Propeller with trailing edge for air jetting

A propeller and trailing edge technology, applied in the field of aviation propulsion, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This embodiment is a propeller with trailing edge jet.

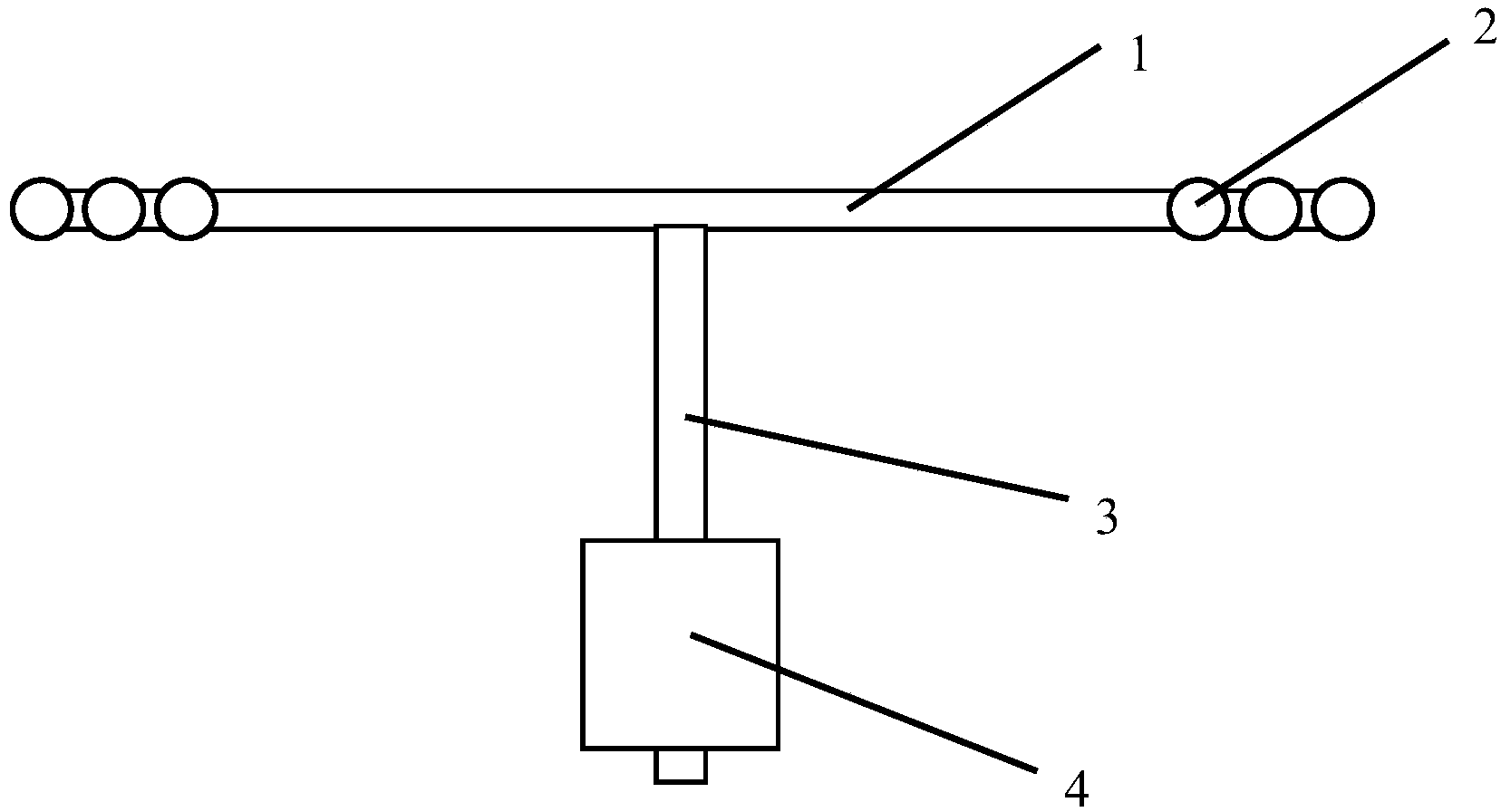

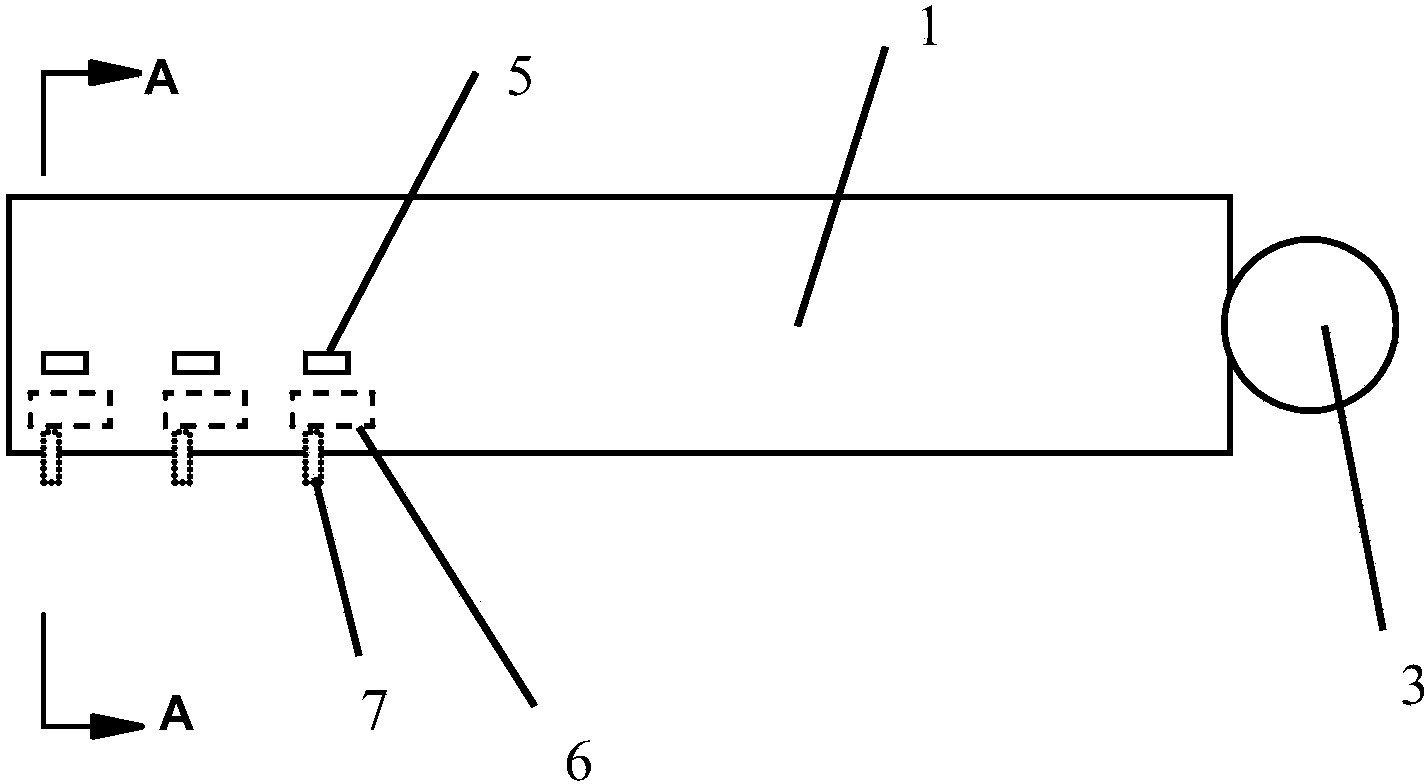

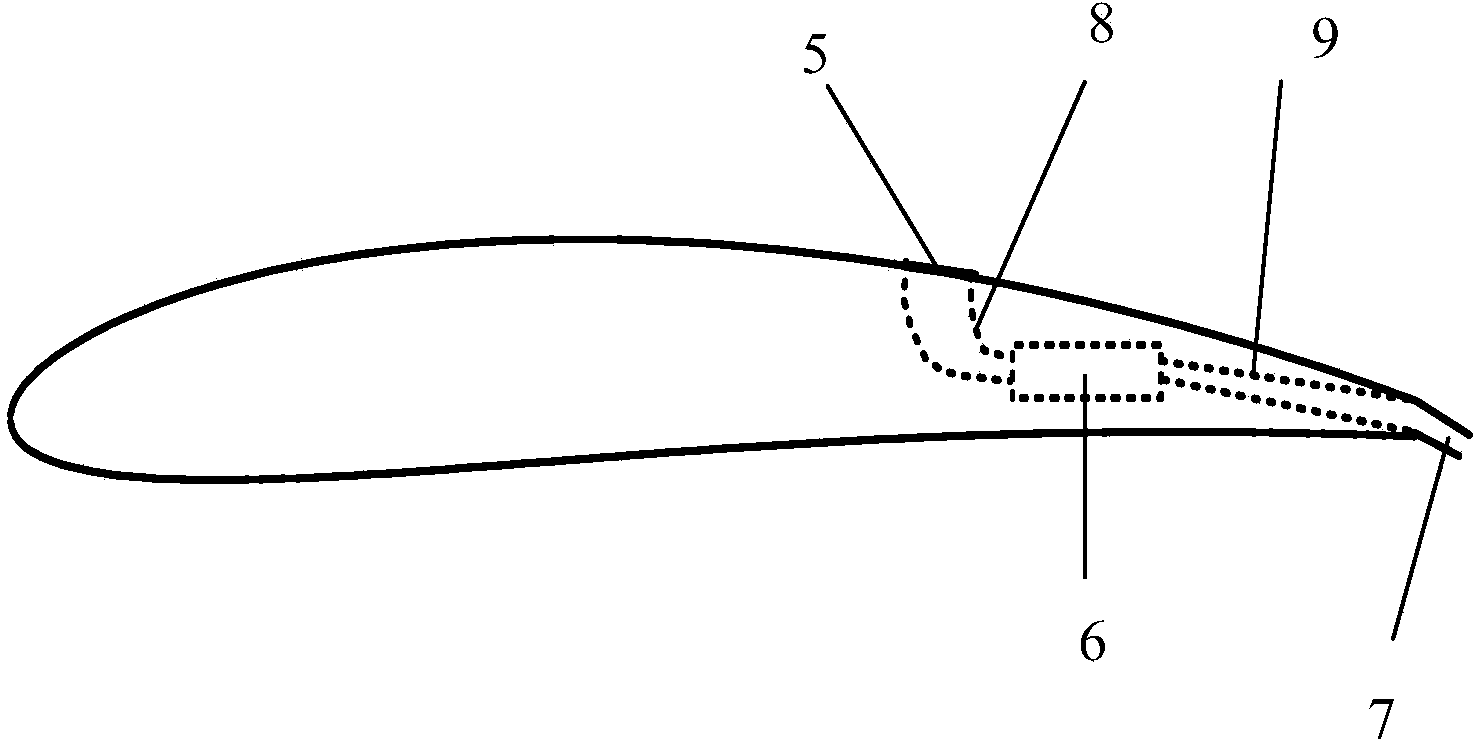

[0018] refer to figure 1 , figure 2 , image 3 , the propeller of the trailing edge jet in the present embodiment is jointly driven by the motor and the jet device. The propeller of the trailing edge jet includes two symmetrical blades 1 , a rotating shaft 3 and a motor 4 , and a plurality of jet devices 2 . The jet device 2 is composed of an air pump 6, a front duct 8, and a rear duct 9. The two ends of the air pump 6 are fixedly connected to one end of the front duct 8 and the rear duct 9 respectively, and the other end of the front duct 8 is connected to the suction port 5 on the upper surface of the blade 1. The other end of the rear conduit 9 is connected to the air outlet 7 on the trailing edge, and the air injection device 2 sucks in the airflow from the air inlet 5 on the upper surface of the blade, and ejects the airflow at a certain angle from the air outlet 7 on the trailing edge after acceleration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com