A Coaxial Centrifugal-Diagonal Flow Counter-rotating Compressor

A compressor, coaxial technology, used in gas turbine devices, mechanical equipment, non-variable-capacity pumps, etc., can solve the problems of increased flow loss, large radial size, and increased load, and achieve uniform outlet airflow and axial The effect of small airflow angle and high single-stage pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments.

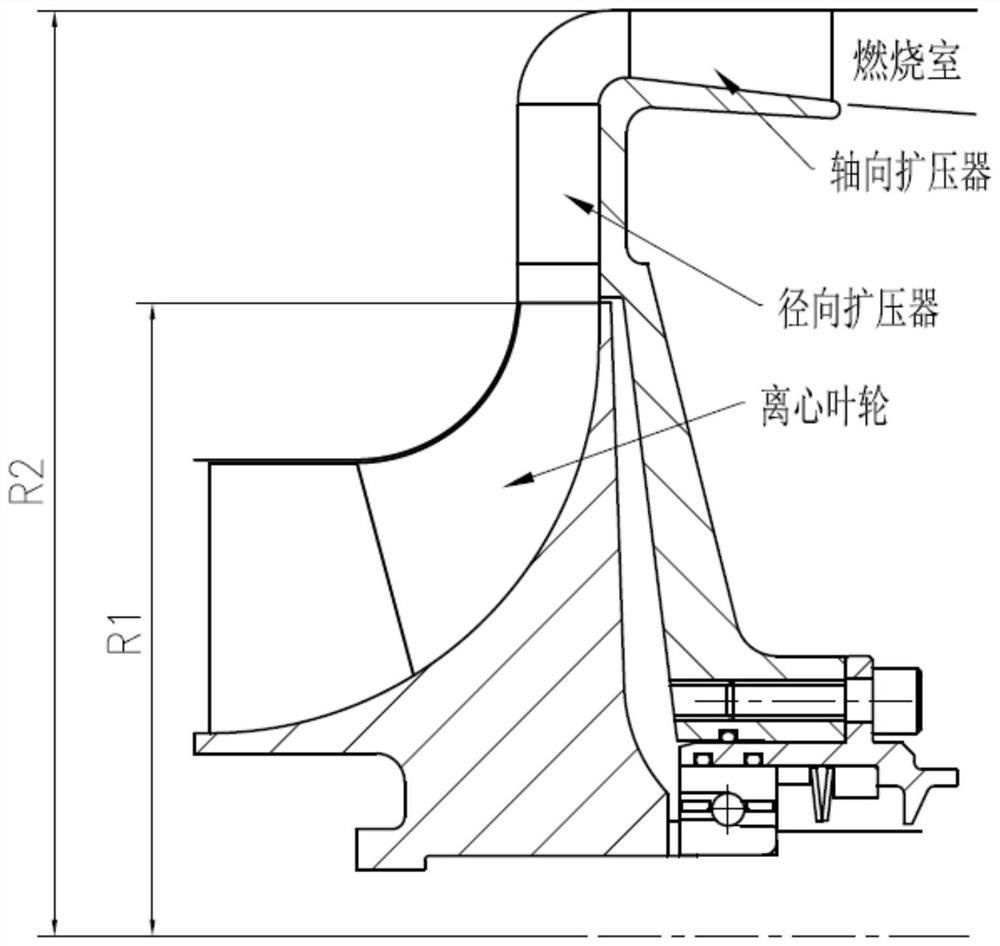

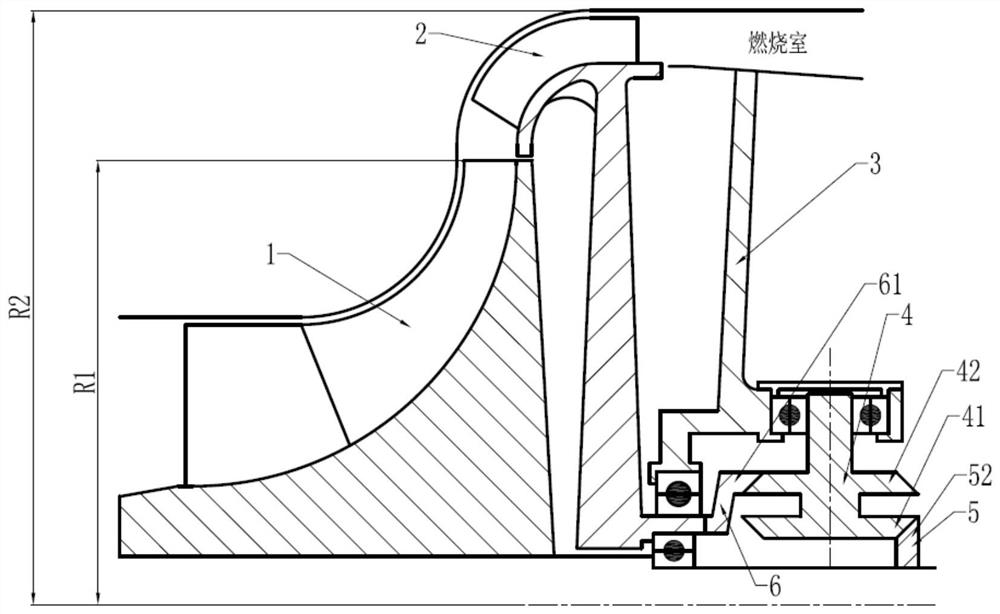

[0023] Such as figure 2 As shown, the coaxial centrifugal-diagonal flow counter-rotating compressor of the present invention consists of a centrifugal impeller 1, a diagonal flow impeller 2, a supporting casing 3, two gear pairs arranged back-to-back gear 4, driving gear 5 and driven gear 6 grade composition. The centrifugal impeller 1 and the diagonal flow impeller 2 are driven to rotate by a turbine or other motive power to perform work on the gas, so that the pressure of the gas can be increased and enter the downstream combustion chamber or the next stage compressor. The support case 3 realizes the support of the front bearing of the rotor and the transmission gear.

[0024] Specifically, in the coaxial centrifugal-diagonal flow counter-rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com