Full-automatic vertical PE (Poly Ethylene) film packaging machine

A fully automatic packaging machine, vertical technology, applied in the direction of packaging, transportation packaging, packaging protection, etc., can solve the problem that it is difficult to meet the requirements of high-speed packaging of non-woven fabric rolls, difficult to meet the requirements of non-woven fabric rolls, and expensive equipment. Achieve unlimited packaging height, reduce energy consumption indicators, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

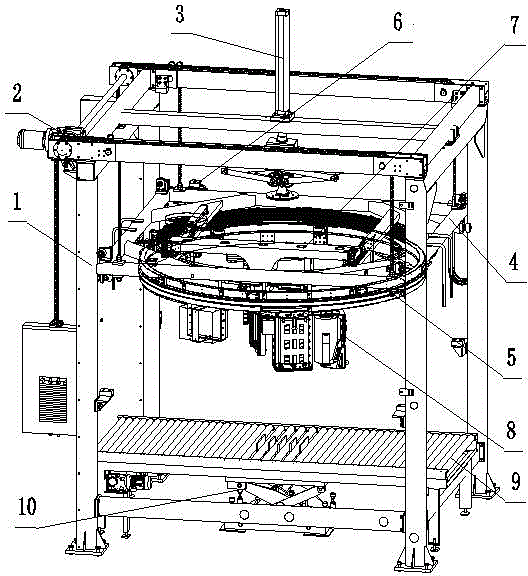

[0032] Figure 1~Figure 12 An embodiment of the invention is shown.

[0033] Such as figure 1 Shown: The vertical PE film automatic packaging machine includes 1-main frame, 2-lifting device, 3-pressing device, 4-walking device, 5-rotating device, 6-driving device, 7-clamping device, 8 - formwork device, 9 - roller conveyor, 10 - jacking device. In addition, it also includes the necessary pneumatic system, hydraulic system, and automatic control system. Each system is connected in sequence.

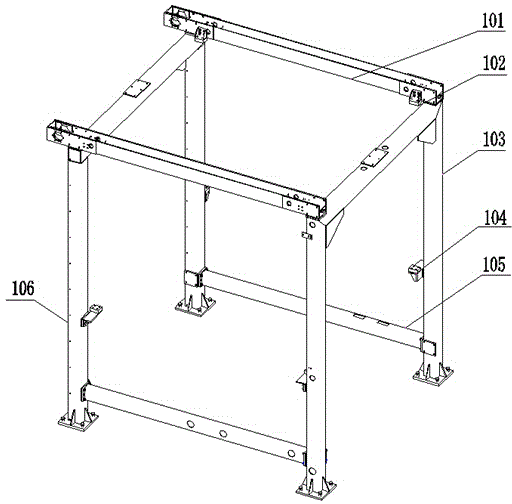

[0034] Such as figure 2 Shown: the main frame includes 101-main beam, 102-upper limit block, 103-right door type composite beam, 104-lower limit block, 105-auxiliary beam, 106-left door type composite beam. The frame composed of 101-main beam, 103-right door-type composite beam, 105-auxiliary beam, 106-left door-type composite beam is the load-bearing foundation, placed on the embedded board, 102-limiting block and 104- The limit block is to carry out the uppermost protection and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com