Stern rotary drum

The technology of a stern drum and a cylinder body is applied in the field of a stern drum of an offshore engineering ship, and achieves the effect of reducing installation accuracy requirements and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

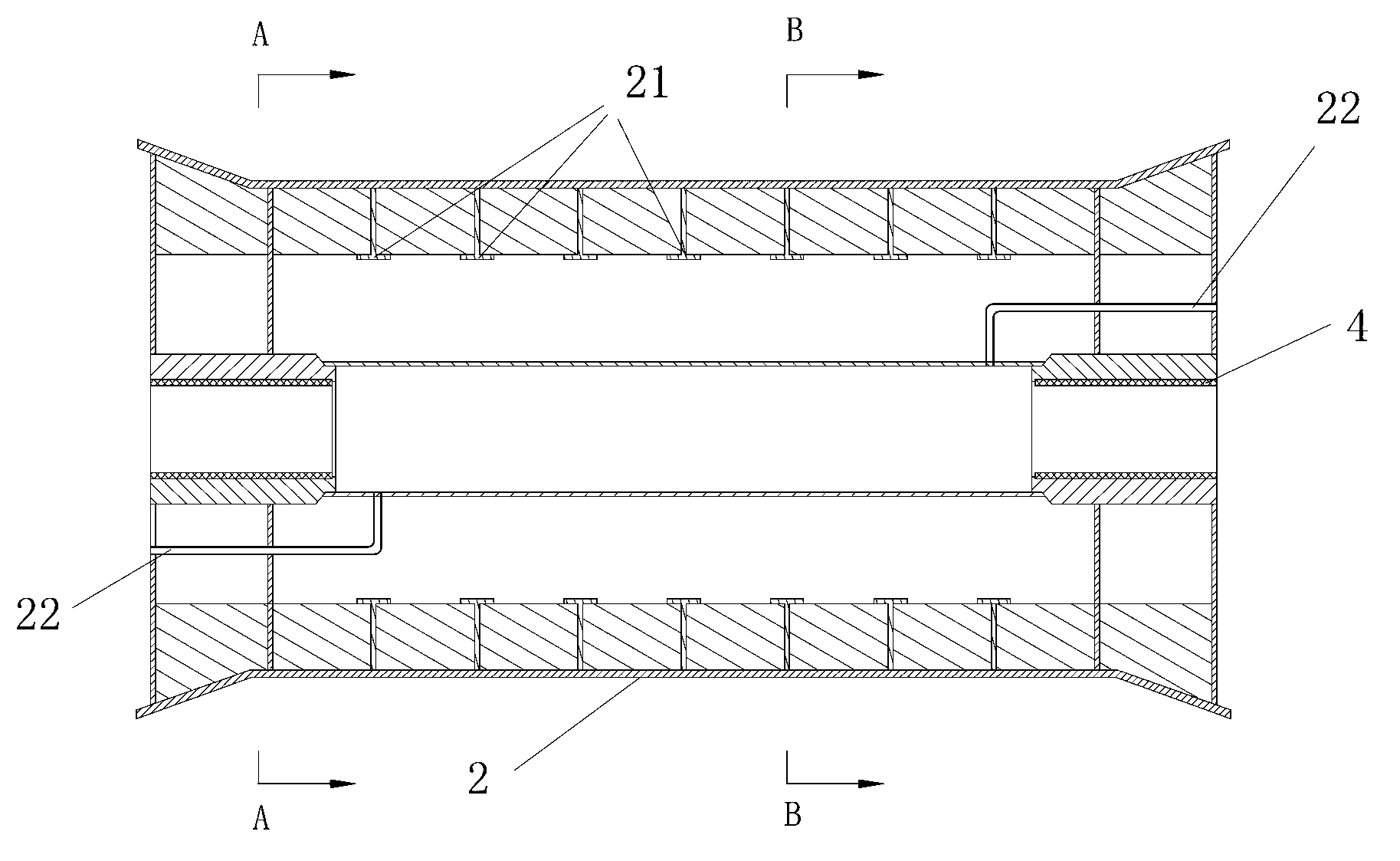

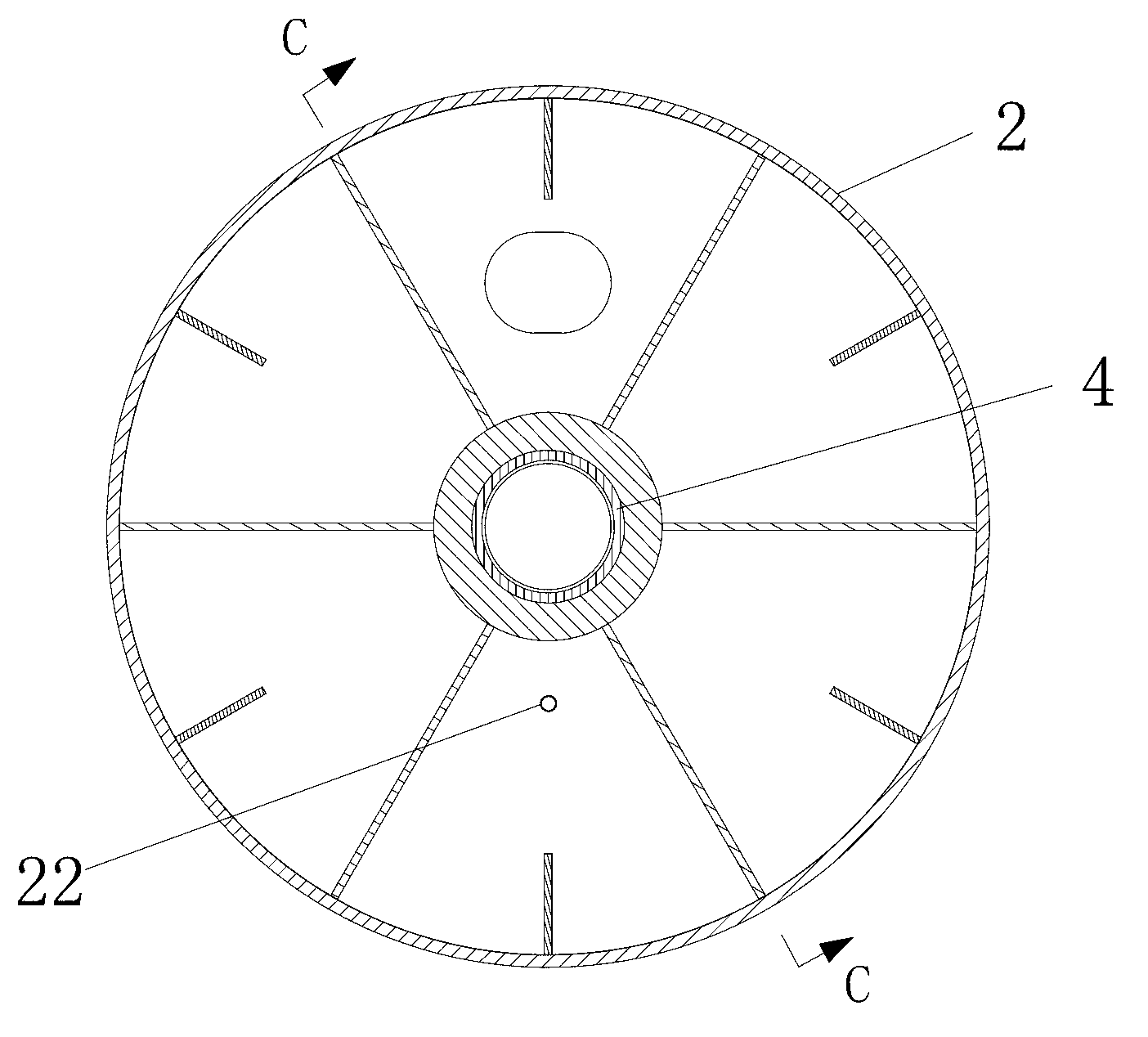

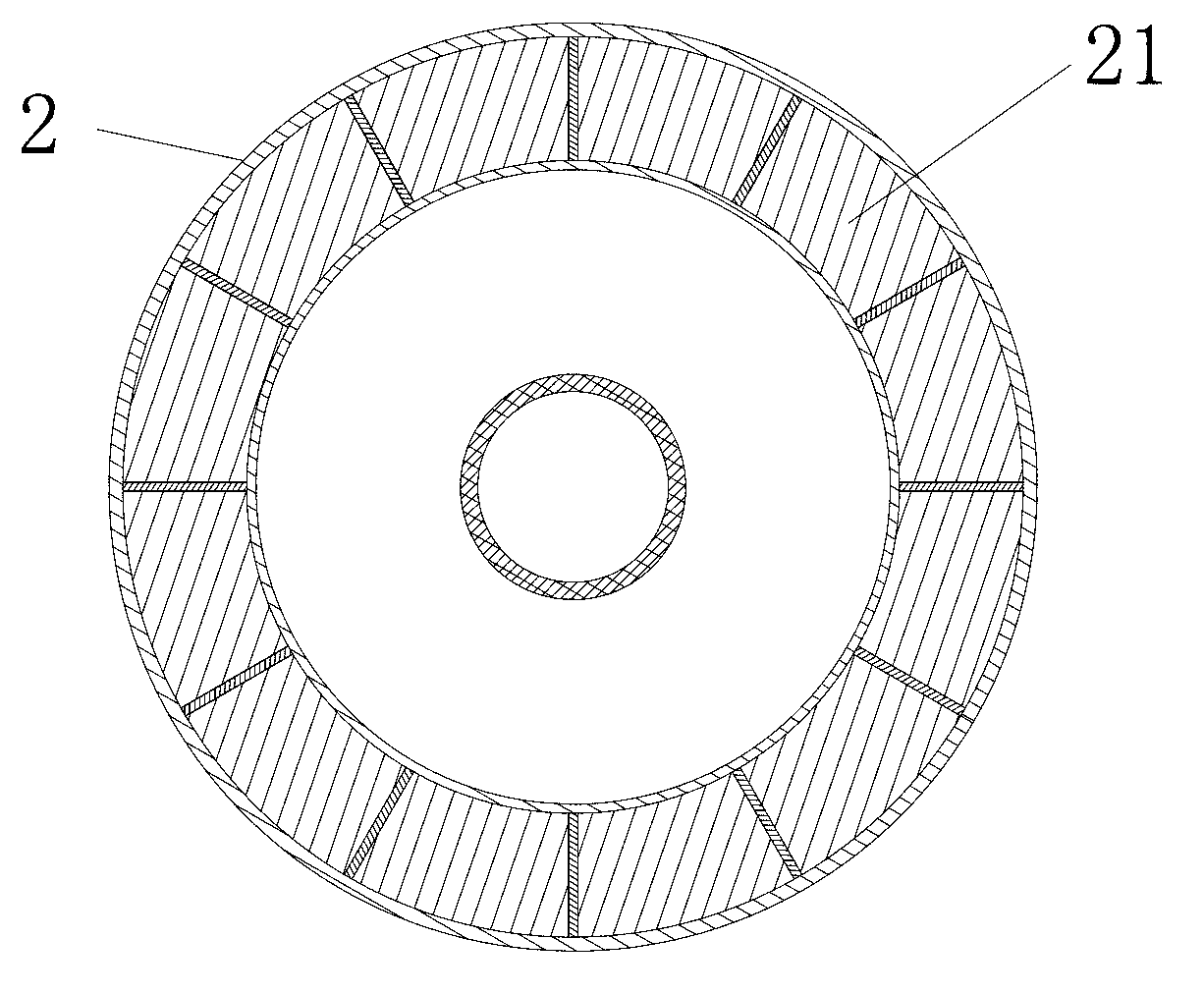

[0027] A stern drum, which includes a shaft body 1 and a cylinder body 2 arranged on the shaft body through a bearing 4, a plurality of transverse annular ribs 21 arranged along the circumferential direction of the shaft body 1 are arranged in the cylinder body 2, and radially The four longitudinal stiffeners arranged in directions of 30°, 60°, 210°, and 240°, the transverse annular rib 21 and the longitudinal annular rib improve the load capacity of the cylinder 2 and reduce the weight of the cylinder 2 at the same time.

[0028] It also includes a shaft fork 3, the shaft fork 3 is welded and fixed on the hull, the shaft fork 3 includes a clamping portion 31, the shaft body 1 forms a matching portion 11 corresponding to the clamping portion of the shaft fork 3, and the coupling portion 11 is fixed in the clamping part 31 , so that the shaft fork 3 can support and fix the shaft body 1 , and an isolation spacer 6 and epoxy resin 5 are also arranged between the shaft fork 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com