Single-cylinder, reaction and impulse turbine

A reactionary steam turbine technology, applied in the field of three-stage three-pressure reheating combined cycle steam turbines, can solve problems such as insufficient rotor stiffness and difficult self-balancing of rotor thrust, and achieve the effect of solving the problem of insufficient stiffness, ideal shaft system response, and improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

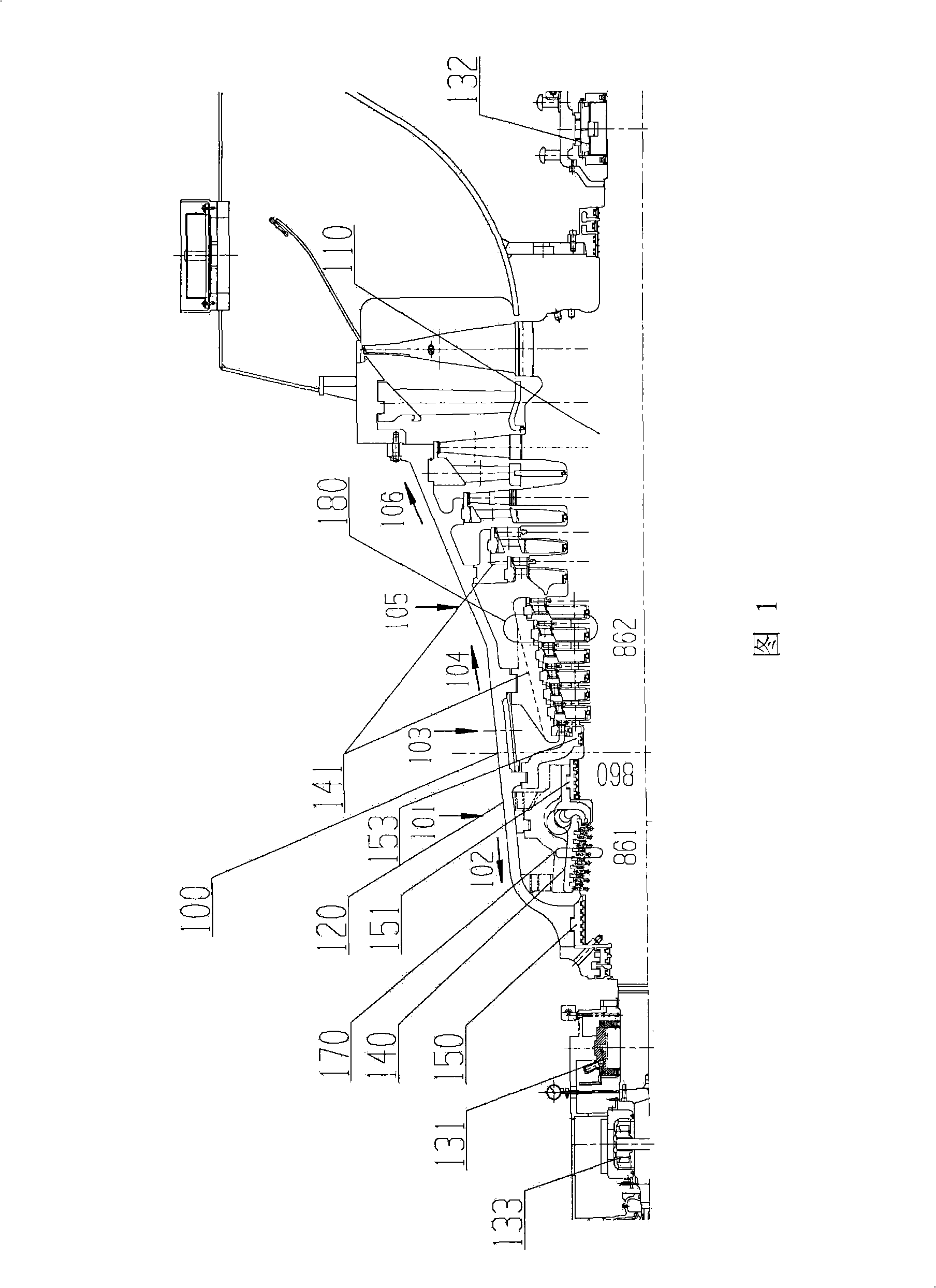

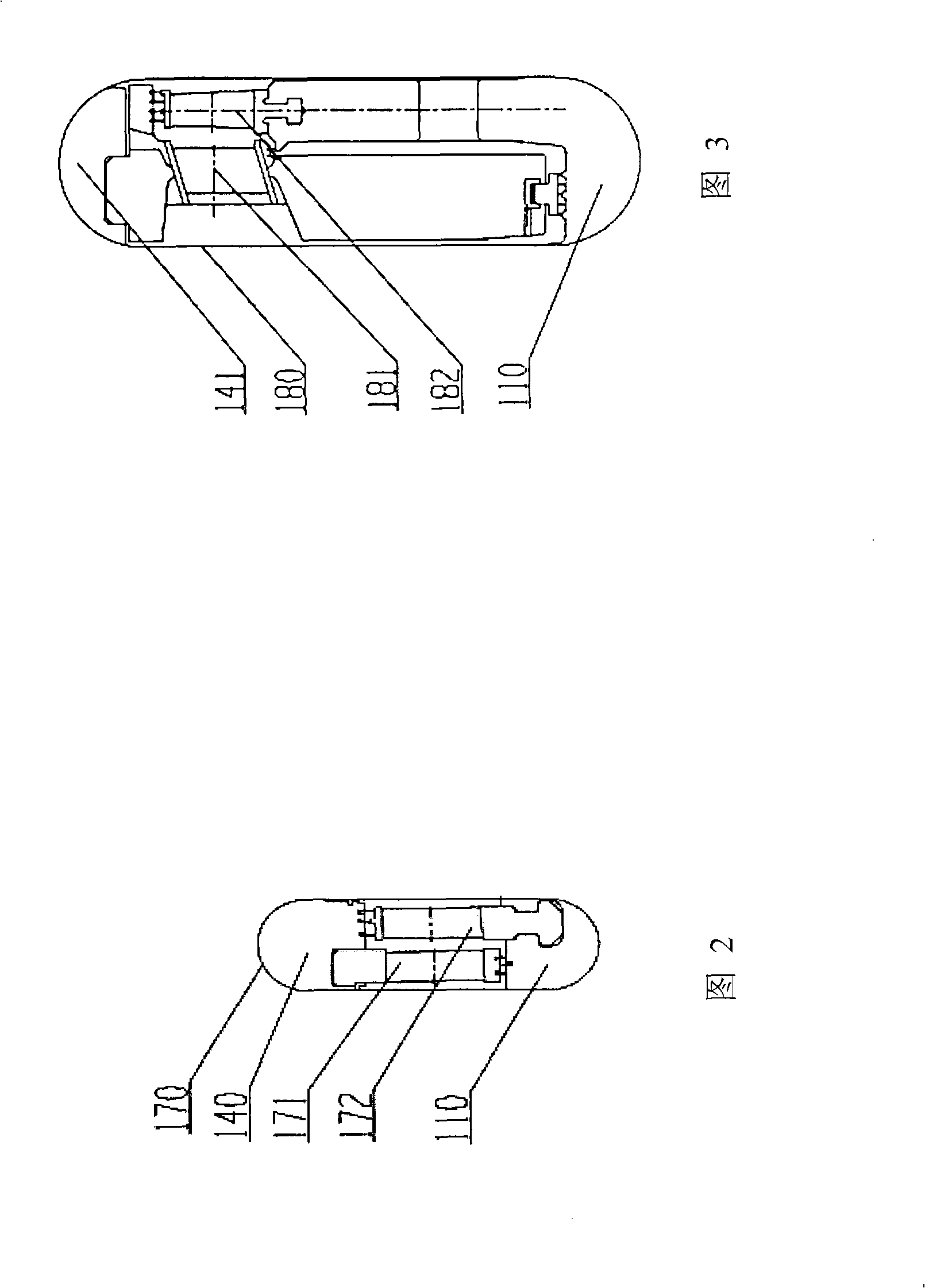

[0019] Referring to Fig. 1, Fig. 2 and Fig. 3, a single-cylinder, reaction plus impulse type, 100MW class triple-pressure reheat combined cycle steam turbine 100 includes a cylinder 120 extending horizontally and horizontally; a rotor is arranged inside the cylinder 120 110 , the rotor 110 extends transversely inside the cylinder 120 , and the rotor 100 is supported by front and rear end bearings 131 and 132 . The cylinder 120 and the rotor 110 are divided into two logical parts along the logical interface 860, namely the high pressure part 861 and the middle and low pressure part 862; and the high pressure part 861 and the middle and low pressure part 862 are arranged in reverse flow to balance part of the steam flow thrust.

[0020] Several reaction stages 170 are arranged in the high-pressure part 861 , and each reaction stage 170 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com