Heavy-load drive axle of 5-ton loader

A technology for driving axles and loaders, which is applied in the directions of transportation and packaging, axles, wheels, etc. It can solve the problem that the strength of the differential cannot meet the requirements of heavy-duty working conditions, the machining accuracy of the cross shaft is difficult to ensure, and the contact strength of the sun gear tooth side is insufficient and other issues, to achieve the effect of improving safety reliability and service life, increasing modulus, and reducing processing technology requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A 5-ton loader heavy-duty driving axle of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

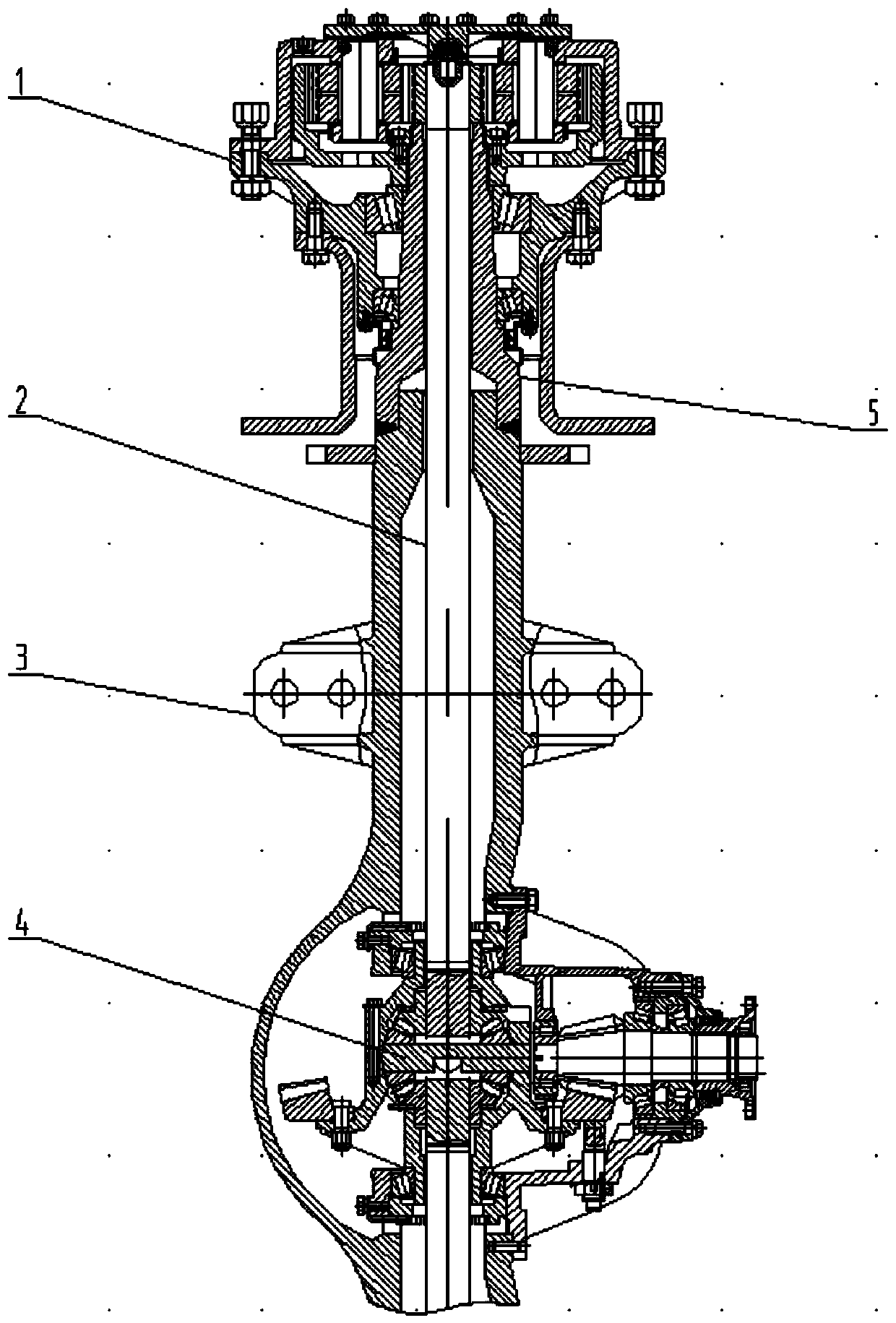

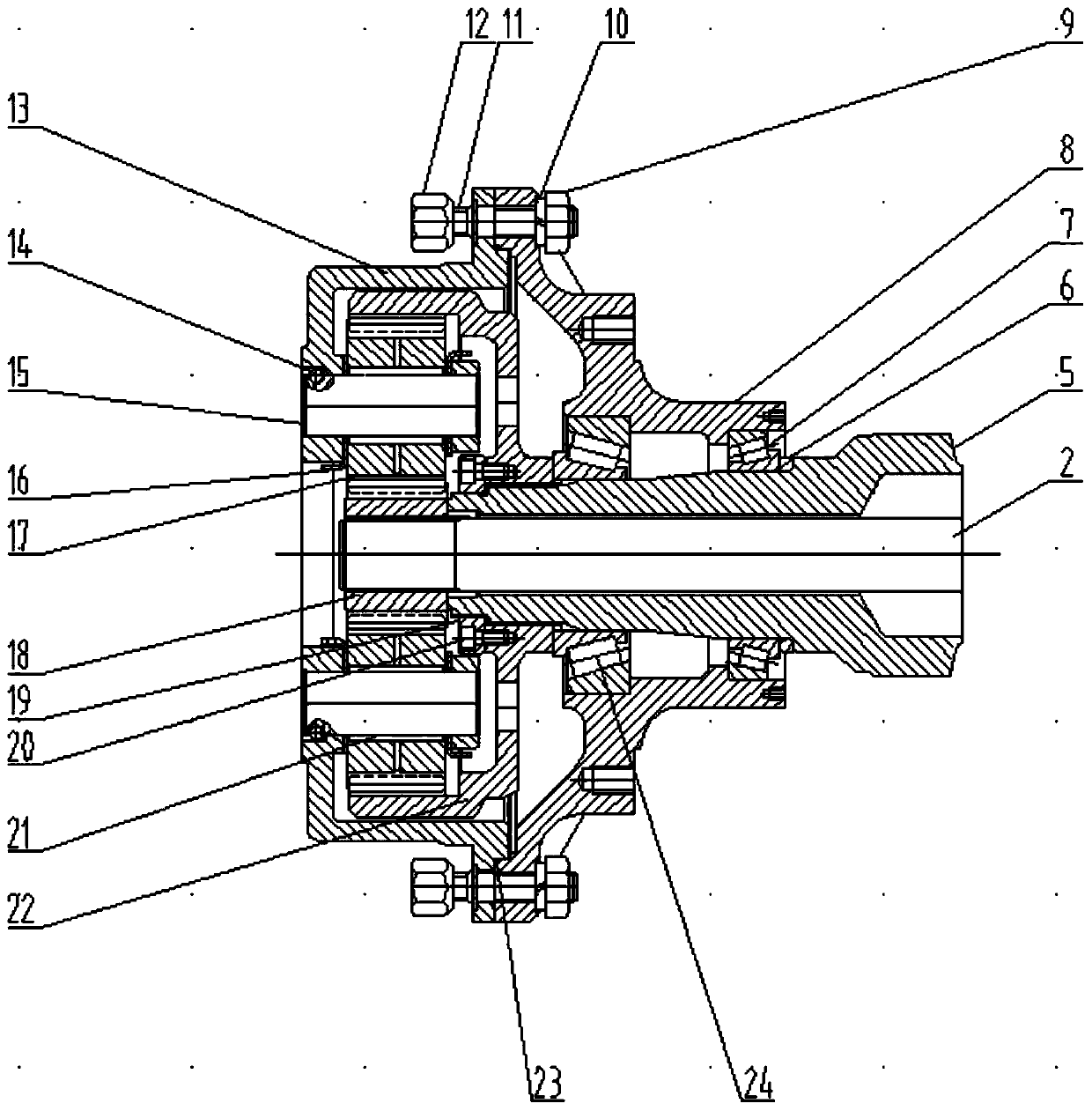

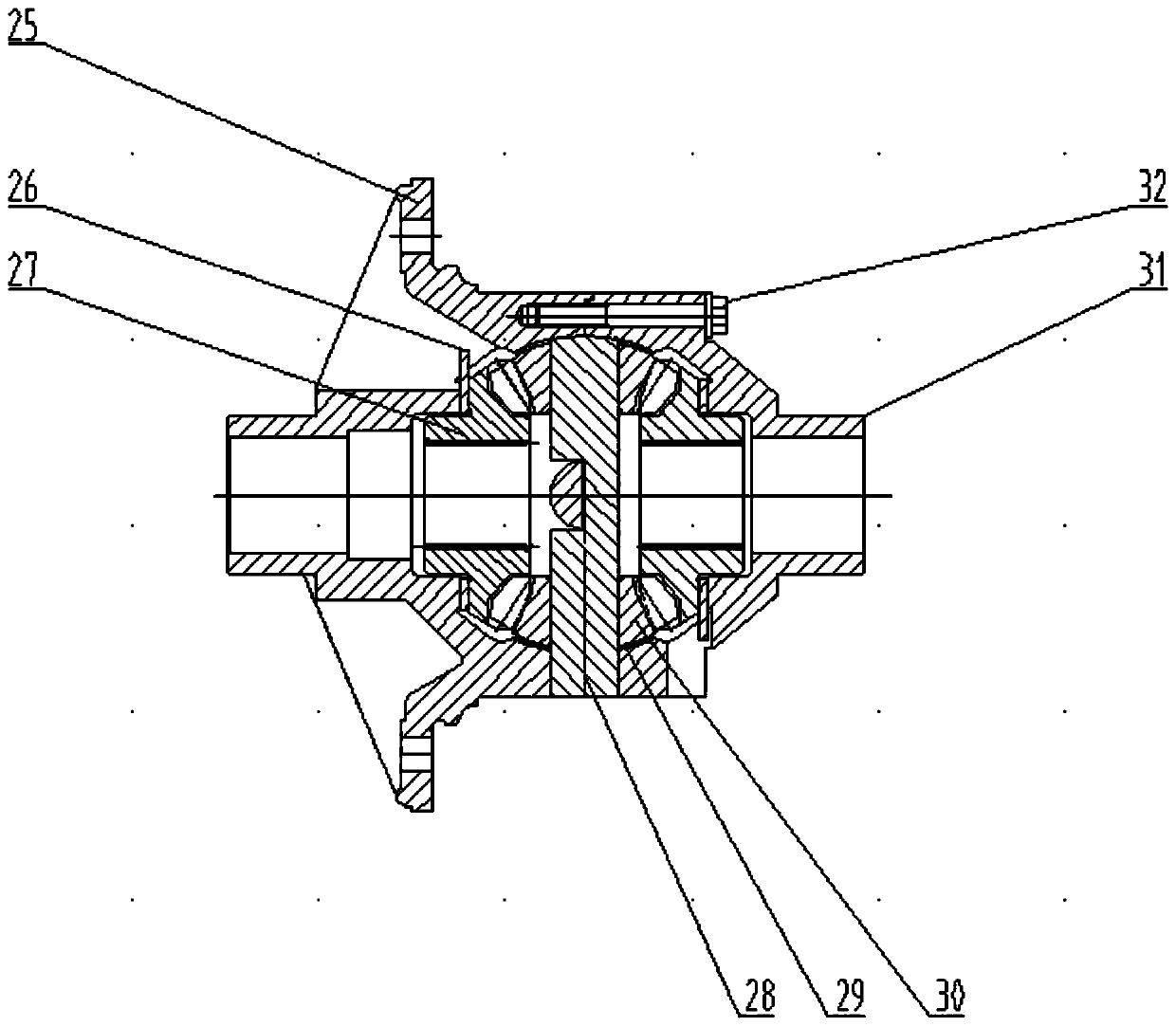

[0015] like figure 1 As shown, a heavy-duty drive axle for a 5-ton loader of the present invention includes a wheel rim assembly 1, a half shaft 2, an axle housing 3, a final reducer assembly 4 and a support shaft 5, and the axle housing 3 and the support shaft 5 After welding, it is used as a load-bearing part, supporting the wheel rim assembly 1 on both sides, the main reducer assembly 4 is installed in the middle of the axle housing 3, and the two sides of the half shaft 2 are connected to the wheel rim assembly 1 and the main reducer assembly 4; figure 2 As shown, the wheel rim assembly 1 includes a bearing spacer 6, a bearing 7, a wheel shell 8, a nut 9, a spring washer 10, a rim bolt 11, a rim nut 12, a wheel frame 13, a steel ball 14, a planet wheel shaft 15, Planetary wheel gasket 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com