Double-support elastic driving type cable coiling block

A cable reel, driven technology, applied in the field of mobile energy supply devices, can solve the problems of occupying a large installation space, thin installation form, insufficient stability, etc., achieving strong installation stability, low production cost, and saving installation space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

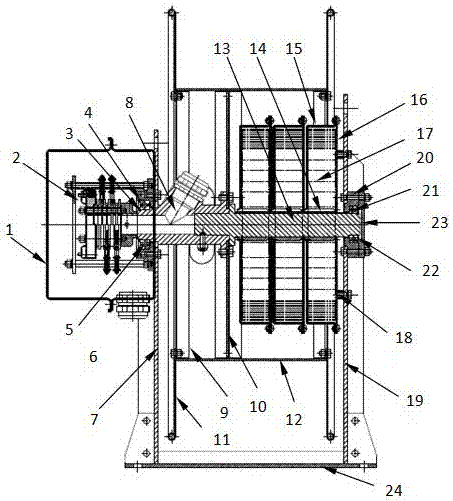

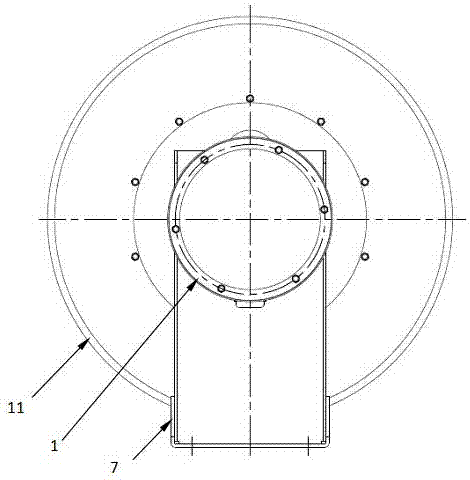

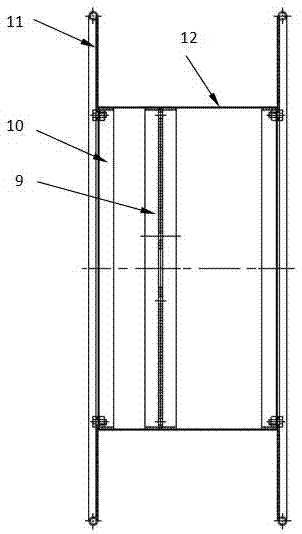

[0022] Depend on Figure 1~3 It can be seen that the present invention is a double-support elastically driven cable reel, which includes a collector cover 1, a collector 2, a shaft retaining ring 3, a hole retaining ring 4, a bearing 5, an electrical bearing seat 6, an electrical Side bracket 7, Denso half shaft 8, Dragon slip ring 1 9, Keel ring 2 10, End plate 11, Rolling cylinder 12, Spring half shaft 13, Spring inner sleeve 14, Spring box 15, Spring box cover 16 , clockwork spring 17, locking stud 18, spring side bracket 19, spring side bearing seat 20, bearing 21, shaft retaining ring 22, bearing gland 23, mounting base plate 24, and some bolts, nuts, set screws .

[0023] The central shaft of the cable reel includes an electrical installation semi-axis 8 and a spring semi-axis 13; The stop ring 3, the stop ring 4 limit for the hole;

[0024] The electric assembly half shaft 8 and the spring half shaft 13 are rigidly connected by set screws.

[0025] Depend on Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com