Multilayer segmentation-stubble leaving cutting knife device of first-crop ratooning rice, control method of multilayer segmentation-stubble leaving cutting knife device, and combine harvester of first-crop ratooning rice

A technology of combine harvester and regenerated rice, which is applied to the lifting device, harvester and adjusting device of agricultural machinery, etc., can solve the problems of high rolling rate, reduced rolling rate, low work efficiency, etc., and achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

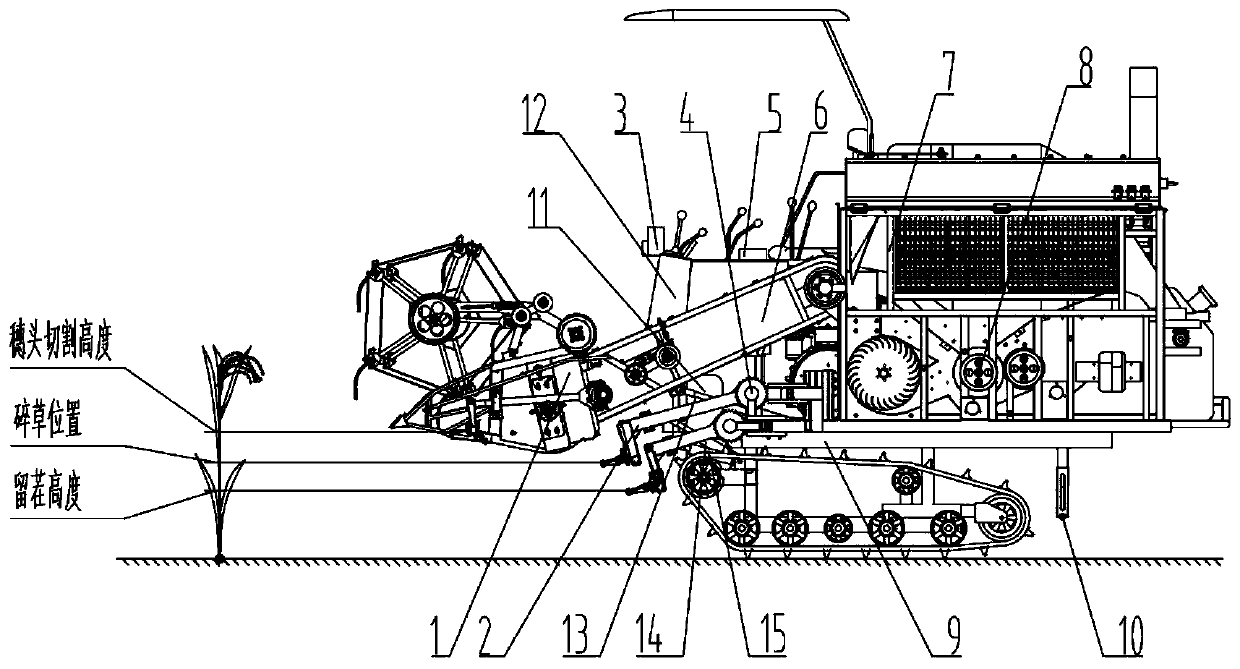

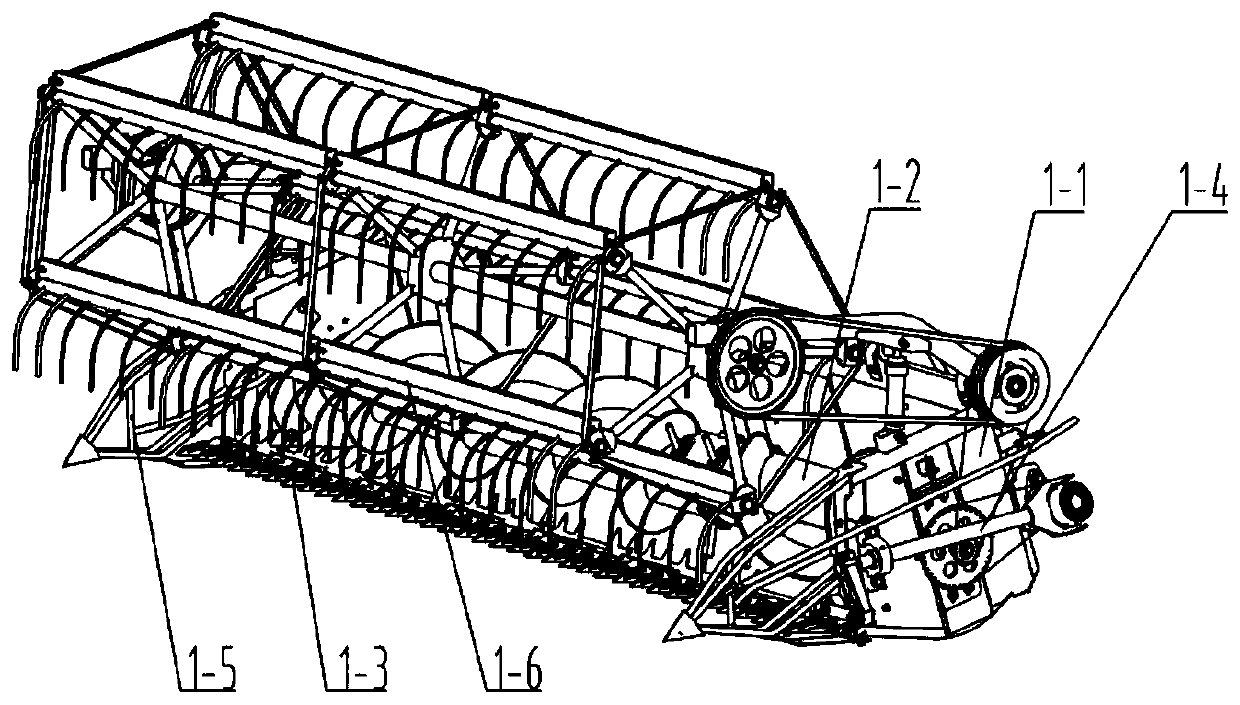

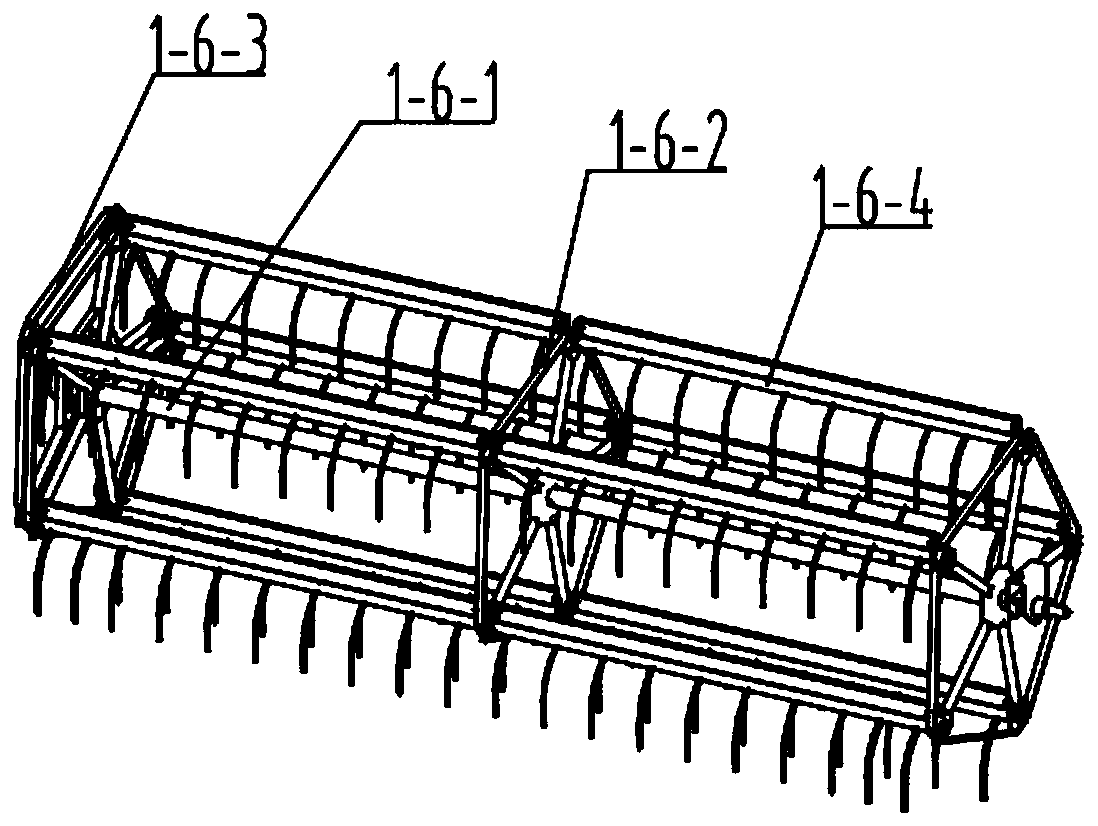

[0070] Such as figure 1 and Figure 5 As shown, the multi-layer segmentation-stubble cutter device of the first season ratooned rice of the present invention comprises a header 1, a segment cutter 2-1 and a stubble cutter 2-2, and the header 1 For cutting the ear heads of regenerated rice, at least one segment cutter 2-1 is located behind the header 1, and the segment cutter 2-1 is hinged on the walking chassis 9, controlled by the second actuator The cutting height of the segment cutter 2-1 is used to cut the stems returning to the field; the stubble cutter 2-2 is located behind the segment cutter 2-1, and the stubble cutter 2- 2 is hinged on the walking chassis 9, and the cutting height of the stubble cutter 2-2 is controlled by a third actuator, which is used to cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com