Optical fiber MEMS Fabry-Perot acceleration sensor and manufacturing method thereof

An acceleration sensor and acceleration technology, applied in the measurement of acceleration, speed/acceleration/shock measurement, instruments, etc., can solve the problems of complex sensor structure and poor quality consistency, and achieve low temperature coefficient, good consistency, and good quality consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

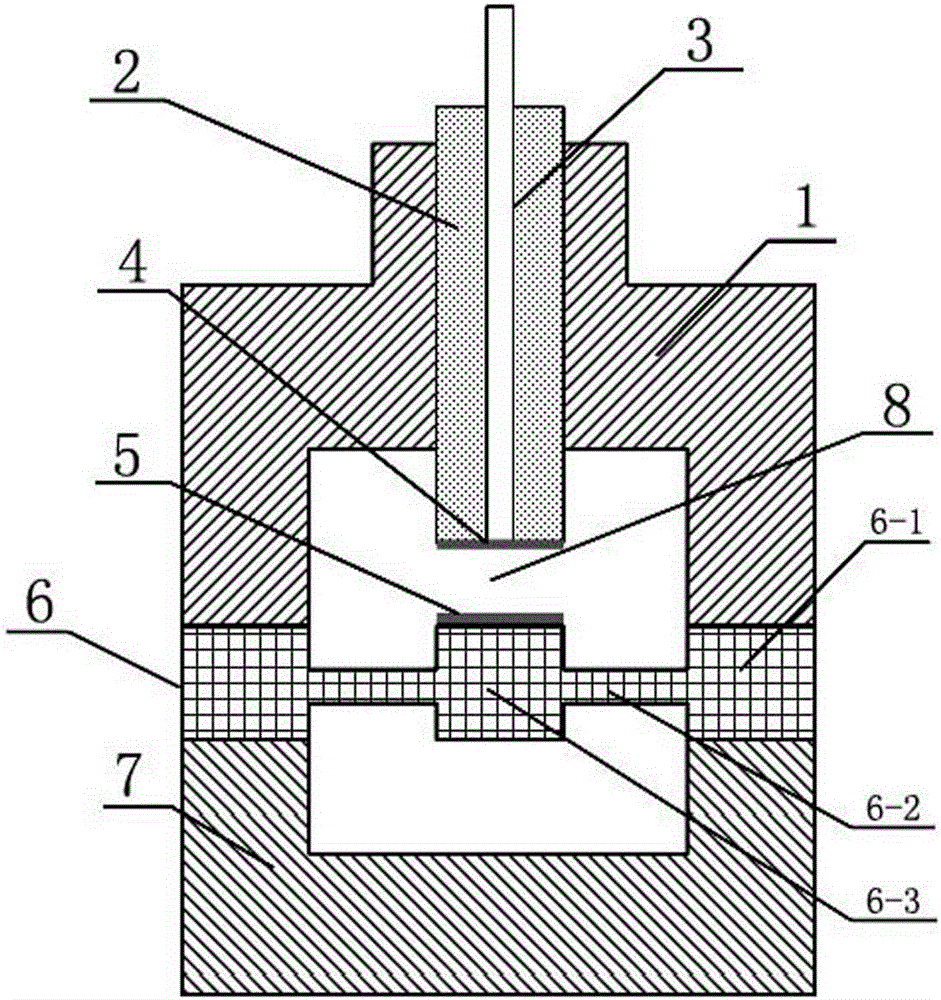

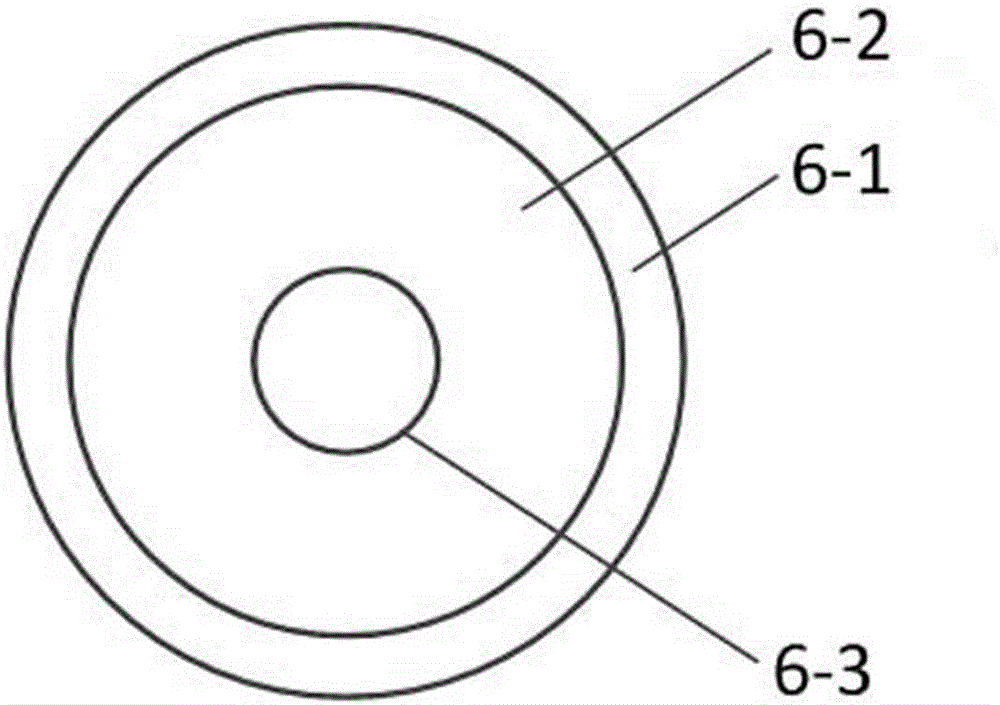

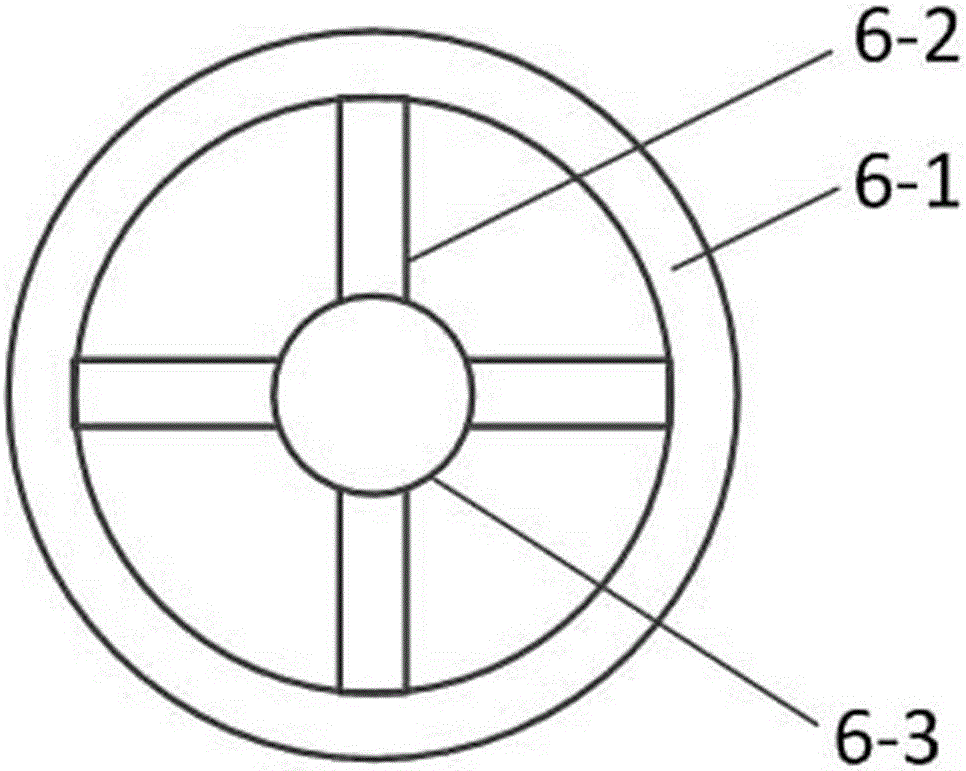

[0022] Such as figure 1 As shown, a fiber optic MEMS Fab acceleration sensor includes a housing 1, an optical fiber sleeve 2, an optical fiber 3, a semi-reverse surface 4, a reflective surface 5, an acceleration sensing element 6 and a base 7; wherein, the housing 1, the acceleration sensing element 6 The outer diameter of the component and the base 7 is the same, and the three are aligned from top to bottom in sequence and connected by MEMS bonding technology; the outer shell 1 is provided with a through hole along its vertical axis, and the optical fiber sleeve 2 is inserted into the outer shell 1 In the through hole, the optical fiber 3 is inserted into the optical fiber sleeve 2, the light-emitting surface of the optical fiber 3 is polished or coated with a semi-reflective film as the semi-reverse surface 4, and the surface at the center of the acceleration sensitive el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com