Automatic tool changing spindle device of PCB edge drilling and milling machine

A technology of automatic tool change and PCB board, applied in positioning devices, metal processing mechanical parts, clamping and other directions, which can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

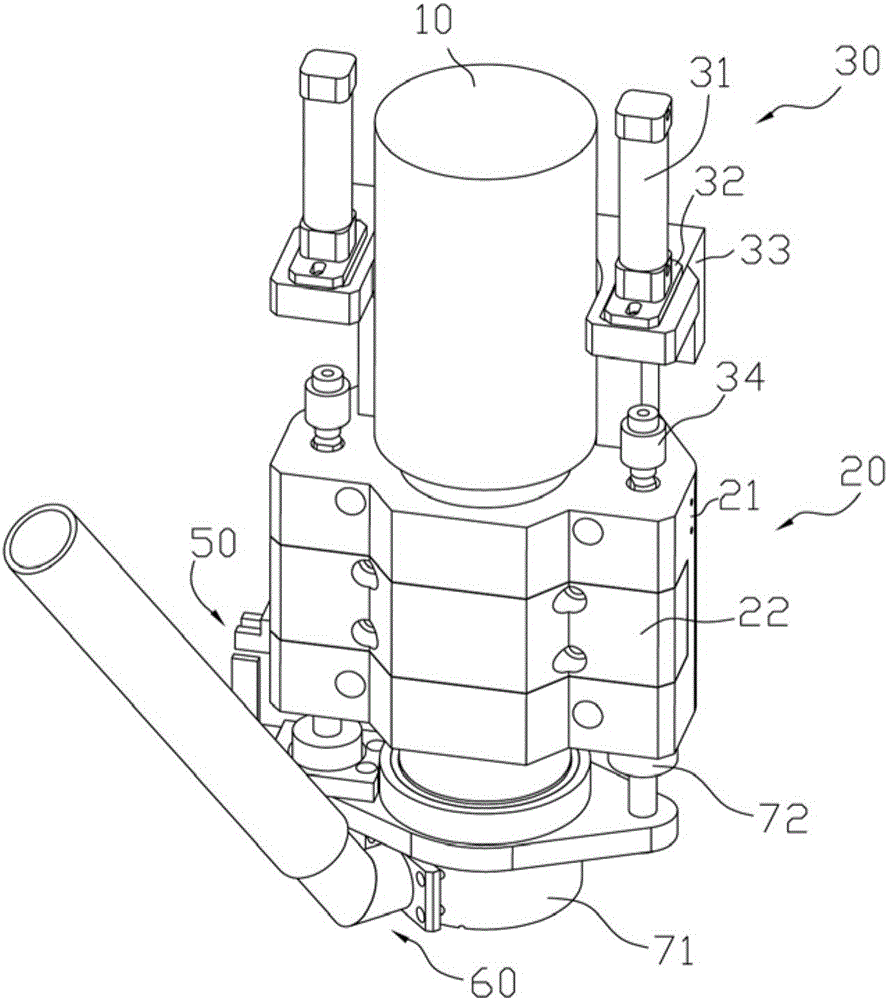

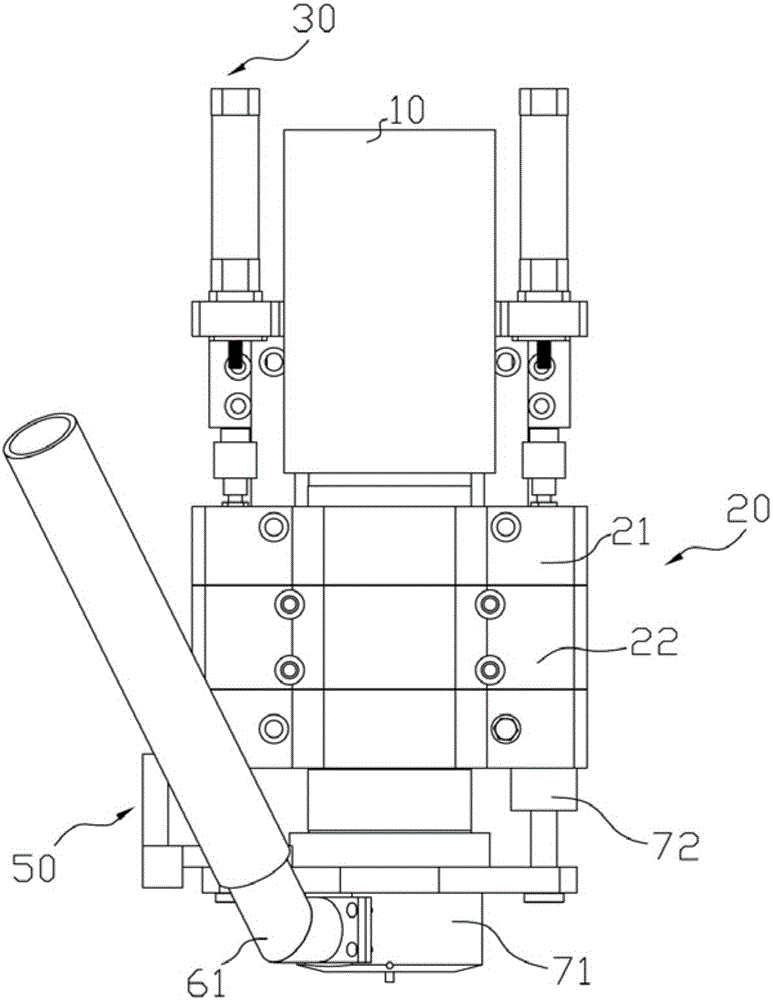

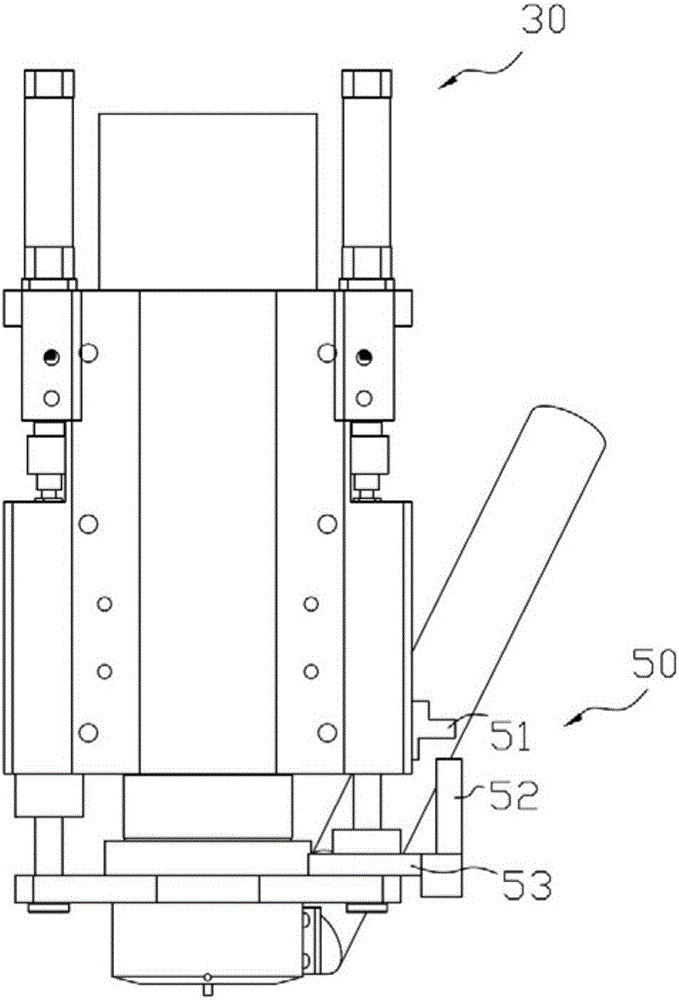

[0022] Such as Figure 1 to Figure 6 , an automatic tool changing spindle device for a PCB board gong edge machine,

[0023] An automatic tool change spindle device for a PCB edge machine, comprising a spindle 10, a clamp block 20, a cylinder assembly 30, a guide rod assembly 40, an induction assembly 50, a dust suction assembly 60 and a presser foot assembly 70; the spindle 10 wears It is installed through the center hole 210 of the clamp block 20, and the center line of the main shaft 10 coincides with the center line of the center hole 210 of the clamp block 20; it is characterized in that: a group of guide rod assemblies 40 are respectively installed on both sides of the symmetrical plane of the clamp block 20, and the The guide rod assembly 40 includes a guide rod 41 located in the clamp block 20, a linear bearing 42 close to the guide rod 41, and a guide rod fixing ring 43 screwed to the bottom of the guide rod 41. The upper end surface of the guide rod fixing ring 43 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com