Rotating shaft apparatus

a technology of rotating shafts and rotating shafts, which is applied in the direction of crankshafts, bearing cooling, manufacturing tools, etc., can solve the problems of shortening the life of the bearings supporting the shaft, affecting the rotation speed of the crankshaft, so as to ensure the rigidity required, reduce heat generation, and be suitable for high-speed rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]With reference to the drawings, a preferred embodiment of the invention will be described below. In this connection, in the embodiment described below, a spindle apparatus of a machine tool is described as an example of the rotating shaft apparatus.

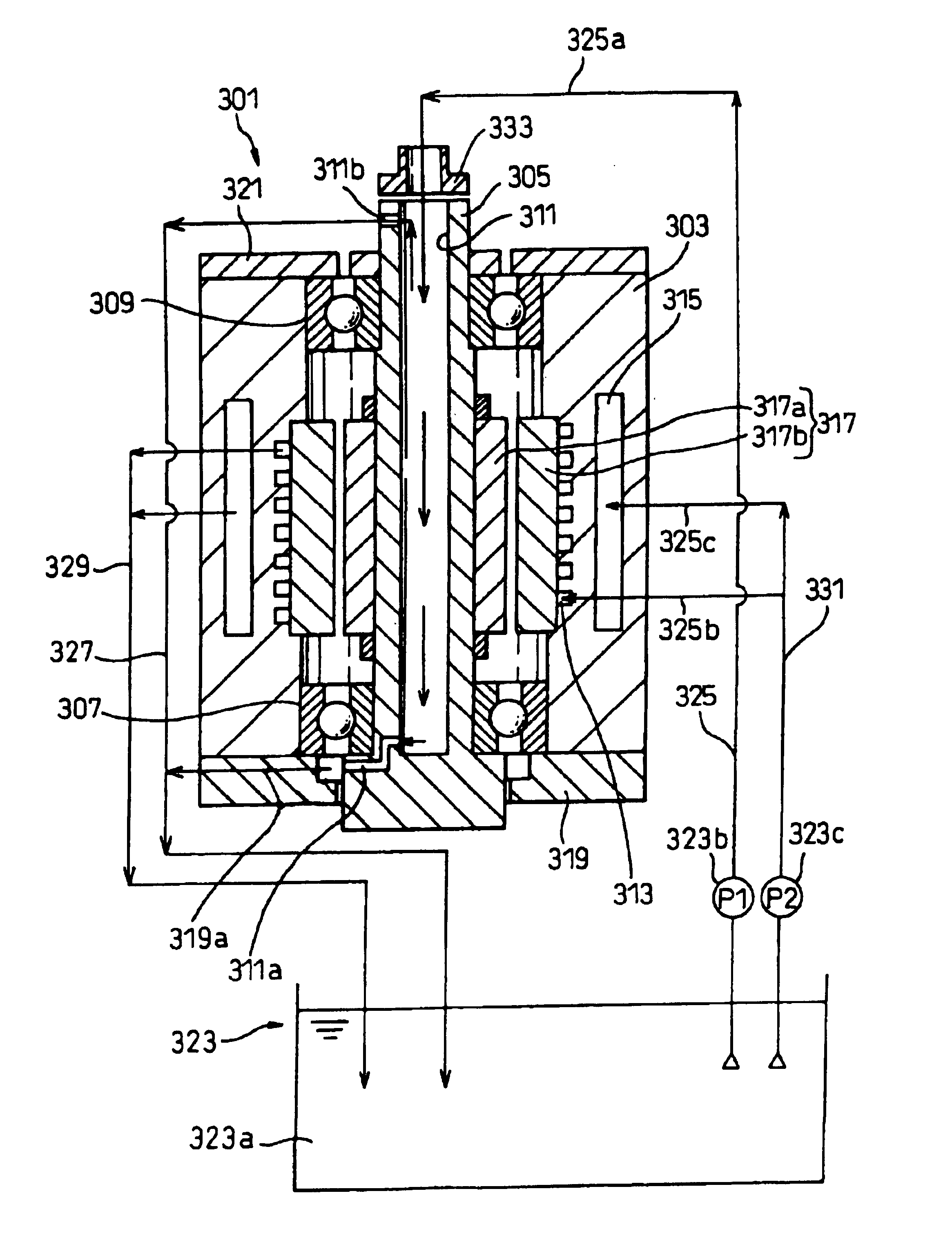

[0038]With reference to FIG. 1, a rotating shaft apparatus 11 comprises a shaft 17 rotatably supported by bearings 19 and 21 within a housing 13 and 15. The housing 13 and 15 has a housing body 13 and a rear cover 15 for closing the rear open end of the housing body 13. The shaft 17 has a front end portion 17a, a rear end portion 17b opposite to the front end portion 17a and an intermediate potion 17c between the front and rear end portions 17a and 17b. A functional member such as a tool (not shown) of the machine tool is attached to the front end portion 17a (loaded side) of the shaft 17. The housing body 13 accommodates a drive motor 23 for rotationally driving the shaft 17 about its central axis O. The drive motor 23 has a rotor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| rotational speed detecting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com