Progressive die for surface plate of electric vehicle seat lock

A technology for car seats and flat panels, applied in storage devices, metal processing equipment, feeding devices, etc., can solve the problems of waste of labor and machinery costs, insufficient stability, poor safety, etc., to improve production efficiency and reduce costs. Labor cost and mechanical cost, the effect of convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

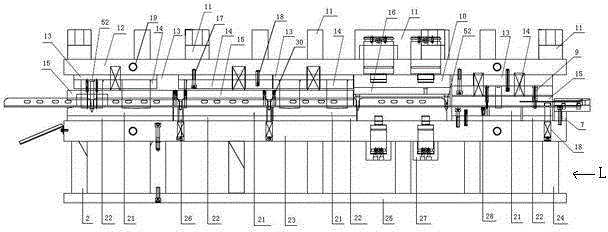

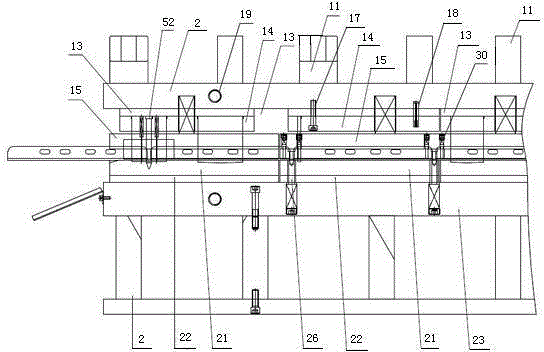

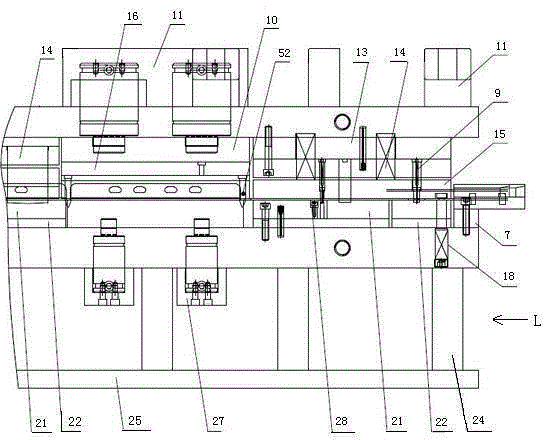

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] see Figure 1 to Figure 13 , the present embodiment includes an upper mold 1 and a lower mold 2, the upper mold 1 includes an upper mold foot 11, an upper mold base 12, an upper mold backing plate 13, an upper mold fixing plate 14 and a stripping plate 15, and the lower mold 2 includes a lower template 21, the lower mold backing plate 22, the lower mold seat 23, the lower mold foot 24 and the lower bearing plate 25.

[0033] The upper mold 1 is located above the lower mold 2, the lower mold 2 is fixed on the workbench, the upper mold backing plate 13 is fixed on the upper mold base 12, and is located below the upper mold base 12, between the upper mold backing plate 13 and the discharge plate 15 There are guide pins 52 fixed between them, and four lifting screw holes 19 are opened on both sides of the upper mold base 12 and the lower mold base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com