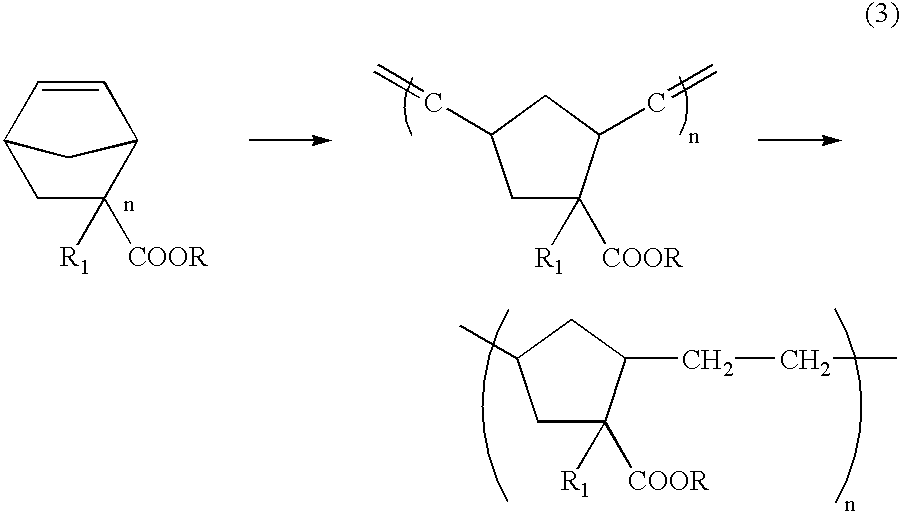

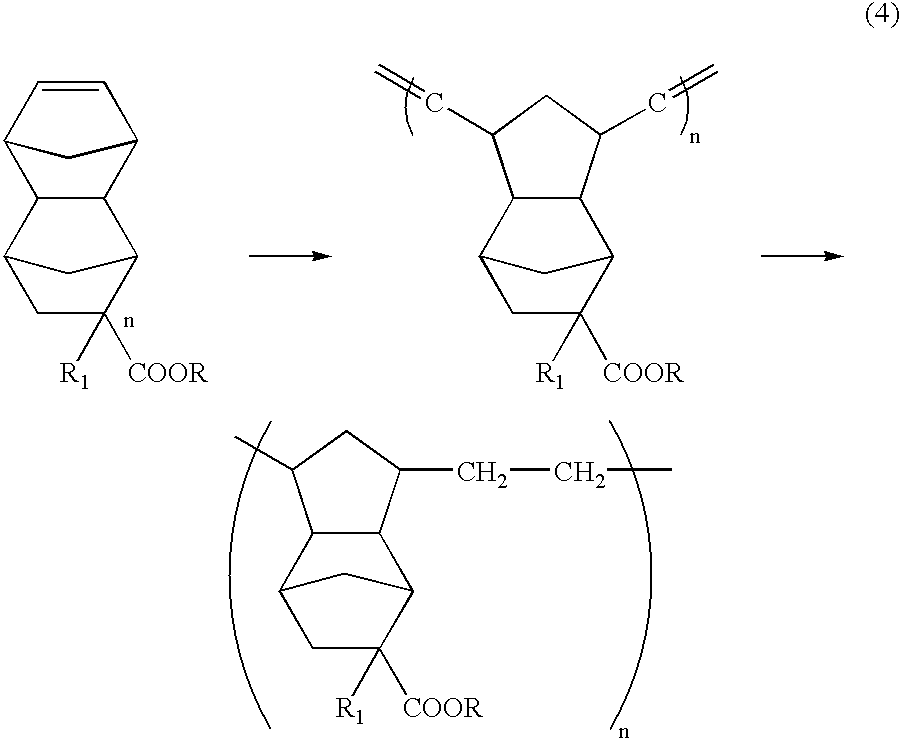

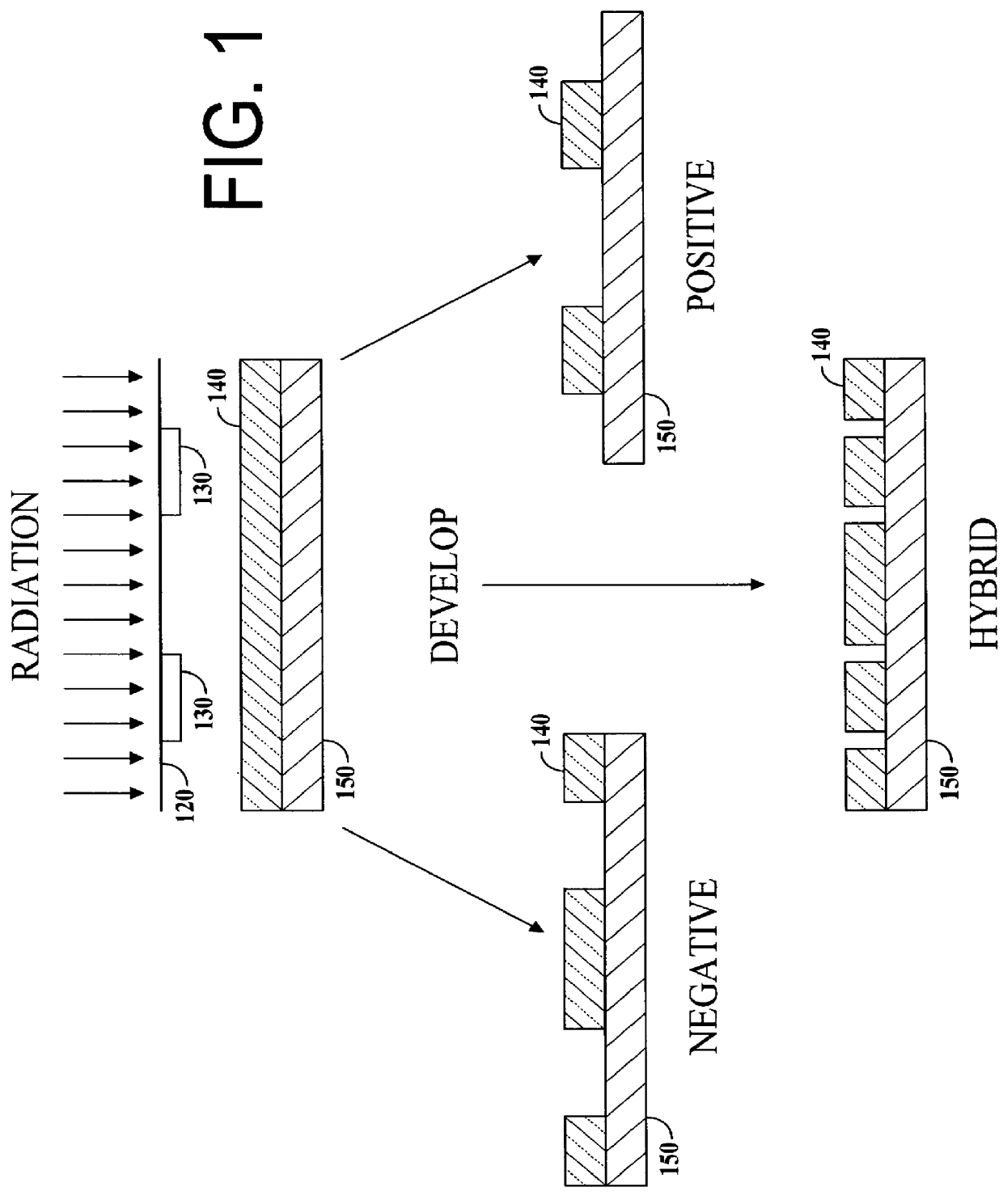

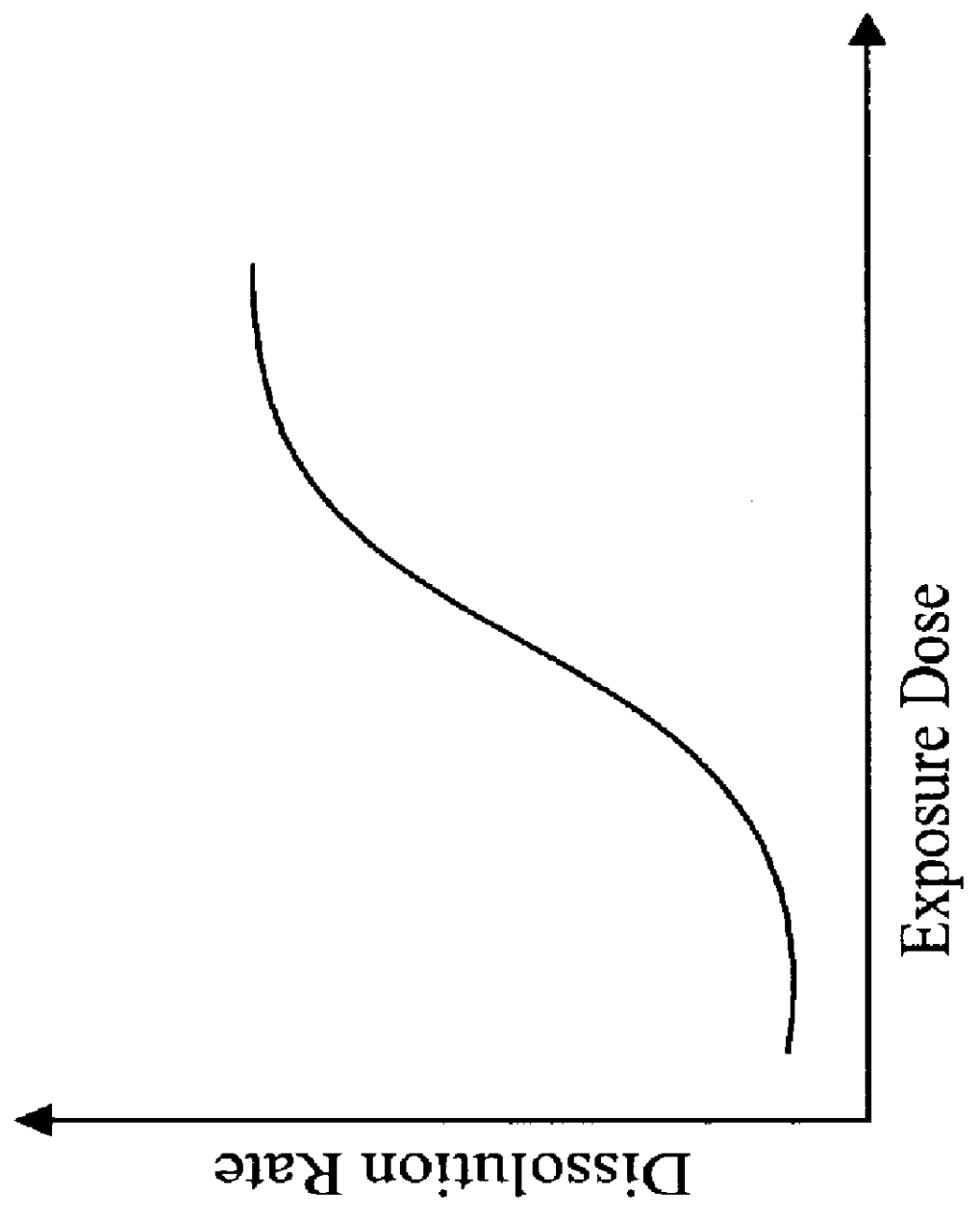

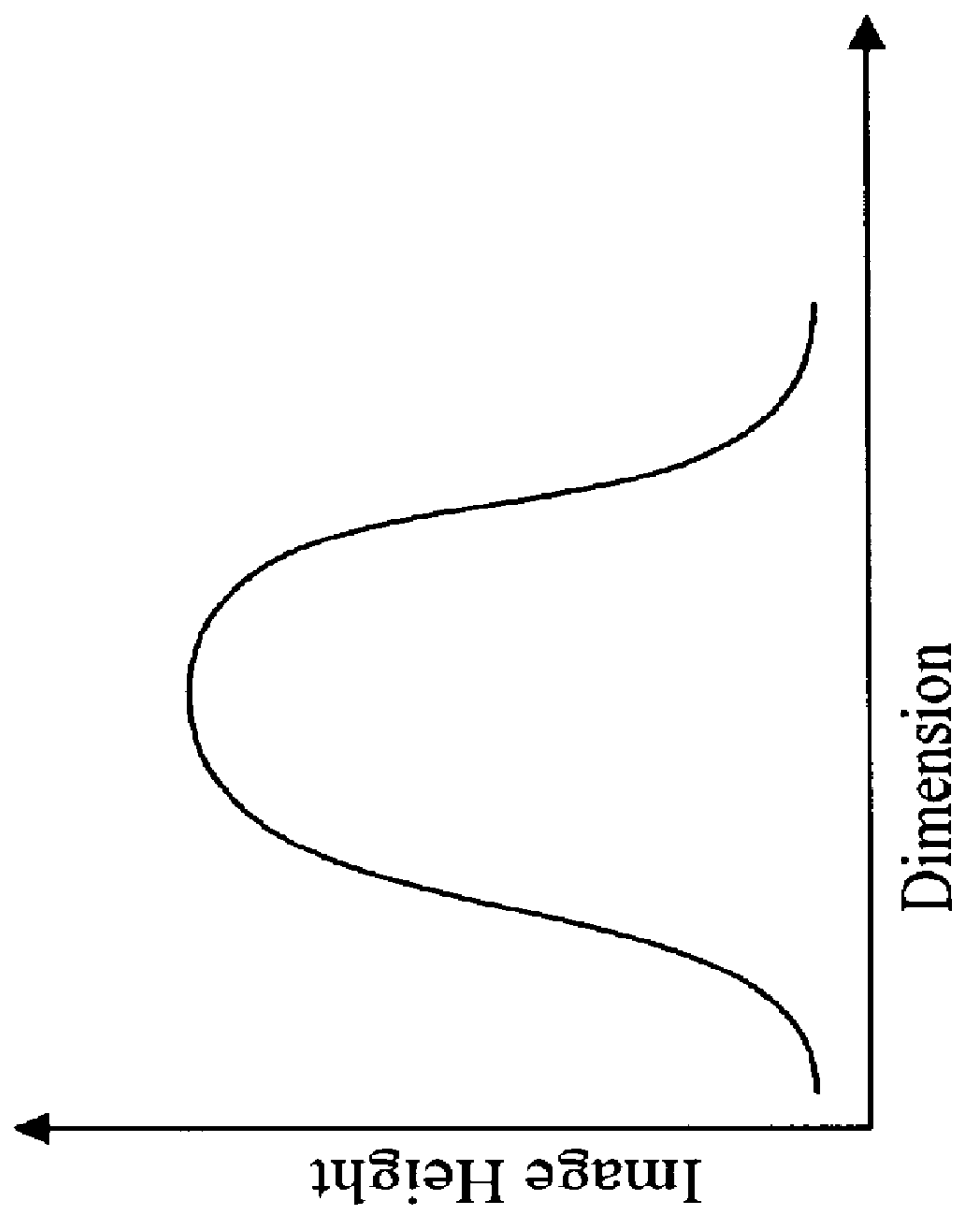

Resist material and method for forming a resist pattern with the resist material

InactiveUS20030143483A1Precise patternRadiation applicationsSemiconductor/solid-state device manufacturingResistSide chain

A resist material is made of a polymer or copolymer having a cyclic hydrocarbon as a skeletal structure and an alkali-soluble group to which a protective group is attached as a side chain. Because of the protective group, the resist material is insoluble in alkali solution. In addition, an acid generating agent is added to the resist material. When the acid generating agent is irradiated with a radiation ray, an acid is generated from the acid generating agent, and the protective group is detached from the alkali-soluble group by the function of the acid. Therefore, a resist film made of the resist material can be formed in a desired pattern by irradiating the resist film with the radiation ray. Also, because the cyclic hydrocarbon is used as the skeletal structure of the polymer or copolymer, a superior dry-etching resistance is obtained as compared with a conventional resist material in which acrylate resin is used as a skeletal structure, so that there is no probability that a patterned resist film is over-etched or deformed even though the patterned resist film is used as a mask in an etching process.

Owner:FUJITSU SEMICON LTD

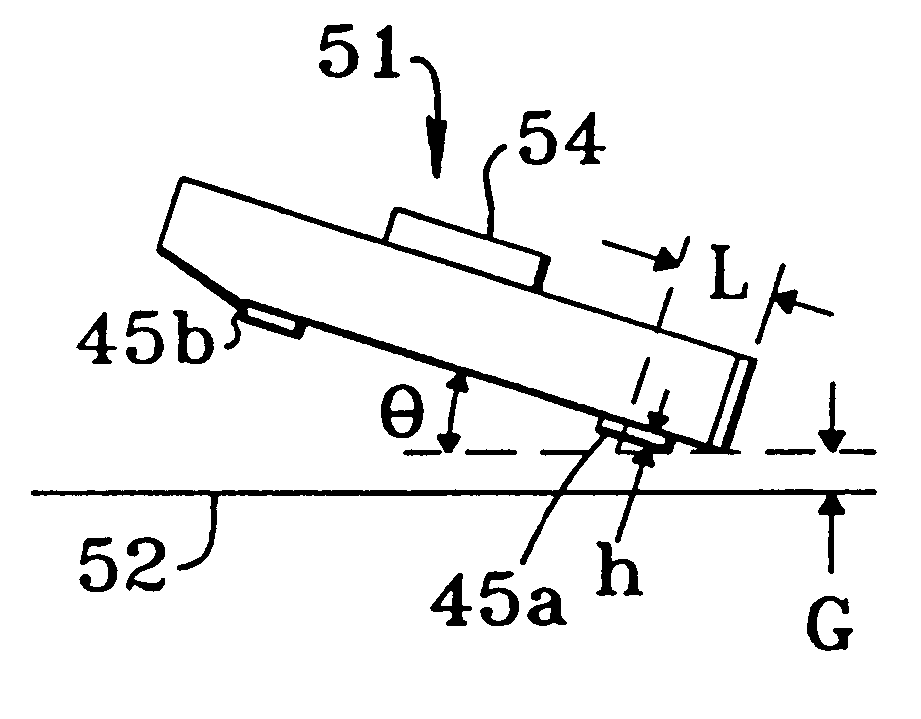

Magnetic disk drive with a floating head slider having projections arranged to float at a greater distance from magnetic disk than slider trailing end

InactiveUS6246538B1High yield rateGuaranteed uptimeManufacture head surfaceProtective coatings for layersMagnetic tapeTransducer

A head slider is composed of a substrate having a transducer on its outflow end, a rail plane formed on a surface near both sides of the substrate facing a magnetic disk. The head slider further includes a plurality of projection elements formed on the rail plane. When the slider is floating over the magnetic disk, the distance between the projection elements and the magnetic disk is greater than the distance between the outflow end of the slider and the magnetic disk.

Owner:TOSHIBA STORAGE DEVICE CORP

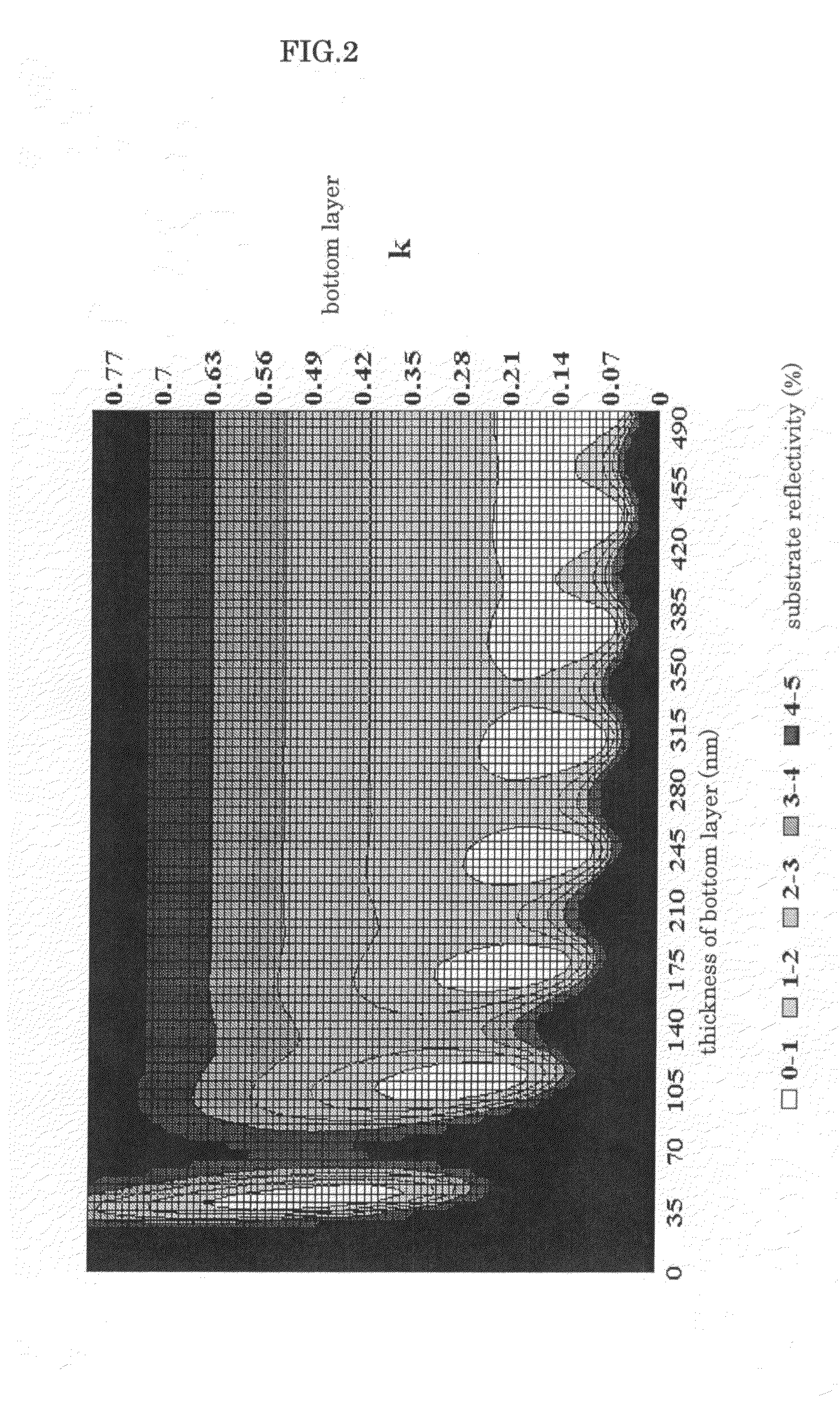

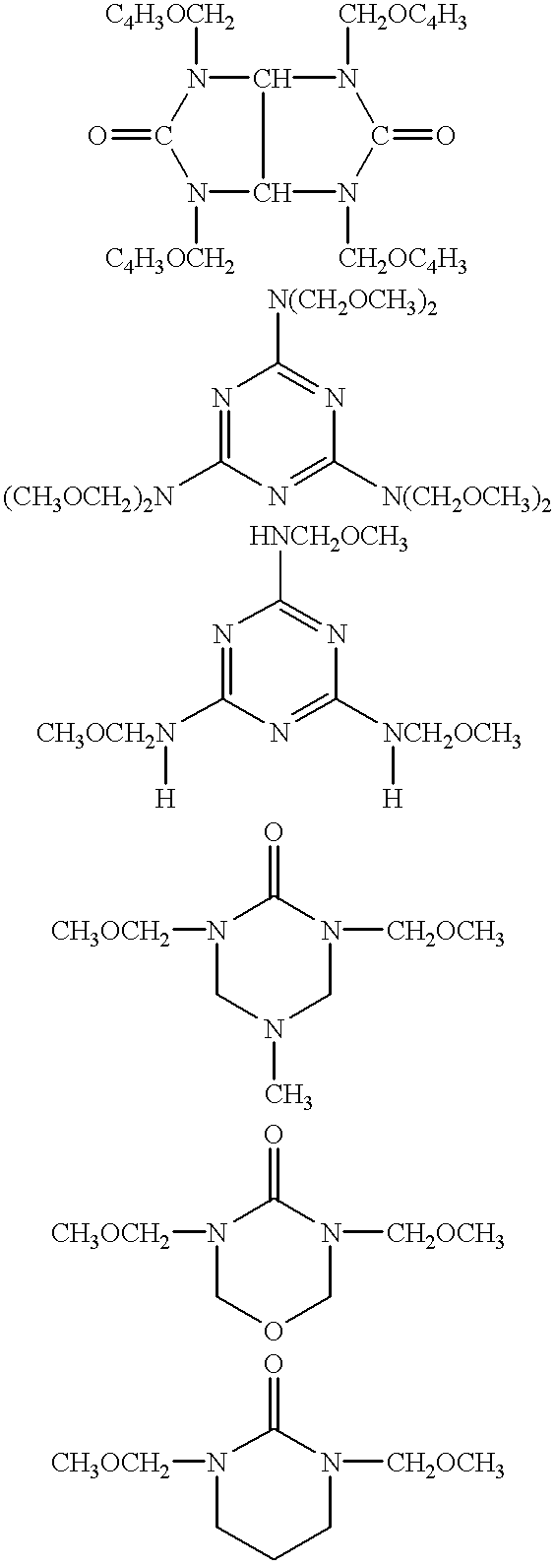

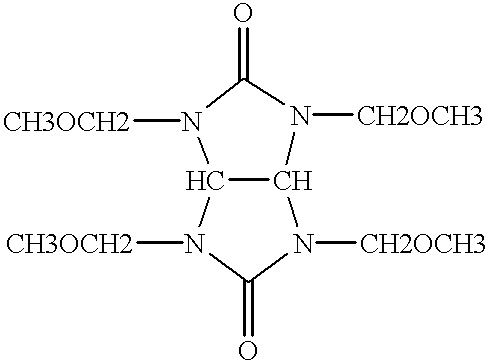

Bottom resist layer composition and patterning process using the same

ActiveUS20080038662A1High resolutionPrecise patternDecorative surface effectsSemiconductor/solid-state device manufacturingResistLength wave

There is disclosed a bottom resist layer composition for a multilayer-resist film used in lithography comprising, at least, a polymer comprising a repeating unit represented by the following general formula (1). Thereby, there can be provided a bottom resist layer composition that exhibits optimum n value and k value on exposure to shorter wavelengths, excellent etching resistance under conditions for etching substrates, and is promising for forming a bottom resist layer used for a multilayer-resist process such as a silicon-containing bilayer resist process or a trilayer resist process using a silicon-containing intermediate resist layer.

Owner:SHIN ETSU CHEM IND CO LTD

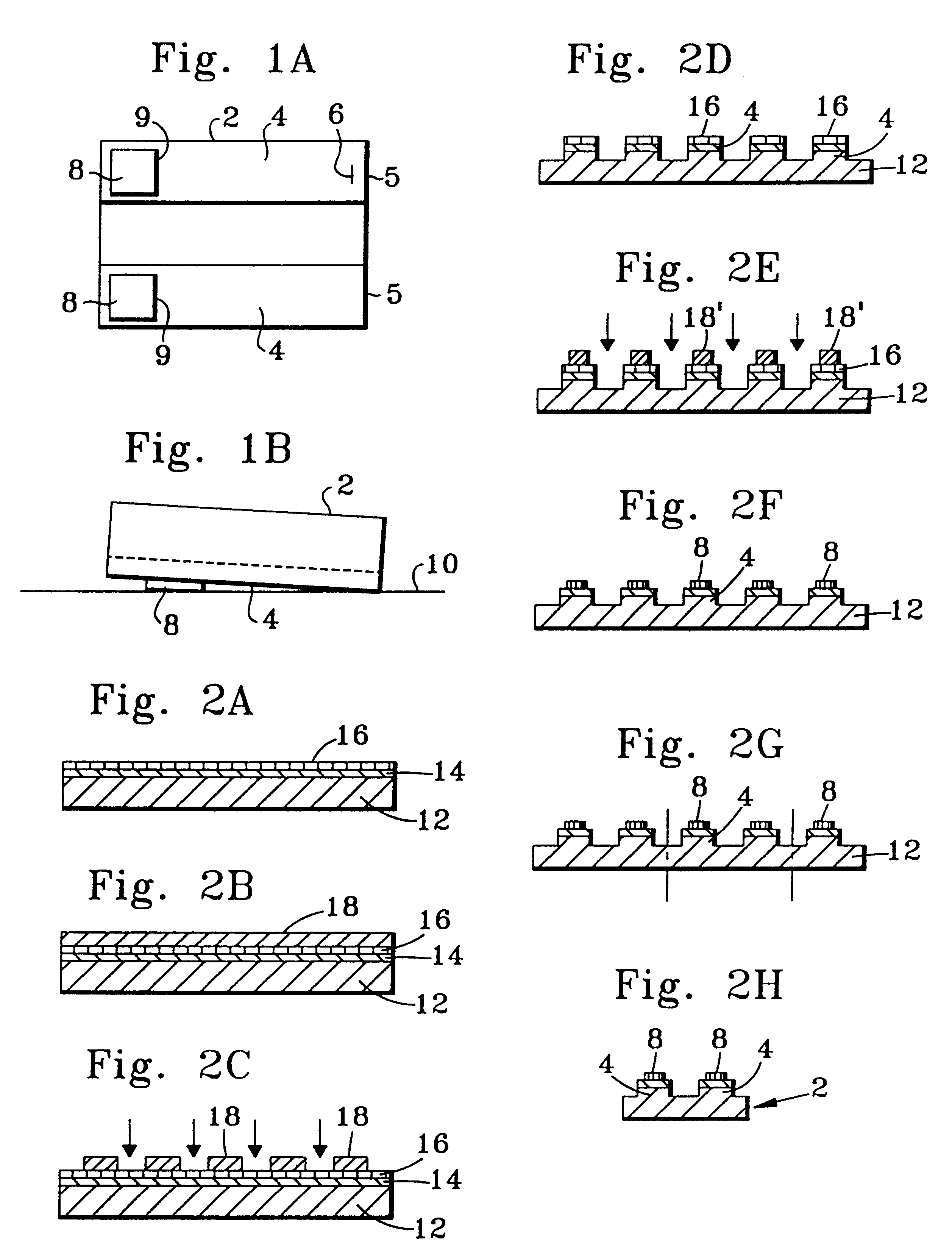

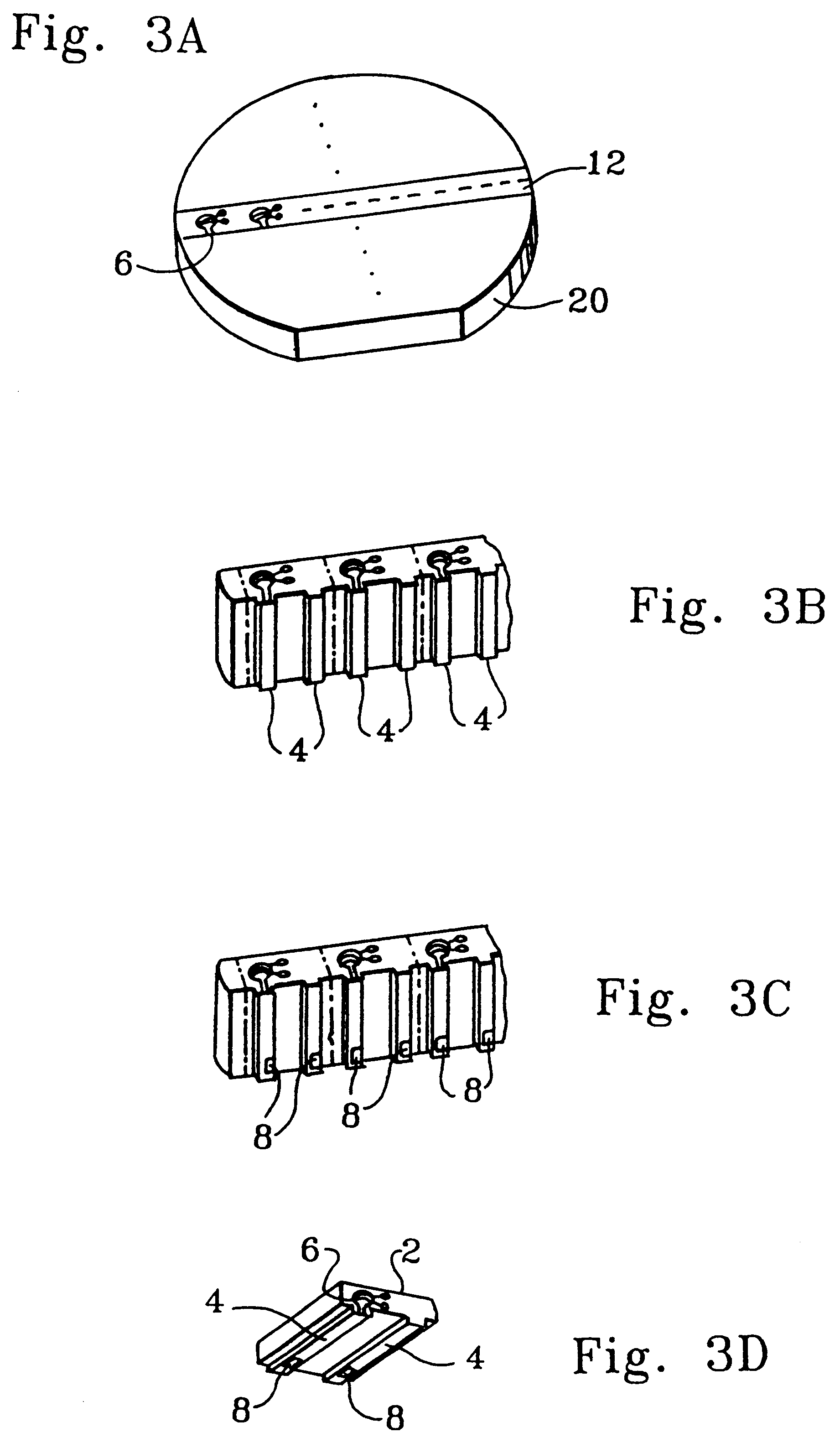

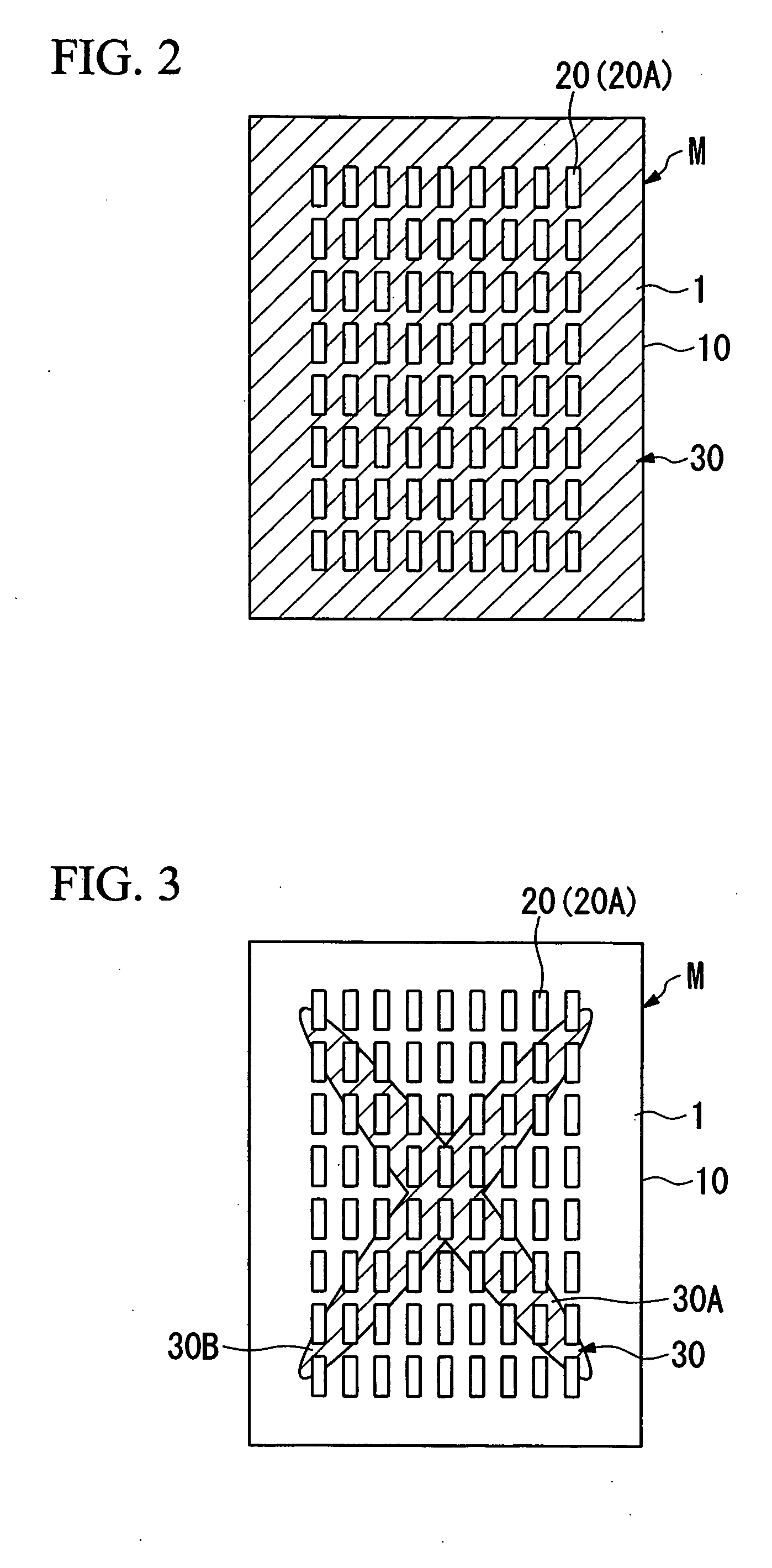

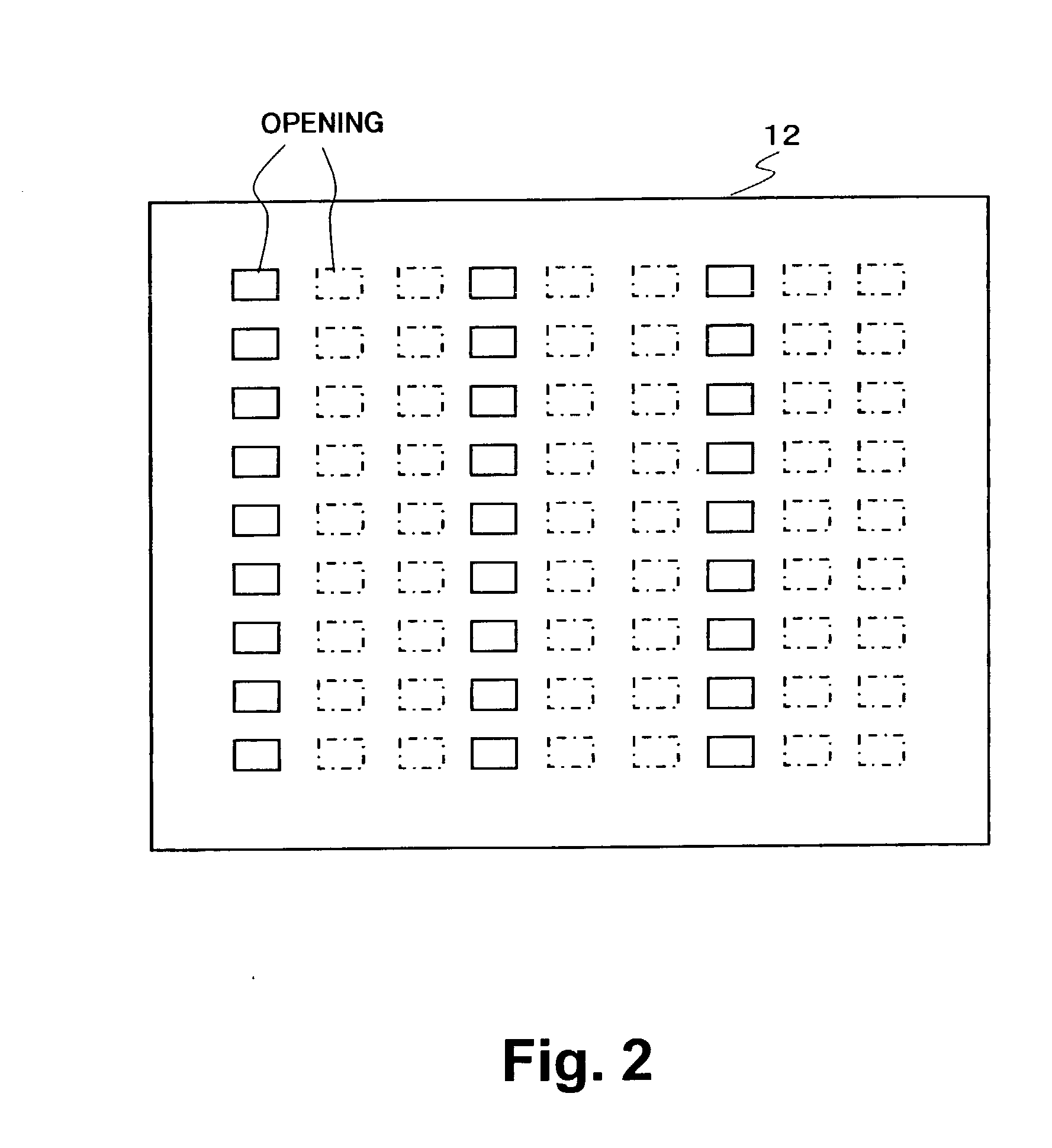

Mask, mask chip, manufacturing method of mask, manufacturing method of mask chip, and electronic device

InactiveUS20070017895A1Precise patternEasy to provideDecorative surface effectsSemiconductor/solid-state device detailsElectronElectrical and Electronics engineering

A mask in which a plurality of mask chips are connected to one another via a supporting member, includes: a plurality of first opening sections that are provided in the plurality of mask chips and that correspond to a pattern to be formed; a cutout section provided at at least one of side faces opposing to each other of the mask chips adjacent to each other; a gap section provided at a connected section connecting the mask chips adjacent to each other, the gap section being composed of the cutout section and including a second opening section corresponding to a pattern to be formed; and a block section that is provided at at least one of the mask chips adjacent to each other and that covers the gap section other than the second opening section.

Owner:SEIKO EPSON CORP

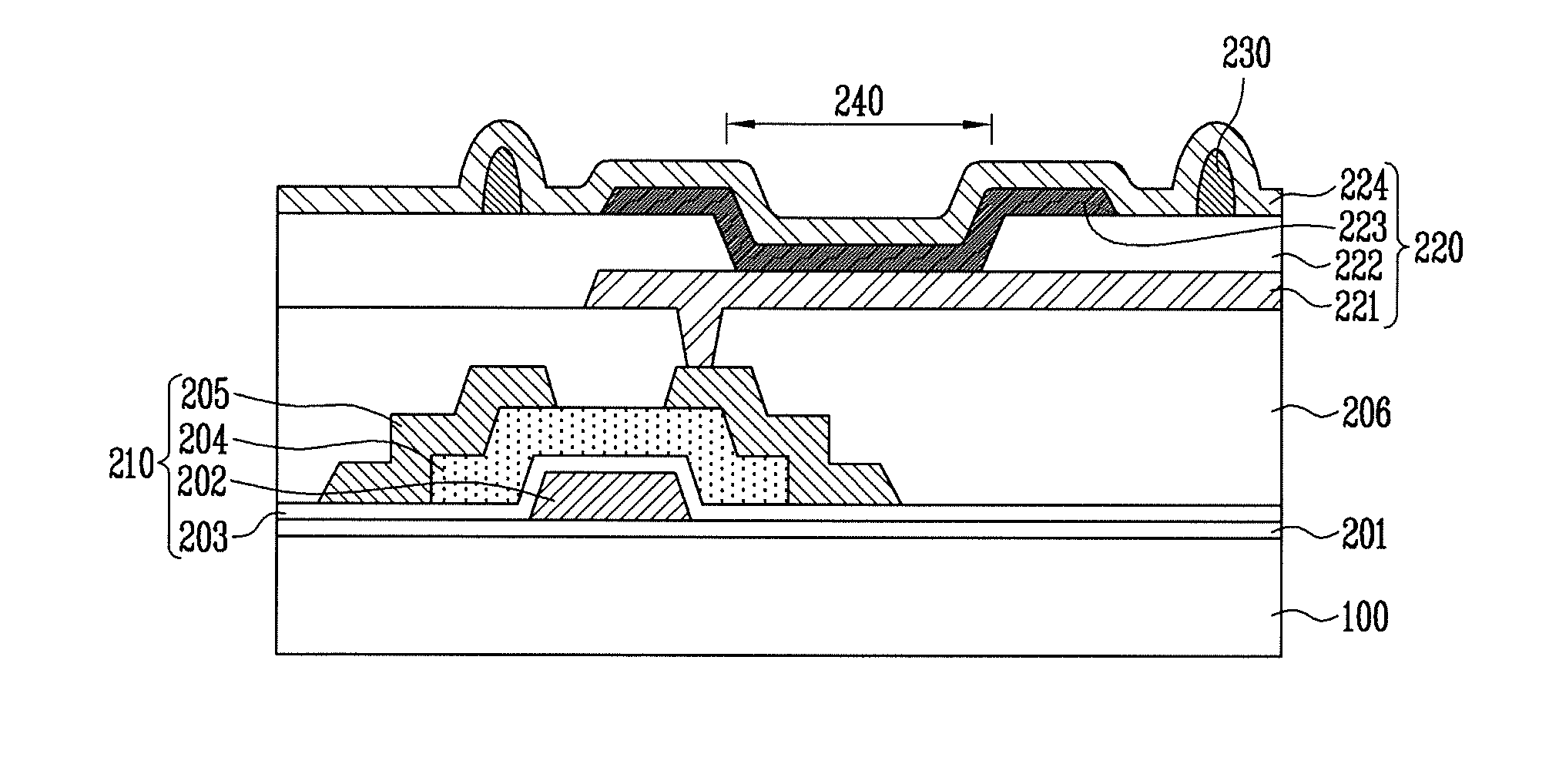

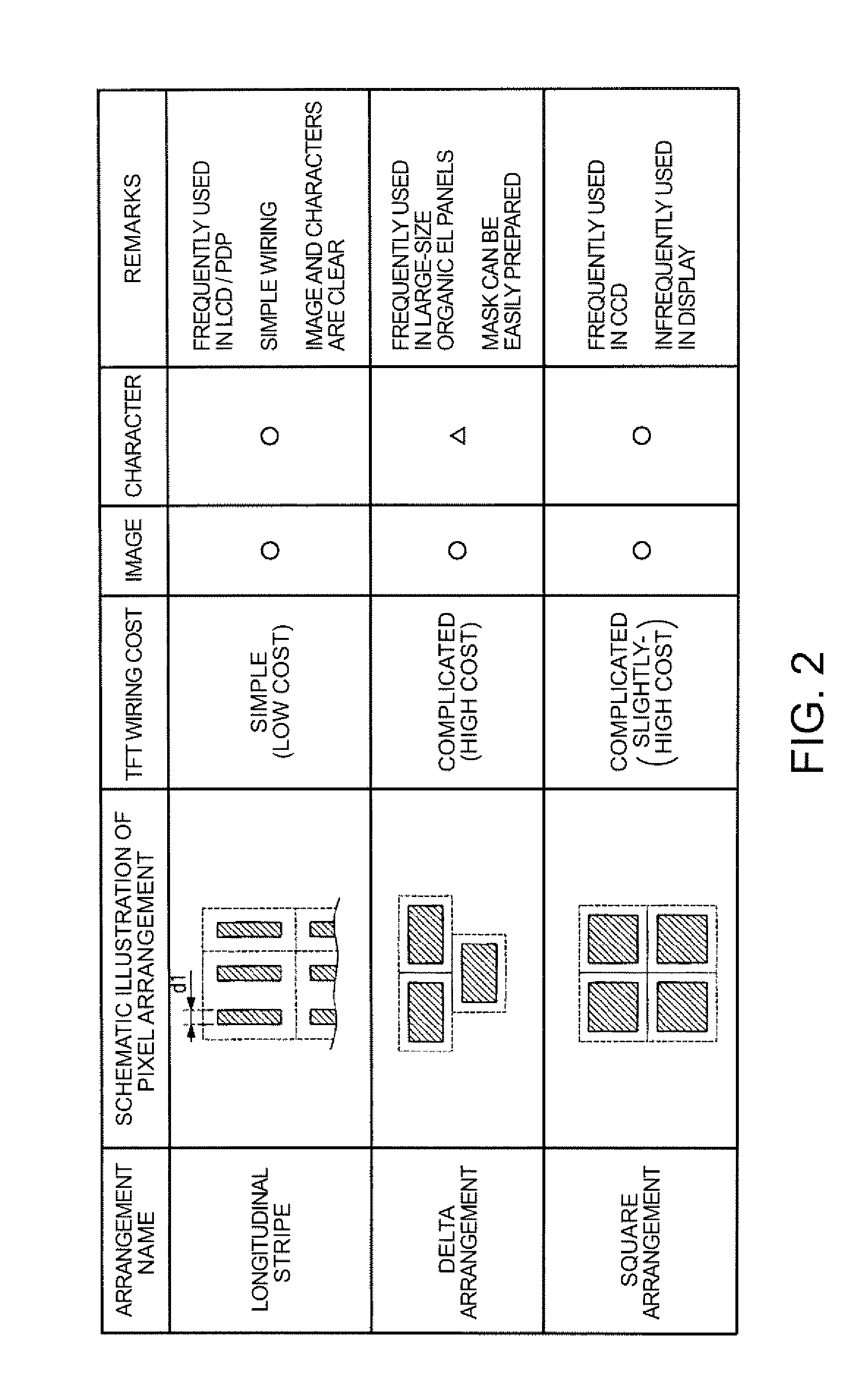

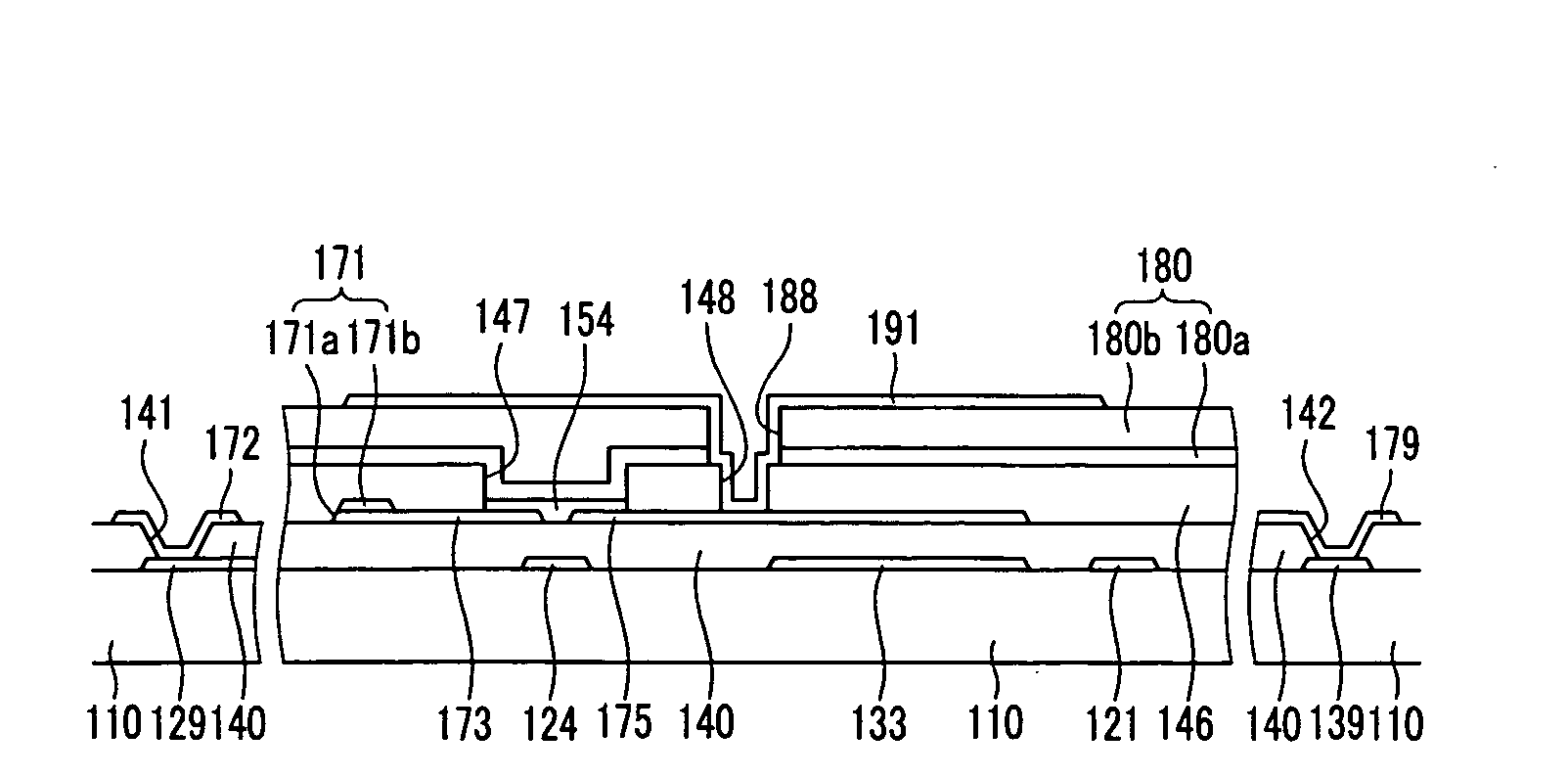

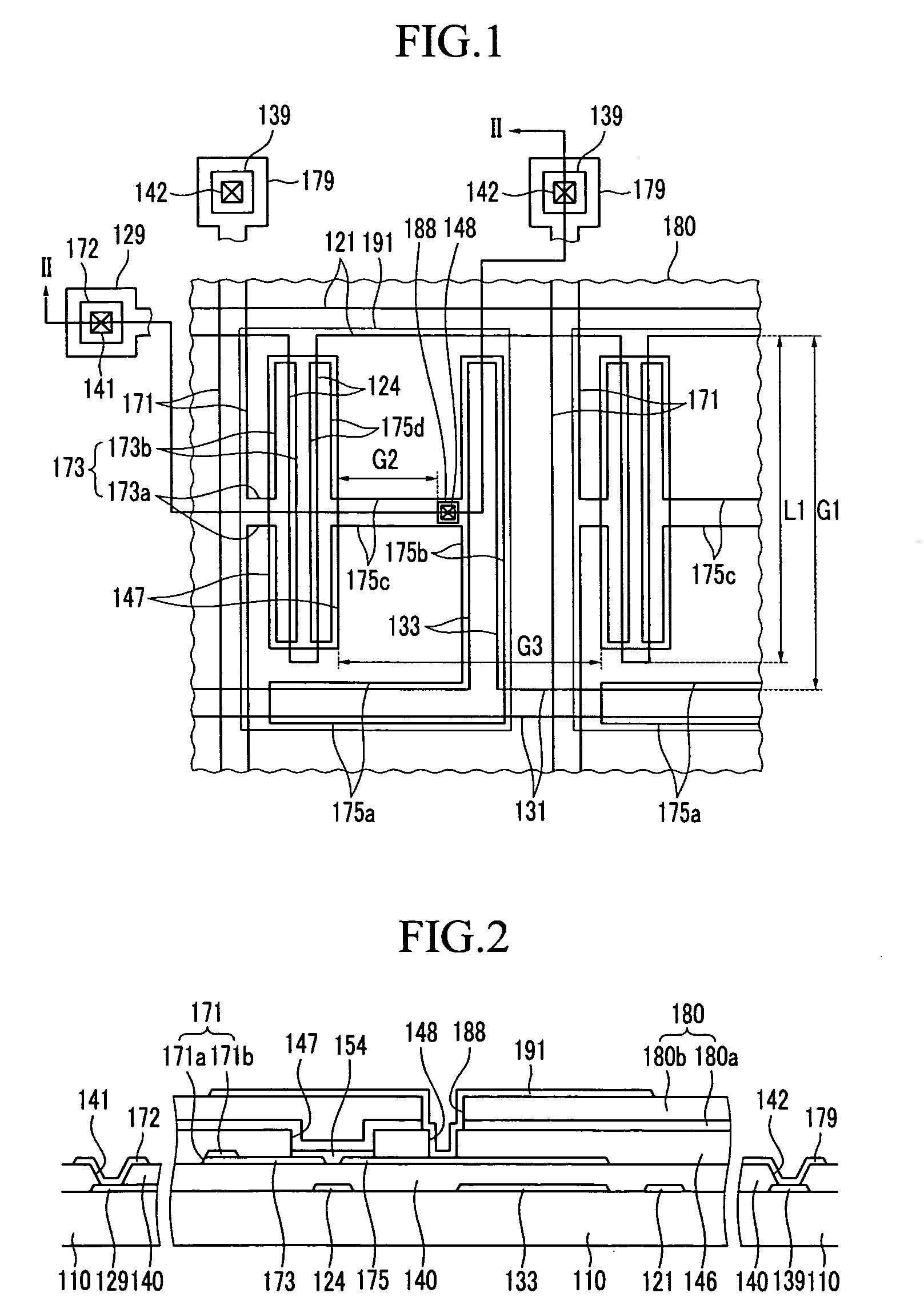

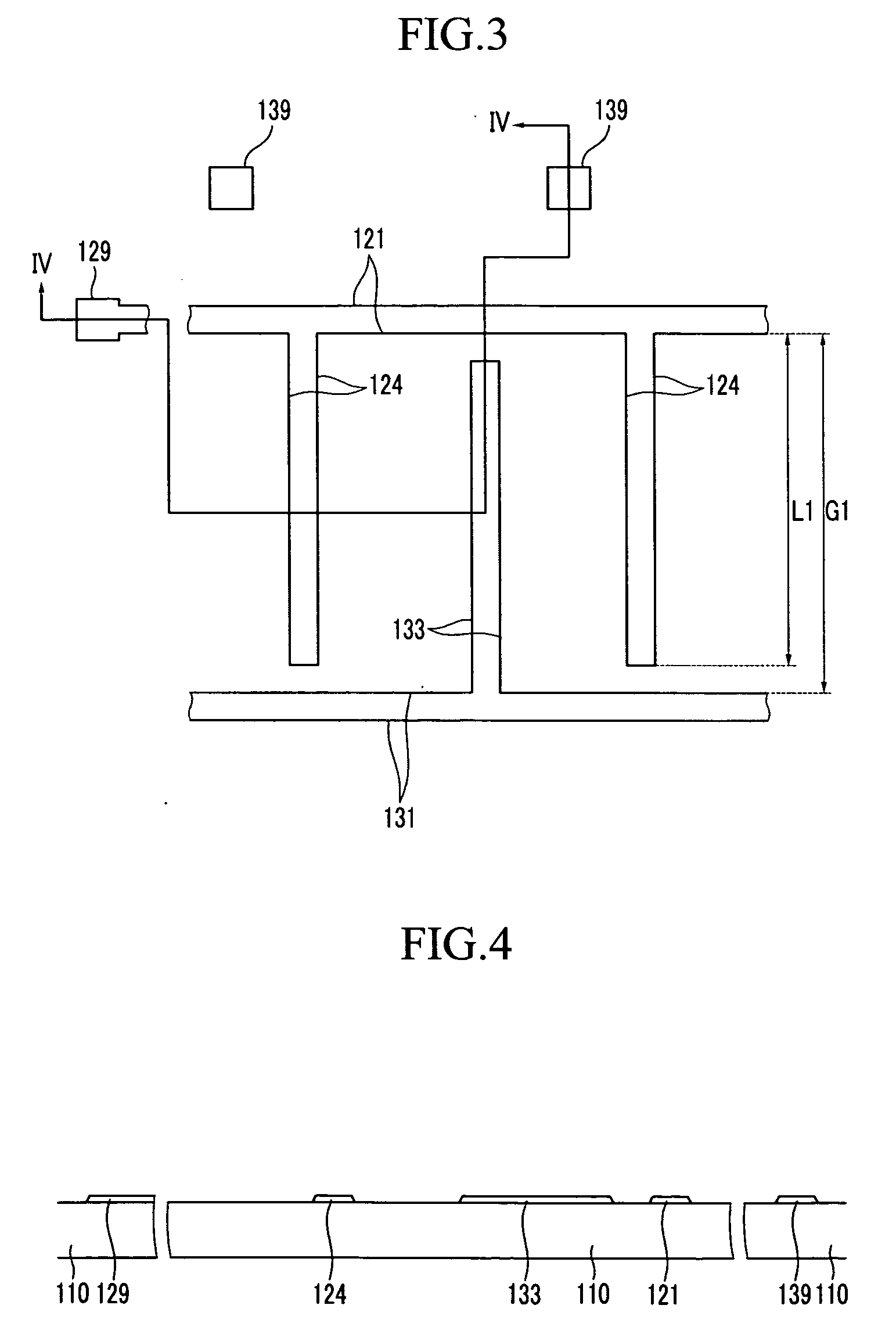

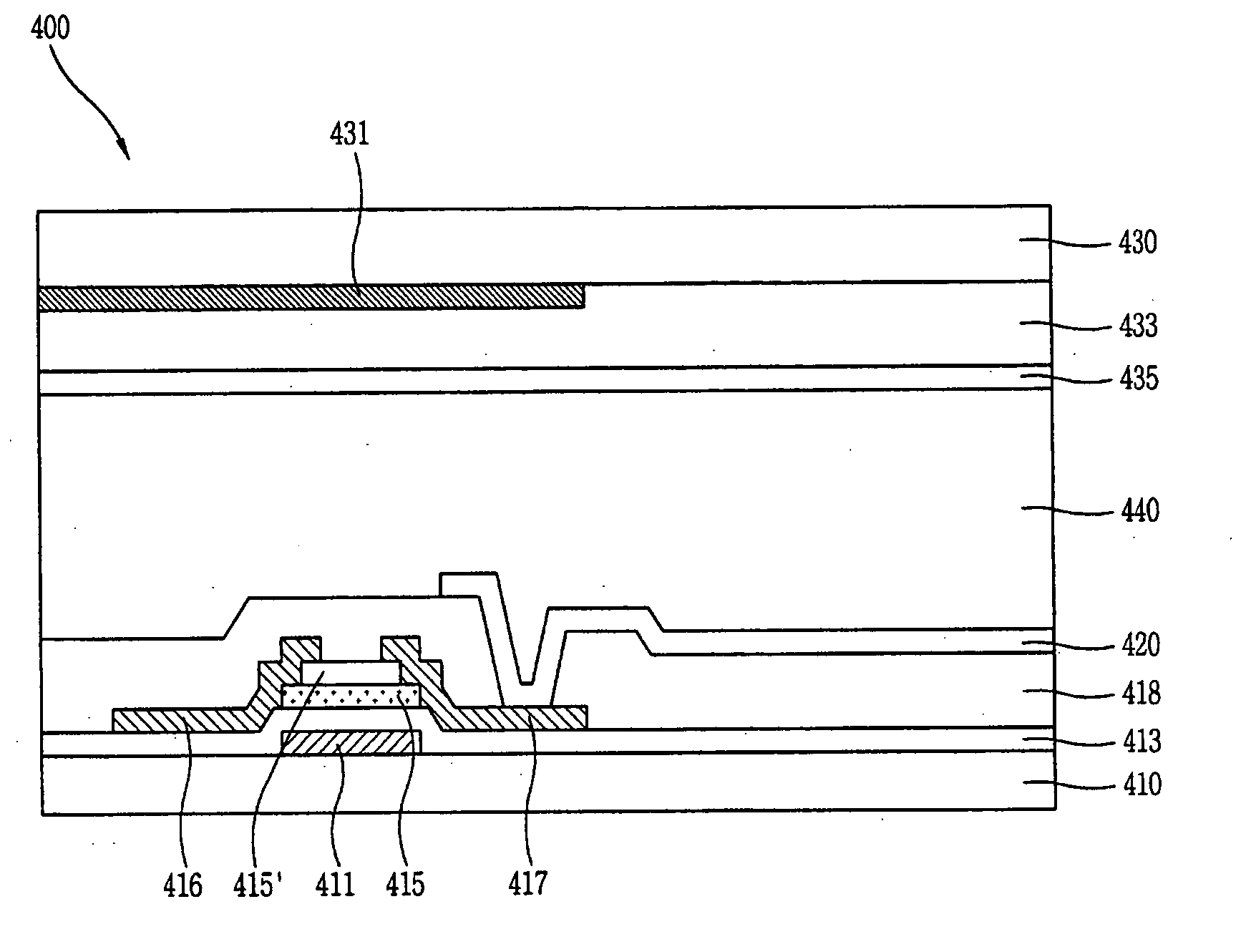

Thin film transistor array panel and fabricating method thereof, and flat panel display with the same

InactiveUS20080258138A1Improve featuresForming accuratelyTransistorSolid-state devicesAdhesiveElectrophoresis

An organic thin film transistor array panel, for an embodiment, includes a plurality of pixel electrodes formed on a top layer to cover organic thin film transistors, with display areas defined by the areas of the pixel electrodes. Accordingly, the aperture ratio of the display device may be increased. A ratio of width to length (W / L) in a channel of an organic thin film transistor may be increased, and thereby on current (Ion) of the organic thin film transistor may be increased. The organic semiconductor may be prevented from overflowing while being formed in holes by an inkjet printing method such that deterioration of thin film transistor characteristics and pixel defects is prevented. The adhesive of the electrophoretic sheet is prevented from penetrating into the organic semiconductor when the electrophoretic display is formed by attaching the electrophoretic sheet to the organic thin film transistor array panel by a lamination method.

Owner:SAMSUNG ELECTRONICS CO LTD

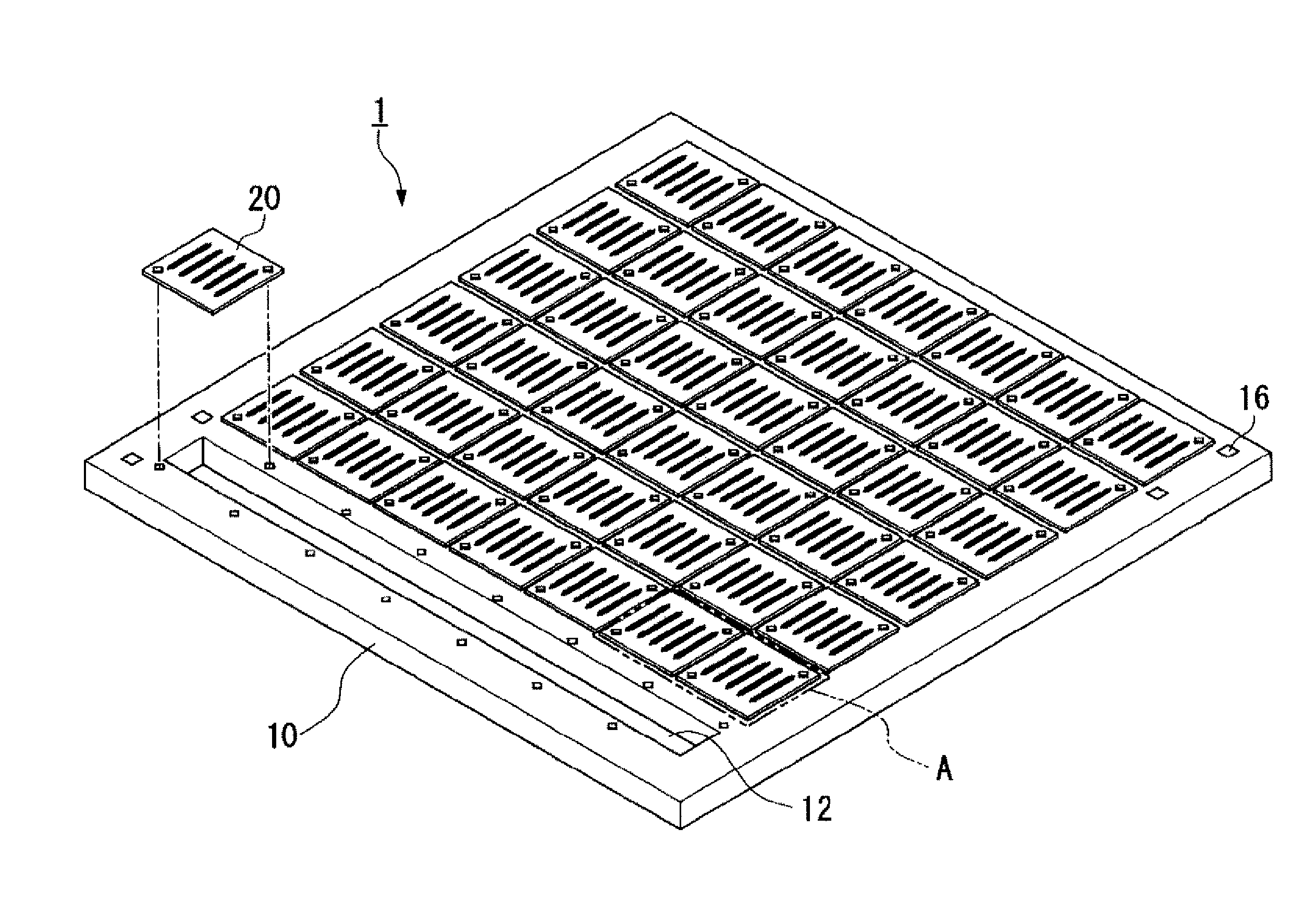

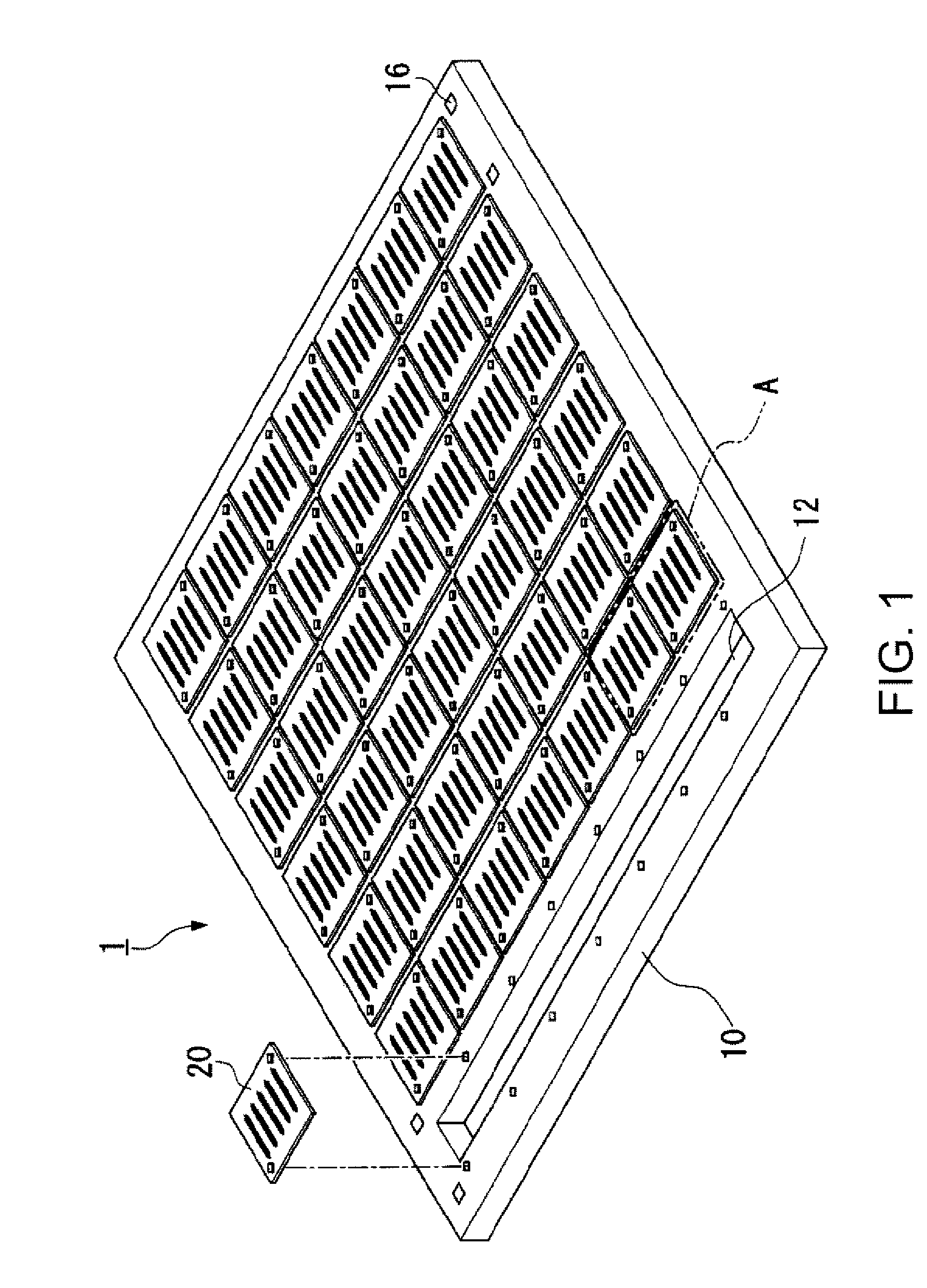

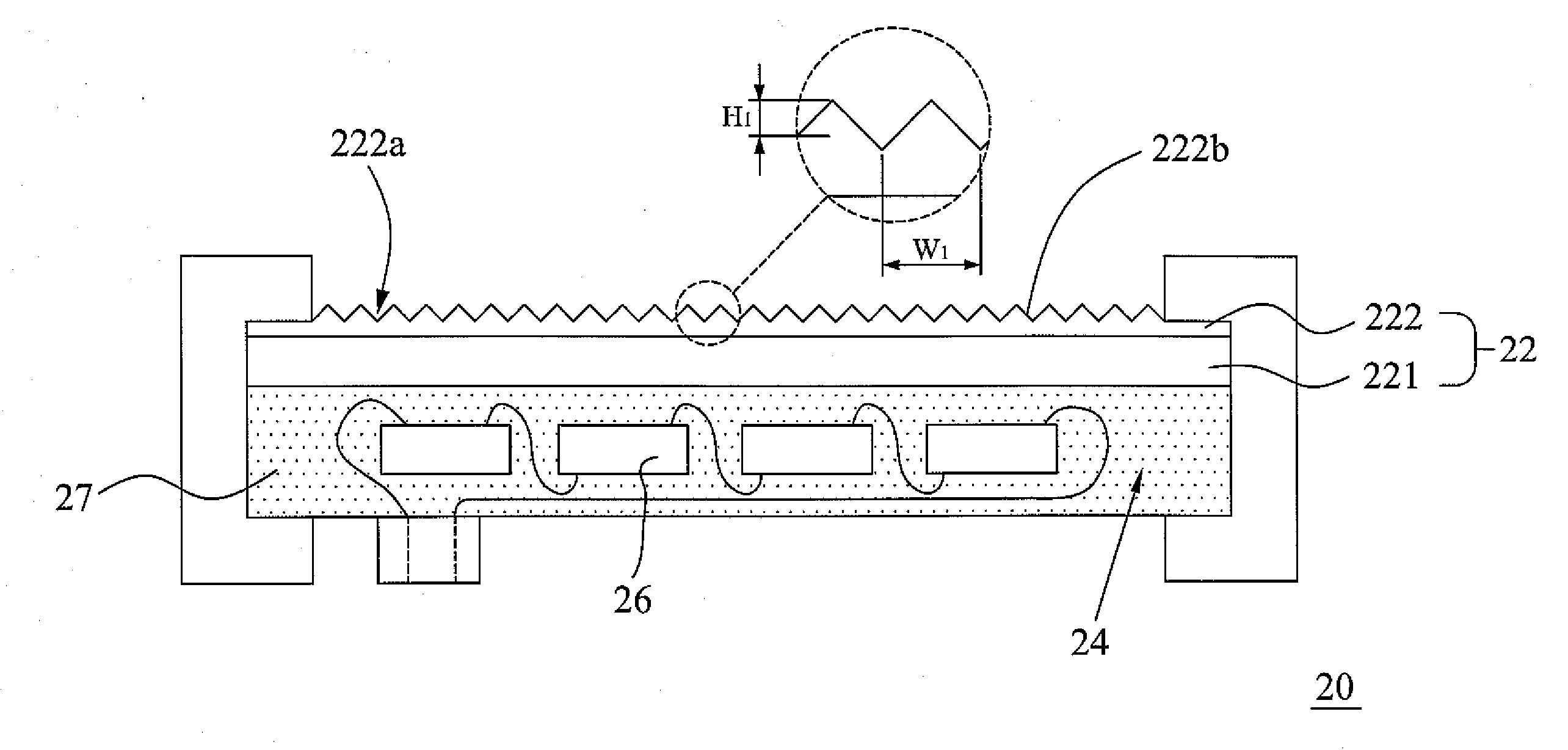

Solar Cell

InactiveUS20090229655A1Avoid dust accumulationAvoid water accumulationPV power plantsPhotovoltaic energy generationEngineeringSolar cell

A solar cell is provided. The solar cell defines a receiving room in where at least a cell unit is located. A transparent cover plate is placed over the cell unit. In addition, the transparent cover plate includes a base plate and a structured plate which are adhered to each other. Wherein, the base plate is made from inflexible material and the structured plate is made from a photo resin. Moreover, there are pluralities of convex first patterns disposed on the incident surface of the structured plate.

Owner:FLYPOWER INT

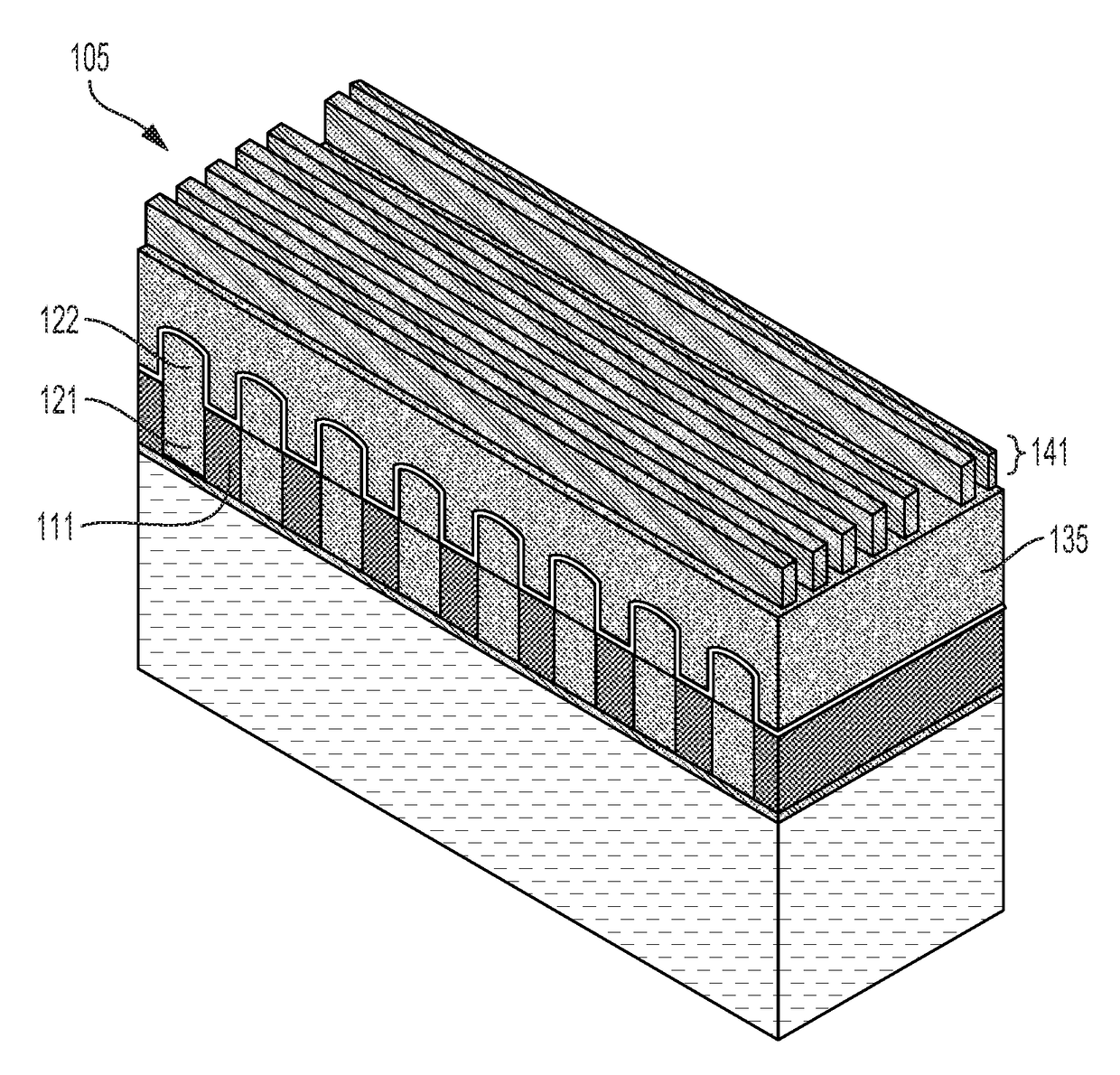

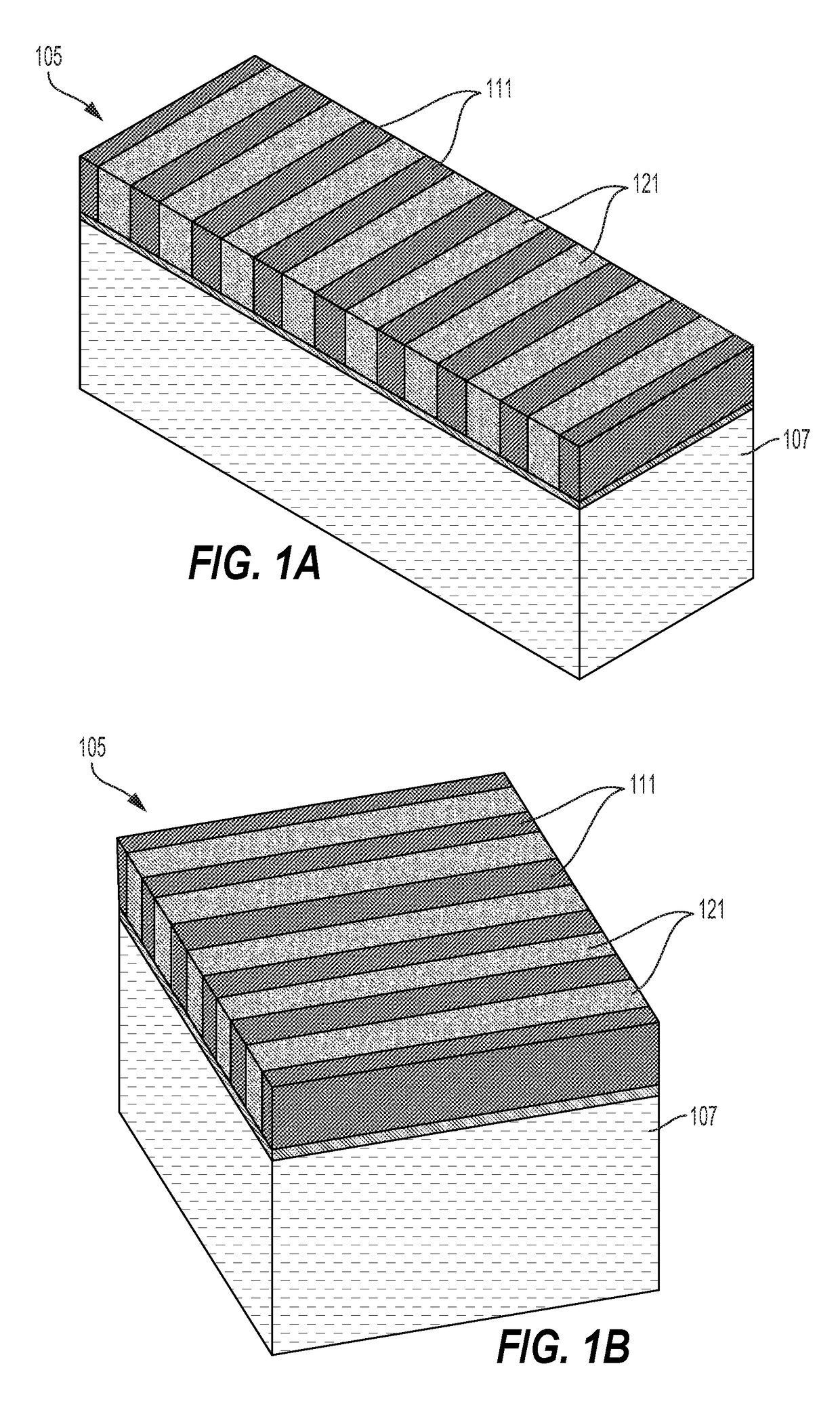

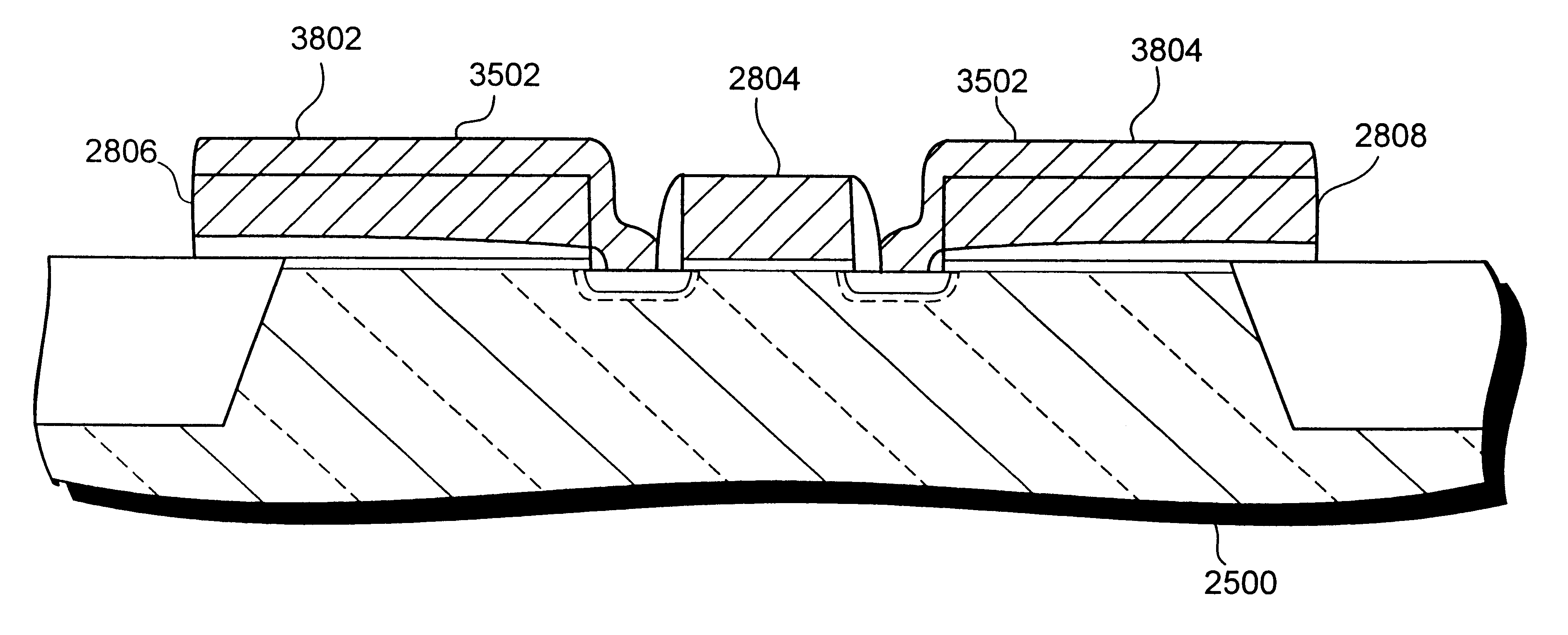

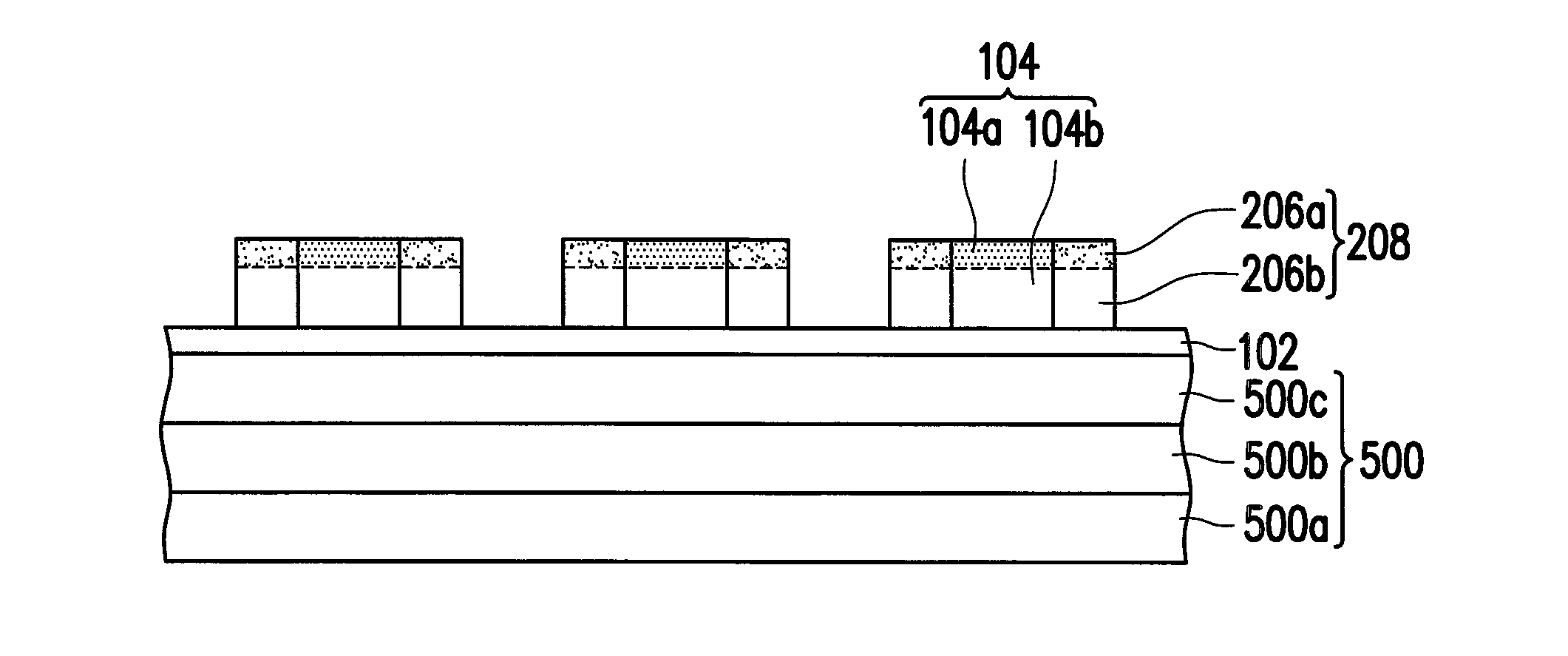

Self-alignment of metal and via using selective deposition

ActiveUS9837314B2Precise patternAvoid etchingSemiconductor/solid-state device manufacturingTectorial membraneSelective deposition

Techniques herein include methods of patterning substrates such as for back end of line (BEOL) metallization processes. Techniques herein enable fully self-aligned vias and lines. Processes herein include using selective deposition, protective films and combination etch masks for accurately patterning a substrate. In a substrate having uncovered portions of metal material and dielectric material, the dielectric material is grown upwardly without covering metal material. This raised dielectric material is conformally protected and used in subsequent patterning step to align via and line placement. Such combinations mitigate overlay errors.

Owner:TOKYO ELECTRON LTD

Transistor having raised source and drain

The preferred embodiment of the present invention provides a transistor structure and method for fabricating the same that overcomes the disadvantages of the prior art. In particular, the preferred structure and method results in lower leakage and junction capacitance by using raised source and drains which are partially isolated from the substrate by a dielectric layer. The raised source and drains are preferably fabricated from the same material layer used to form the transistor gate. The preferred method for fabricating the transistor uses hybrid resist to accurately pattern the gate material layer into regions for the gate, the source and the drain. The source and drain regions are then connected to the substrate by growing silicon. The preferred method thus results in an improved transistor structure while not requiring excessive fabrication steps.

Owner:IBM CORP

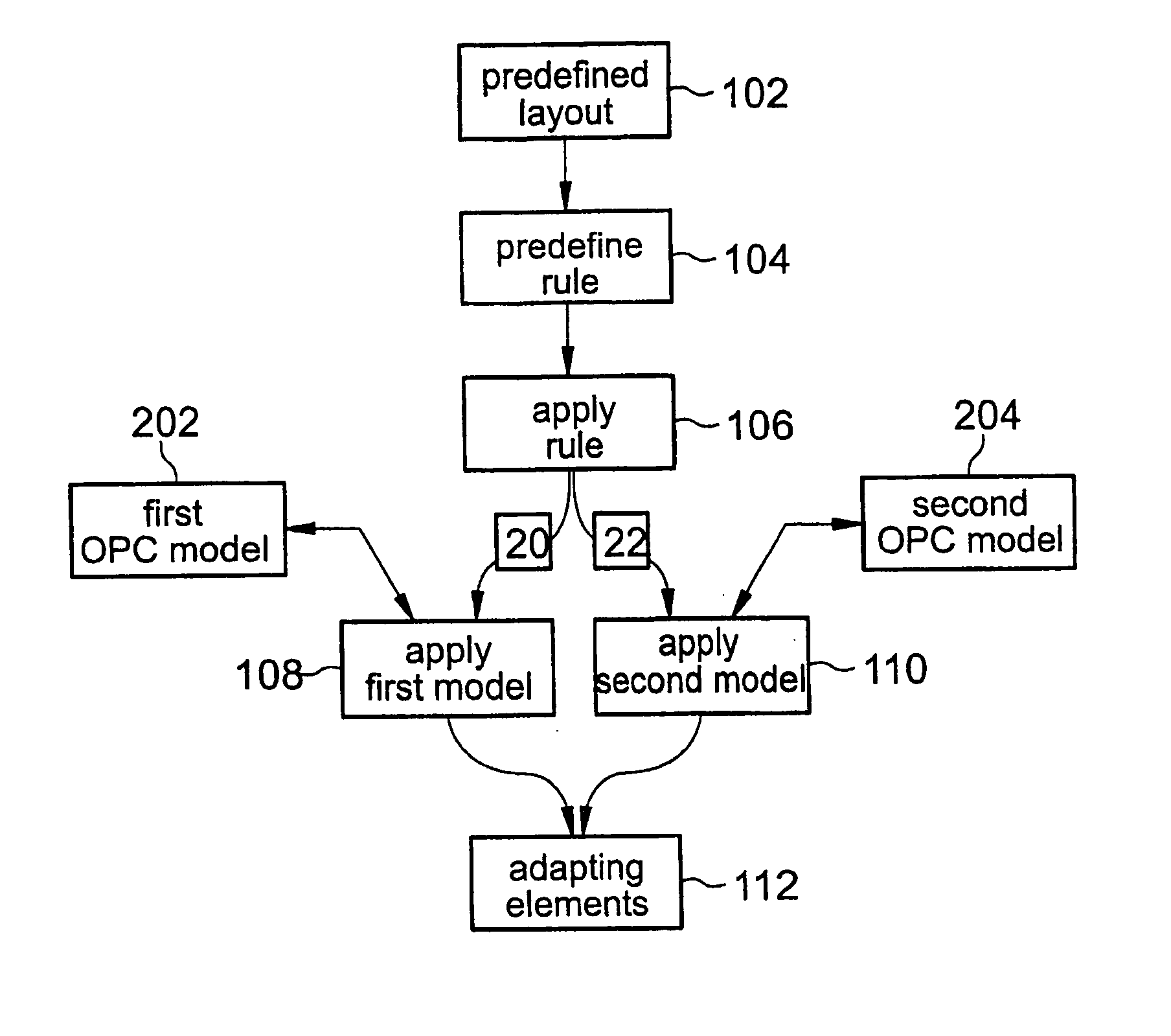

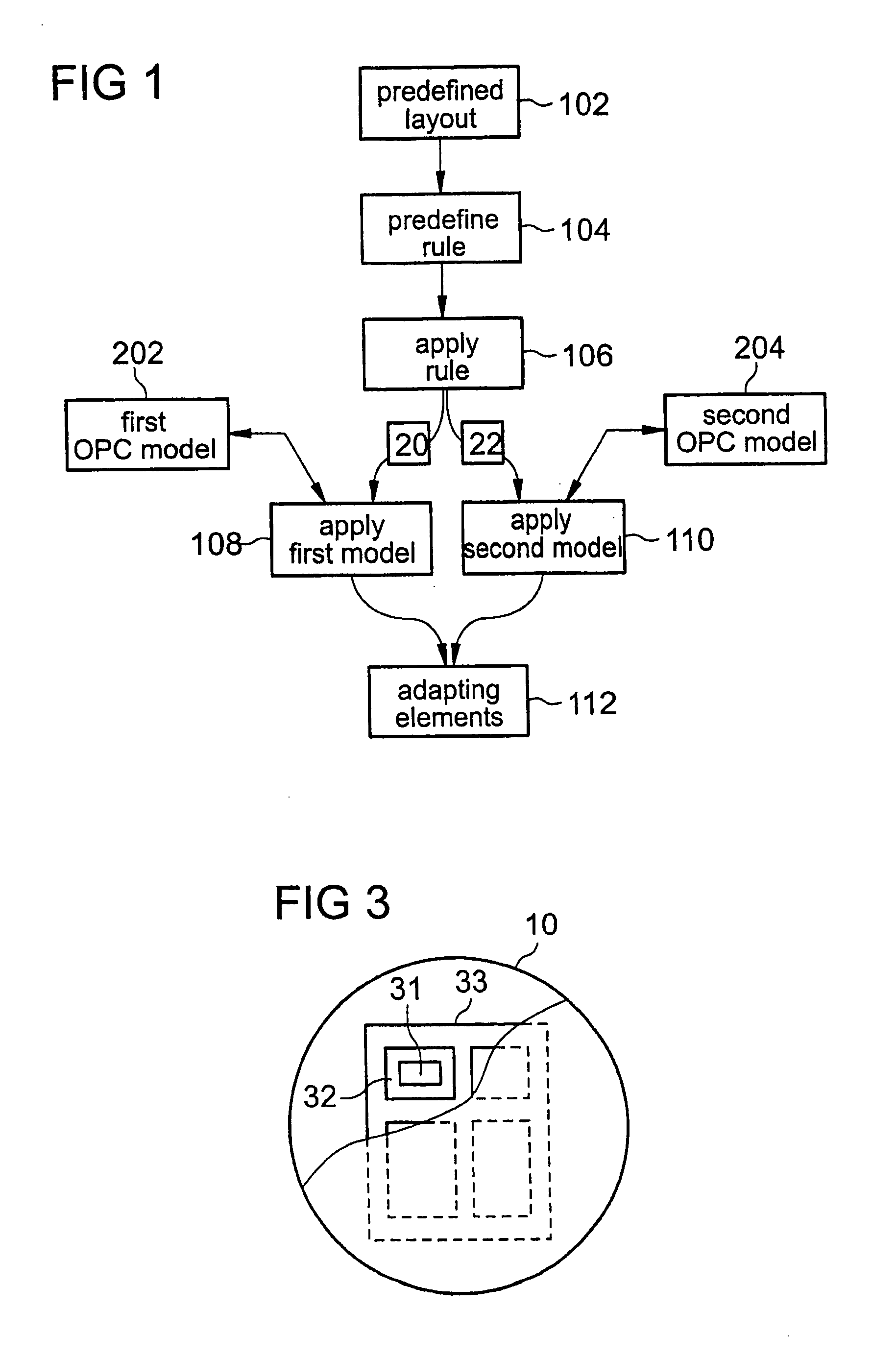

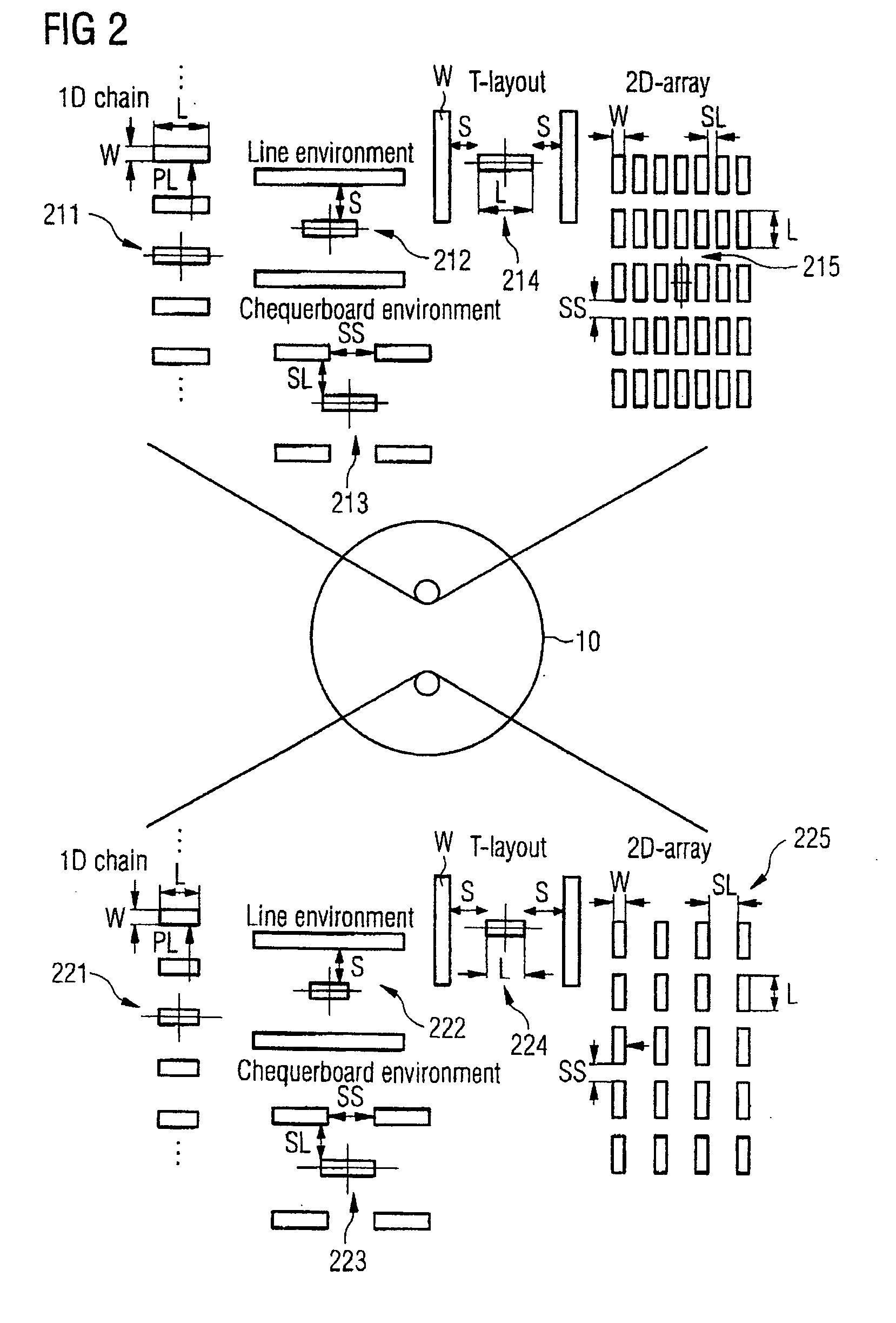

Method for correcting the optical proximity effect

InactiveUS20060195808A1Quality improvementImprove matchElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringStructuring element

A respectively separate optical proximity correction (OPC) process model and method is formed for selected structure classes or partial patterns of a layout is disclosed. For this purpose, the corresponding structure elements are treated separately as early as during the modeling. During the modeling and also for OPC correction, the structure elements in the layout to be corrected are selected in correspondingly rule-based fashion. The thus selected elements of the layout are simulated and corrected with the separately formed OPC process models. The errors in the description of the imaging process are smaller for the separate OPC process models than for a uniform OPC process model, which has the effect of improving the accuracy of the imaging on the wafer in subsequent layout transfer processes.

Owner:QIMONDA

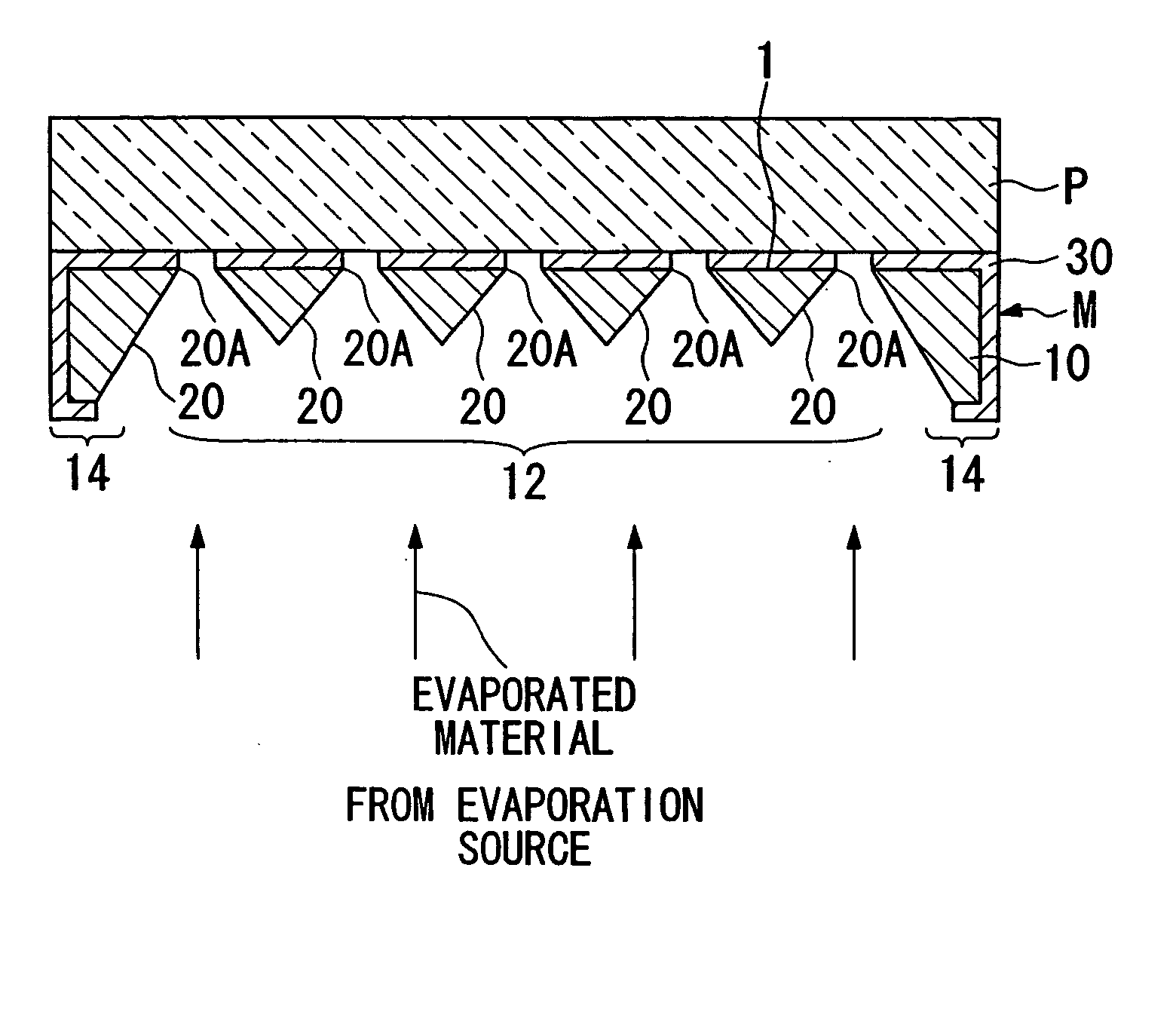

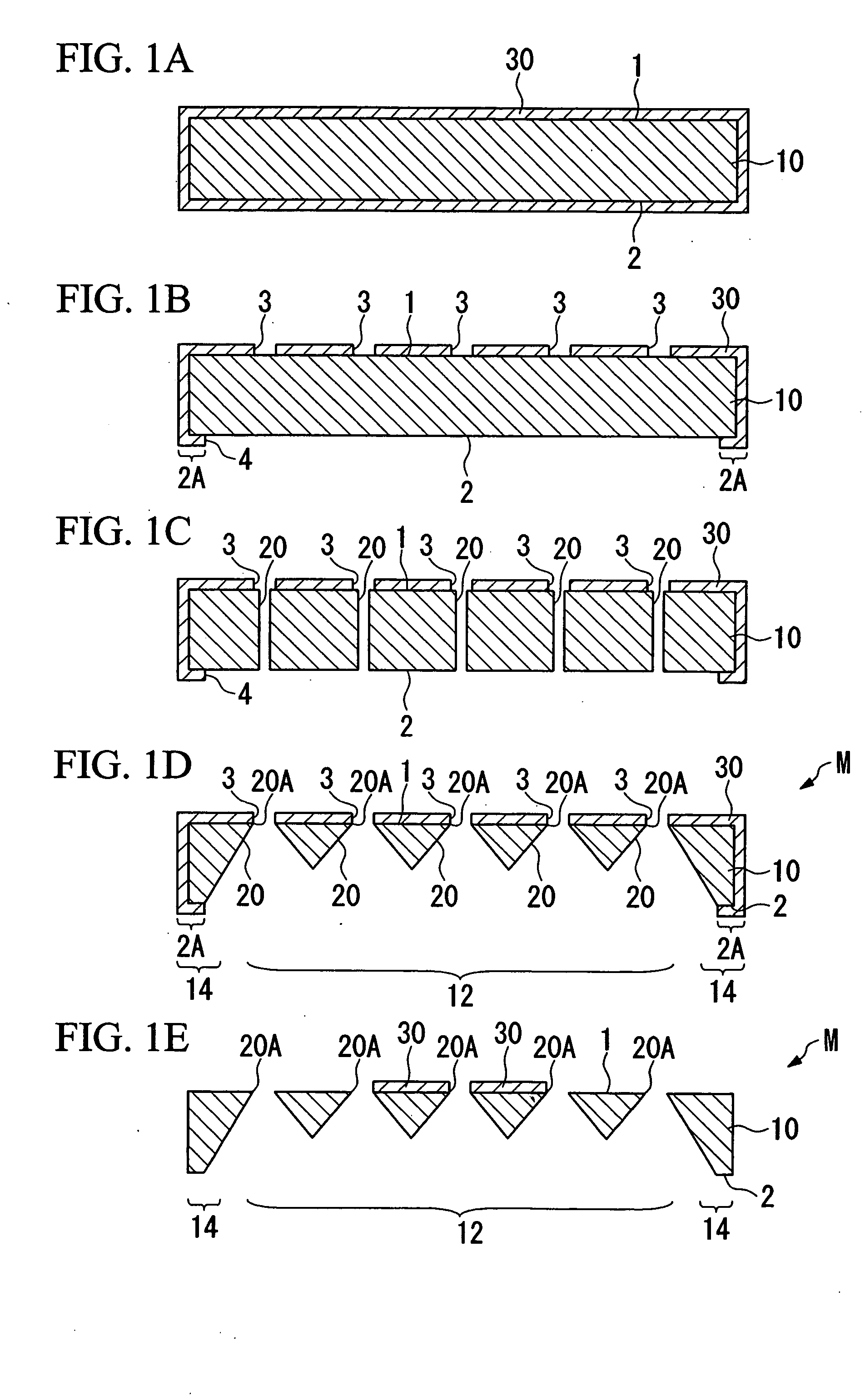

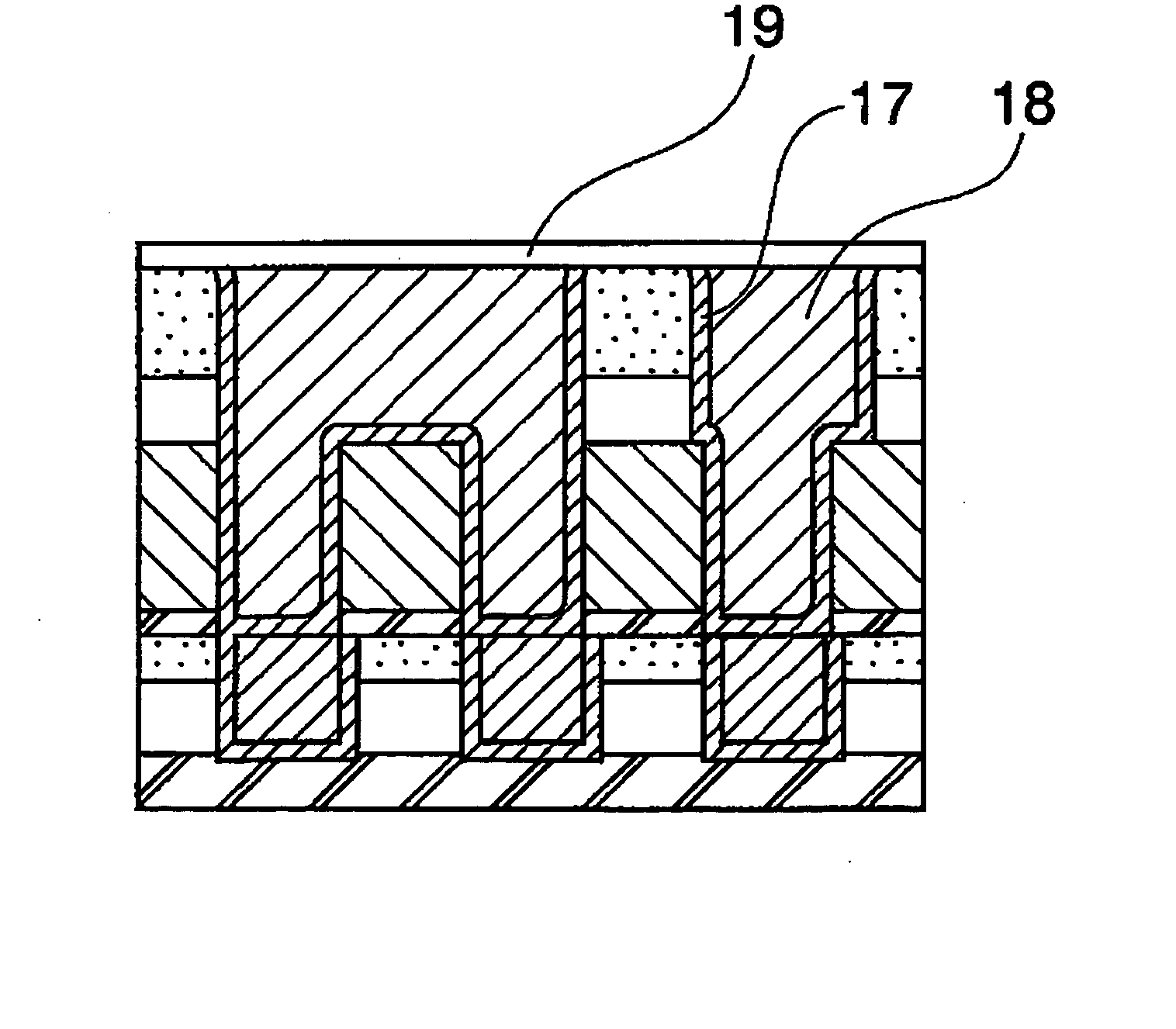

Mask and method for manufacturing the same, method for manufacturing display, method for manufacturing organic electroluminescent display, organic electroluminescent device, and electronic device

InactiveUS20050123676A1Improve the display effectHigh quality displaySemiconductor/solid-state device detailsElectroluminescent light sourcesEngineeringOrganic electroluminescence

A mask includes a substrate which includes a front side and a back side and is provided with through-holes; and a film which adjusts a shape of the substrate provided above at least one of the front side and the back side of the substrate. A method of manufacturing a mask includes the steps of: providing a substrate having a front side and a back side; forming a film which adjusts a shape of the substrate above at least one of the front side and the back side of the substrate; and drilling through-holes in the substrate.

Owner:SEIKO EPSON CORP

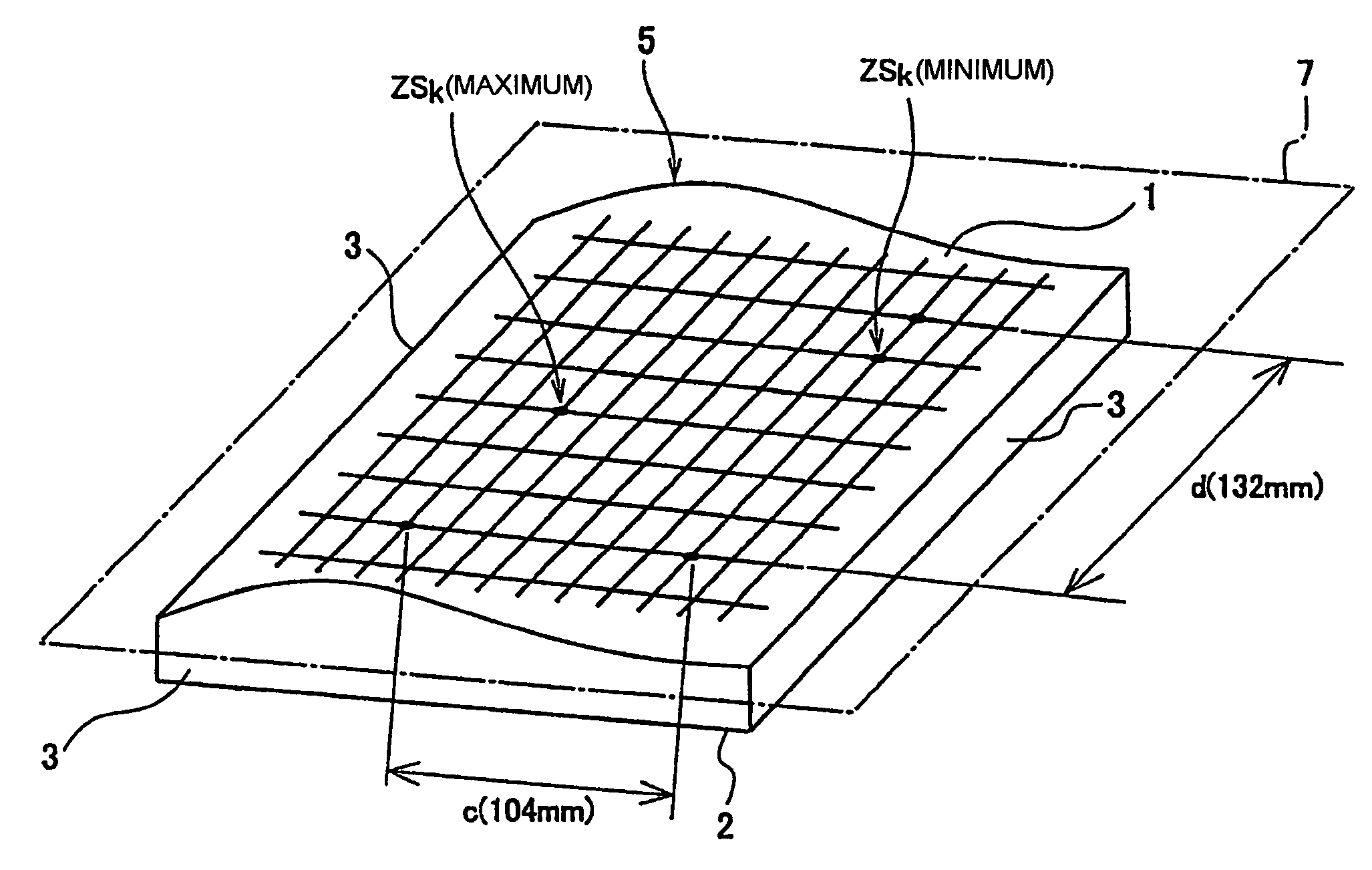

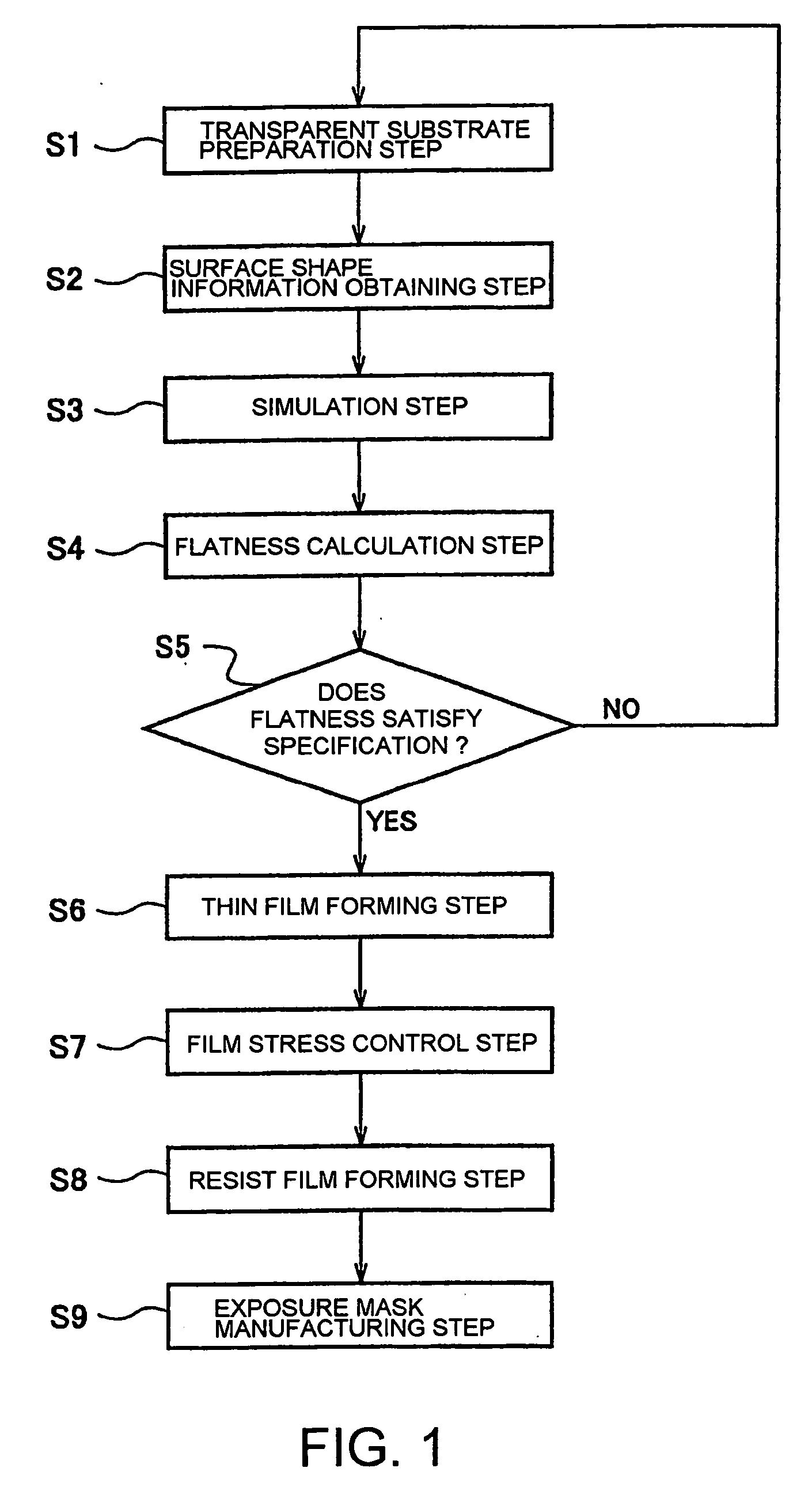

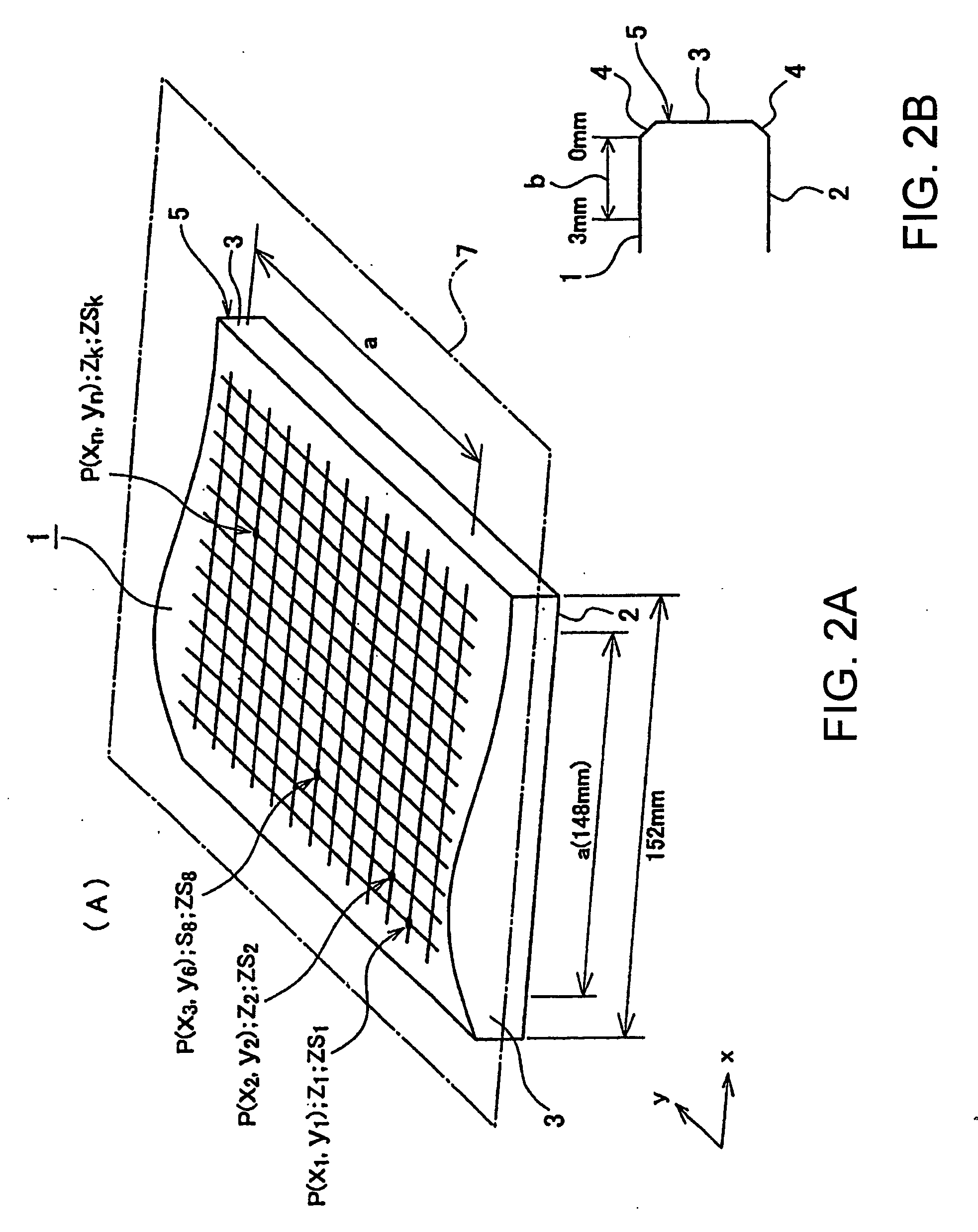

Mask blank transparent substrate manufacturing method, mask blank manufacturing method, and exposure mask manufacturing method

ActiveUS20060194126A1Inhibition of defect generationImprove accuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingMeasurement pointEngineering

A method includes a preparation step of preparing a transparent substrate having a precision-polished main surface, a surface shape information obtaining step of obtaining, as surface shape information, height information at a plurality of measurement points on the main surface of the transparent substrate that contacts a mask stage of an exposure apparatus, a simulation step of obtaining, based on the surface shape information and shape information of the mask stage, height information at the plurality of measurement points by simulating the state where the transparent substrate is set in the exposure apparatus, a flatness calculation step of calculating, based on the height information obtained through the simulation, a flatness of the transparent substrate when it is set in the exposure apparatus, a judging step of judging whether or not the calculated flatness satisfies a specification, and a thin film forming step of forming a thin film as serving as a mask pattern, on the main surface of the transparent substrate whose flatness satisfies the specification.

Owner:HOYA CORP

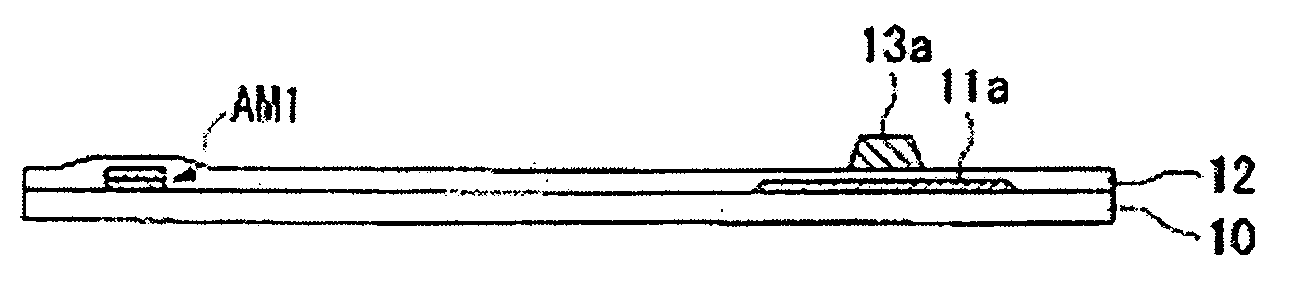

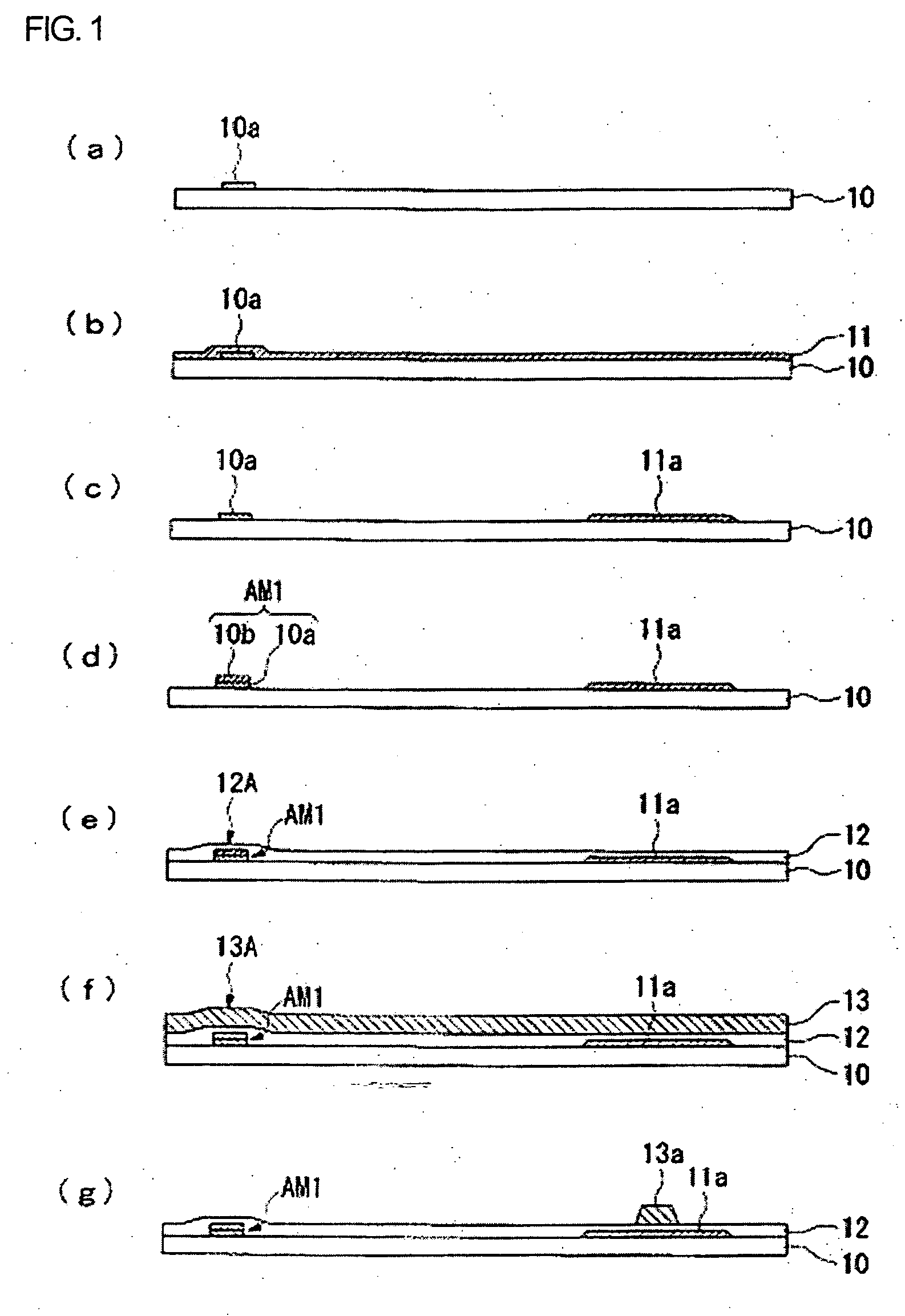

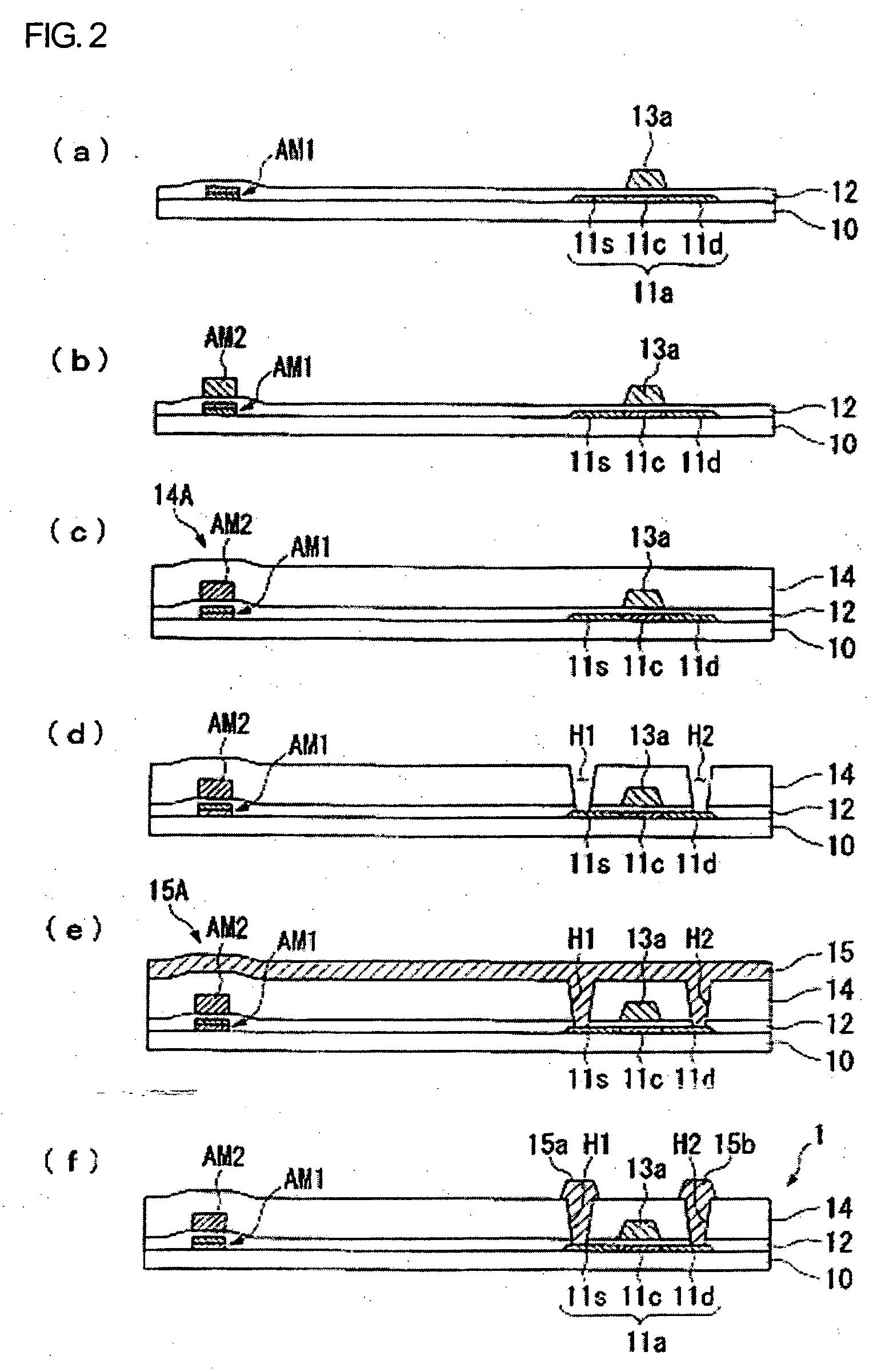

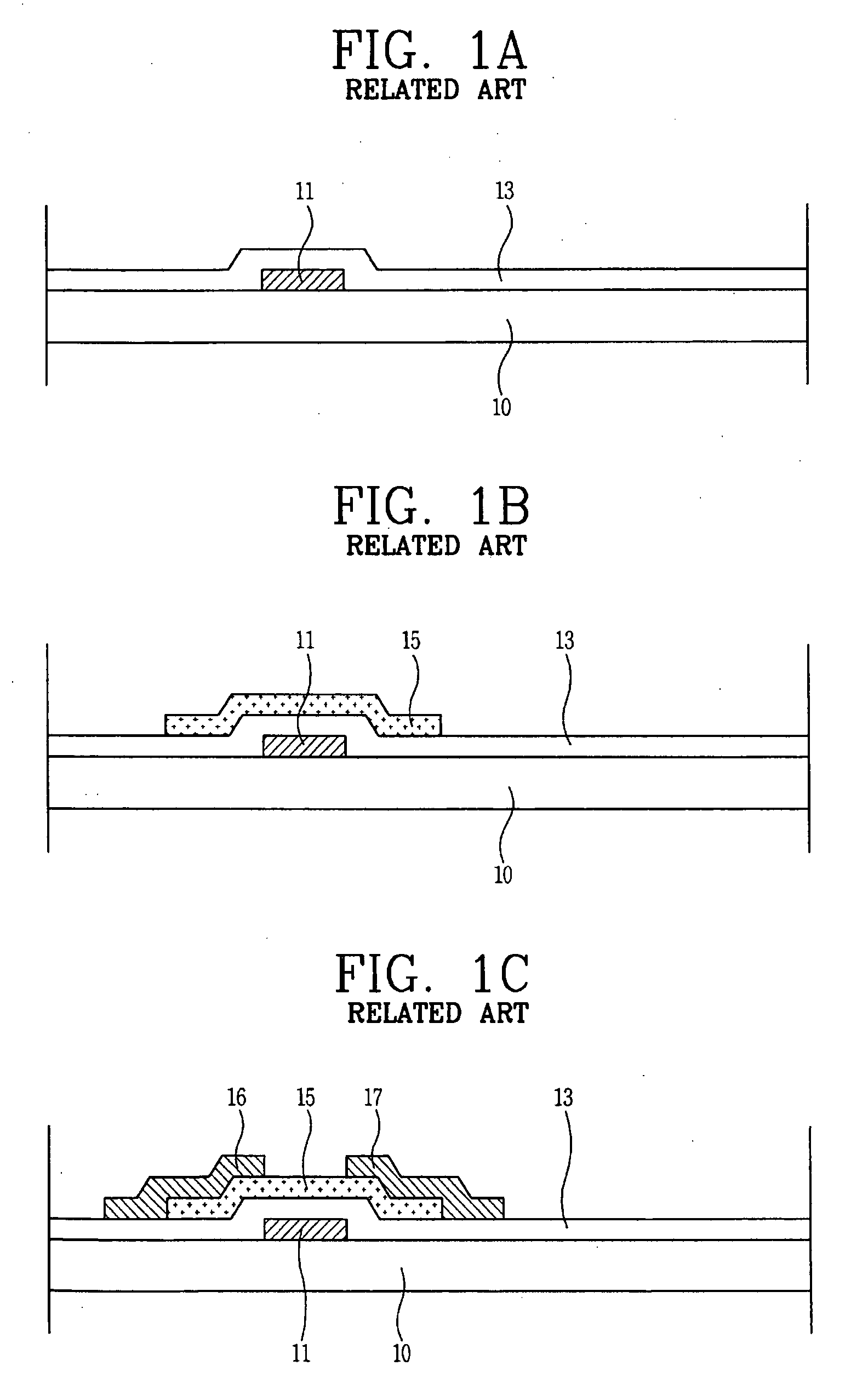

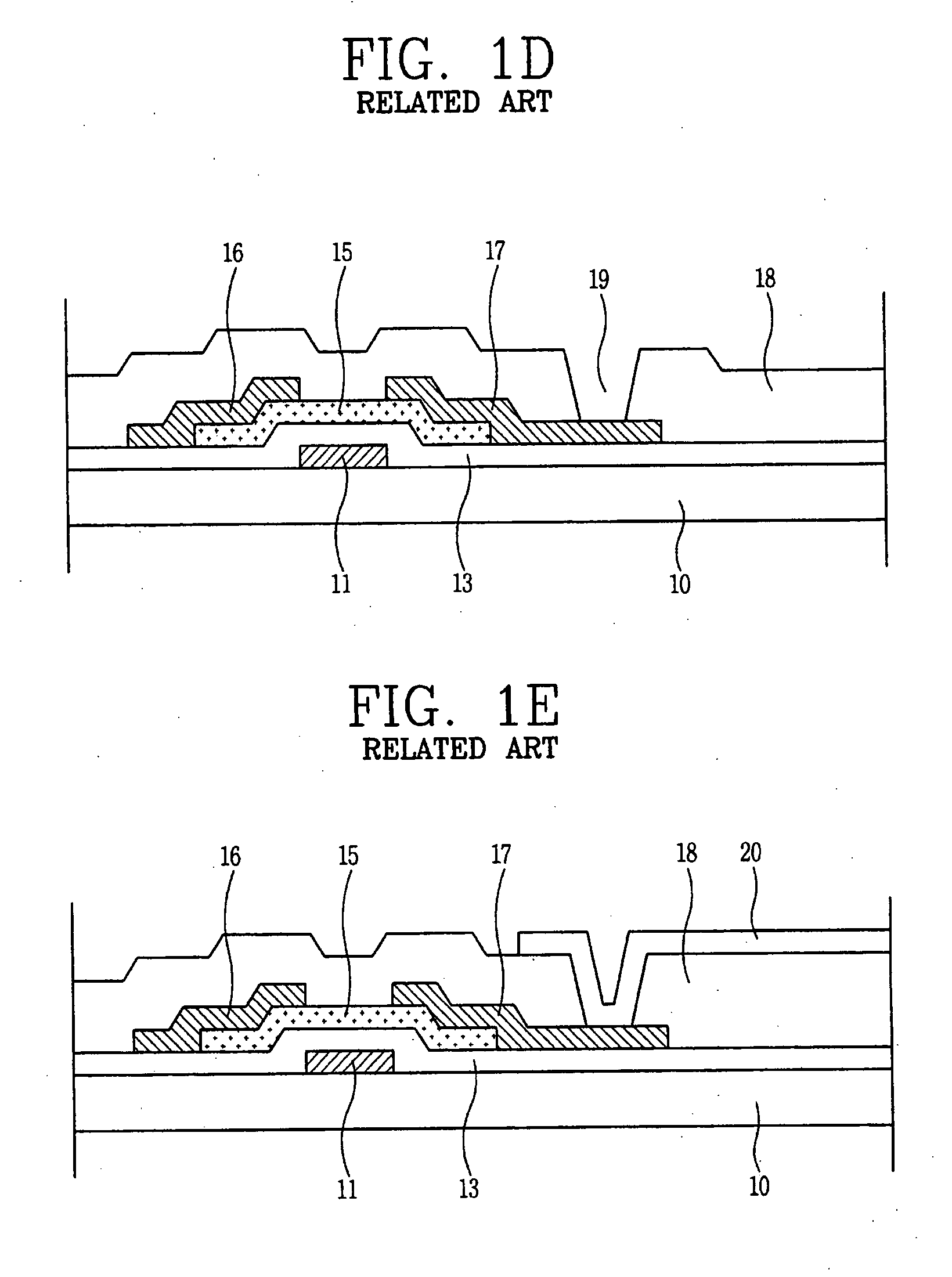

Method for fabricating organic thin film transistor and method for fabricating liquid crystal display device using the same

ActiveUS20060046339A1Precise patternSimplify the manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayThin-film transistor

A method for fabricating an organic thin film transistor includes forming a gate electrode on a substrate, forming a gate insulating layer on the substrate including the gate electrode, forming an organic active pattern on the gate insulating layer using a rear exposing process, and forming source and drain electrodes on the organic active pattern.

Owner:LG DISPLAY CO LTD

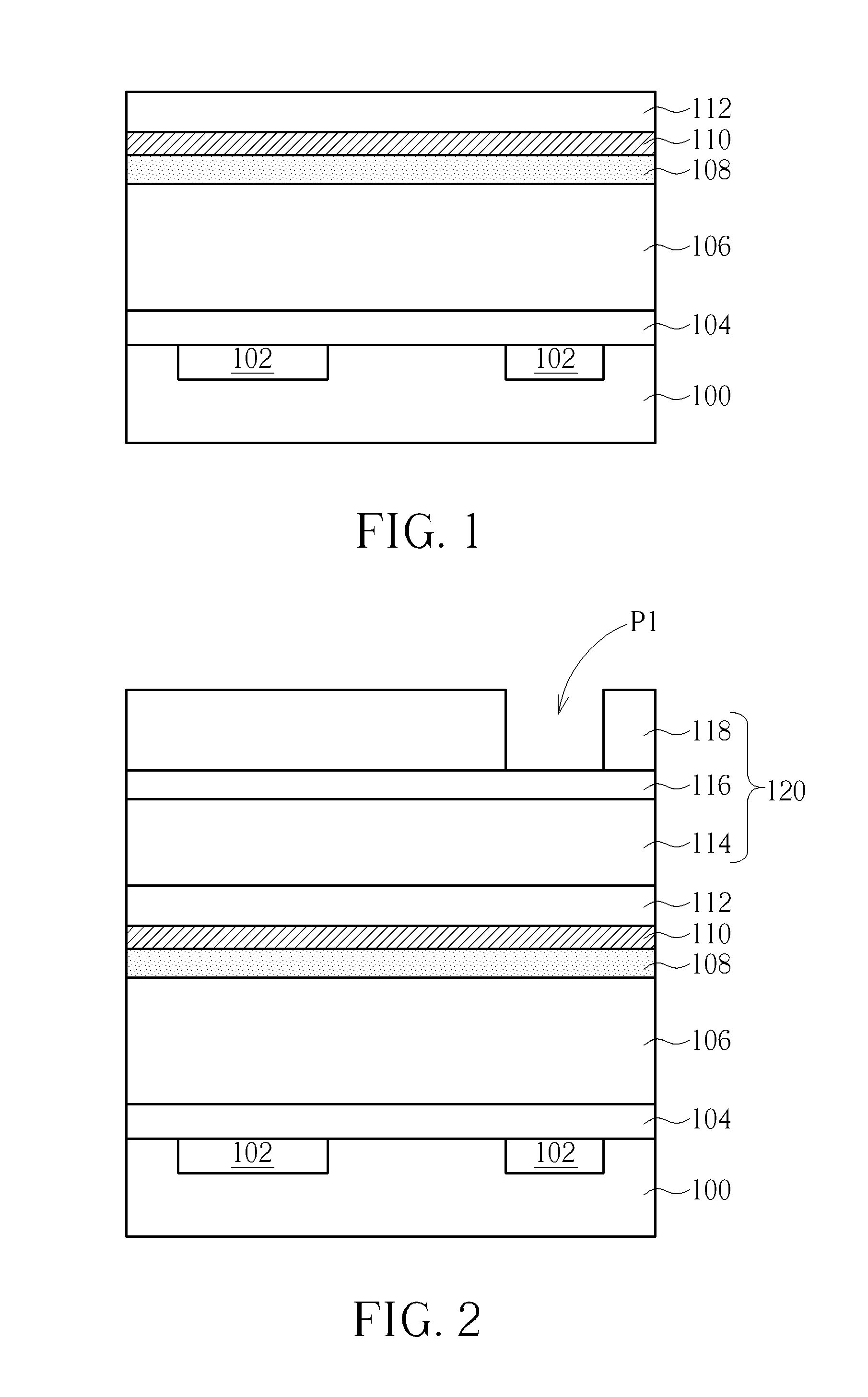

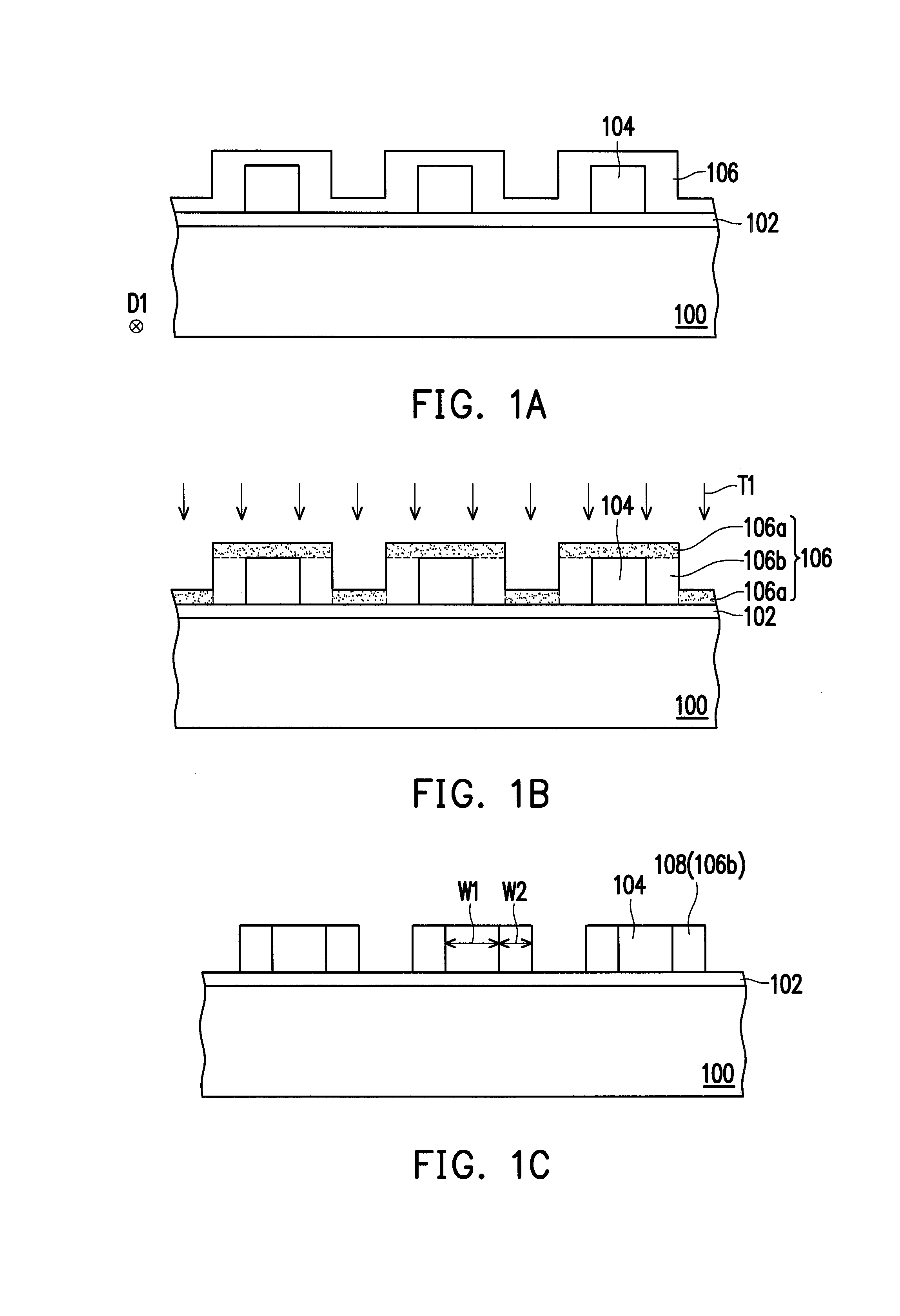

Semiconductor process

ActiveUS20130078778A1Decrease pattern line widthAccurate pattern transferSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

A semiconductor process is described as follows. A plurality of dummy patterns is formed on a substrate. A mask material layer is conformally formed on the substrate, so as to cover the dummy patterns. The mask material layer has an etching rate different from that of the dummy patterns. A portion of the mask material layer is removed, so as to form a mask layer on respective sidewalls of each dummy pattern. An upper surface of the mask layer and an upper surface of each dummy pattern are substantially coplanar. The dummy patterns are removed. A portion of the substrate is removed using the mask layer as a mask, so as to form a plurality of fin structures and a plurality of trenches alternately arranged in the substrate. The mask layer is removed.

Owner:UNITED MICROELECTRONICS CORP

Method for manufacturing electroluminescence element and evaporation mask

InactiveUS20030044517A1Precise patternSolve the lack of durabilityElectroluminescent light sourcesVacuum evaporation coatingHeat resistancePlastic materials

An evaporation mask is placed between an evaporation source and a plastic substrate. An evaporation substance from the evaporation source is allowed to selectively pass through one or more openings formed on the evaporation mask corresponding to the pattern of an evaporation layer of an EL element, to form the evaporation layer on the plastic substrate. As the material for the evaporation mask, a material whose thermal expansion coefficient is similar to (for example, within a range of ±30% of) the thermal expansion coefficient of the plastic substrate, for example, a plastic material such as a polyimide, is employed. It is preferable to employ a material having a thermal endurance which is, for example, at least approximately 50° C. higher than the thermal endurance of the plastic substrate. By employing such a material for the evaporation mask, it is possible to ensure that the plastic substrate and the evaporation mask will exhibit the same degree of thermal deformation during evaporation, thereby enabling improvement in the precision of evaporation patterning.

Owner:SANYO ELECTRIC CO LTD

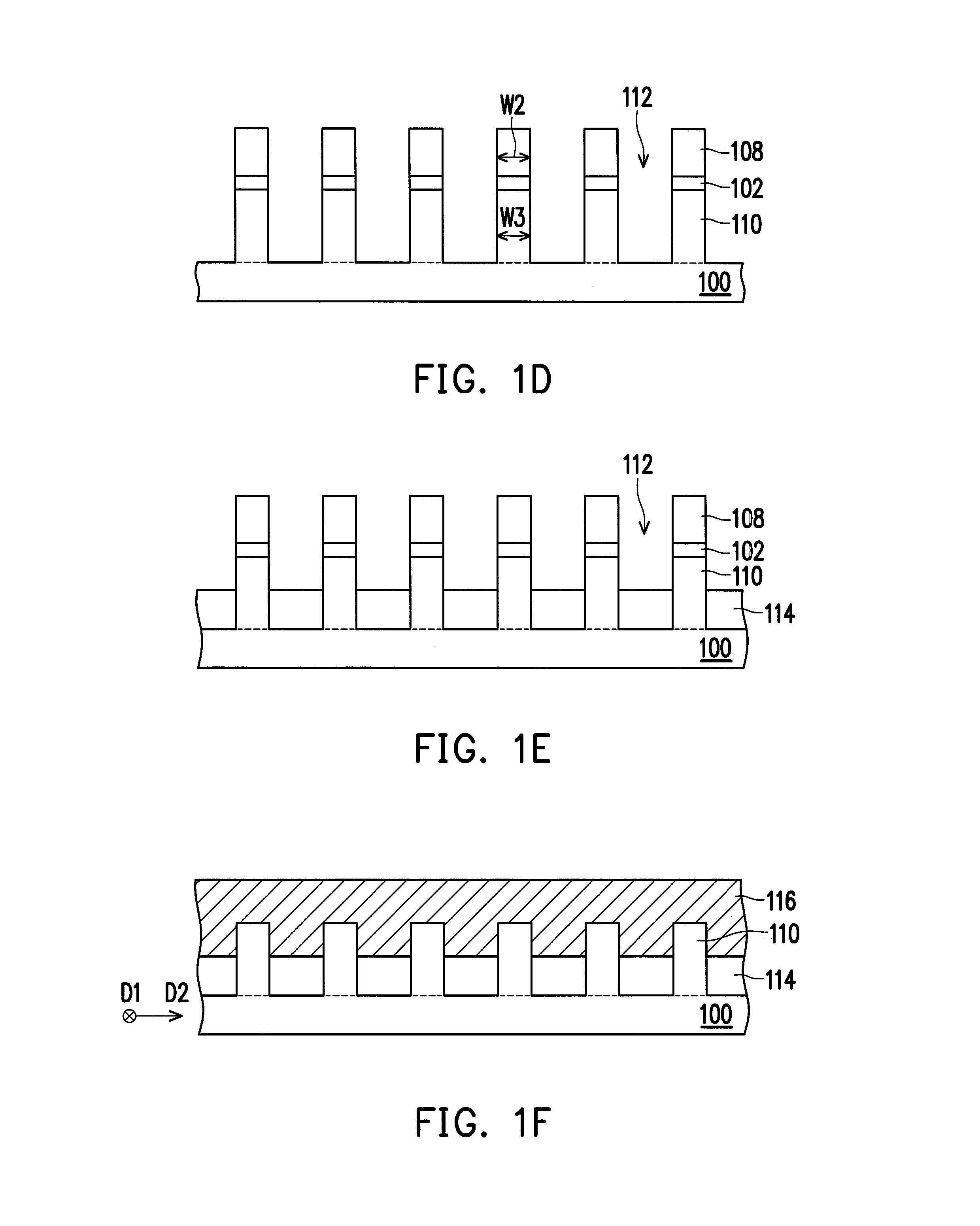

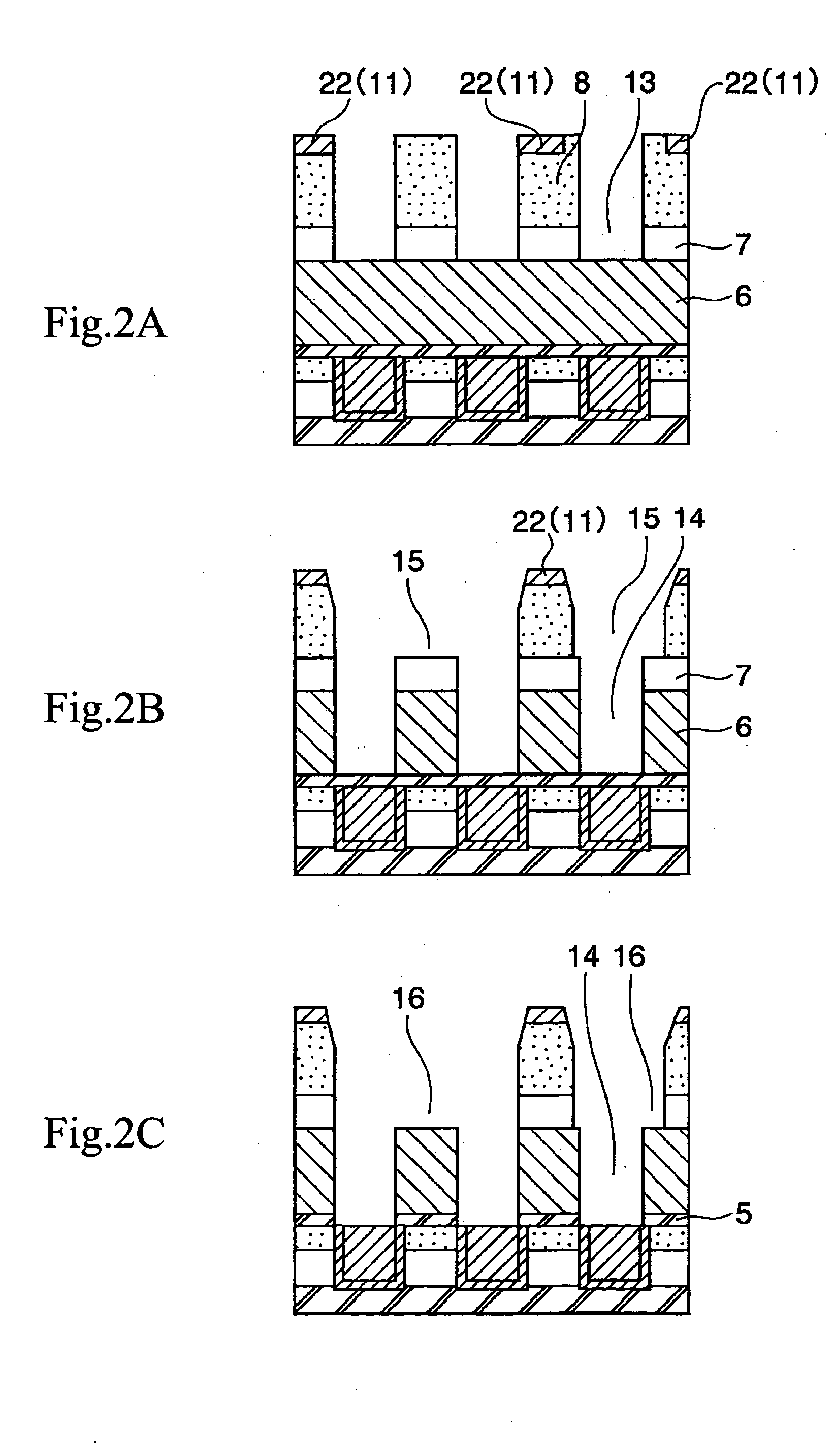

Production method for semiconductor device

InactiveUS20050003653A1Precise patternSemiconductor/solid-state device manufacturingSemiconductor devicesResistDevice material

Disclosed herein is a production method of a semiconductor device having multilayer interconnections of well-formed dual damascene structure in the low dielectric constant interlayer insulating film. The method includes a step of forming on an underlayer wiring a first insulating film, a second insulating, and first mask forming layer; a step of forming a first resist mask (20) having an inverted pattern of wiring trenches for the upper wiring; a step of etching the first mask forming layer through the first resist mask, thereby forming in the first mask forming layer a concave part conforming to the inverted pattern of wiring trenches for the upper wiring, and then forming on the first mask forming layer a second mask forming layer, thereby filling the concave part with the second mask forming layer; a step of selectively removing the second mask forming layer on the region in which the wiring trench is formed, thereby forming the second mask having the wiring trench pattern; a step of forming on the first mask forming layer a second resist mask (12) having an opening pattern of the via holes; a step of etching the first mask forming layer and the second insulating film through the second resist mask, thereby forming the via holes. This process is followed by the ordinary procedure to form the dual damascene structure.

Owner:SONY CORP

Method for forming transistors with raised source and drains and device formed thereby

InactiveUS6100013AEnhanced transistor performanceOvercome limitationsTransistorDecorative surface effectsCapacitanceResist

The preferred embodiment of the present invention provides a transistor structure and method for fabricating the same that overcomes the disadvantages of the prior art. In particular, the preferred structure and method results in lower leakage and junction capacitance by using raised source and drains which are partially isolated from the substrate by a dielectric layer. The raised source and drains are preferably fabricated from the same material layer used to form the transistor gate. The preferred method for fabricating the transistor uses hybrid resist to accurately pattern the gate material layer into regions for the gate, the source and the drain. The source and drain regions are then connected to the substrate by growing silicon. The preferred method thus results in an improved transistor structure while not requiring excessive fabrication steps.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com