Planetary gear mechanism and power transmission member thereof

A planetary gear, power transmission technology, applied in the direction of gear transmission, transmission parts, belt/chain/gear, etc., can solve the problem of not easy to repair, and achieve the effect of suppressing the increase in volume, saving strength, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0088] {Power transmission member and planetary gear mechanism: Embodiment 2}

[0089] Next, use Figure 9 Embodiment 2 of the power transmission member and the planetary gear mechanism of the present invention will be described.

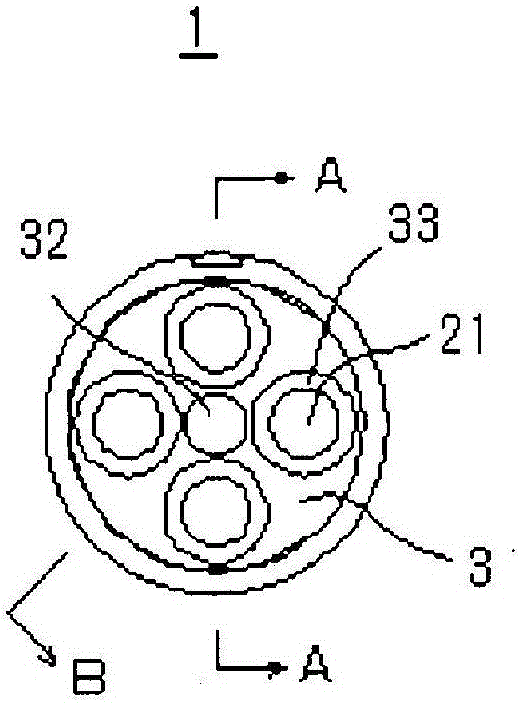

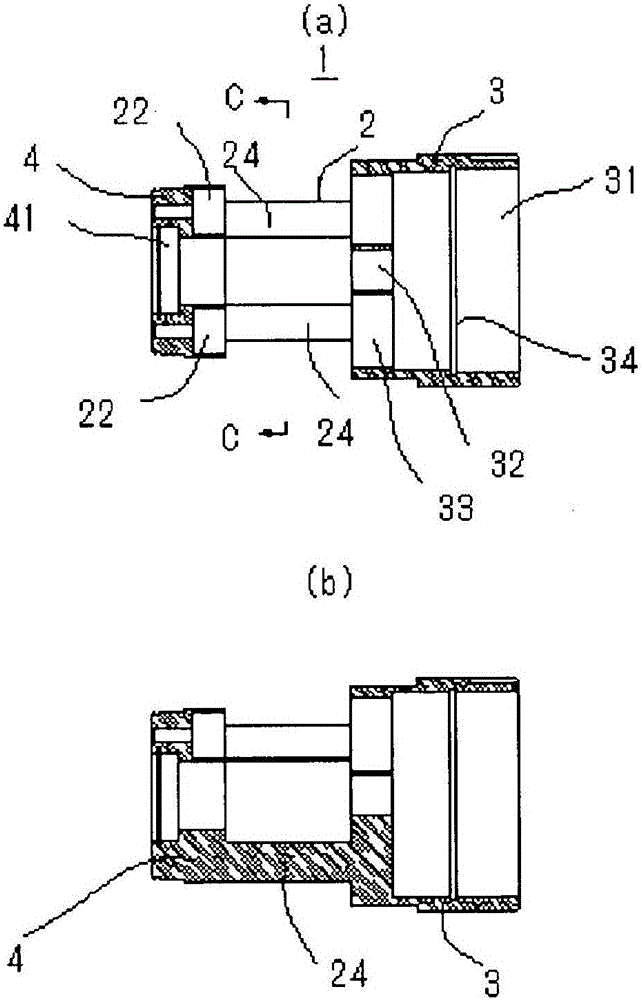

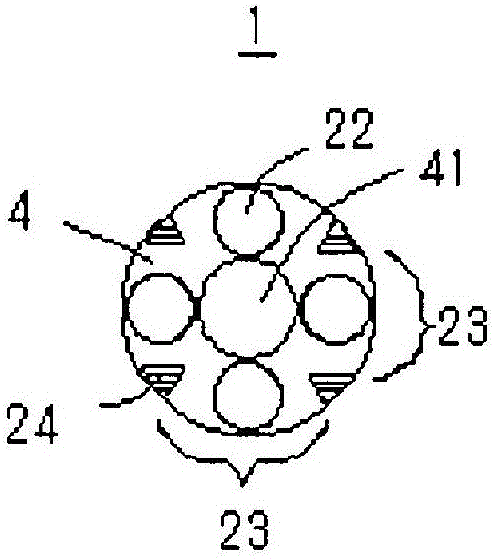

[0090] Figure 9 (a) is a schematic right side view showing the arrangement of the planetary gears of the planetary gear mechanism according to the second embodiment of the present invention incorporating the power transmission member according to the second embodiment of the present invention, Figure 9 (b) is a schematic left view, Figure 9 (c) is a schematic view of the J-J section. exist Figure 9 In (a), the arrangement of the planetary gears is shown by a dotted line.

[0091] The power transmission member 1C according to the second embodiment of the present invention is a power transmission member of a planetary gear mechanism that rotatably supports a planetary gear 5 that meshes with a sun gear 7 and an internal gear 6 with bearings, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com