Engines VVT phase machine oil supply duct structure

A channel structure and phaser technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of limiting the arrangement space of the bolt holes of the camshaft cover, affecting the design, machining, strength and installation of the camshaft cover. Problems such as increasing the diameter of the camshaft journal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

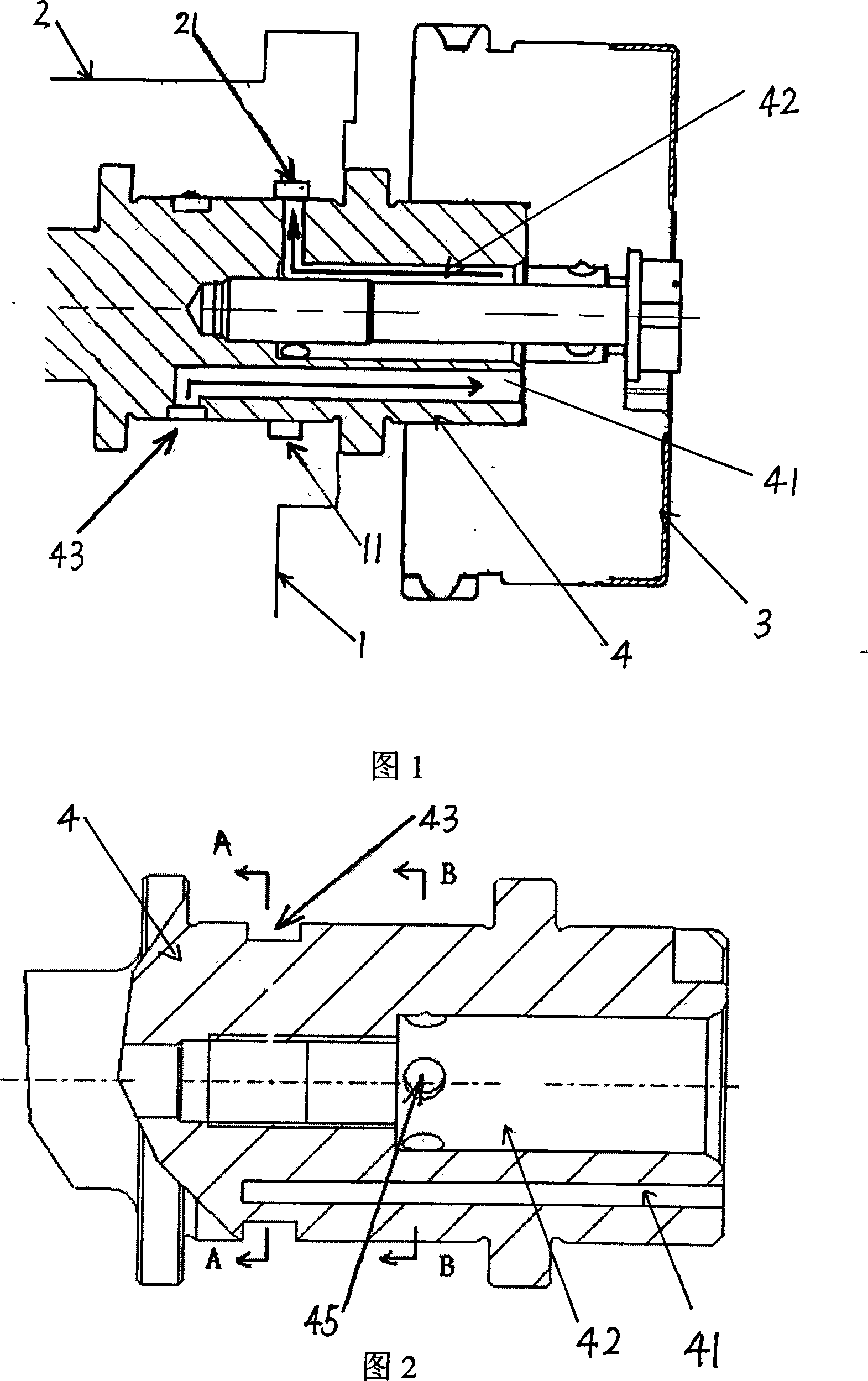

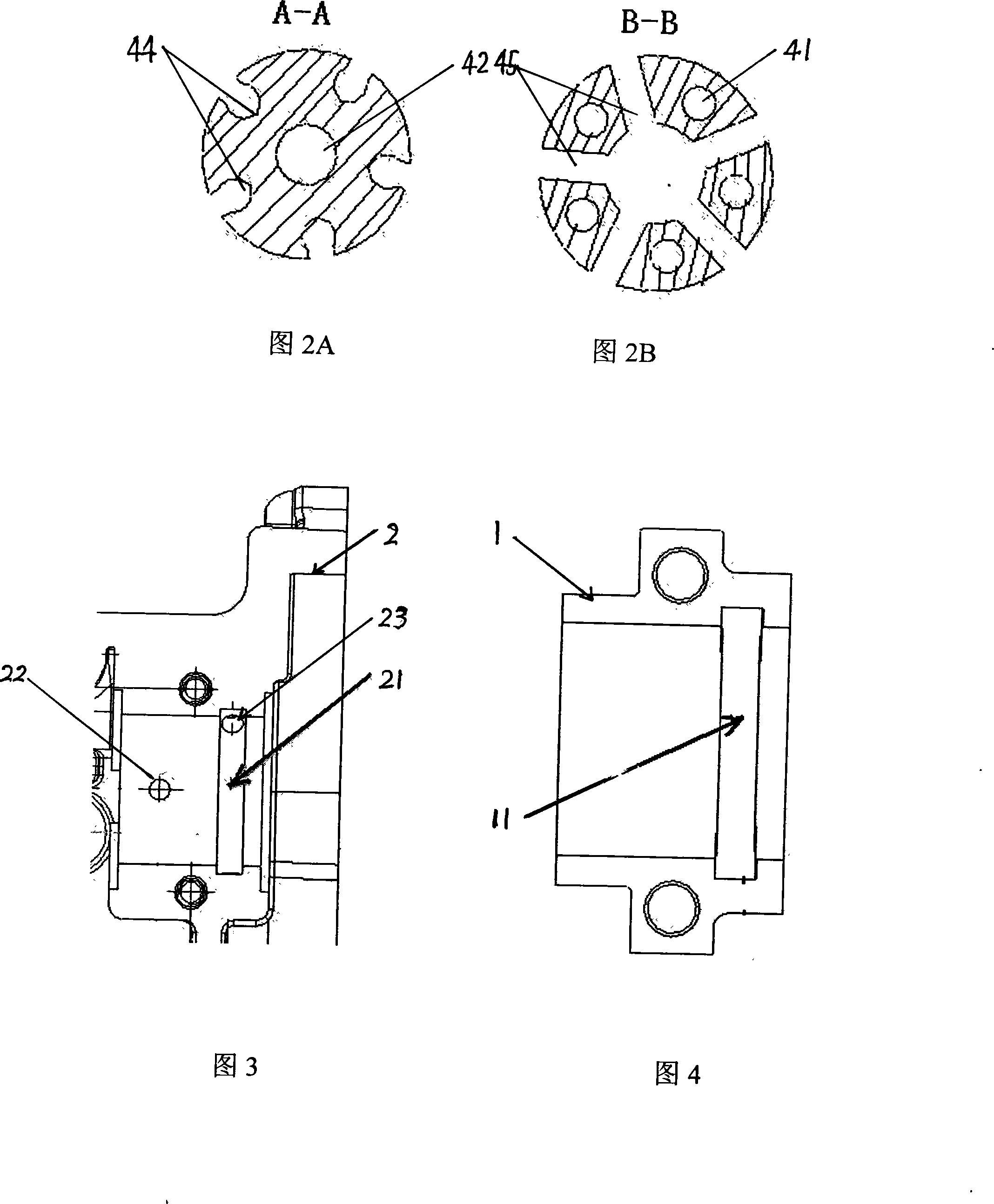

[0014] Refer to Figure 1, Figure 2, Figure 3 and Figure 4, the VVT phaser oil supply channel structure involves the engine's camshaft 4, cylinder head 2, camshaft cover 1 and VVT phaser 3, combined refer to Figure 2 and Figure 2A 2B, the camshaft 4 is axially provided with an oil inlet channel 41 and an oil return channel 42 that communicate with the inner and outer oil chambers of the VVT phaser 3, and a ring of oil groove 43 is machined on the outer wall of the journal of the camshaft 4. The oil groove 43 communicates with the oil hole 44 of the oil inlet passage or the oil return passage of the camshaft leading to the inner and outer oil chambers of the VVT phaser, and at the same time corresponds to the oil inlet 22 of the cylinder head 2 that is set in the corresponding position and leads to the OCV valve. See Figure 3. At the same time, referring to Figures 3 and 4, oil grooves 21 and 11 are respectively provided on the inner wall of the camshaft hole of the cylinder h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com